Patents

Literature

40results about How to "Increase the maximum pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

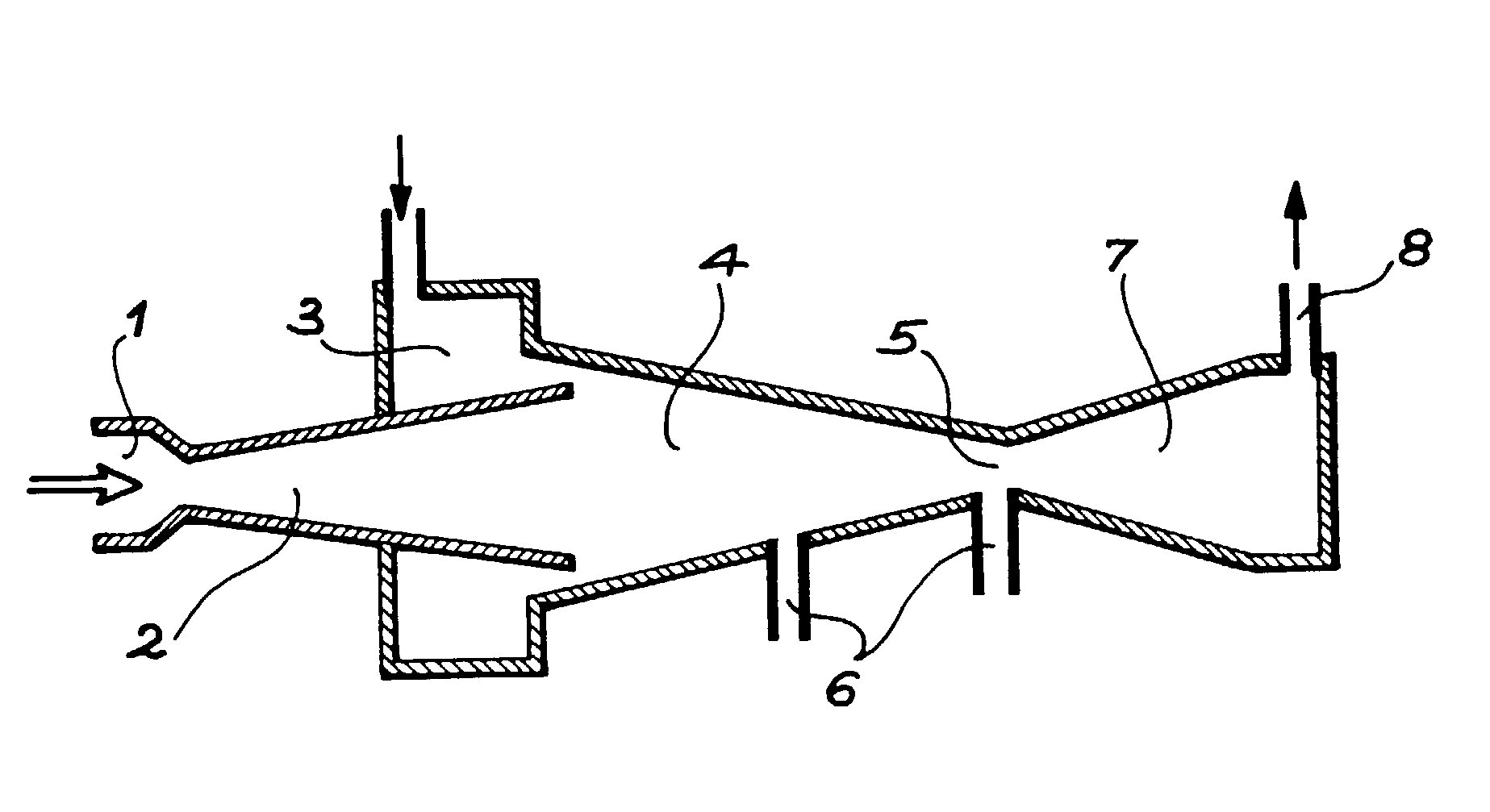

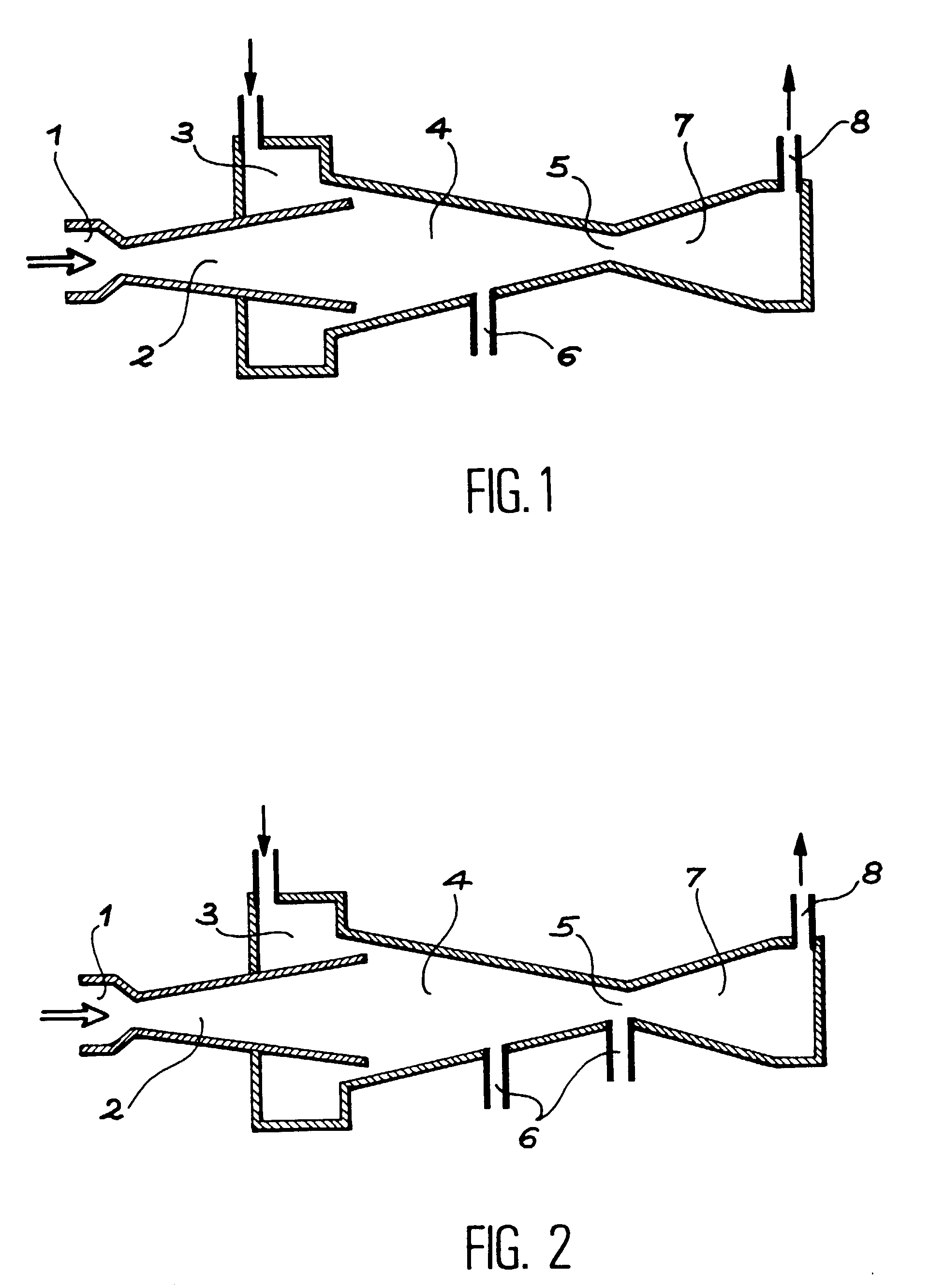

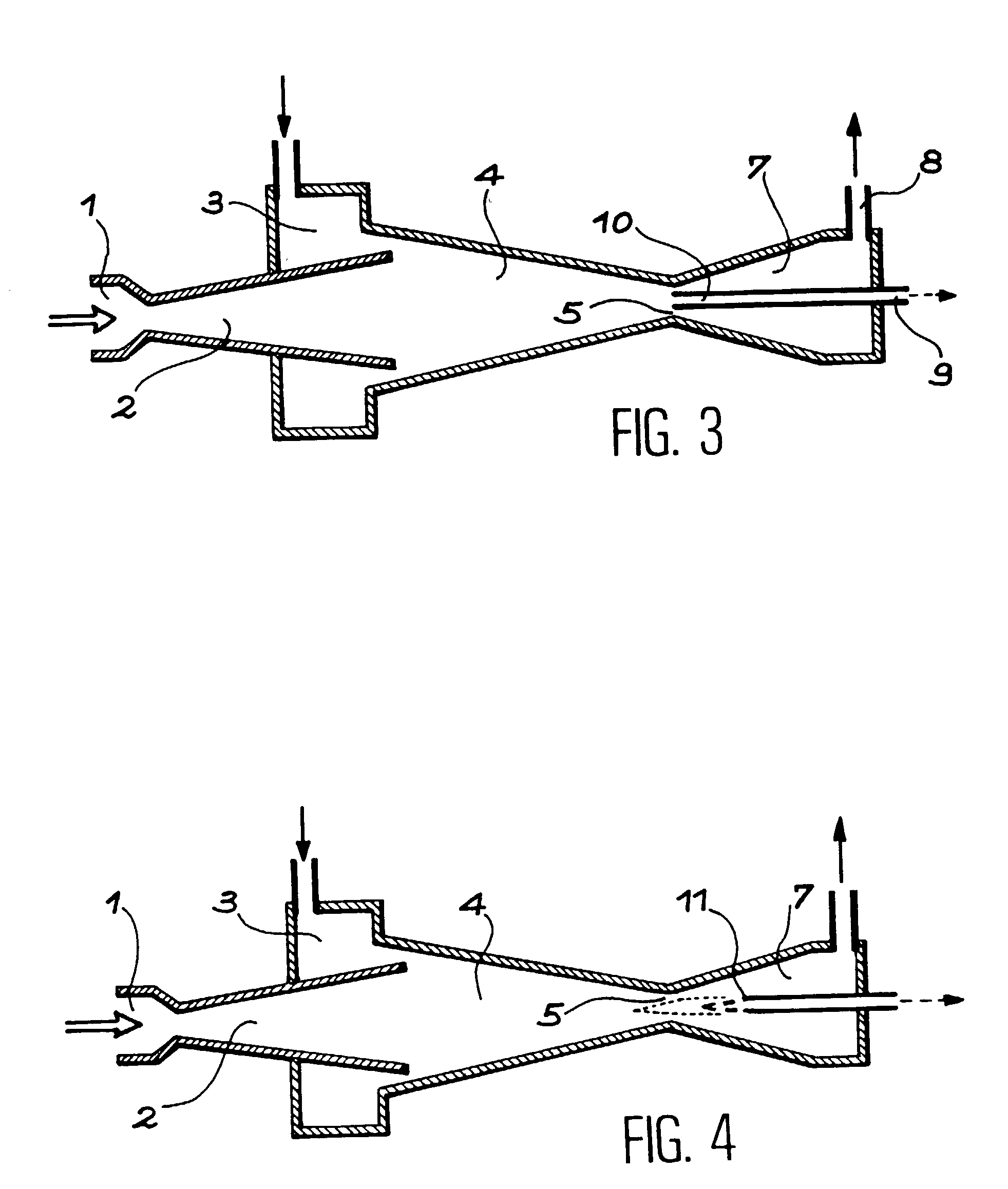

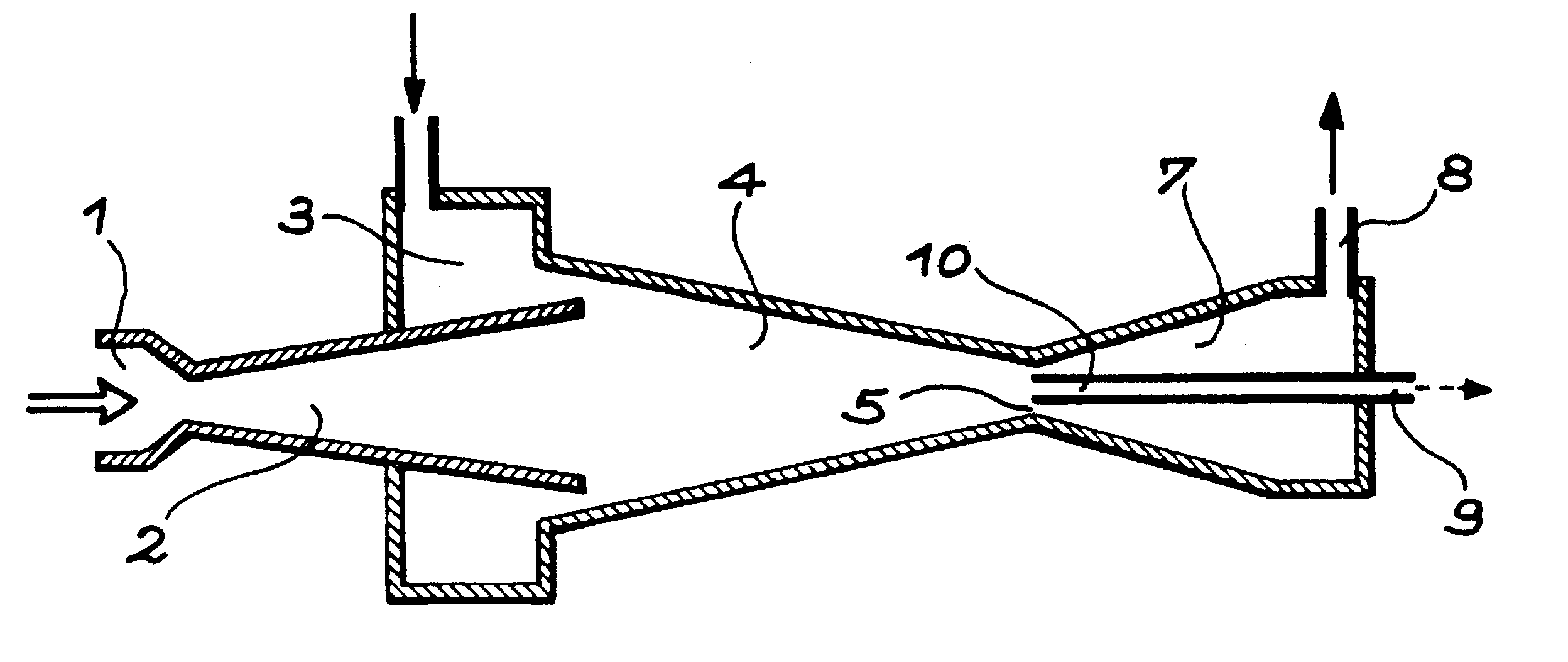

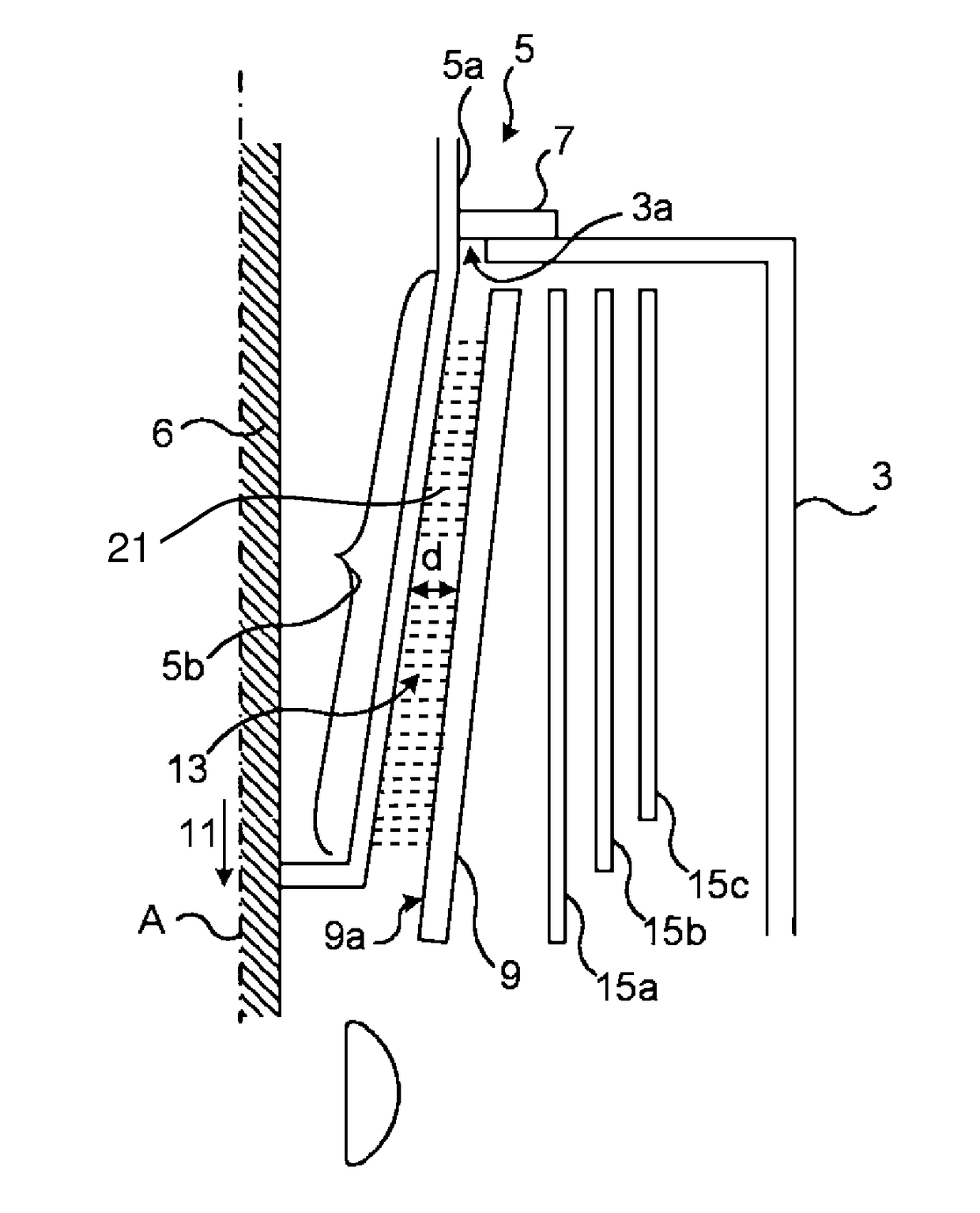

High pressure steam water injector comprising an axial drain

InactiveUS20020162518A1Increase the maximum pressureLow sectionFlow mixersWater circulationNuclear reactorHigh pressure

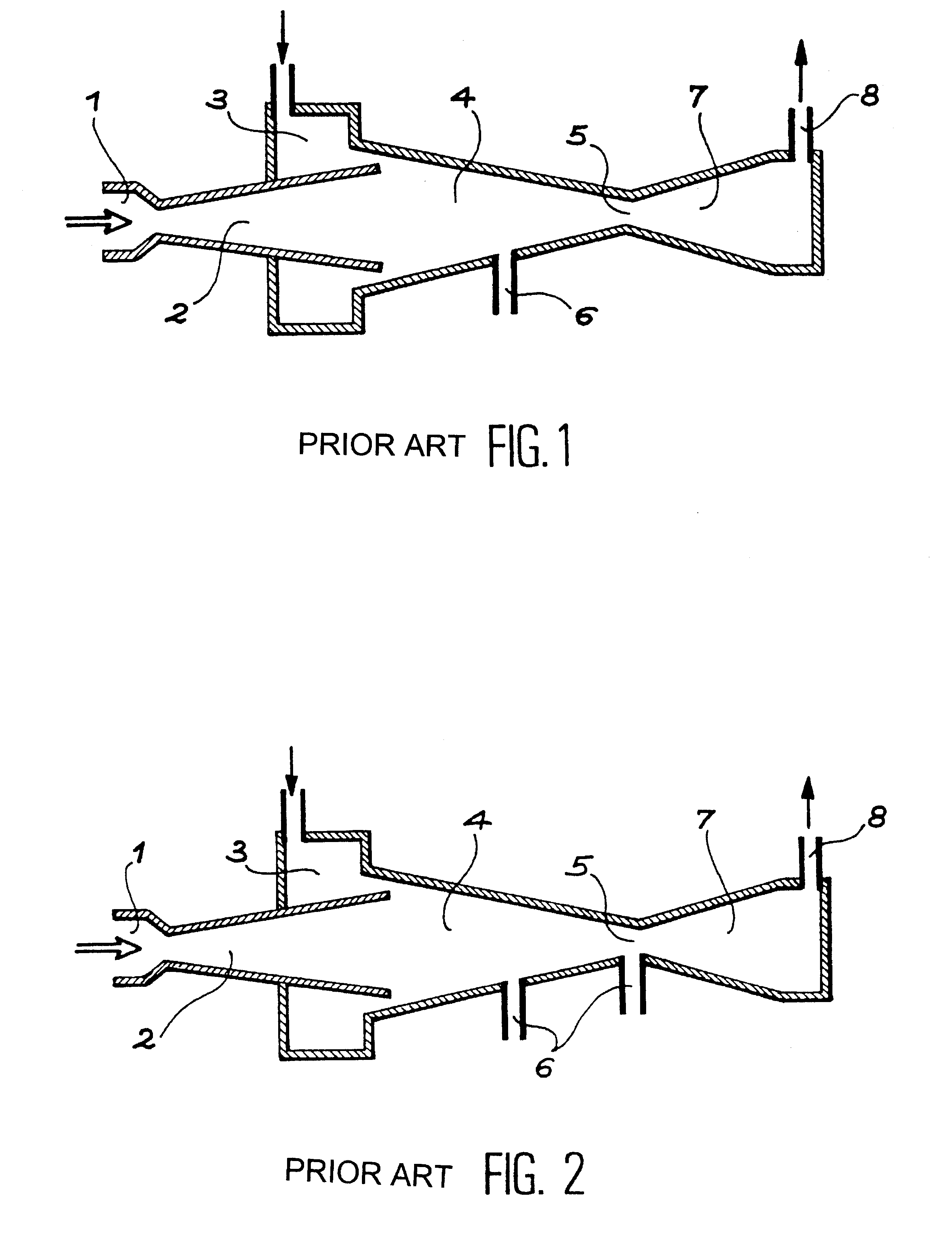

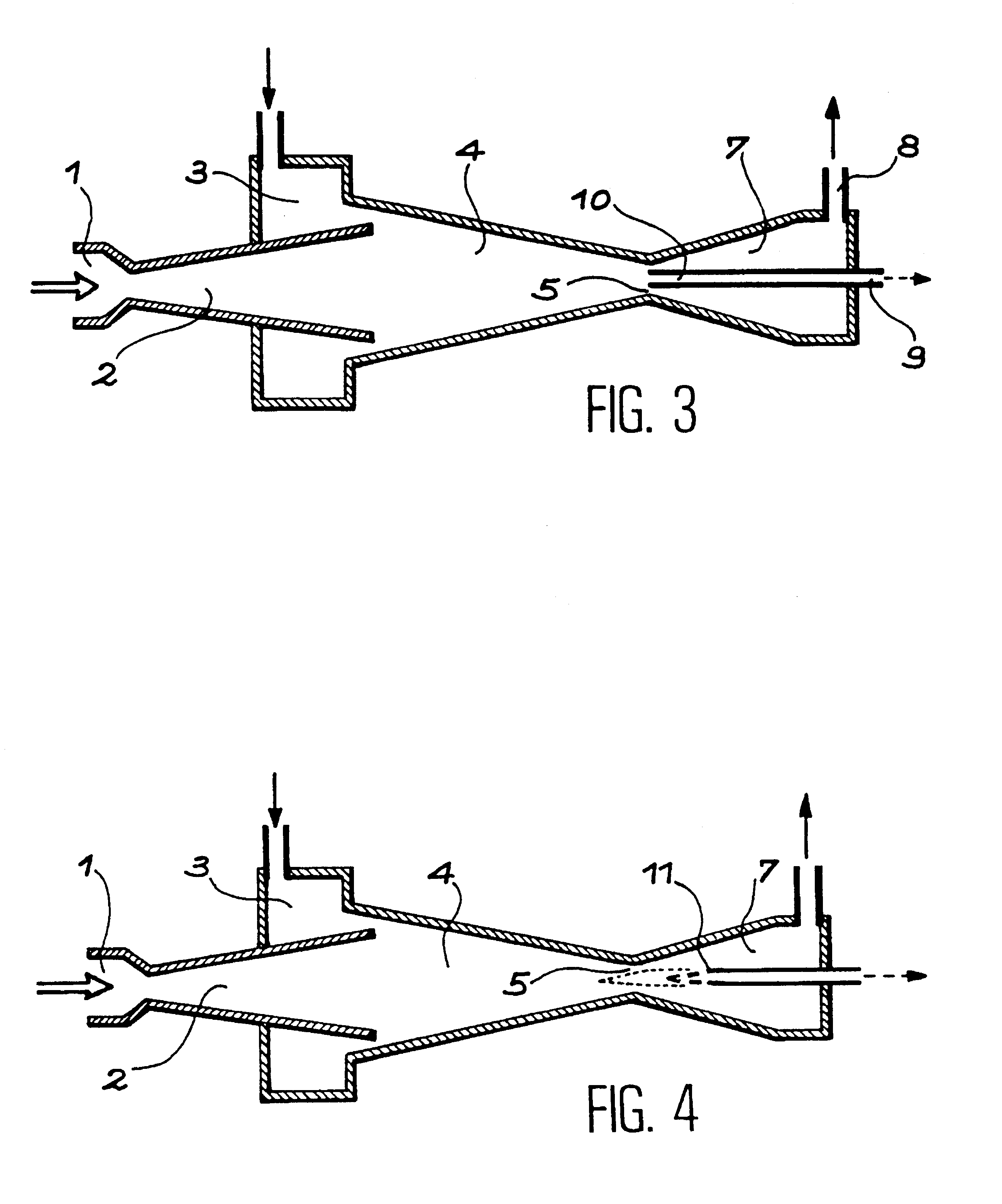

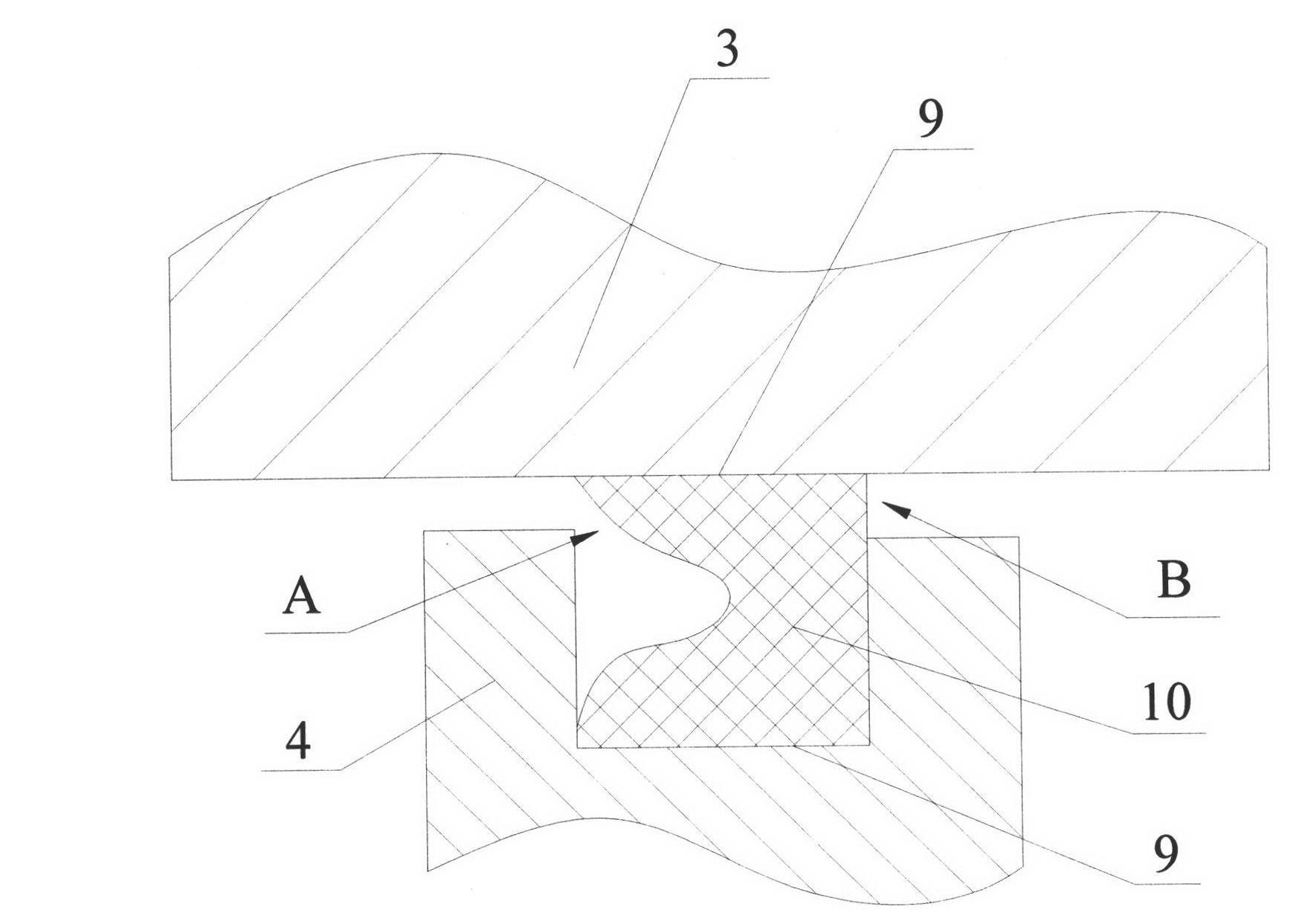

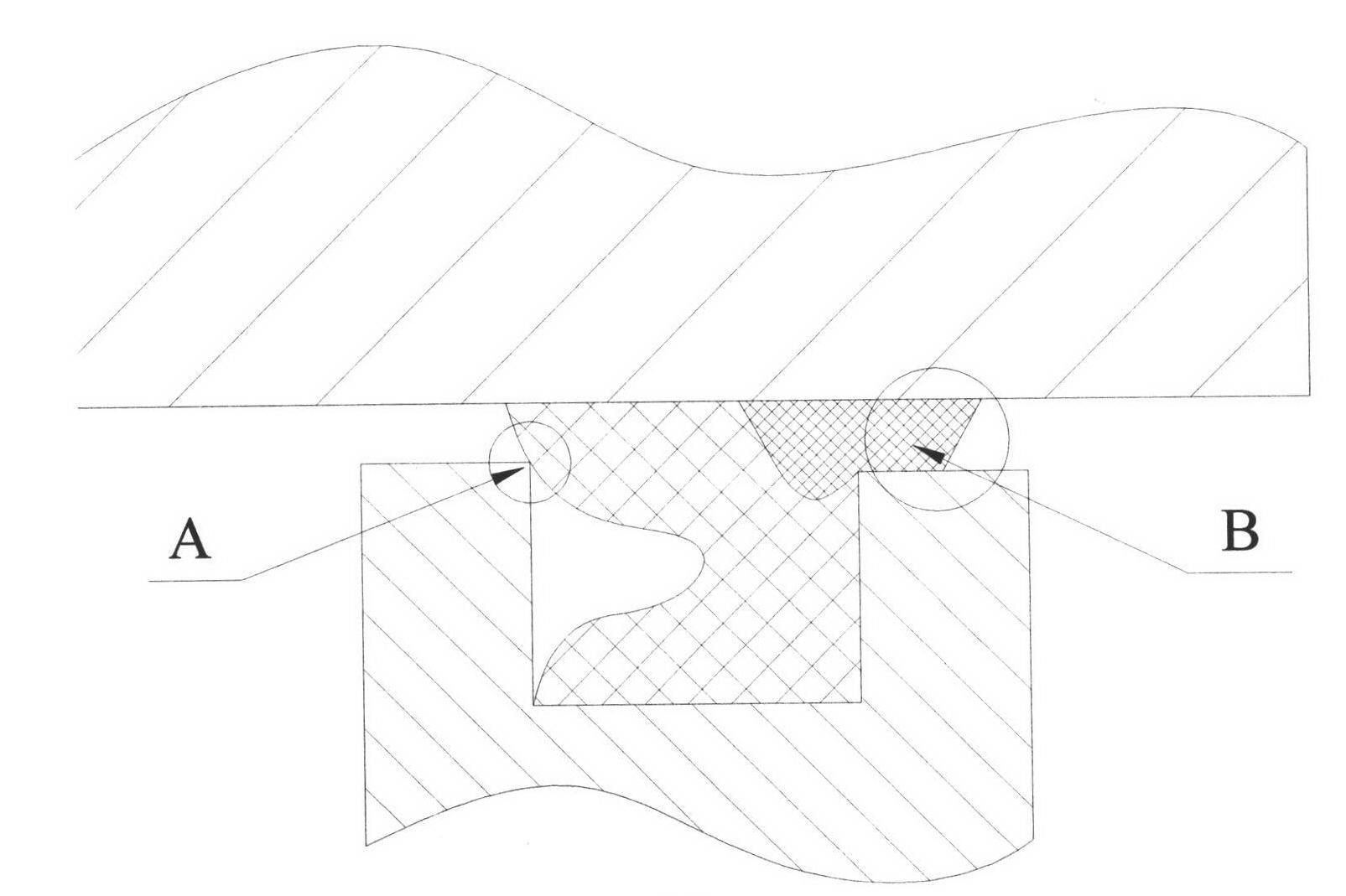

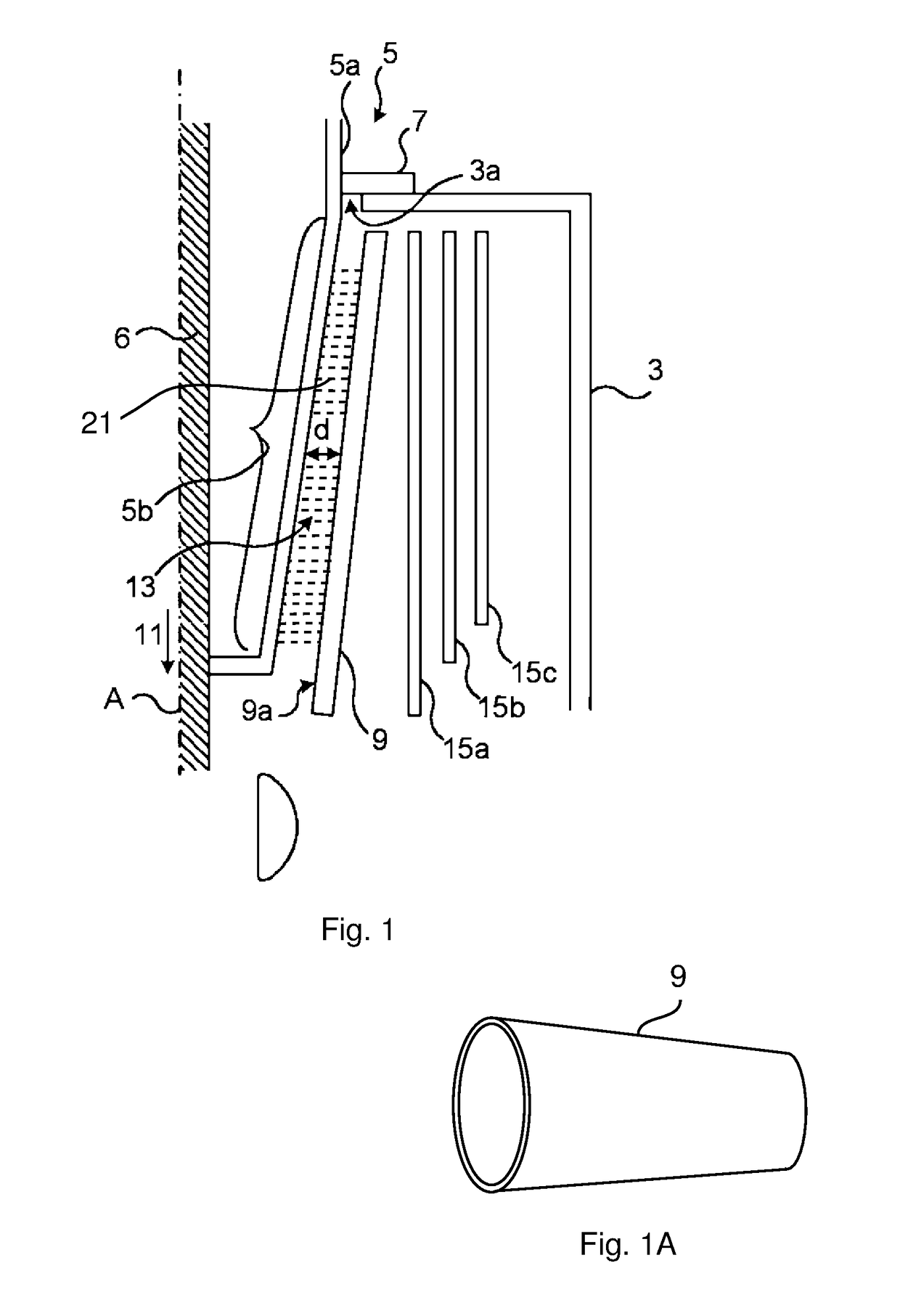

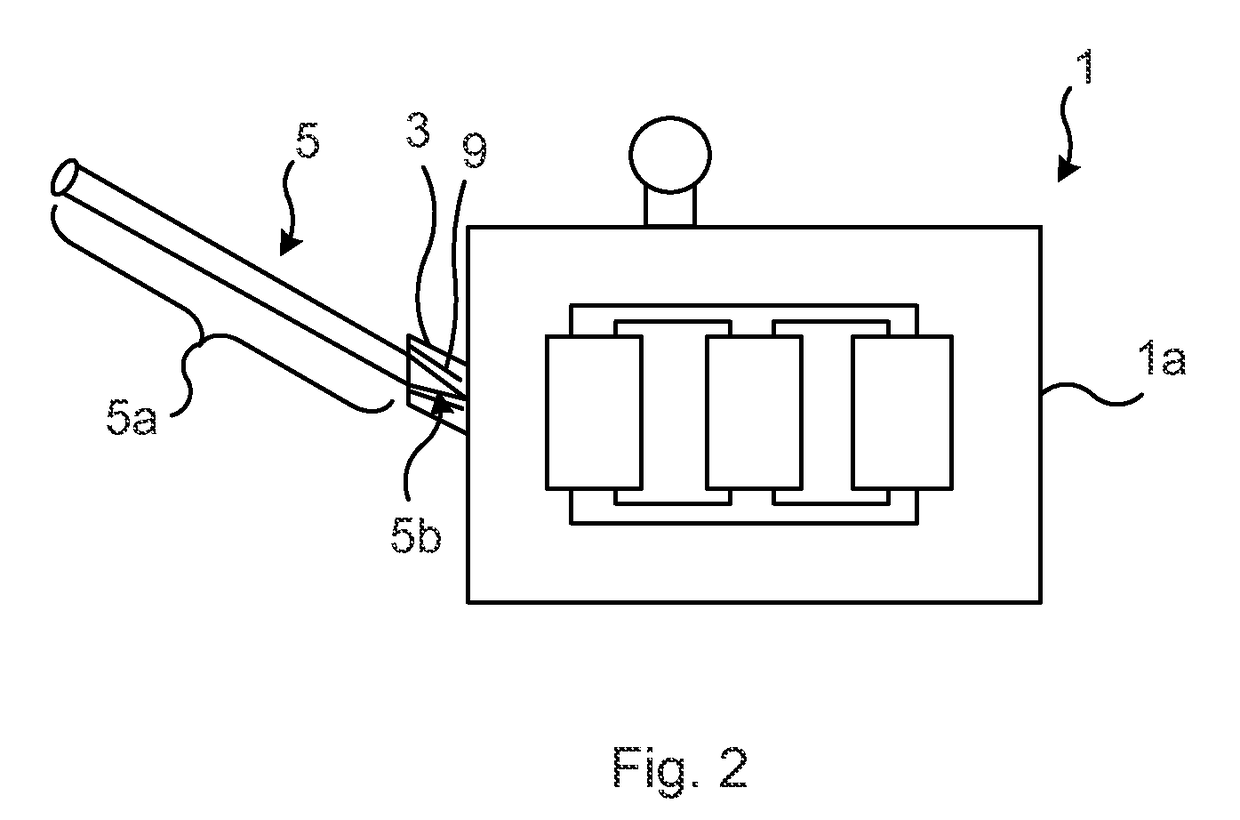

The steam injector is characteristic in its high pressure and improved start-up. It uses an axial drain (10) positioned in the centre of the neck (5) downstream from the mixing chamber (4) and inserted in the diffuser (7) for the purpose of narrowing the section of the neck (5) and evacuating a large part of the steam which has not been condensed. The axial drain (10) may be mounted so that it is axially mobile. Application to the water supply for steam generators in pressurized water nuclear reactors.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

High pressure steam water injector comprising an axial drain

InactiveUS6595163B2Increase the maximum pressureLow sectionFlow mixersWater circulationNuclear reactorHigh pressure

The steam injector is characteristic in its high pressure and improved start-up. It uses an axial drain (10) positioned in the centre of the neck (5) downstream from the mixing chamber (4) and inserted in the diffuser (7) for the purpose of narrowing the section of the neck (5) and evacuating a large part of the steam which has not been condensed. The axial drain (10) may be mounted so that it is axially mobile.Application to the water supply for steam generators in pressurized water nuclear reactors.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

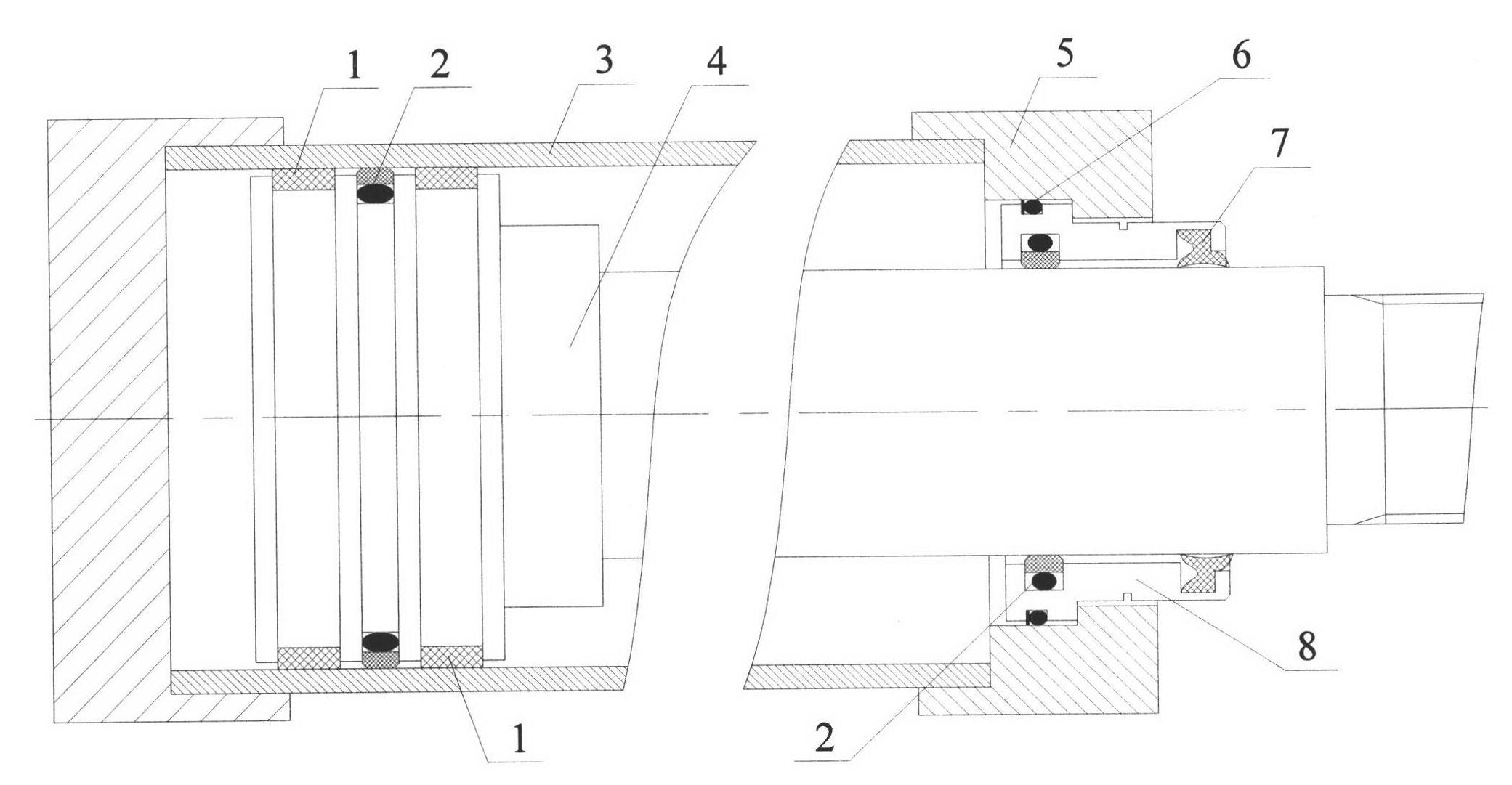

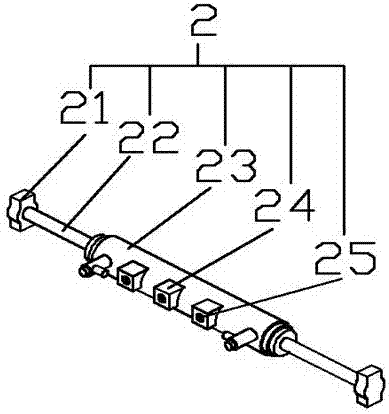

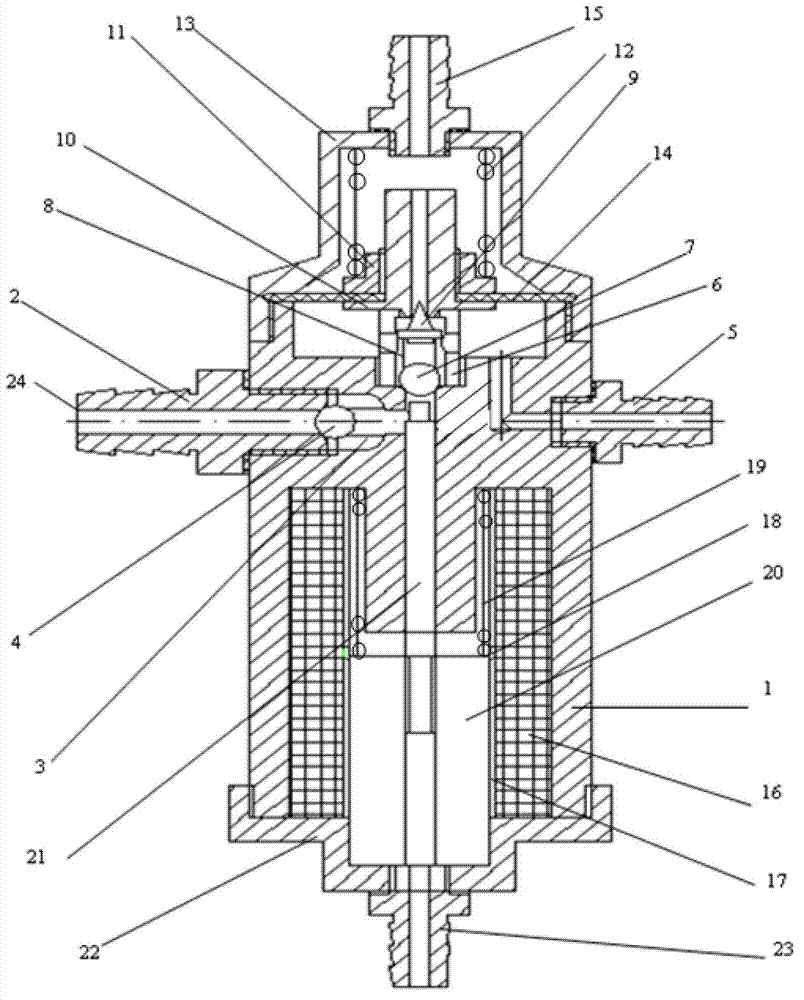

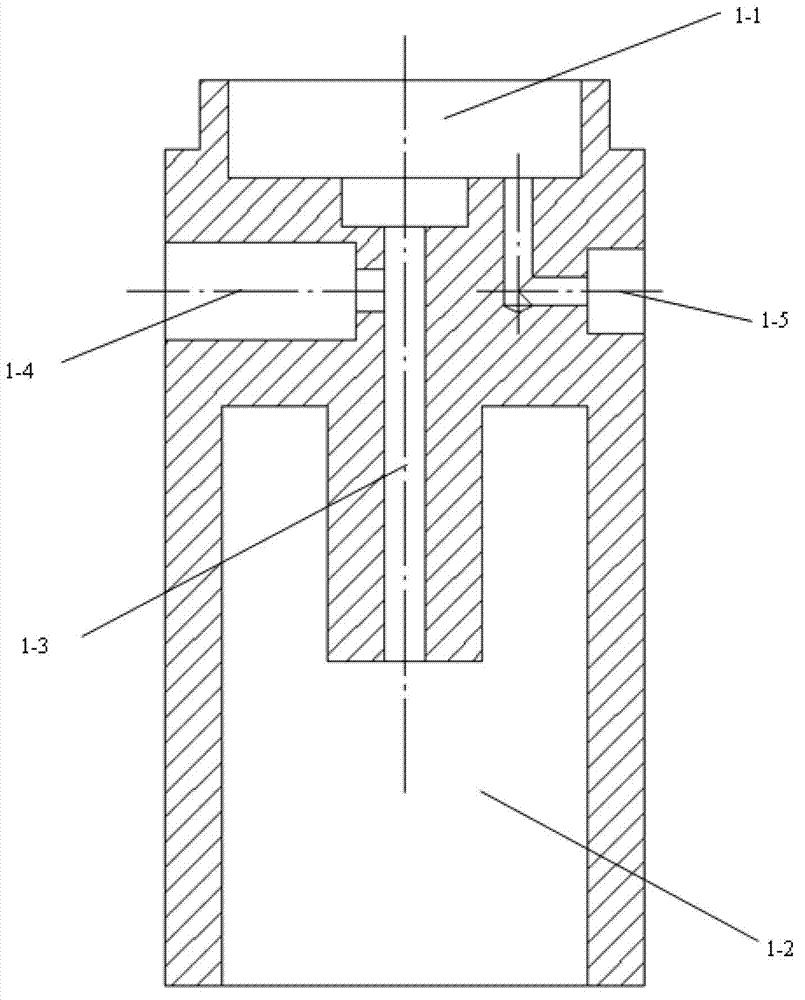

Electronic control diesel engine fuel injector with control valve

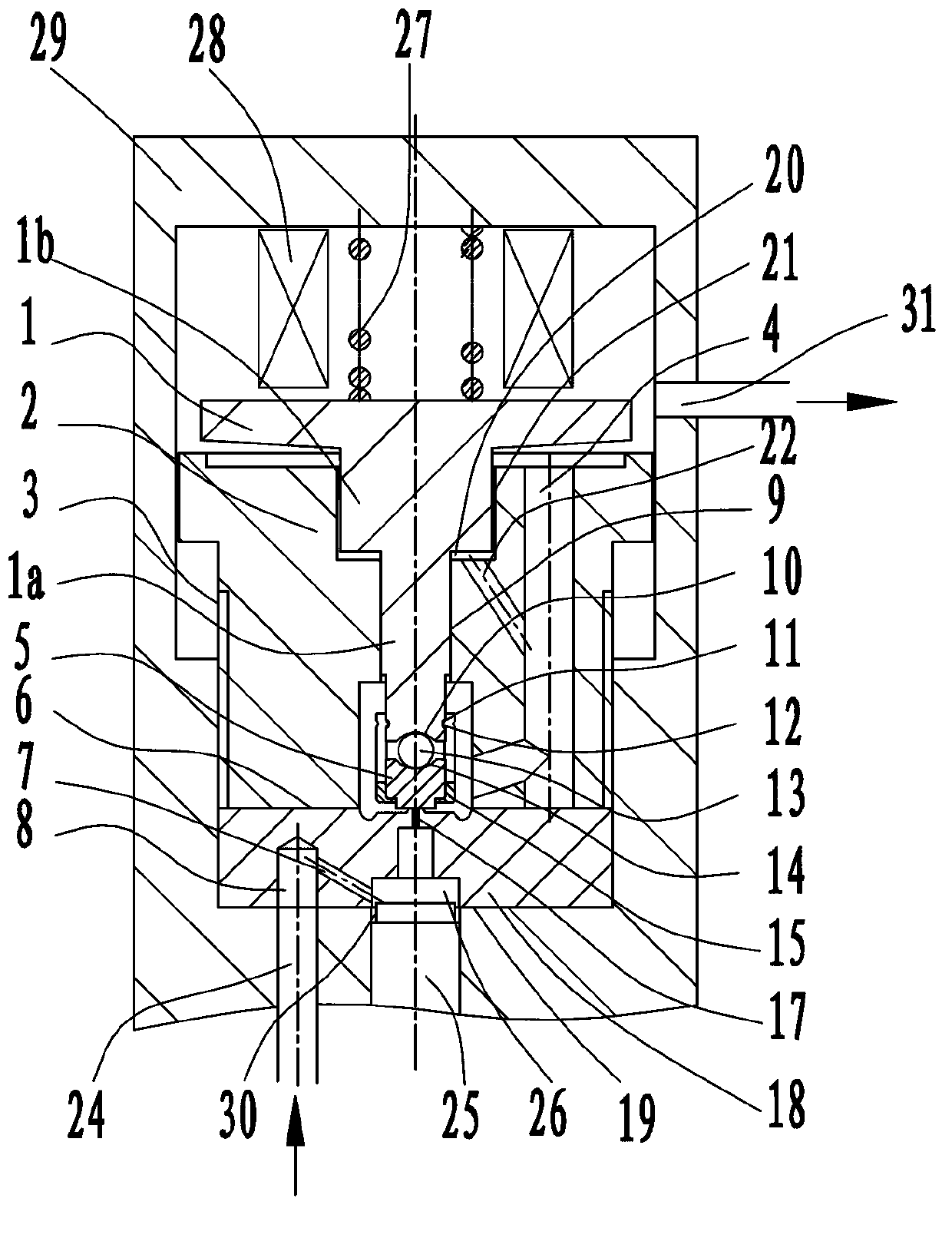

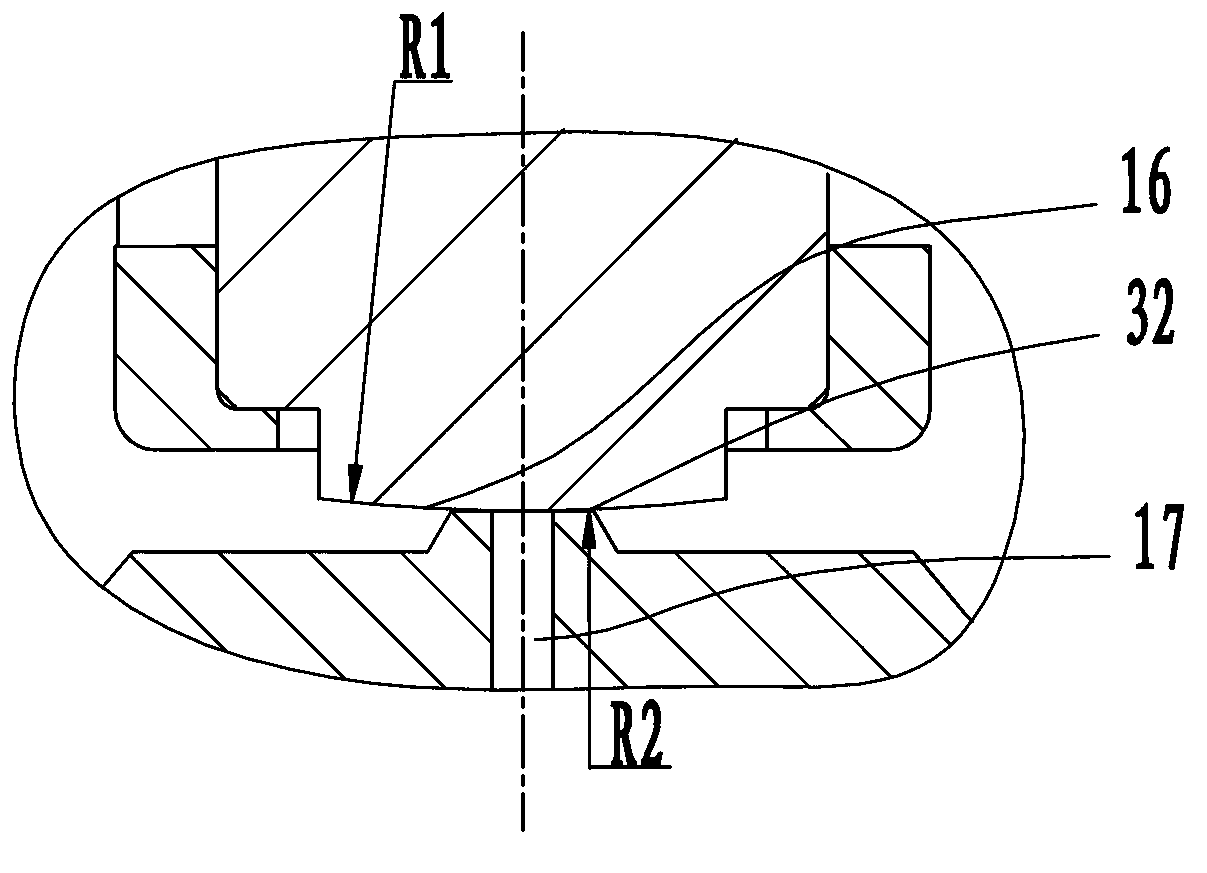

ActiveCN103104391AIngenious structureSmall preloadFuel injection apparatusMachines/enginesCommon railDieseling

The invention relates to an electronic control diesel engine fuel injector with a control valve. The electronic control diesel engine fuel injector with the control valve comprises a fuel injector body and the control valve which is arranged in an inner cavity of the fuel injector body. The electronic control diesel engine fuel injector with the control valve is characterized in that the control valve comprises an armature, a control valve base, a sealing matching member and a throttle sealing board. The throttle sealing board is placed on an installation end face of the inner cavity of the fuel injector body. The control valve base is placed on the throttle sealing board and is installed with the fuel injector body in a connected mode. The control valve base generates downward press force through installing torque to be pressed on the upper end face of the throttle sealing board, so that the lower end face of the throttle sealing board is tightly pressed on the installation end face of the inner cavity of the fuel injector body. The control valve is ingenious in structure, electronic control diesel engine fuel injector with the control valve applied is applicable to occasions with high pressure, pretightening force of a return spring of the armature of the common-rail fuel injector is greatly reduced, even though only small spring pretightening force is used, a pressure control cavity can be completely sealed, and highest pressure of a common-rail system can be improved to above 200 MPa.

Owner:CHINA FIRST AUTOMOBILE

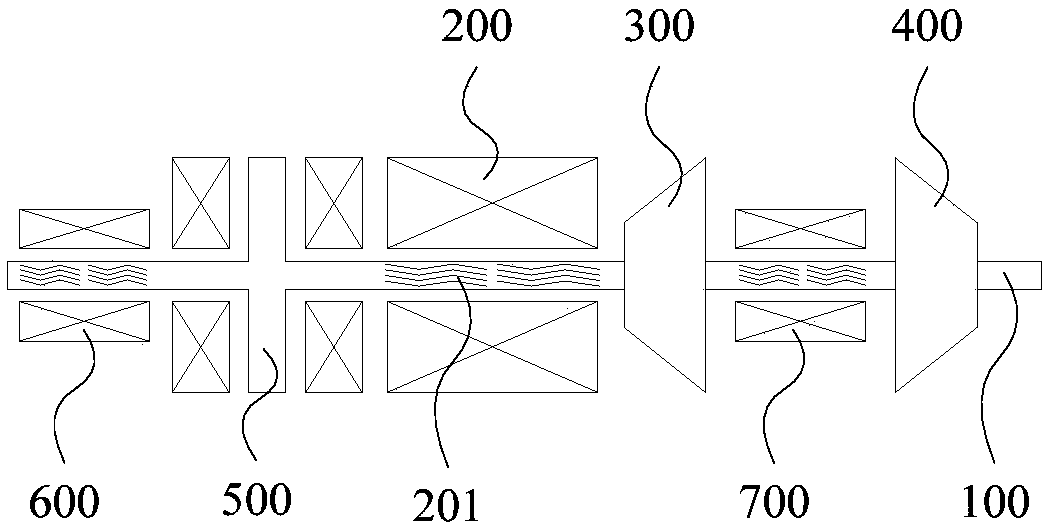

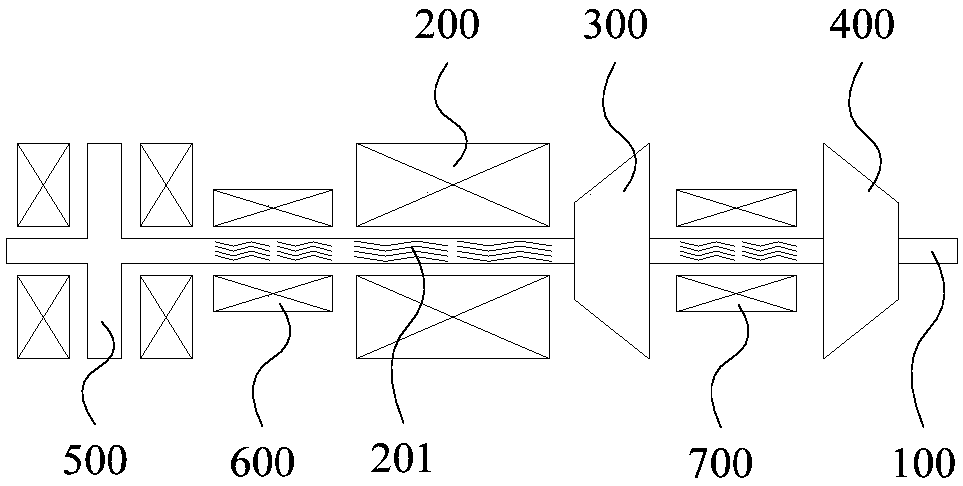

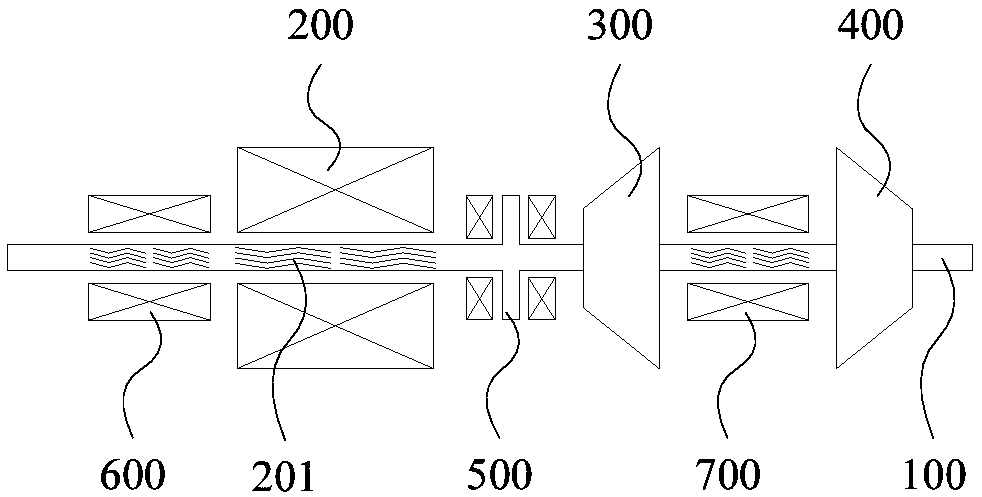

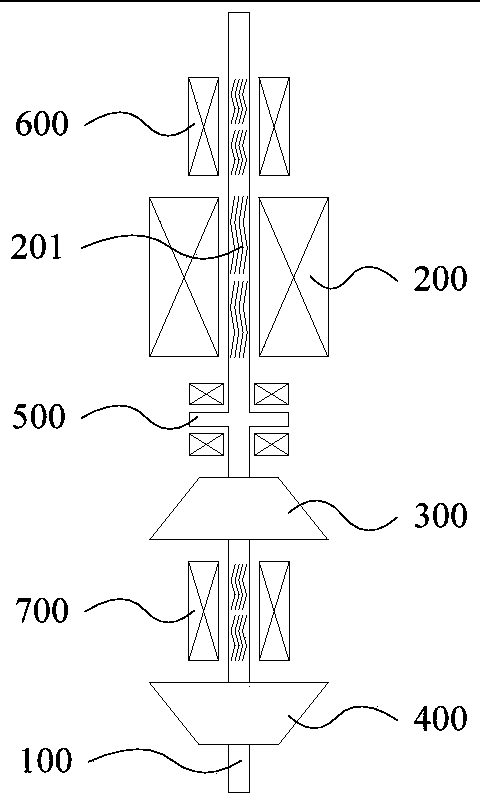

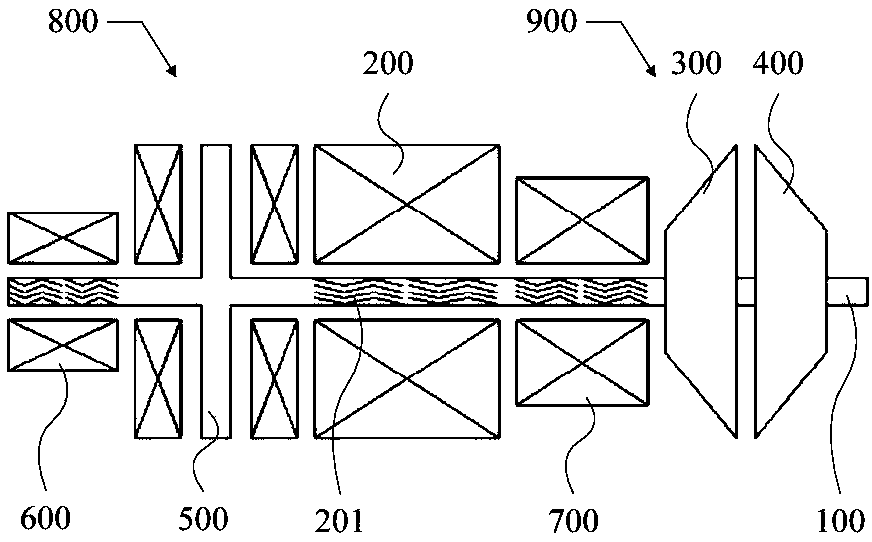

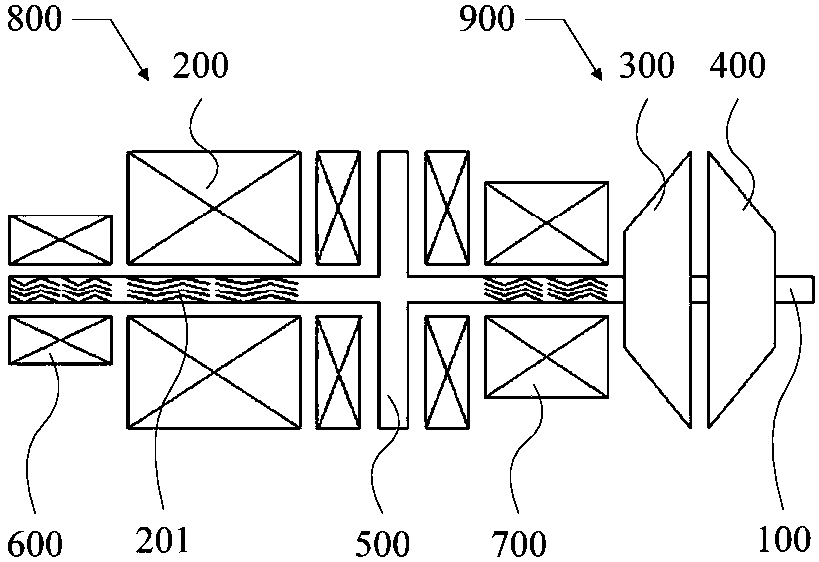

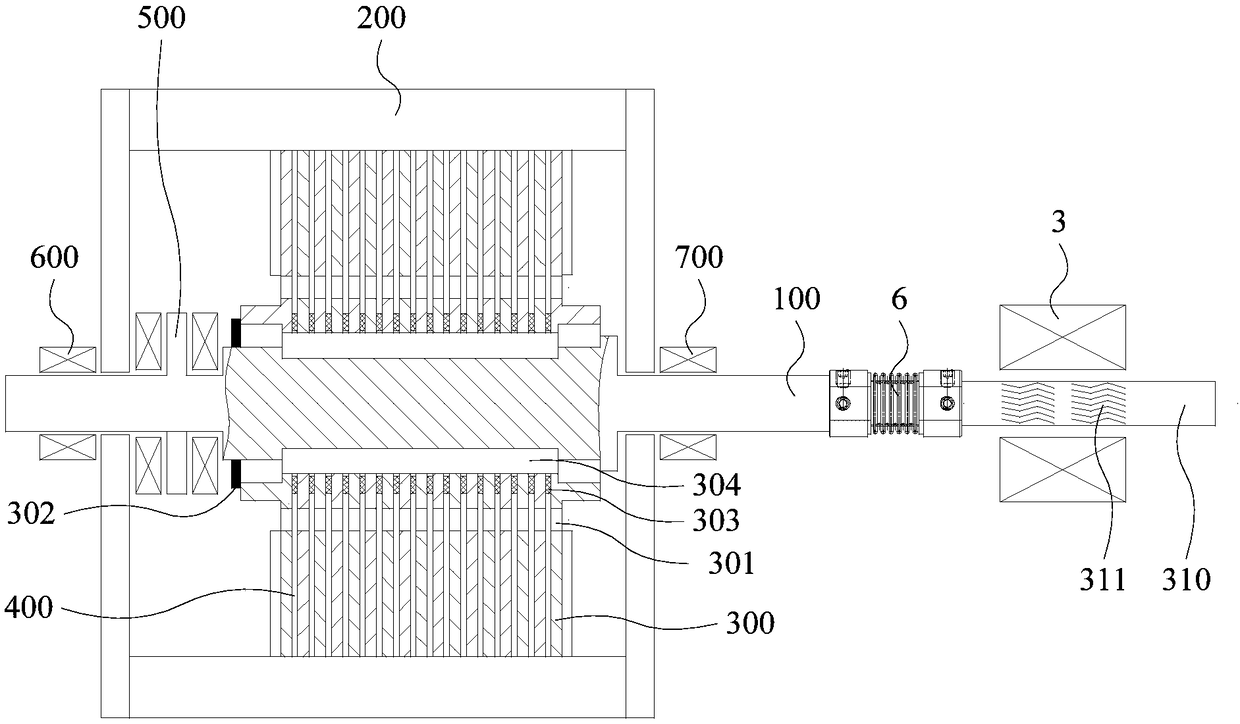

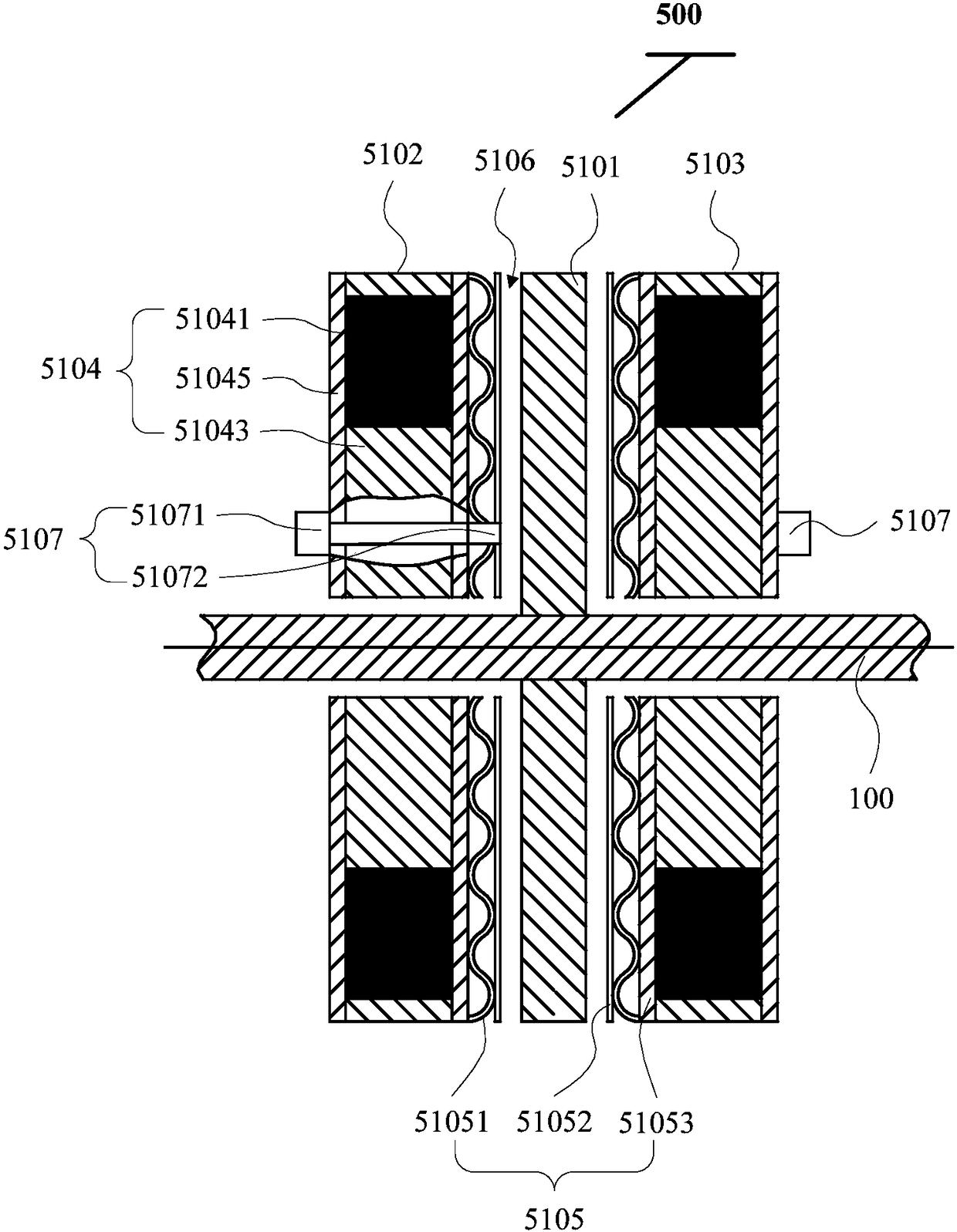

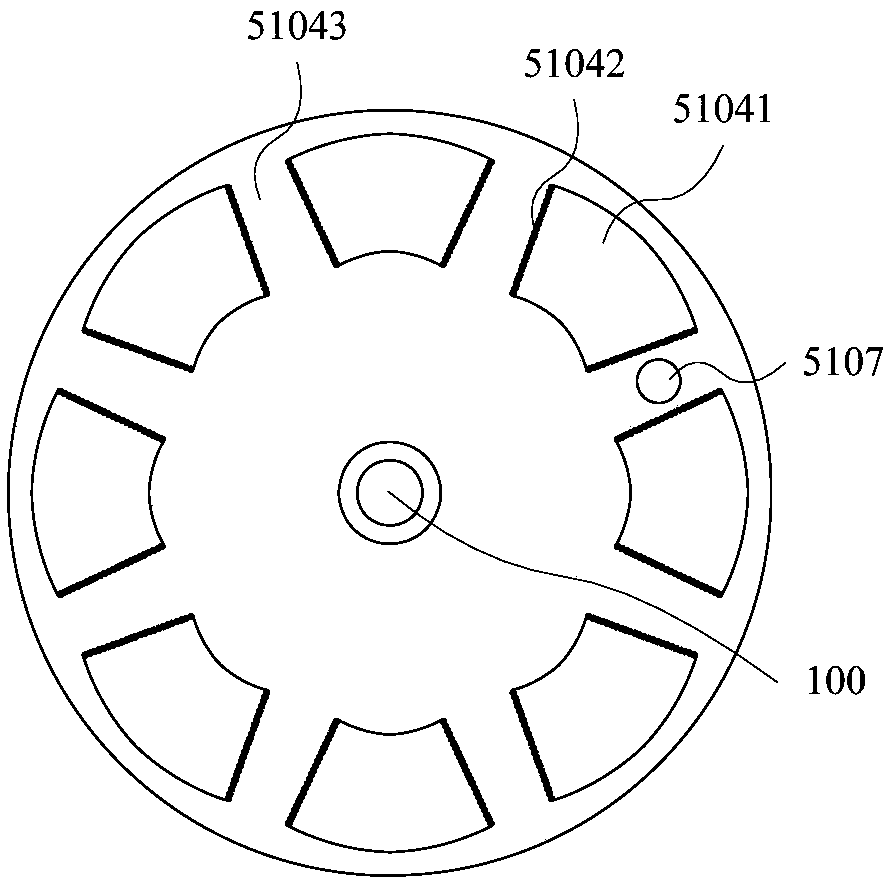

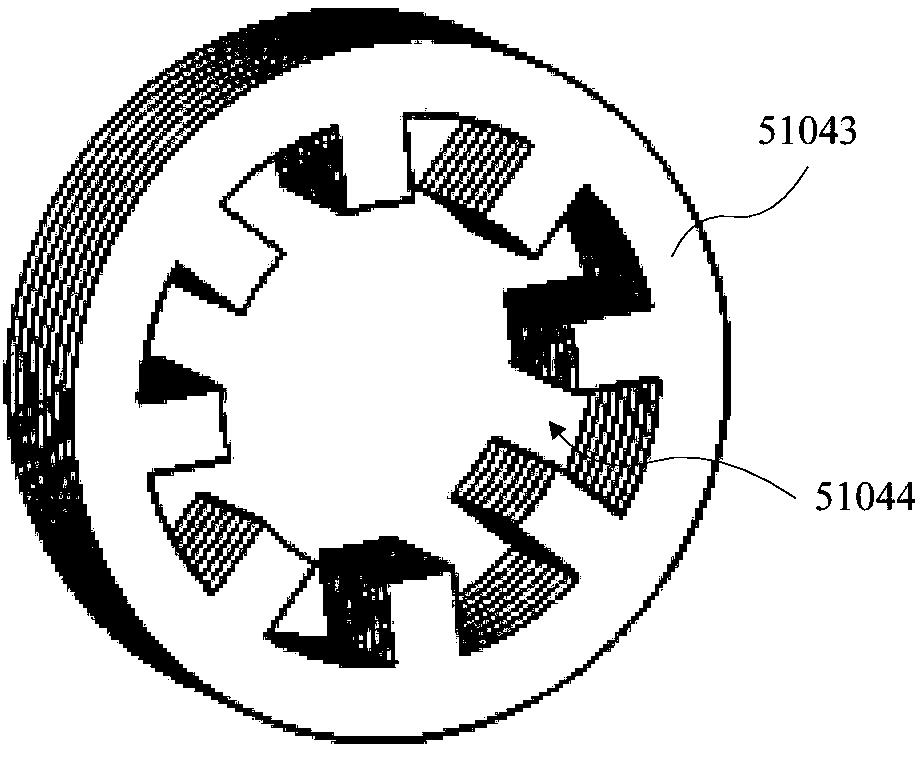

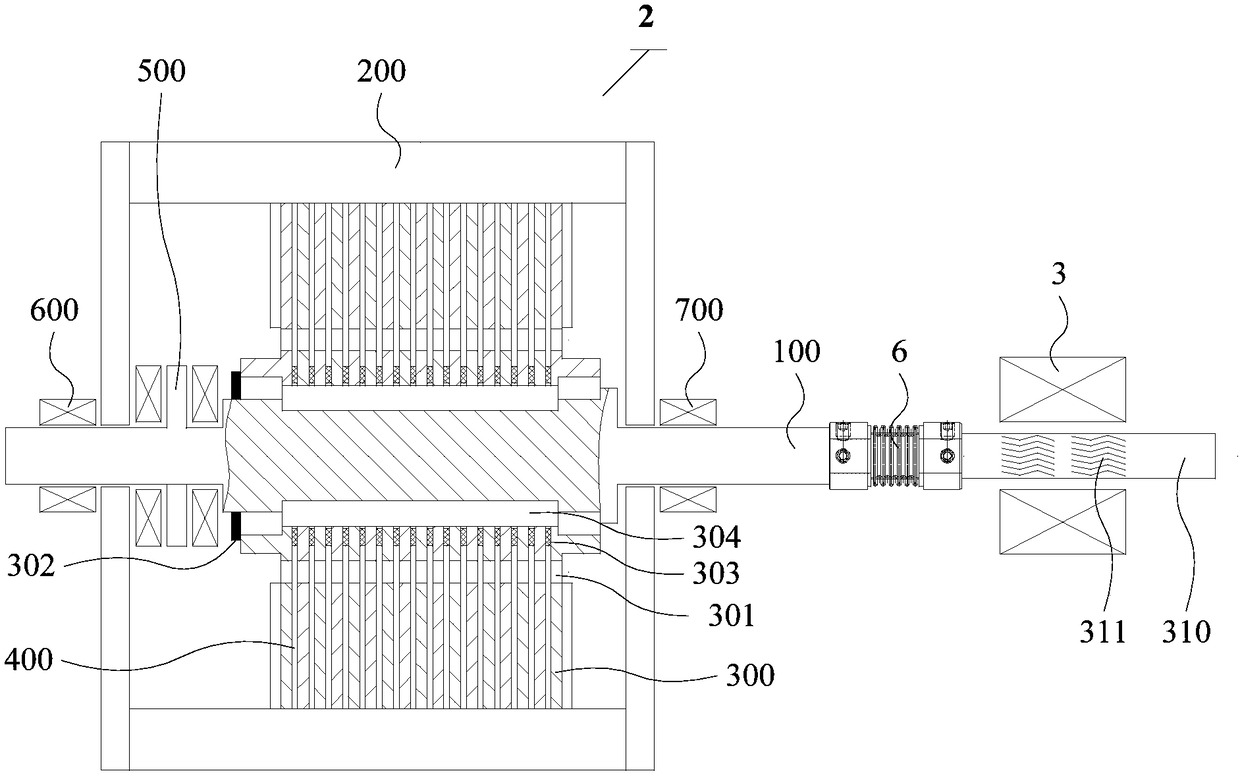

Rotor system and control method of rotor system as well as gas turbine generator set and control method of gas turbine generator set

PendingCN108868892AImprove dynamic performanceImprove stabilityBlade accessoriesGas turbine plantsCouplingGas compressor

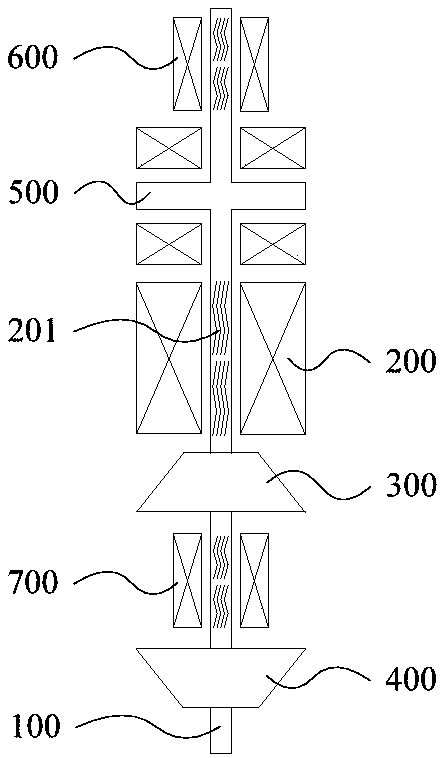

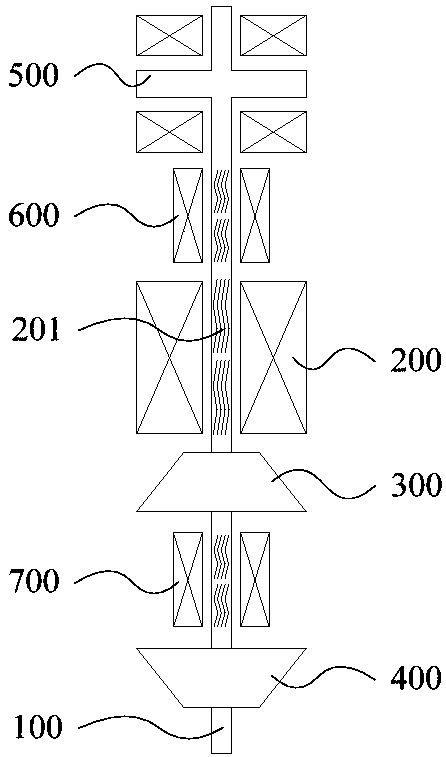

The invention provides a rotor system and a control method of the rotor system as well as a gas turbine generator set and a control method of the gas turbine generator set. The rotor system comprisesa rotating shaft, a generator, a gas compressor and a turbine as well as a thrust bearing and at least two radical bearings, wherein a shaft body of the rotating shaft is of an integrated structure and is horizontally arranged, the generator, the gas compressor and the turbine are sequentially arranged on the rotating shaft, the thrust bearing and the radial bearings are arranged on the rotating shaft, the thrust bearing and the radial bearings are non-contact bearings, and the thrust bearing is arranged at the position where the gravity center of the rotor system can be located between two radial bearings which are spaced by the largest distance. According to the rotator system, the shaft body of the rotating shaft in the rotor system is arranged into the integrated structure, so that theproblem that the installation position of a gas-magnetic hybrid thrust bearing is limited due to the fact that a coupling is used for connection in an existing gas turbine generator set is solved; and the arrangement position of the thrust bearing is adjusted, so that the gravity center of the whole rotator system is located between the two radial bearings which are arranged at the farthest distance, and the structure can be kept stable when the whole rotor system rotates at a high speed.

Owner:刘慕华

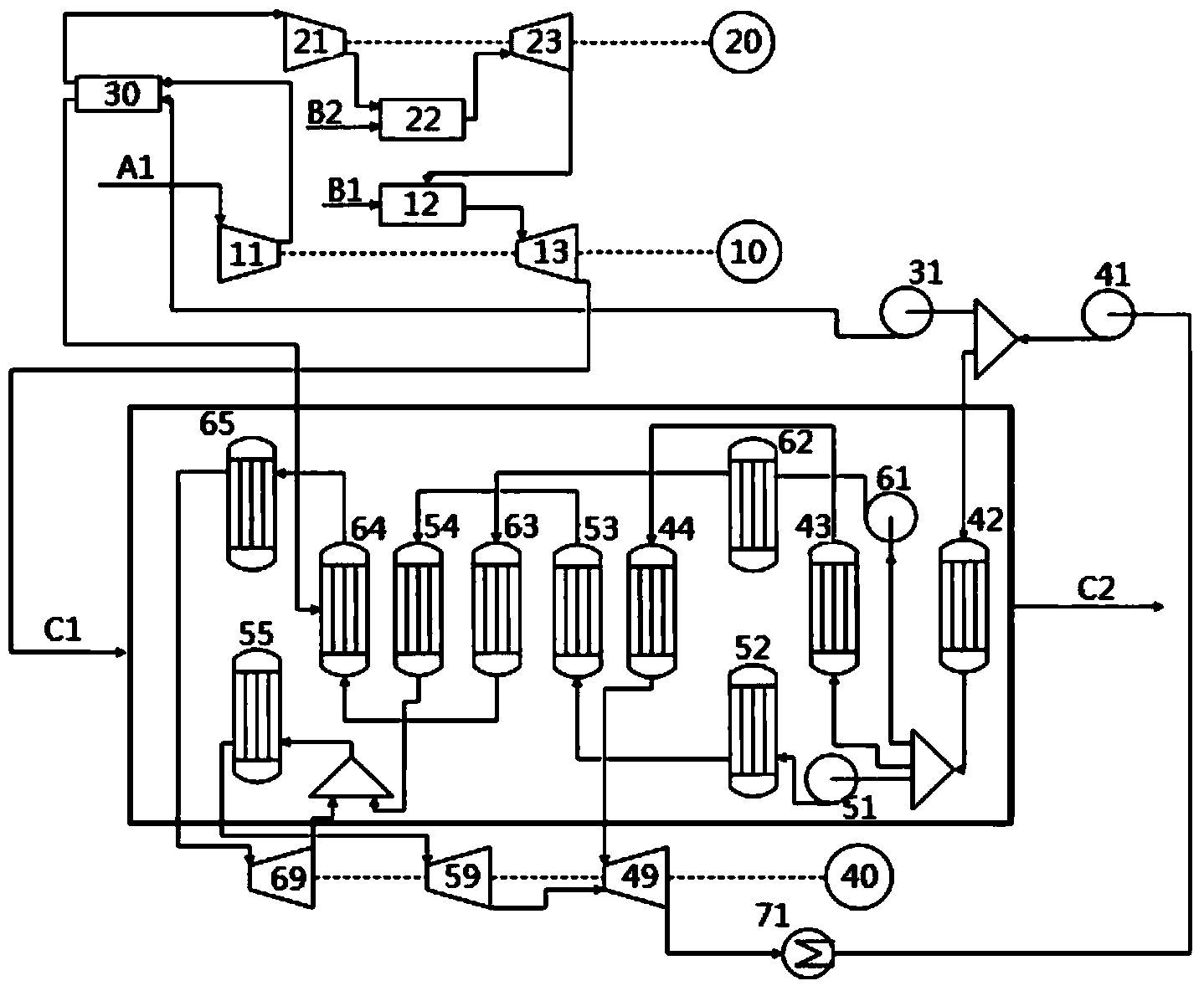

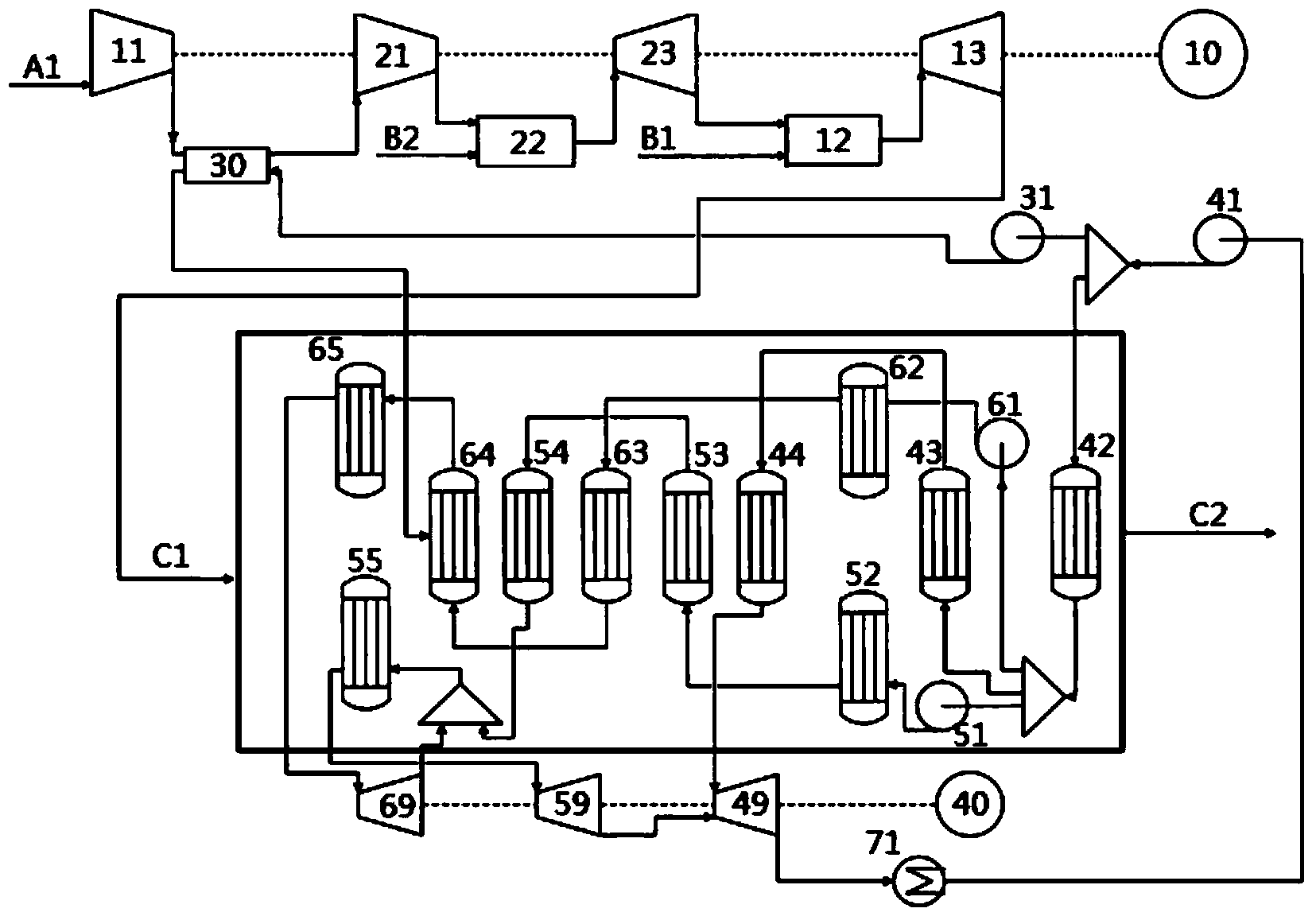

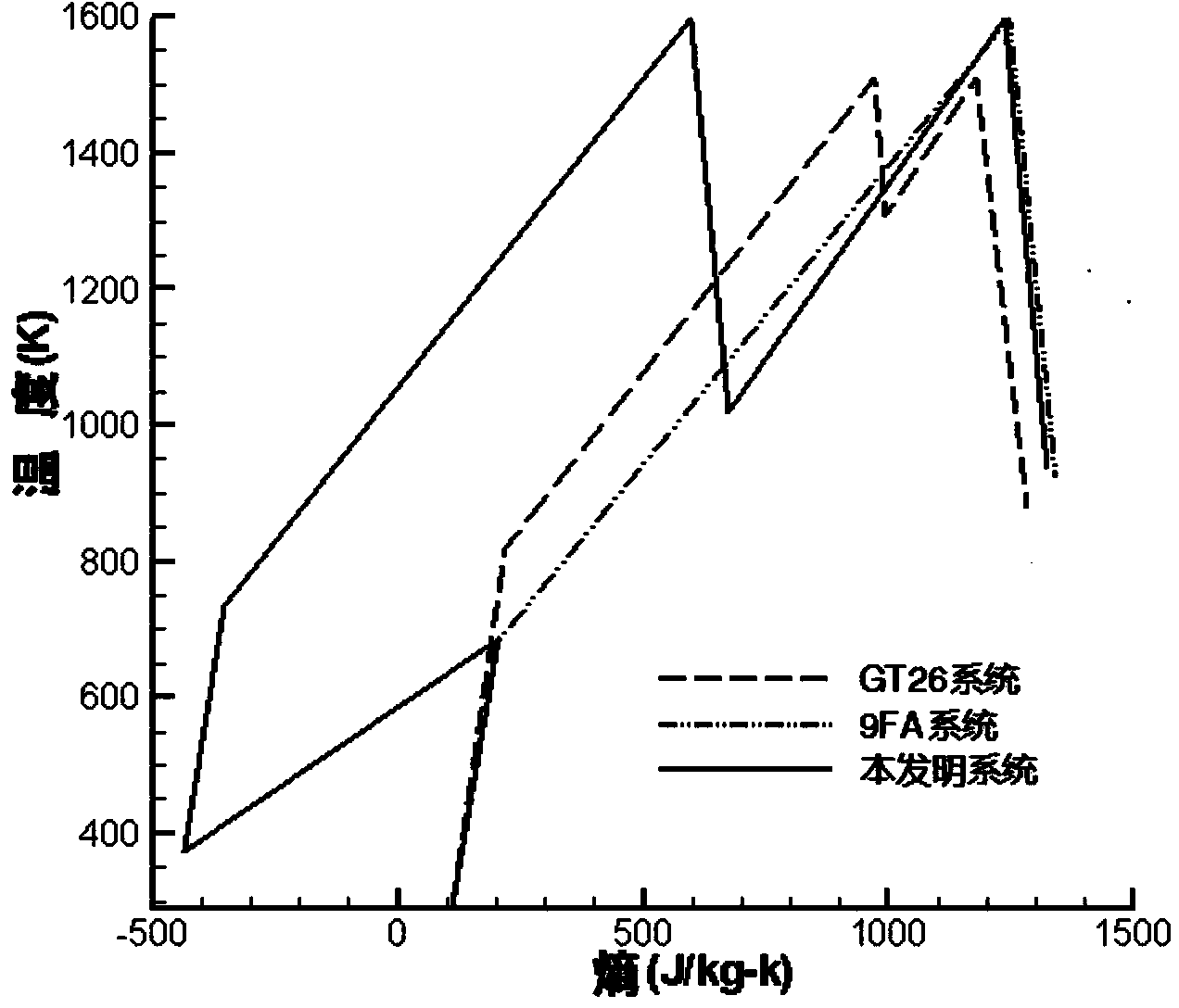

High-pressure reheating gas-steam combined cycle power generation system and power generation method

ActiveCN103711587AAvoid undragable conditionsReduce the difficulty of startingGas turbine plantsSteam engine plantsThermal energyCombustion chamber

The invention relates to a high-pressure reheating gas-steam combined cycle power generation system and a power generation method. The system consists of a gas turbine subsystem and a steam turbine subsystem, wherein the gas turbine subsystem comprises a device used for two-stage air compression, twice combustion as well as high-pressure and medium-pressure twice turbine acting; after primary acting of high-temperature gas, the high-temperature gas enters a medium-pressure combustion chamber and is reheated for secondary acting, so that the average heat absorption temperature of the whole cycle is improved; and at least a one-stage intercooler is arranged between two-stage compressors, and heat flow of the intercooler is connected with the two-stage compressors. The steam turbine subsystem adopts a three-pressure reheating type boiler and a steam turbine, cooling water of the intercooler is connected with high-pressure water, and high-pressure, medium-pressure and low-pressure water as well as the cooling water of the intercooler absorb heat in a staged manner for multiple times, so that heat energy is efficiently utilized. When the high-pressure reheating gas-steam combined cycle power generation system provided by the invention operates with the best parameters, the combined cycle efficiency is increased by 3-5 percentage points compared with a combined cycle system which mainly adopts a gas turbine class F, and the single-machine output power is increased by more than 70%, and reaches 800MW class.

Owner:GUODIAN NEW ENERGY TECH INST

Y type sealing unit

InactiveCN102278479AEliminate hidden dangersImprove sealingEngine sealsNumerical controlHydraulic cylinder

The invention discloses a sealing unit, which is installed between a piston rod and a hydraulic oil cylinder, and includes a guide sleeve and a Y-shaped sealing ring. An oil inlet is arranged on the guide sleeve corresponding to the opening of the inner cavity of the Y-shaped sealing ring. The mouth is located between the end face of the guide sleeve and the sealing groove. The invention is a sealing assembly based on a Y-shaped ring, which solves the problems of poor sealing and low moving speed of a hydraulic oil cylinder in frequent reciprocating motion, reduces wear and improves the sealing compensation effect on the wear part. The present invention eliminates the hidden danger of Y-shaped sealing ring oil passage by setting the oil inlet; the present invention also reduces the wear of the inner wall of the cylinder by setting the support ring, improves the sealing performance and service life of the hydraulic oil cylinder, and reduces the maintenance cost Adopt the numerically controlled machine tool hydraulic balance oil cylinder of the present invention, the life-span increase is about 4 times (more than 8 years) of the original design, and the maximum movement speed increases about 3 times of the original design (working pressure P≤32MPa, 15m / s).

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Rotor system and control method of rotor system as well as gas turbine generator set and control method of gas turbine generator set

PendingCN108868891AImprove dynamic performanceImprove stabilityBlade accessoriesGas turbine plantsLarge distanceGas turbines

The invention provides a rotor system and a control method of the rotor system as well as a gas turbine generator set and a control method of the gas turbine generator set. The rotor system comprisesa rotating shaft, a motor, a gas compressor and a turbine as well as a thrust bearing and at least two radical bearings, wherein a shaft body of the rotating shaft is of an integrated structure, the rotating shaft is vertically arranged, the motor, the gas compressor and the turbine are sequentially arranged on the rotating shaft, the thrust bearing and the radial bearings are arranged on the rotating shaft, the thrust bearing and the radial bearings are non-contact bearings, the thrust bearing is arranged at a preset position of one side, close to the gas compressor, of the turbine, and the preset position is the position where the center of gravity of the rotator system can be located between the two radial bearings which are spaced by the largest distance. According to the rotator system, the non-contact type bearings are adopted so that the rotor system can be vertically arranged; and in this way, the gravity center of the rotator system is located at the axis, static deflection cannot be generated, moreover, the torque generated by the gravity on the axis is zero, therefore, the influence of the gravity on the rotation of the rotator system can be eliminated, and then the stability of the rotator system can be improved.

Owner:刘慕华

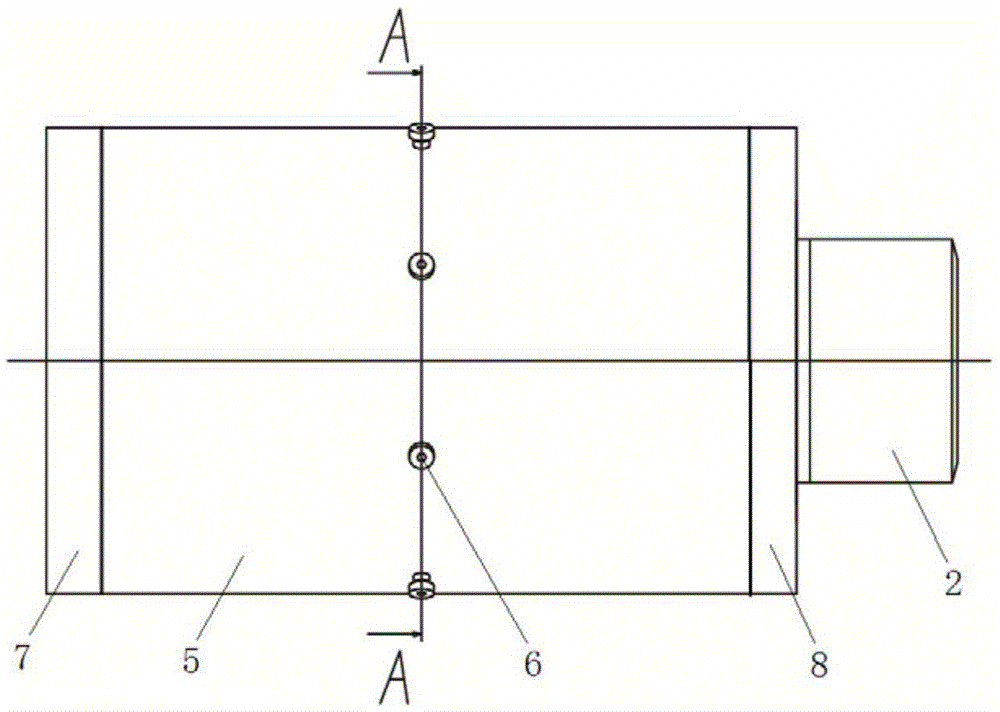

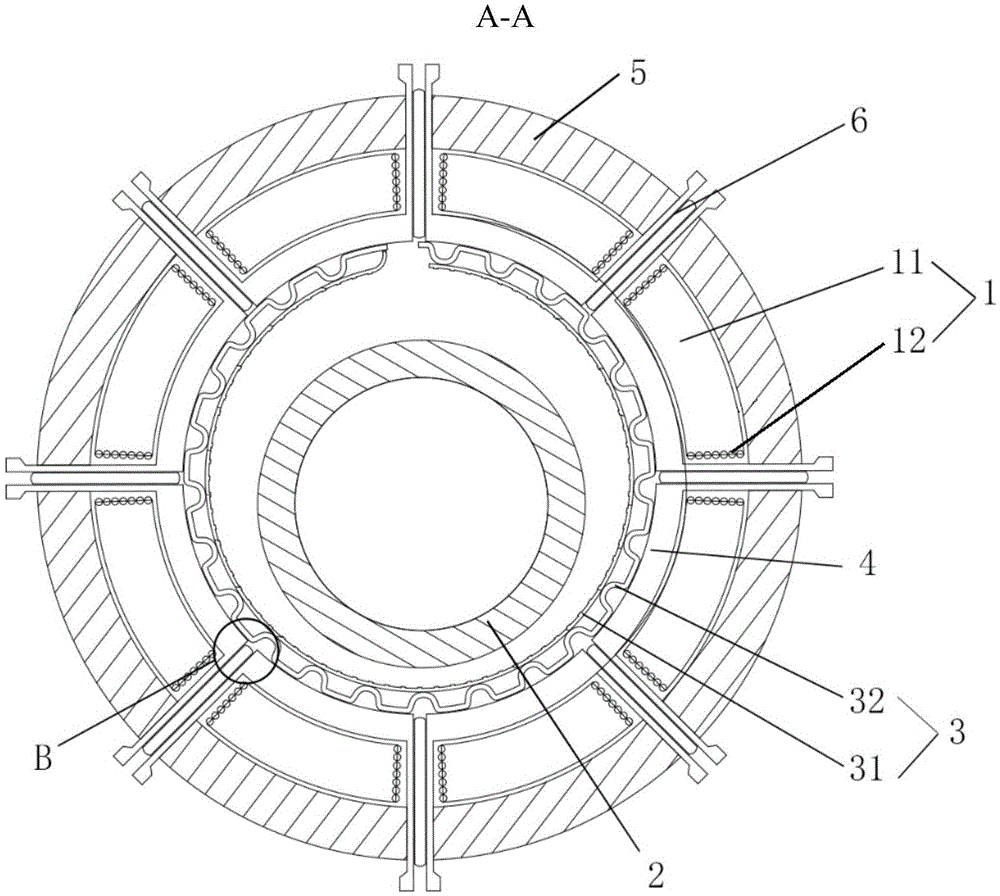

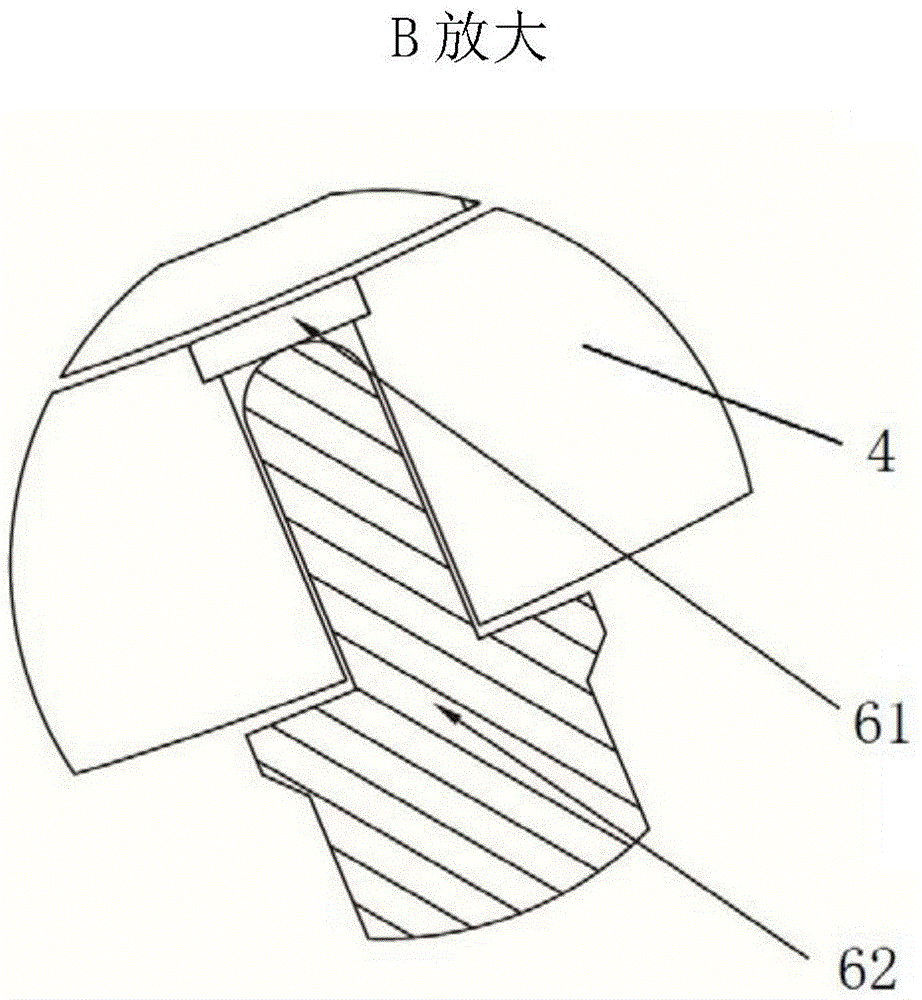

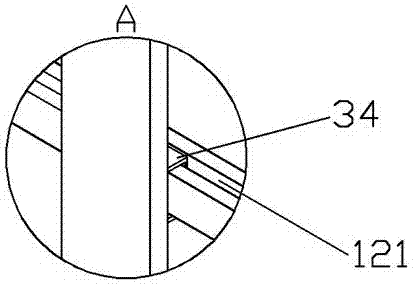

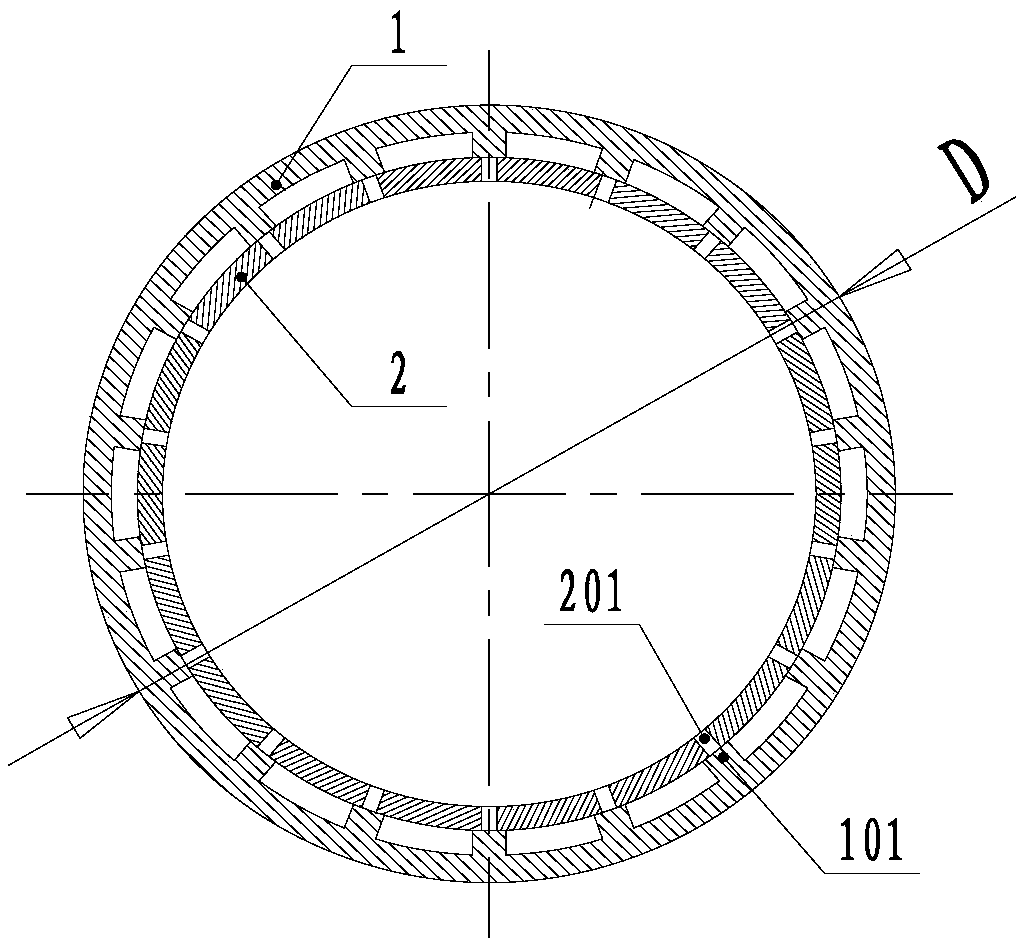

Electromagnetically enabled active hydrodynamic gas-lubricated bearing

ActiveCN105545956AImprove carrying capacityImprove the ability of anti-disturbed eccentric wall collisionGas cushion bearingsShaftsLow speedMagnetic bearing

The invention provides an electromagnetically enabled active hydrodynamic gas-lubricated bearing. The electromagnetically enabled active hydrodynamic gas-lubricated bearing comprises an electromagnetic bearing (1) and an elastic foil bearing (3) nested between the electromagnetic bearing (1) and a rotor shaft (2), and is characterized in that the elastic foil bearing (3) comprises elastic top foil (31) and elastic bottom foil (32), the elastic top foil (31) is a non-magnetic material, and a plurality of mutually independent magnetic material areas are distributed on the surface of the elastic top foil (31). The electromagnetically enabled active hydrodynamic gas-lubricated bearing is simple in structure, has low requirement for precision, adopts a gas-magnetism mixed bearing structure, is provided with the adjustable magnetic flat foil and low-cost pressure sensors, and solves the problem that lubrication airflow leaks and is difficult to control due to low low-speed bearing capacity and bearing disturbance eccentricity during work of the conventional hydrodynamic gas-lubricated bearing.

Owner:TECH XANADU OF RESONATORY SOLAR SYSTD CO LTD +1

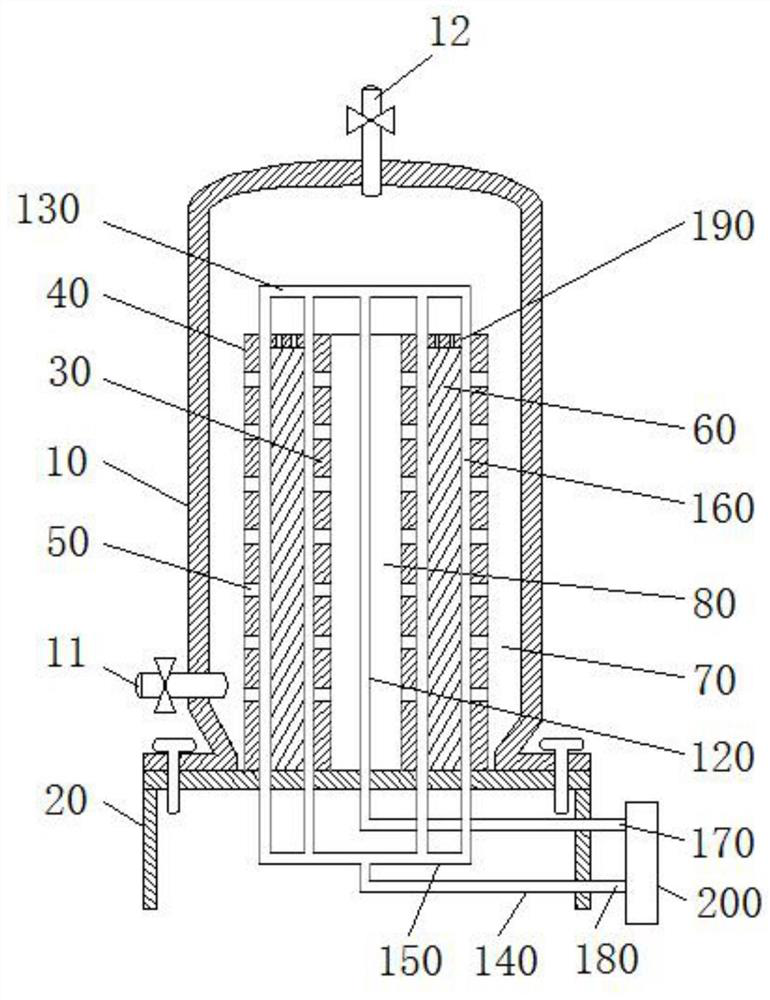

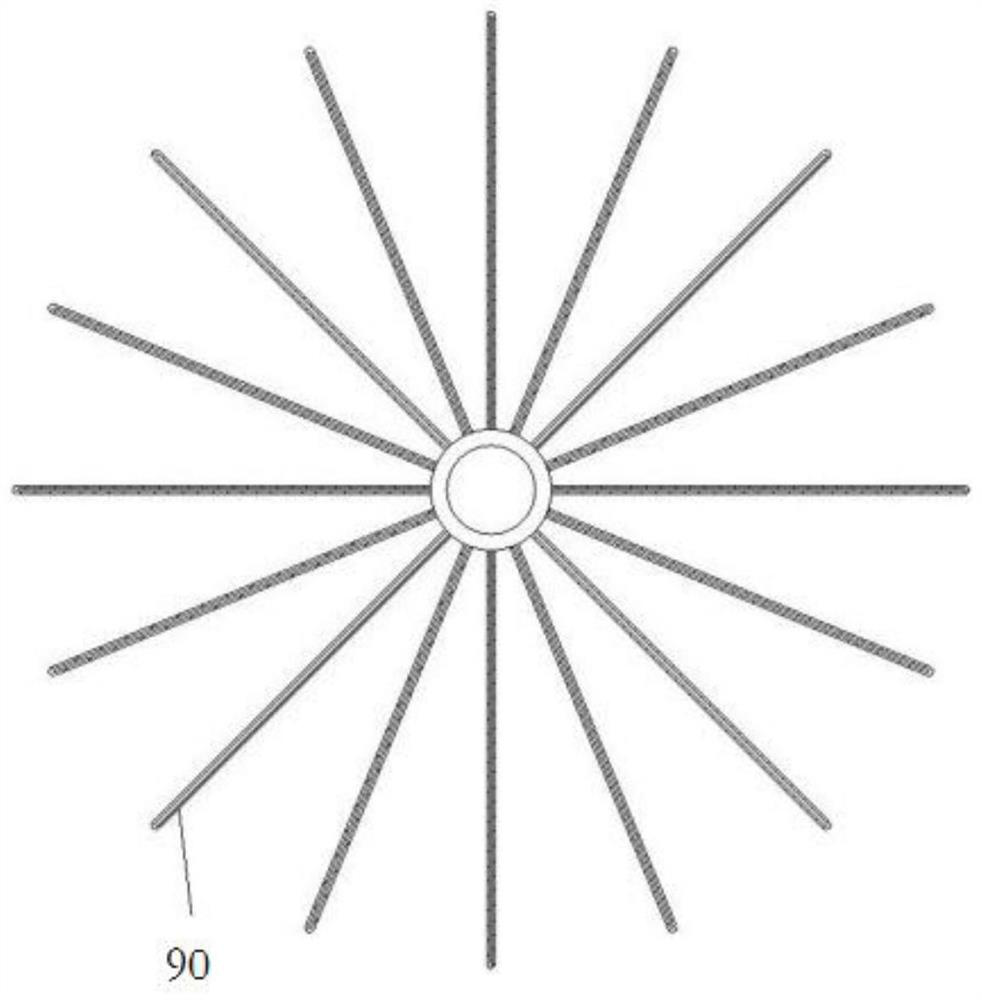

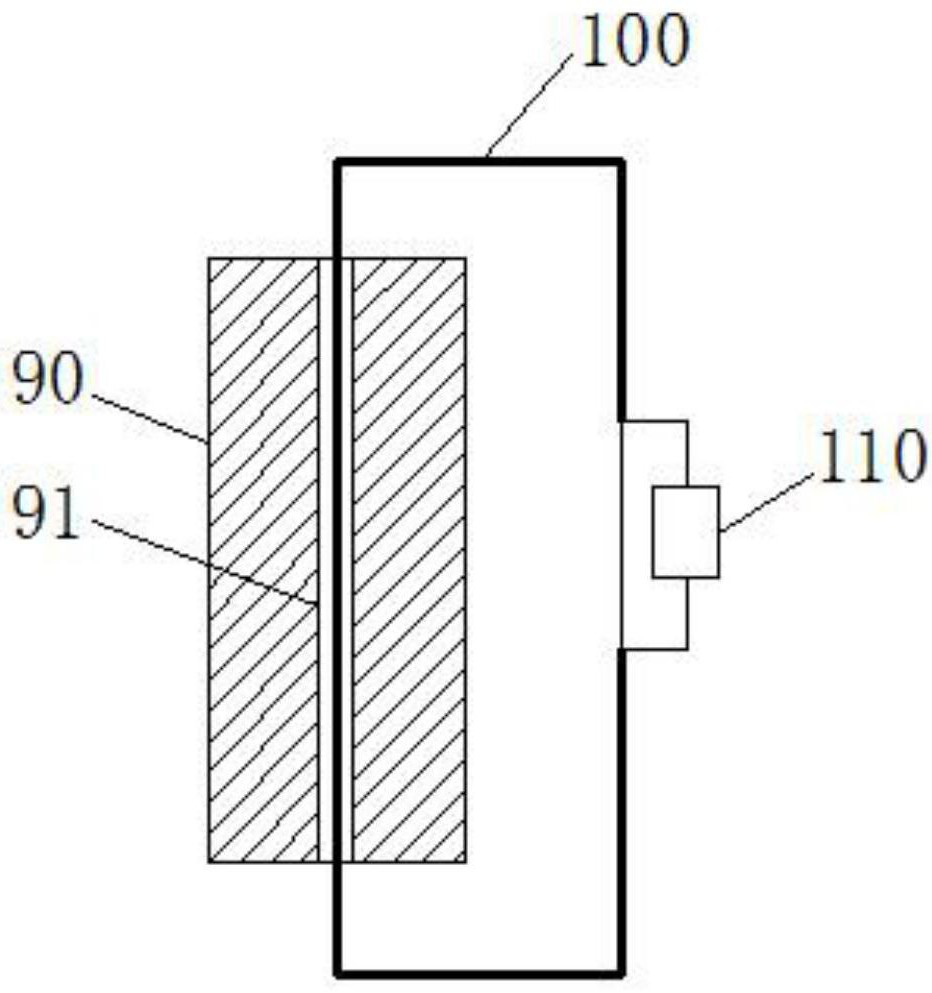

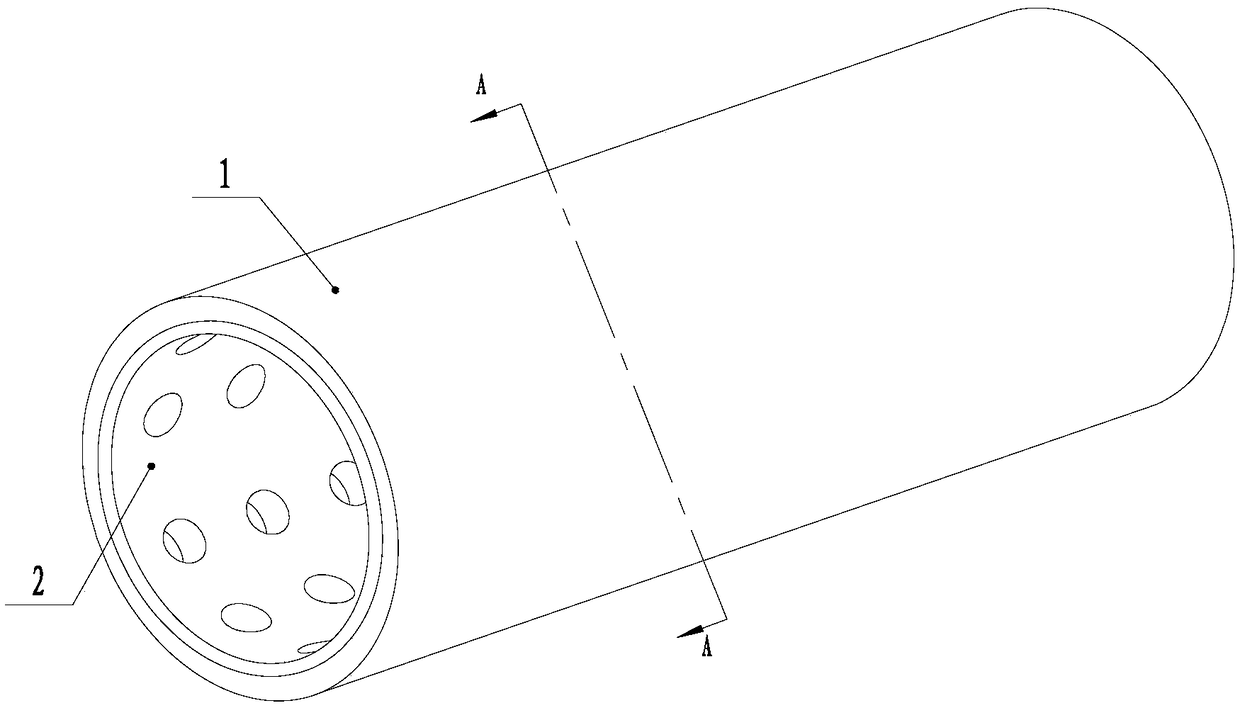

High-pressure composite metal hydride hydrogen storage tank and hydrogen storage method thereof

ActiveCN113375039AAbundant storageHigh mass density of hydrogen storageVessel geometry/arrangement/sizeContainer filling methodsMetallurgyGaseous hydrogen

The invention discloses a high-pressure composite metal hydride hydrogen storage tank and a hydrogen storage method thereof. The hydrogen storage tank comprises a base support and a hydrogen storage tank shell with an opening in the bottom, and the hydrogen storage tank shell is installed on the base support in a sealed and buckled mode. A hydrogen inlet and a hydrogen outlet are formed in the hydrogen storage tank shell. A hydrogen storage alloy storage space, a gaseous hydrogen storage gap and a circulating heat exchange system are arranged in the hydrogen storage tank shell. The hydrogen storage alloy storage space is filled with hydrogen storage alloy, and the circulating heat exchange system is used for absorbing heat when the hydrogen storage alloy absorbs hydrogen and heating the hydrogen storage alloy when the hydrogen storage alloy releases hydrogen. According to the high-pressure composite metal hydride hydrogen storage tank and the hydrogen storage method thereof, a gas hydrogen storage gap is formed in the hydrogen storage tank, the size of a reserved gap can be adjusted according to the requirement of hydrogen storage mass density, hydrogen storage of different mass densities is achieved, the advantages of high mass density of high-pressure gas hydrogen storage and high volume density of solid hydrogen storage are fully combined, and the volume of the solid hydrogen storage part is adjusted, the purpose of storing more hydrogen under equal pressure is achieved.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD

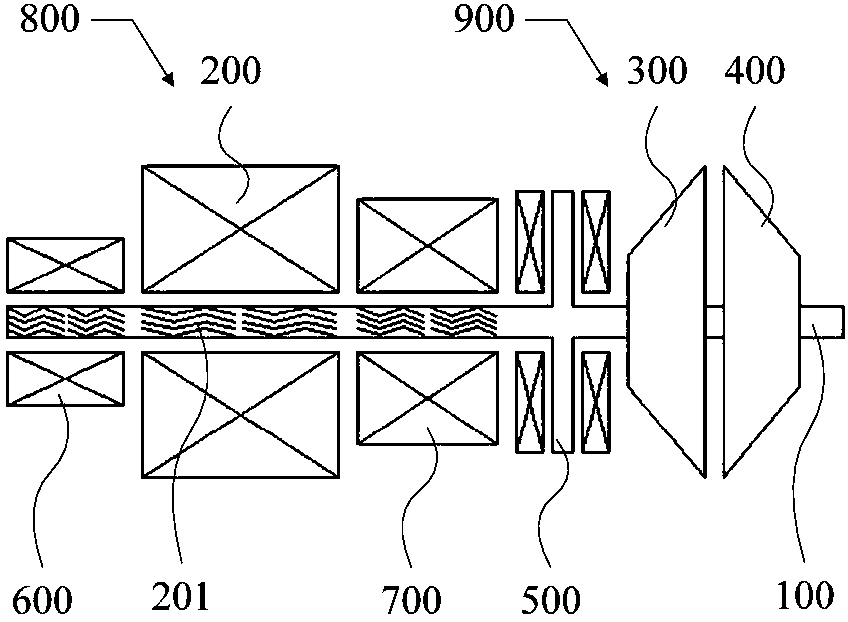

Rotor system and control method thereof and gas turbine generator set and control method thereof

PendingCN108868893AImprove dynamic performanceImprove stabilityBlade accessoriesGas turbine plantsImpellerGas compressor

The invention provides a rotor system and a control method thereof and a gas turbine generator set and a control method thereof. The rotor system comprises a rotating shaft, a generator, a gas compressor, a turbine, a thrust bearing, two radial bearings, a first casing and a second casing; the shaft body of the rotating shaft is of an integrated structure, and the rotating shaft is horizontally arranged or vertically arranged; the generator, the gas compressor, the turbine, the thrust bearing and the two radial bearings are arranged on the rotating shaft, and the thrust bearing and the two radial bearings are non-contact bearings; the first casing is connected to the second casing; the generator, the thrust bearing and the two radial bearings are arranged in the first casing, and the gas compressor and the turbine are arranged in the second casing; and the impeller of the gas compressor is arranged close to the impeller of the turbine in the second casing. According to the system and the control method, the machining precision and assembly precision of the gas turbine generator set are reduced, the cost is reduced, and the gas turbine generator set is suitable for engineering batchproduction.

Owner:刘慕华

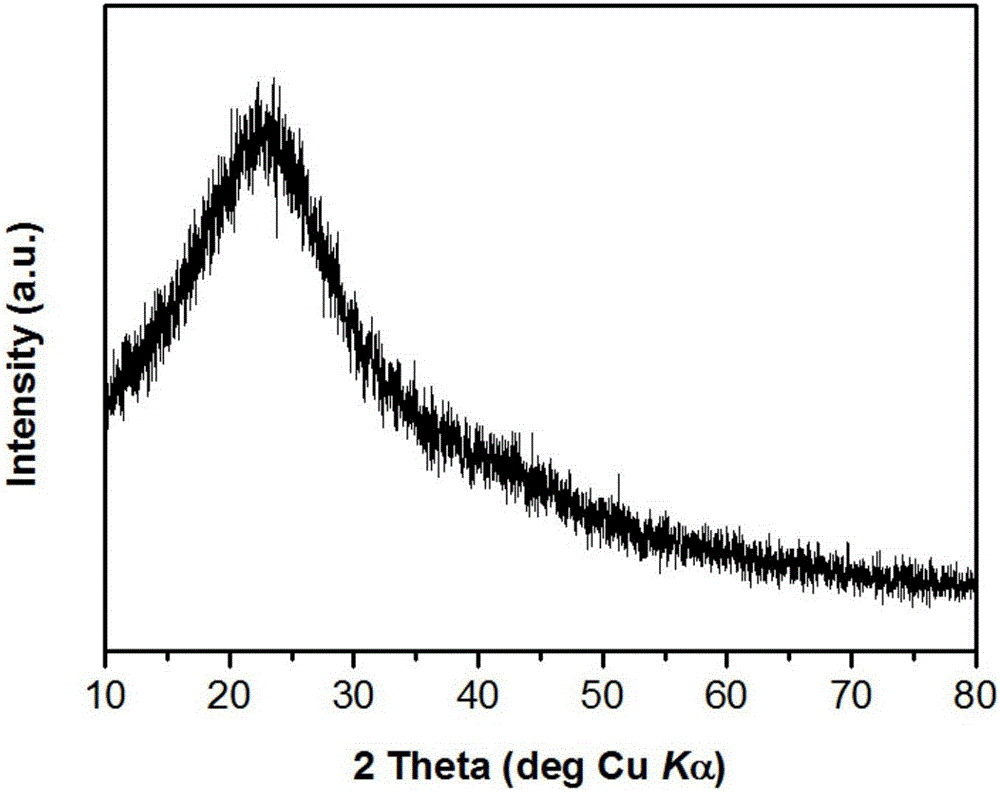

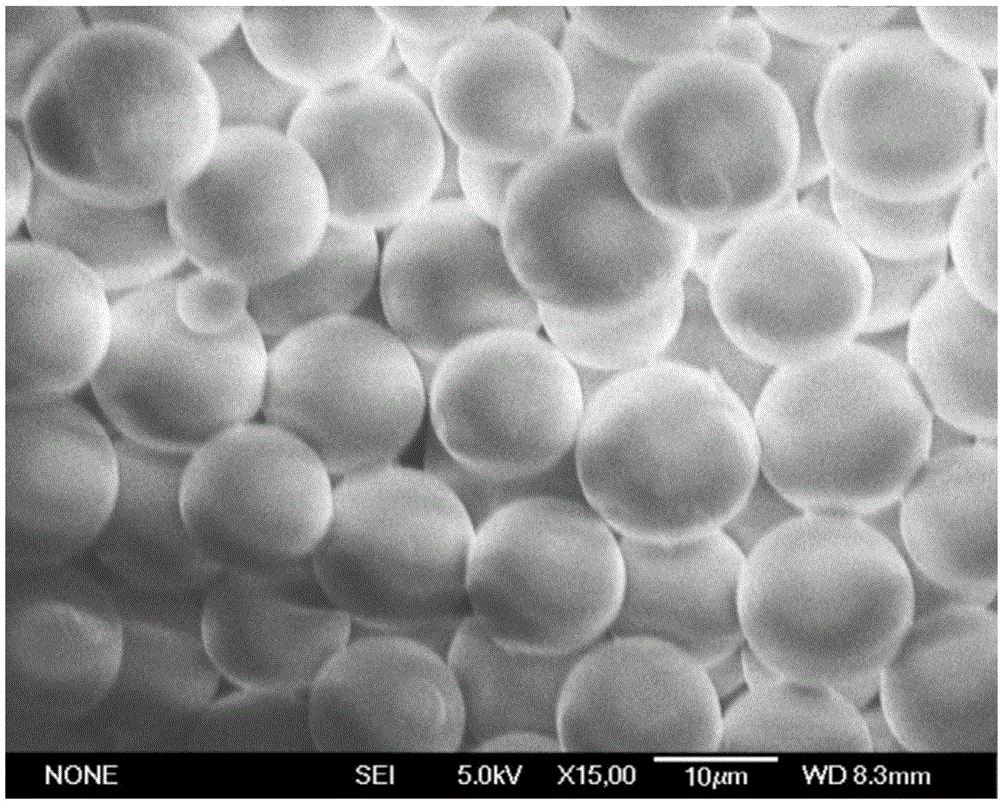

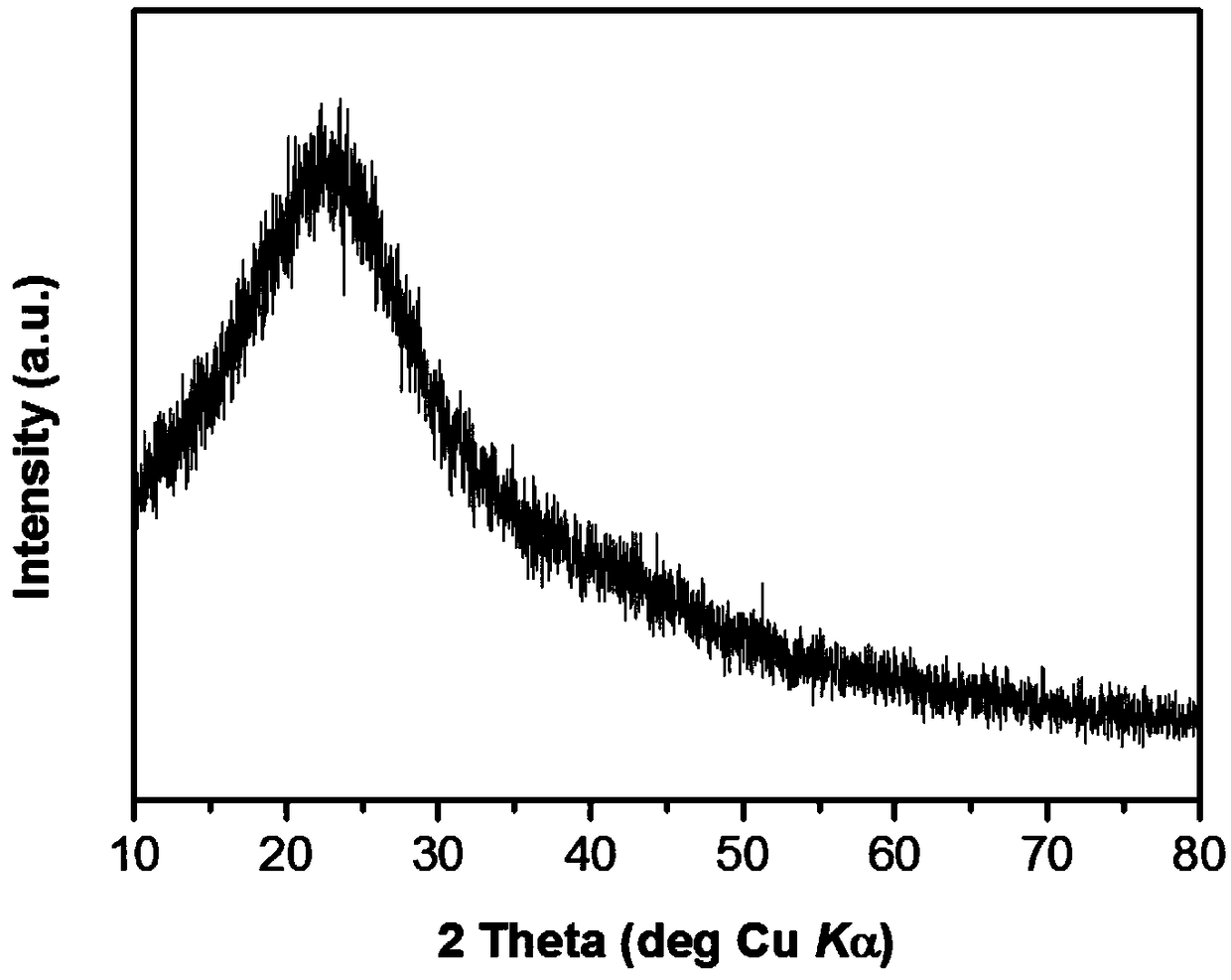

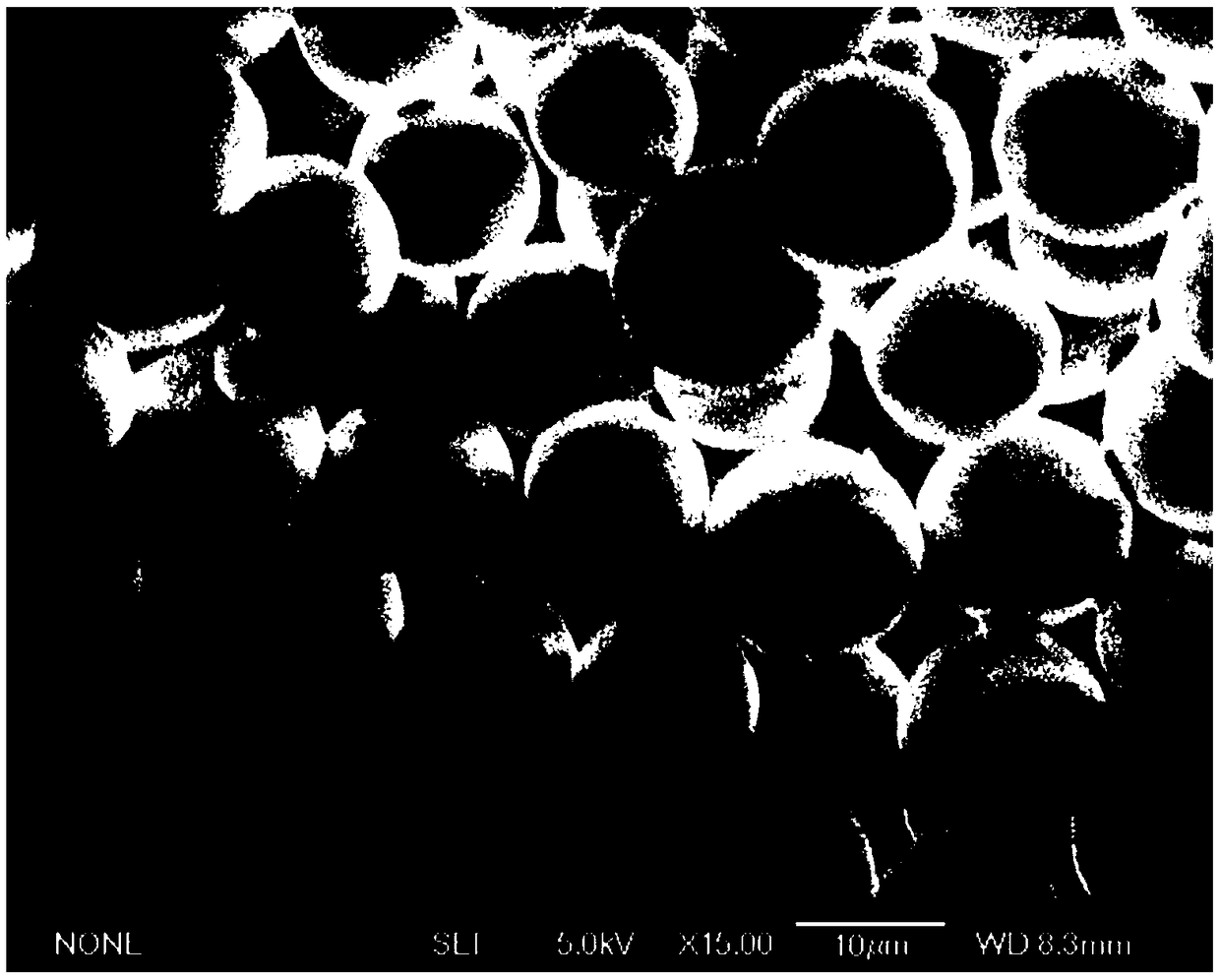

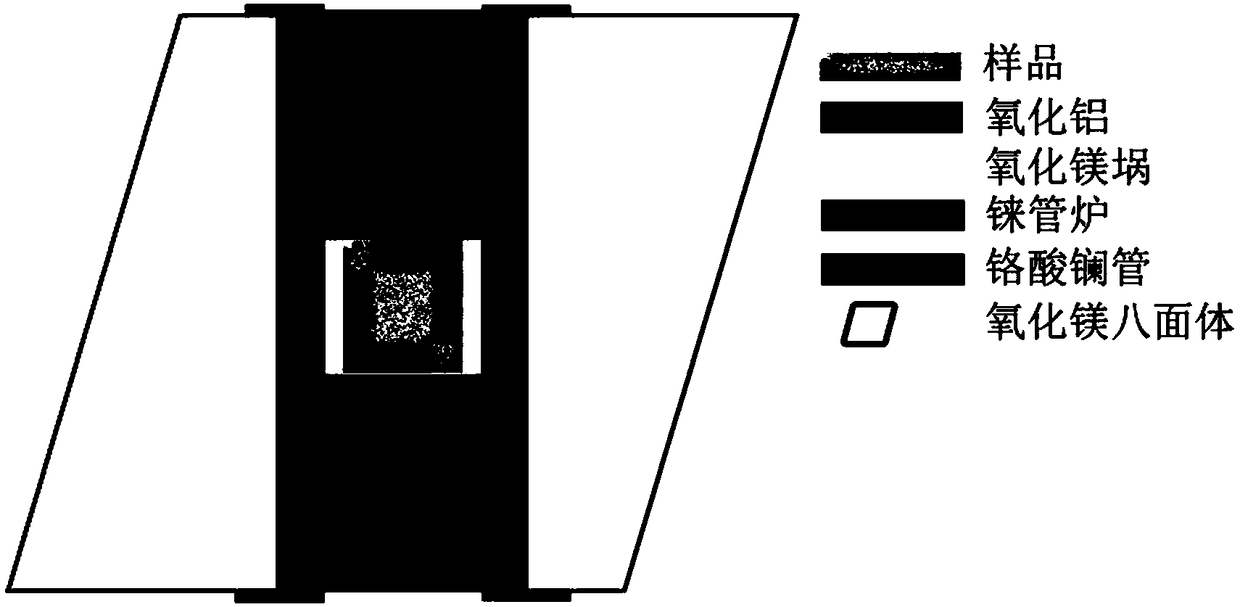

Method of preparing polycrystalline diamond microspheres by hydro-thermal synthesis of carbon spheres

ActiveCN106582448AThe size is easy to controlUniform sizeUltra-high pressure processesCarbon preparation/purificationRheniumMicrosphere

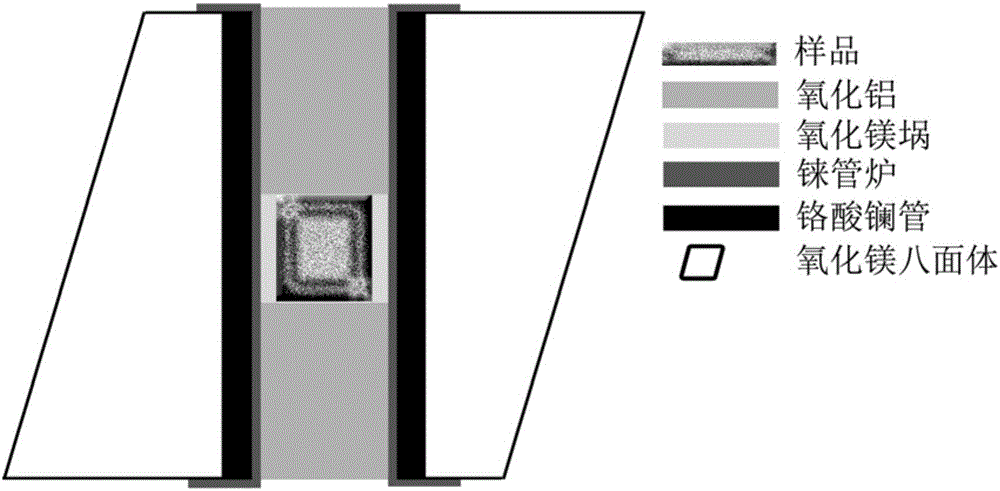

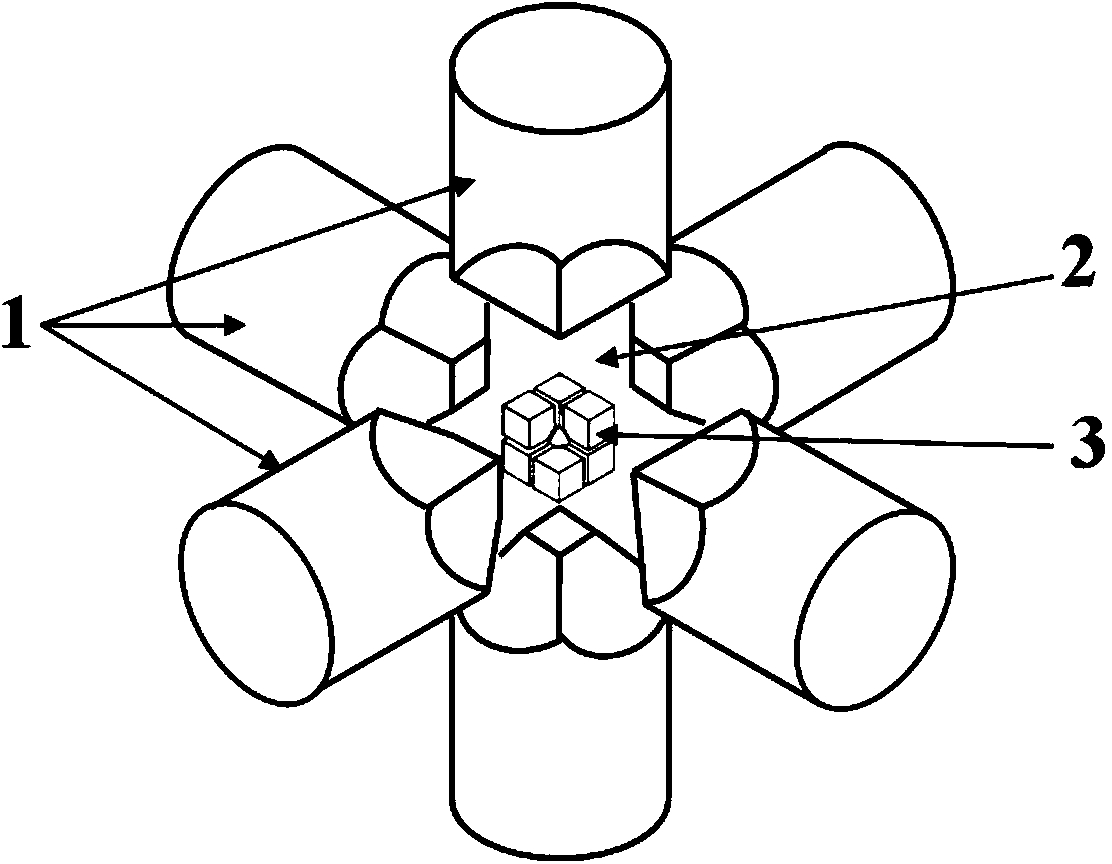

The invention discloses a method of preparing polycrystalline diamond microspheres by hydro-thermal synthesis of carbon spheres and belongs to the field of material preparation. The method comprises the steps: by taking a 0.1-0.2mol / L glucose solution as a raw material, synthesizing carbon microspheres at constant temperature 2-4 hours in an oven at 200 DEG C by virtue of a hydrothermal method; dispersing the prepared carbon microspheres to ball-milled sodium chloride superfine powder to form a mixture as a raw material, filling a mould with the raw material and performing compression moulding, filling a magnesium oxide pot after demoulding, forming an assembly block with a pressure transmitting medium magnesium oxide, a rhenium tube furnace, a lanthanum chromite ring and an aluminum oxide column, and putting the assembly block in the oven at constant temperature of 120 DEG C in the oven 3-4 hours; and taking out the assembly block and putting the assembly block in a high-temperature high-pressure device, and performing a high-temperature reaction at an ultrahigh pressure to obtain the polycrystalline diamond microspheres. According to the method disclosed by the invention, no catalysts are added, and the obtained diamond microspheres are uniform in size and compact in block, and the Vickers hardness reaches 60-80 GPa.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

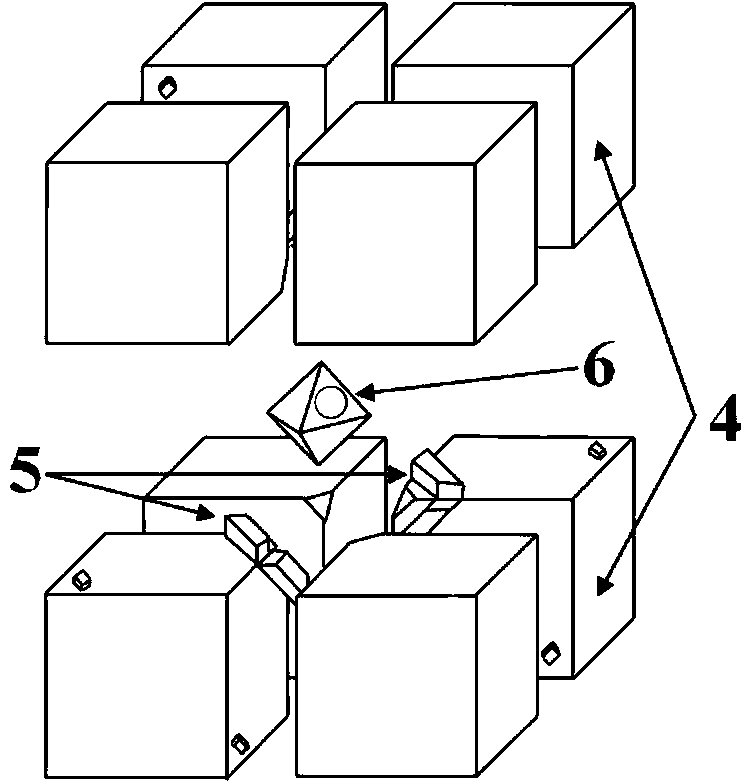

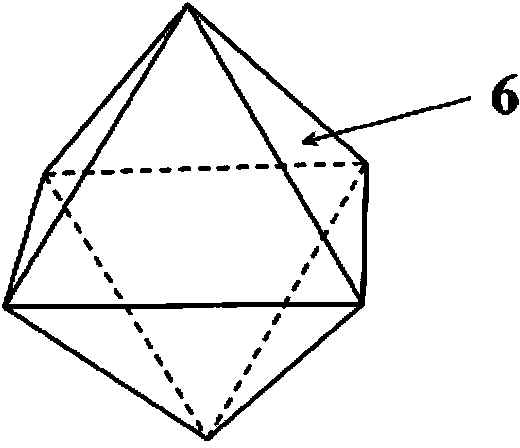

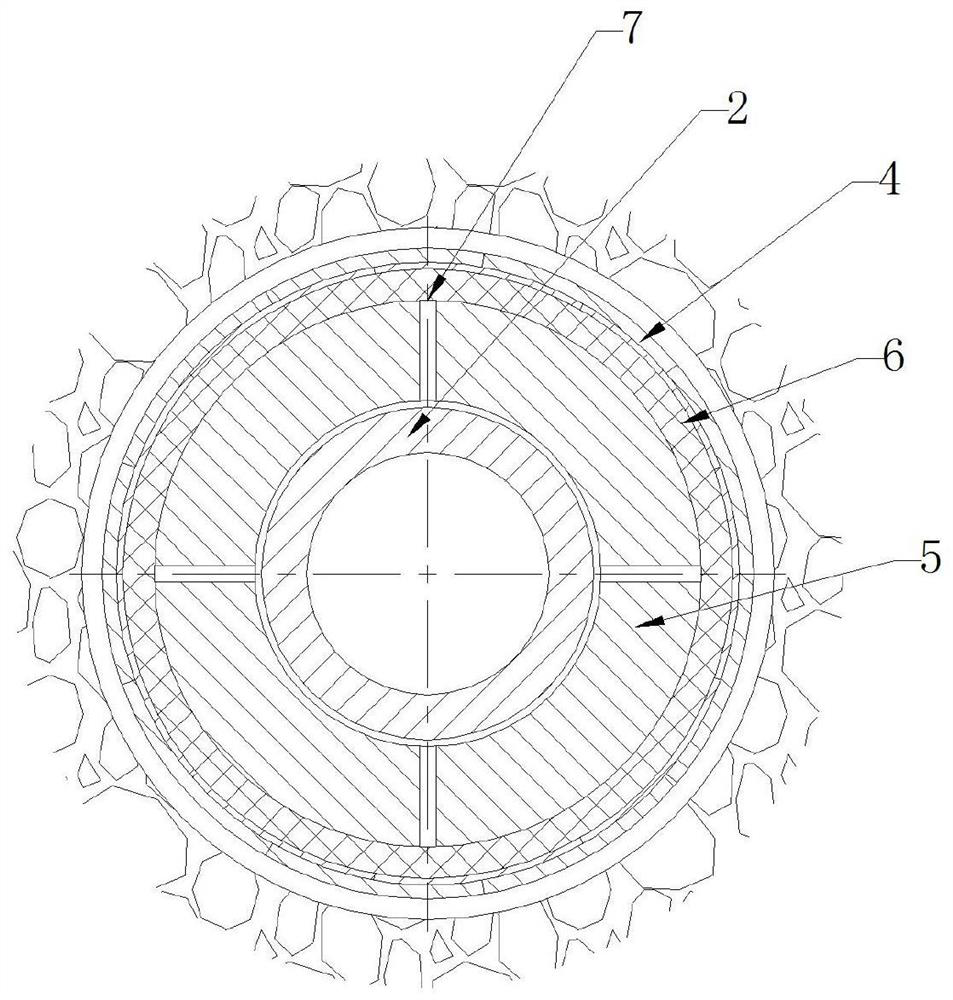

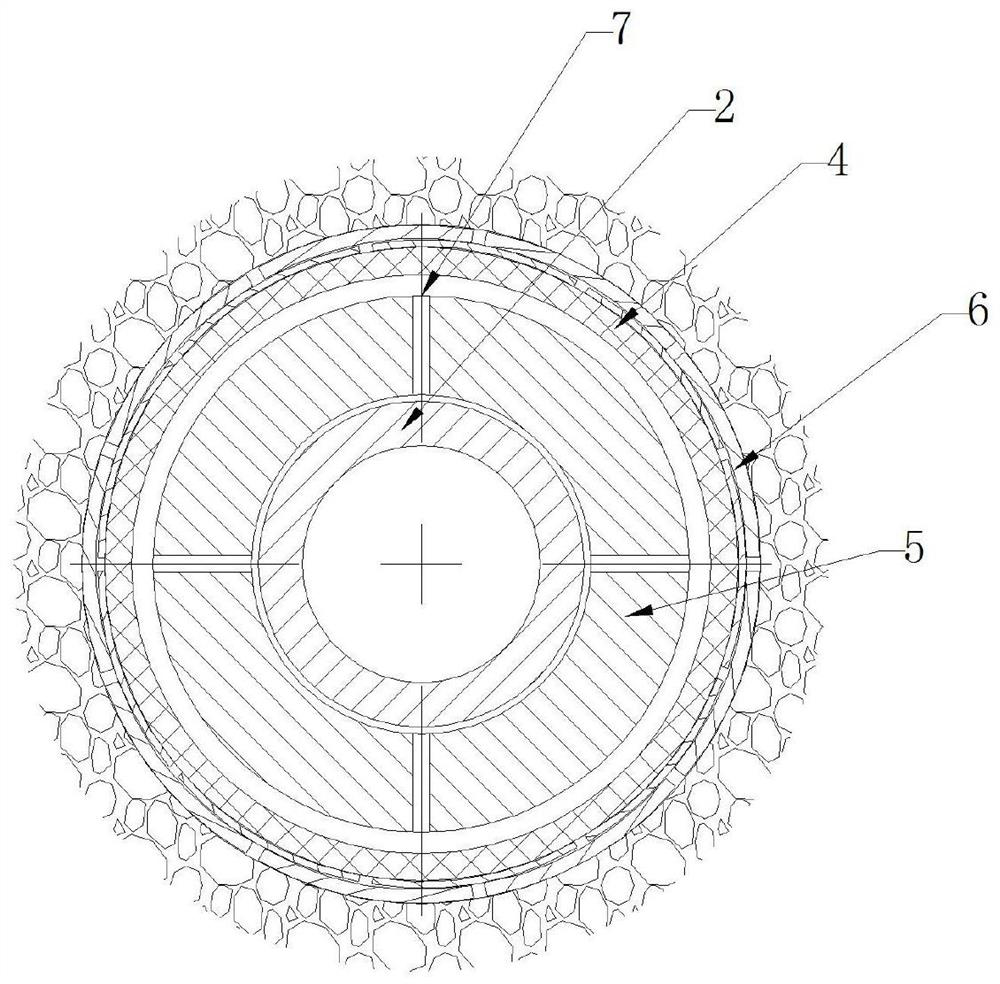

Secondary anvil and secondary pressurizing unit of octahedral pressure cavity static high-pressure device

ActiveCN103446946AEnhanced pressure sealing capabilityIncreasing the thicknessUltra-high pressure processesEngineeringHigh pressure

The invention relates to a secondary anvil of an octahedral pressure cavity static high-pressure device. An anvil body is in a cube shape; an anvil surface is a regular triangular surface formed by cutting a corner of the cubic anvil body; at least one circle of outer ring surface is arranged around the anvil surface; the outer ring surface in each same circle comprises three trapezoidal slants which are same in shape and size; a regular triangle is enclosed by the bottom edges of the three trapezoidal slants. The secondary pressurizing unit of the octahedral pressure cavity static high-pressure device comprises the eight secondary anvils, a previous sealing strip and an octahedral pressure transmitting medium. Compared with the traditional secondary pressurizing unit, for the secondary pressurizing unit which comprises the secondary anvils disclosed by the invention, experiments indicate that the blasting probability is obviously reduced during operation and the maximal pressure which can be achieved a the body of an octahedral pressure cavity can be increased.

Owner:FUNIK ULTRAHARD MATERIAL

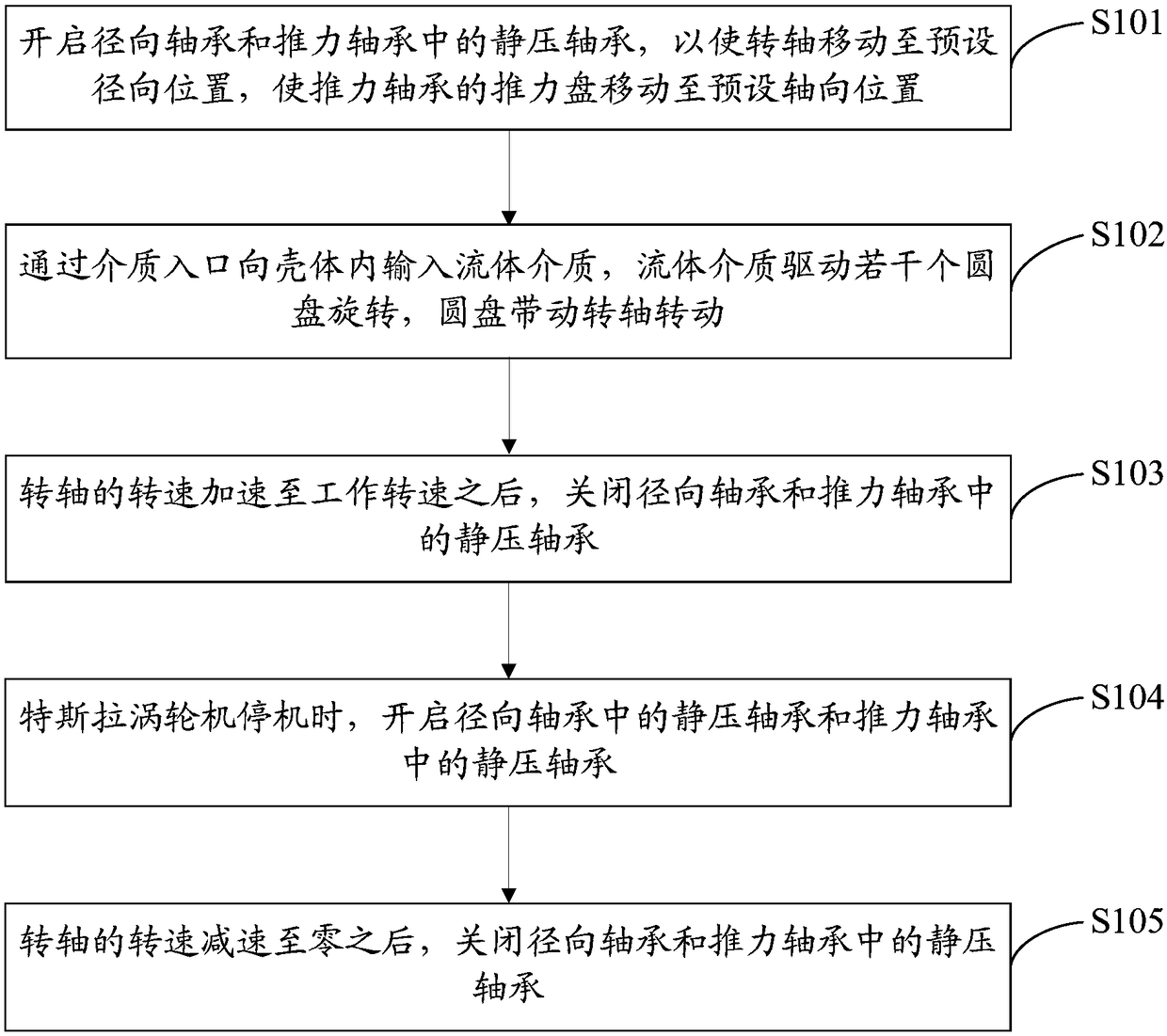

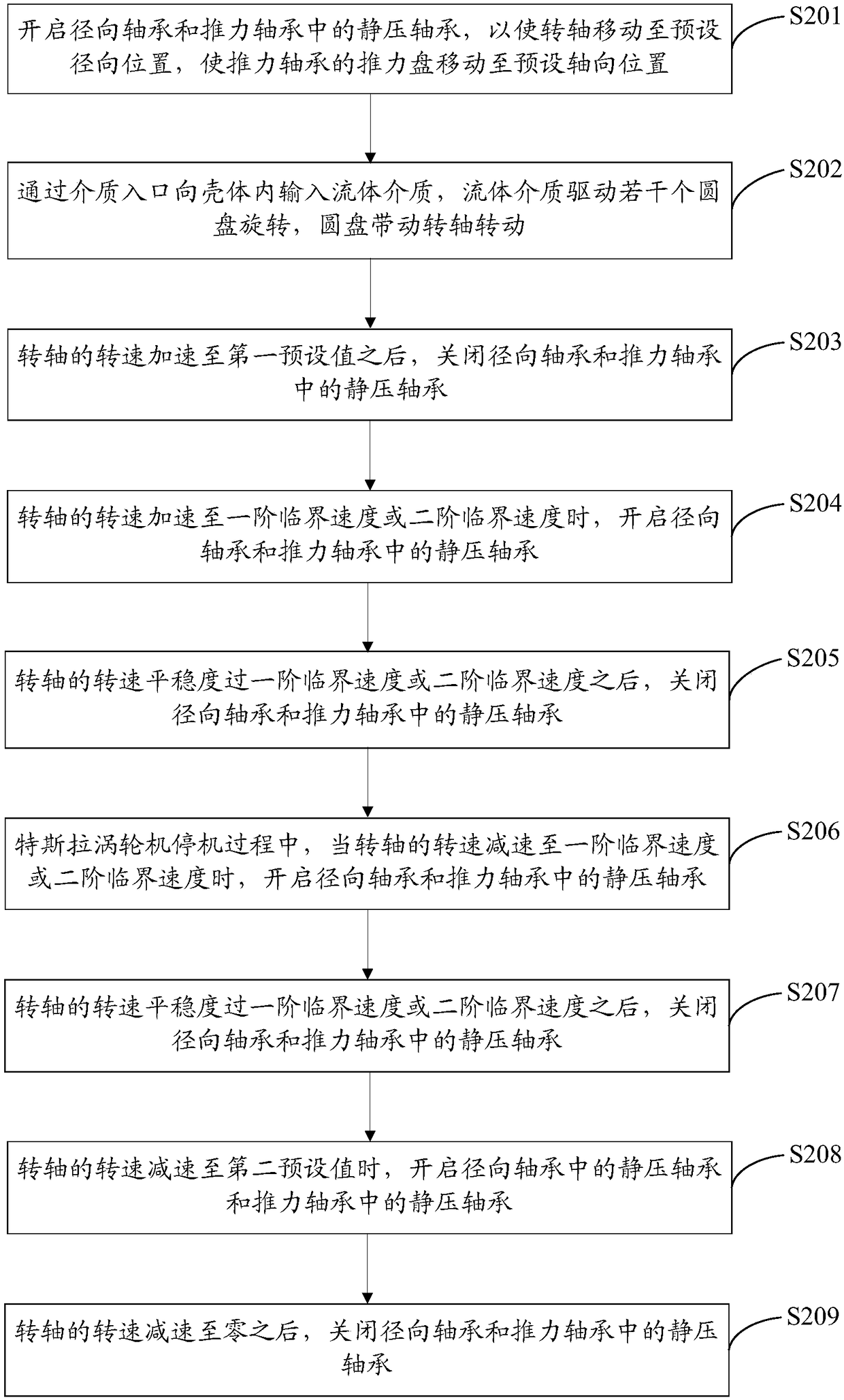

Tesla turbine and control method

PendingCN108868890AImprove dynamic performanceImprove stabilitySafety/regulatory devicesNon-positive displacement enginesThrust bearingTesla turbine

The invention provides a tesla turbine and a control method. The tesla turbine comprises a rotating shaft, a shell, a plurality of discs, a thrust bearing and at least two radial bearings; the shell is arranged on the rotating shaft, and a medium inlet and a medium outlet are formed in the shell; the plurality of discs are arranged in the shell, the plurality of discs are fixedly connected to therotating shaft, a gap is formed between every two adjacent disks of the plurality of disks, and at least one exhaust hole is formed in each of the plurality of disks; and the thrust bearing and at least two radial bearings are arranged on the rotating shaft, and the thrust bearing and the at least two radial bearings are non-contact bearings. According to the tesla turbine, non-contact thrust bearings of the thrust bearing and the radial bearings are adopted, the power loss of the tesla turbine on the bearings is reduced, so that the efficiency of the tesla turbine is improved.

Owner:靳普

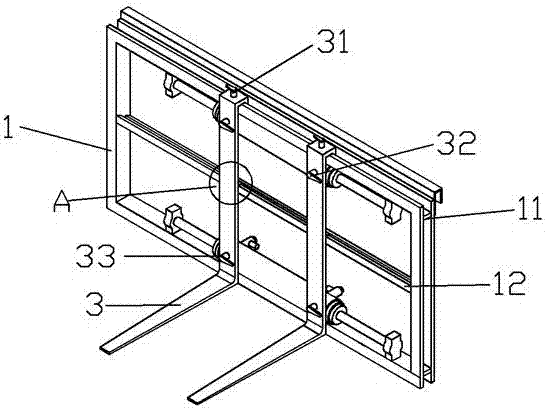

Side shifter device in the up and down linkage

InactiveCN107445118AEasy loadingIncrease diversityLifting devicesMechanical engineeringLoad capacity

The invention mainly provides a side shifter device in the up and down linkage, the side shifter device comprises a side-shift frame and a fork arm fixed on the side-shift frame, wherein cylinders on which a plurality of fixed blocks are fixed are respectively fixed on the inner wall of the upper and lower beams of the side-shift frame and a second threaded hole is formed in each fixed block respectively, a plurality of screwing handles are fixed on the contacting side of the fork arm and the side-shift frame in a vertical direction, and the fork arm can be fixed on the two cylinders by the screwing handles; Inside the side-shift frame, a connecting rod, on the upper and lower end surfaces of which slide rails are respectively arranged, is fixed in a horizontal direction, slide blocks are fixed on the vertical contacting side of the fork arm and the connecting rod, and the slide blocks can slide left and right on the slide rails. The side shifter device has the advantages that the load capacity of the side shifter and the linkage of the fork arm are increased, and further the requirement of transportation is met to the maximum extent through fixing two oil cylinders on the side shift frame.

Owner:安徽东皖车桥科技有限公司

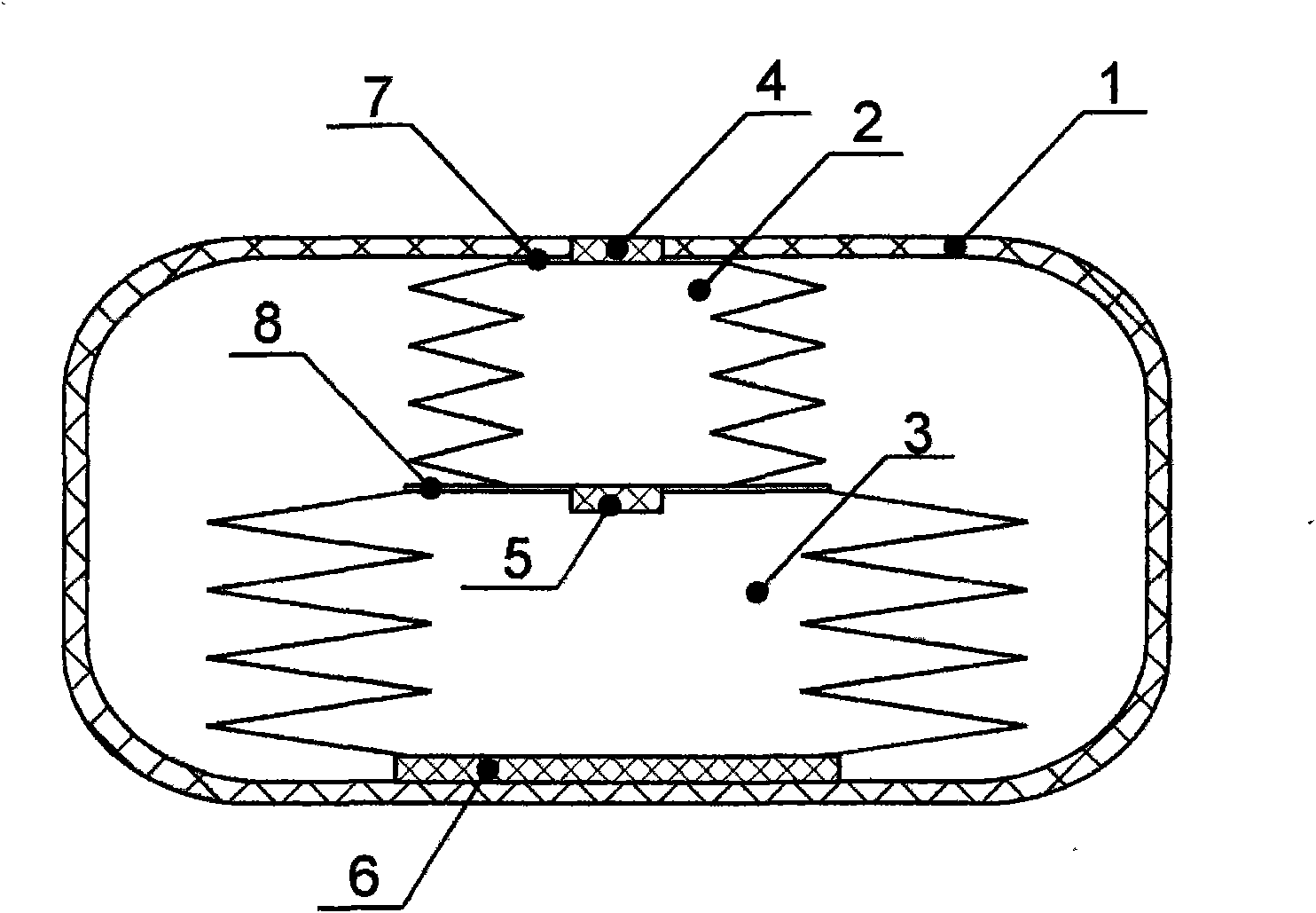

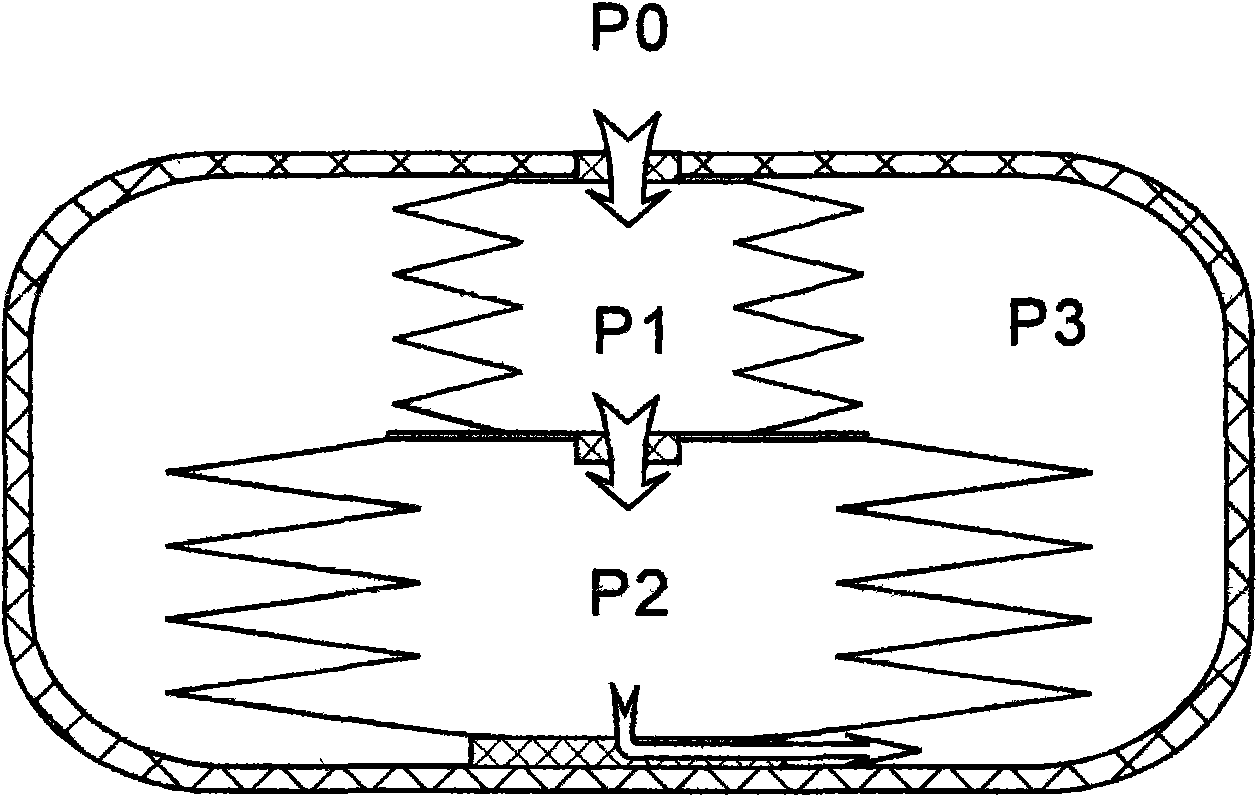

Self-deformation aeration constant pressure device in elastic confined space

InactiveCN101644250AMeet the rated air pressure requirementsCompact pressure-resistant structureHollow inflatable ballsFlexible member pumpsElastomerConfined space

The invention discloses a device installed in an elastomer in confined space, which aerates air for the confined space by deformation generated by repeated constant pressure and realizes constant pressure. The device is composed of a large air pump and a small air pump which are connected in series; the compression area of the small air pump is smaller than that of the large air pump; and in practical work process, the two air pumps work together or work alternatively, so as to realize the aeration of high-pressure air in the elastomer and stops charging air under a constant pressure. The final aeration air pressure can be regulated by regulating the starting air pressure of the single-way valve at the output end of the large air pump.

Owner:王晓光

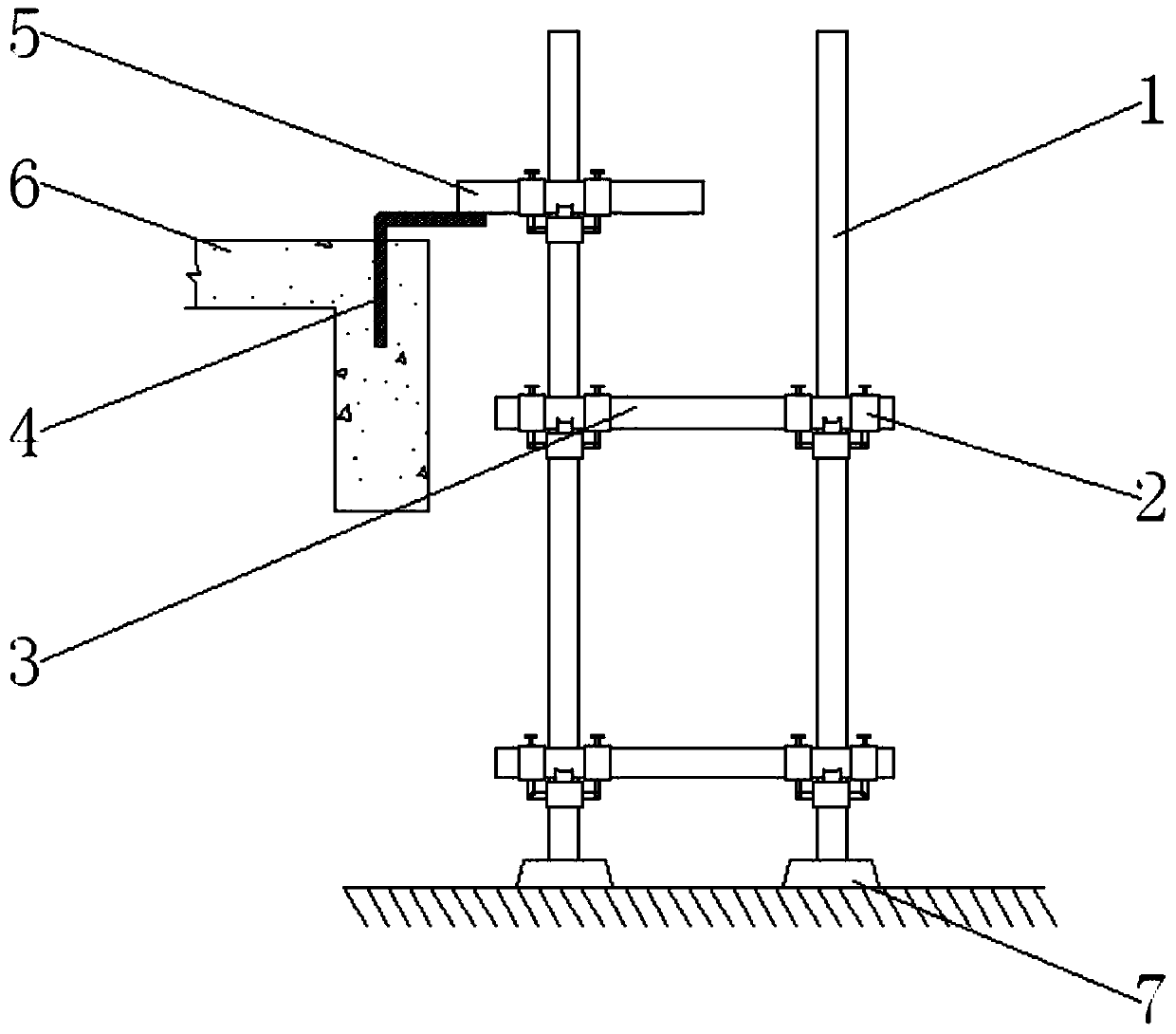

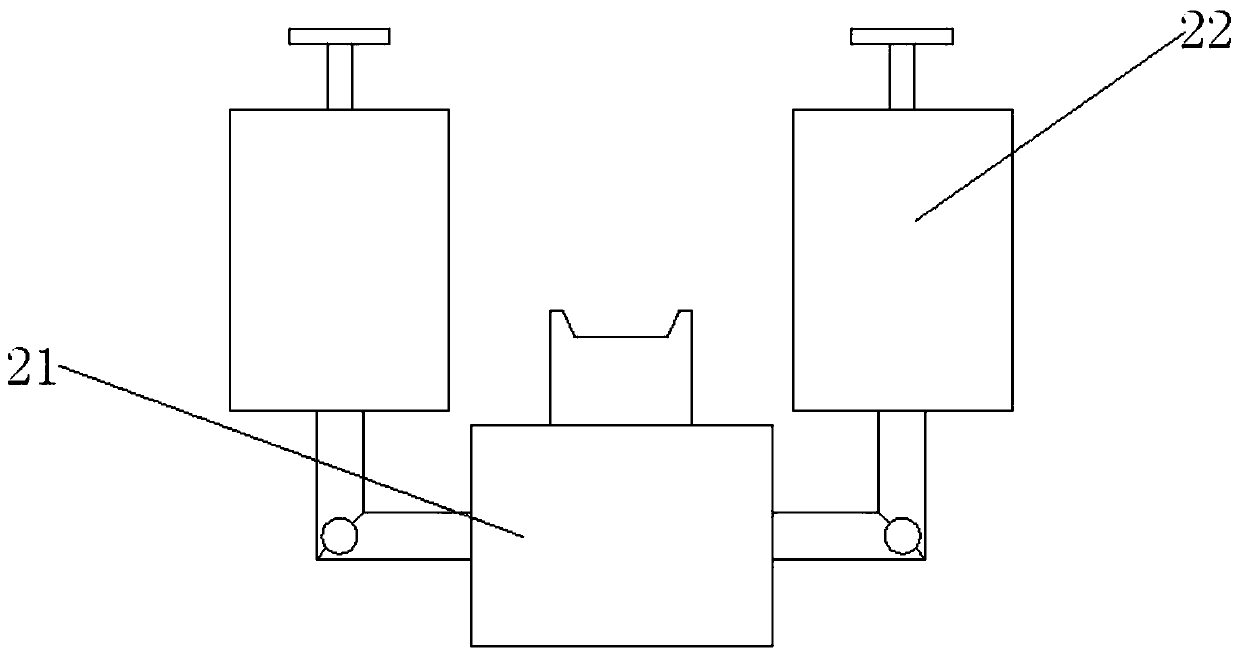

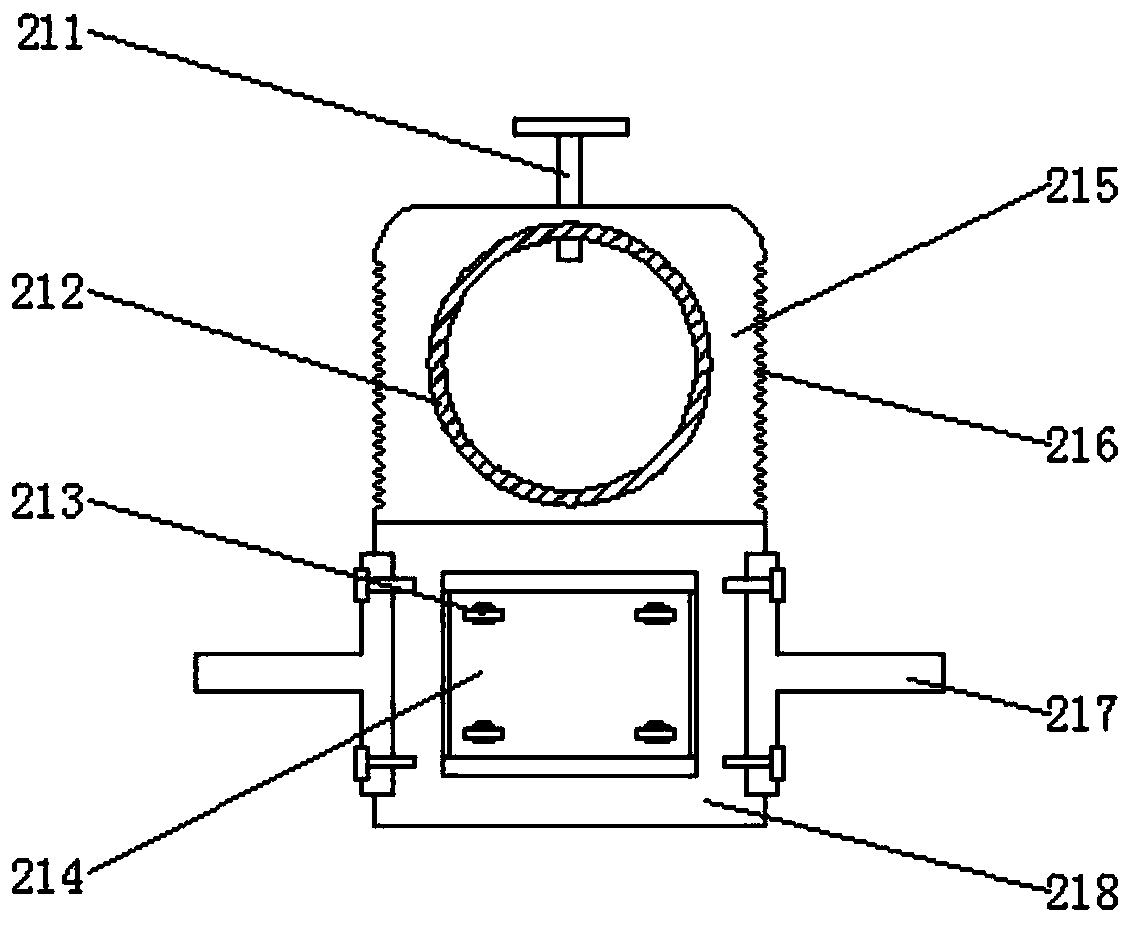

A kind of external scaffolding and wall parts of multi-storey residential buildings

ActiveCN109779238BEnsure safetyGuaranteed stabilityScaffold accessoriesArchitectural engineeringRebar

The invention discloses a scaffold wall connecting piece outside a multi-storey residential building, and relates to the technical field of industrial buildings. The scaffold wall connecting piece outside the multi-storey residential building comprises two vertical rods, a transverse rod is fixedly connected between the two vertical rods through connecting pieces, the vertical rod located on the left side is fixedly connected with a connecting rod through a connecting piece, and a short steel bar is welded to the bottom of the end, away from the corresponding vertical rod, of the connecting rod and is a steel bar bent by 90 degrees. The invention discloses the scaffold wall connecting piece outside the multi-storey residential building, the wall connecting piece is manufactured in advance,the wall connecting piece is a small component formed by welding the HRB400[fai]20 short steel bar bent into 90-degree and the connecting rod in a double-sided mode. Compared with the prior art, thesafety and the stability of the outer scaffold are guaranteed, meanwhile, through improvement of the connecting pieces, longitudinal fixing parts, transverse fixing parts and supporting devices, the stability degree of the outer scaffold is further increased, and the maximum pressure capable of being borne by the outer scaffold is increased in a structure changing mode.

Owner:CHINA MCC17 GRP

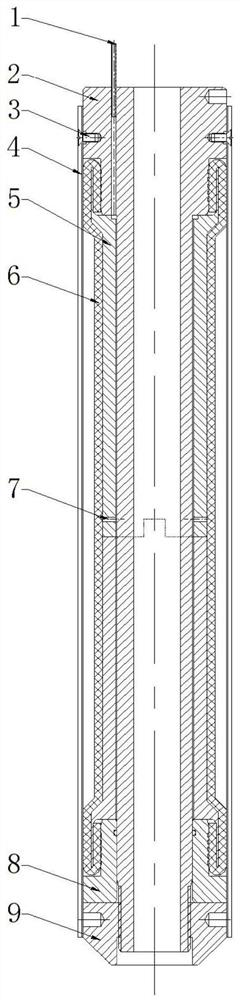

Single-cavity high-pressure pre-drilling shear lateral pressure gauge

PendingCN112796744ANo detachmentIncrease the maximum pressureBorehole/well accessoriesRubber membraneControl system

The invention belongs to the technical field of geological survey, and discloses a single-cavity high-pressure pre-drilling shear lateral pressure gauge. The single-cavity high-pressure pre-drilling shear lateral pressure gauge comprises a jacking device, a lateral pressure gauge probe, a control system and a pipeline system, wherein the lateral pressure gauge probe comprises a core rod, a neck bush and a rubber film; the upper end of the core rod is sequentially provided with a first shaft shoulder and a second shaft shoulder; the lower end of the core rod is provided with an annular pressing cap; the neck bush is sleeved at the outer side of the core rod between the second shaft shoulder and an annular pressing sleeve; pressing rings for pressing the rubber film are arranged at the two ends of the neck bush; a fixing screw nut is arranged at the lower side of the annular pressing cap; the periphery of the core rod is sleeved with a double-layer metal armor; the upper end of the double-layer metal armor is fixedly connected with the first shaft shoulder; the lower end of the double-layer metal armor is attached to the fixing screw nut; the pipeline system comprises a liquid inlet pipeline; the liquid inlet pipeline communicates with a gap between the neck bush and the core rod; and a liquid inlet through hole is formed in the middle part of the neck bush. After high pressure is applied a measuring cavity, the two ends of the rubber film can be prevented from extending outwards in the axial direction, and the rubber film can be prevented from being pierced or cut by rocks in a hard soil layer.

Owner:SOUTHWESTERN ARCHITECTURAL DESIGN INST

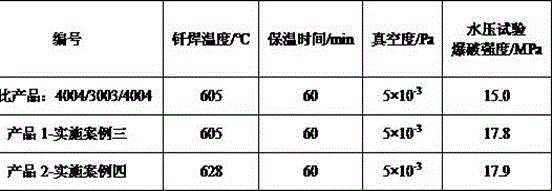

4004 aluminum alloy containing bismuth and tellurium for brazing and production method of 4004 aluminum alloy

ActiveCN104694789AReduce surface tensionImprove wettabilityWelding/cutting media/materialsSoldering mediaTrace elementBismuth

The invention relates to a 4004 aluminum alloy containing bismuth and tellurium for brazing and a production method of the 4004 aluminum alloy. The 4004 aluminum alloy is characterized by comprising the following chemical components in percentage by mass: 9.0-10.5% of Si, 1.0-2.0% of Mg, smaller than or equal to 0.8% of Fe, smaller than or equal to 0.25% of Cu, smaller than or equal to 0.1% of Mn, smaller than or equal to 0.20% of Zn, 0.02-0.2% of Sr, 0.02-2.0% of Bi, 0.01-1.0% of Te, smaller than or equal to 0.05% of single content of other impurity elements, smaller than or equal to 0.15% of total content of other impurity elements and the balance of Al. The production method of the aluminum alloy is smelted, degassed, deslagged, cast, distressed and sawed; trace elements Bi and Te are added; the surface tension of the 4004 alloy is reduced; the liquidity and wettability of the 4004 alloy during brazing are improved; the reject ratio of a welding joint is reduced; the occurrence rate of welding leakage points is reduced.

Owner:广西南南铝加工有限公司

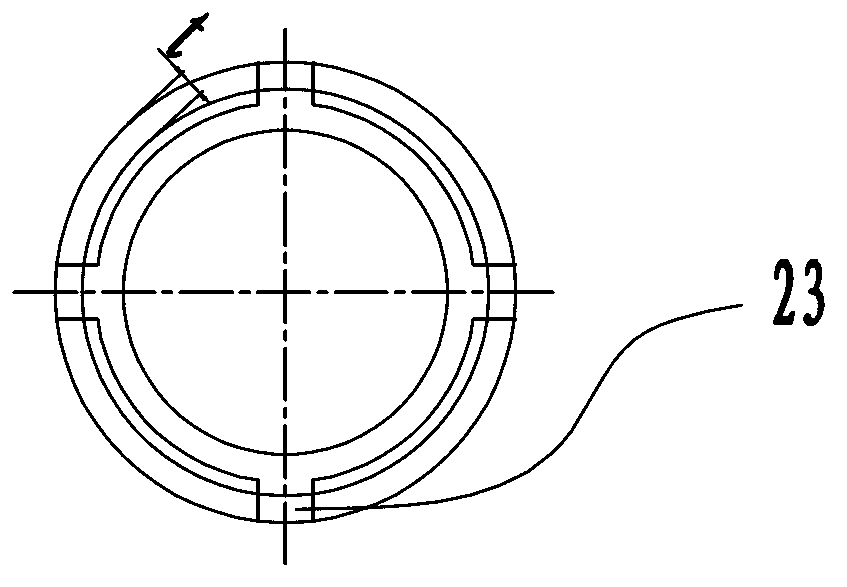

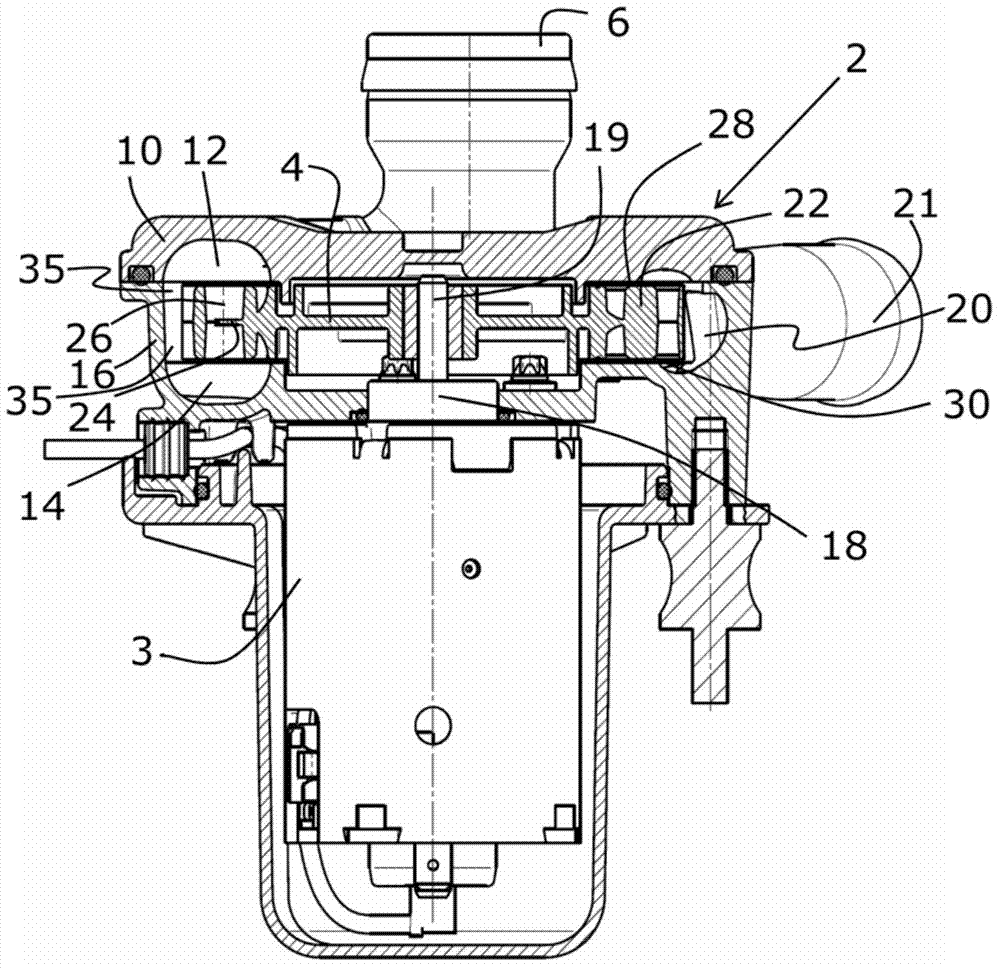

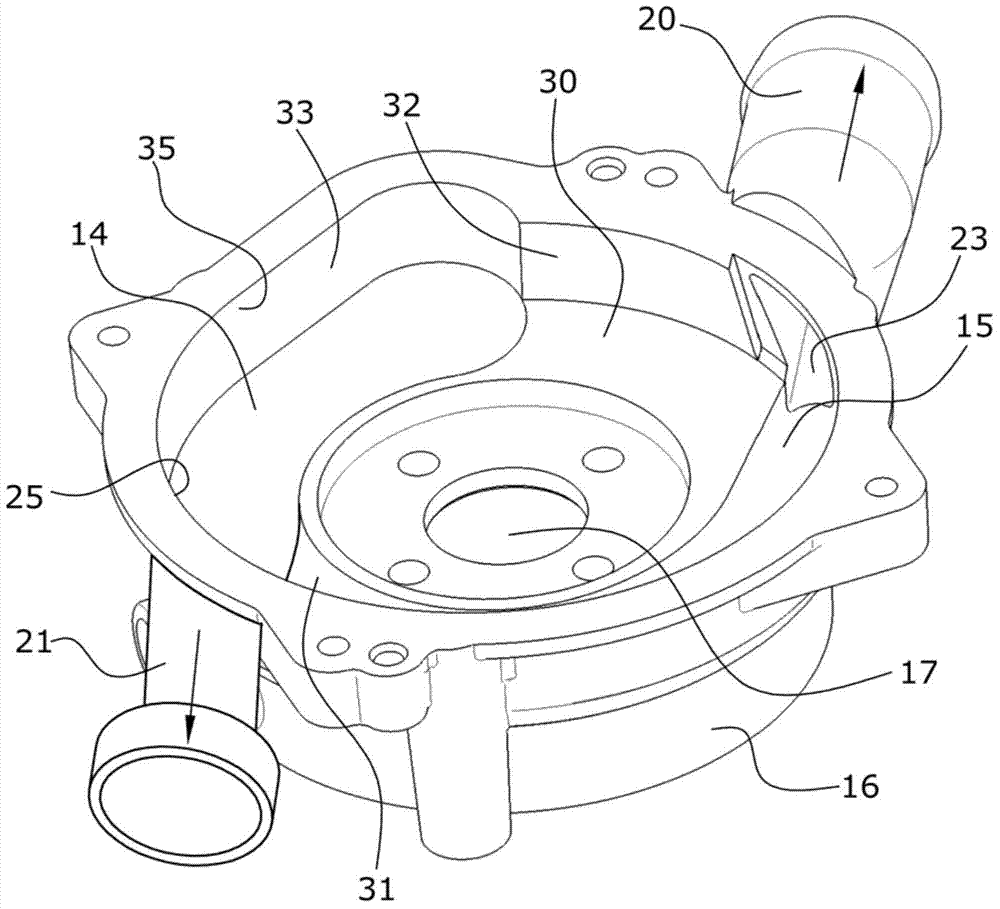

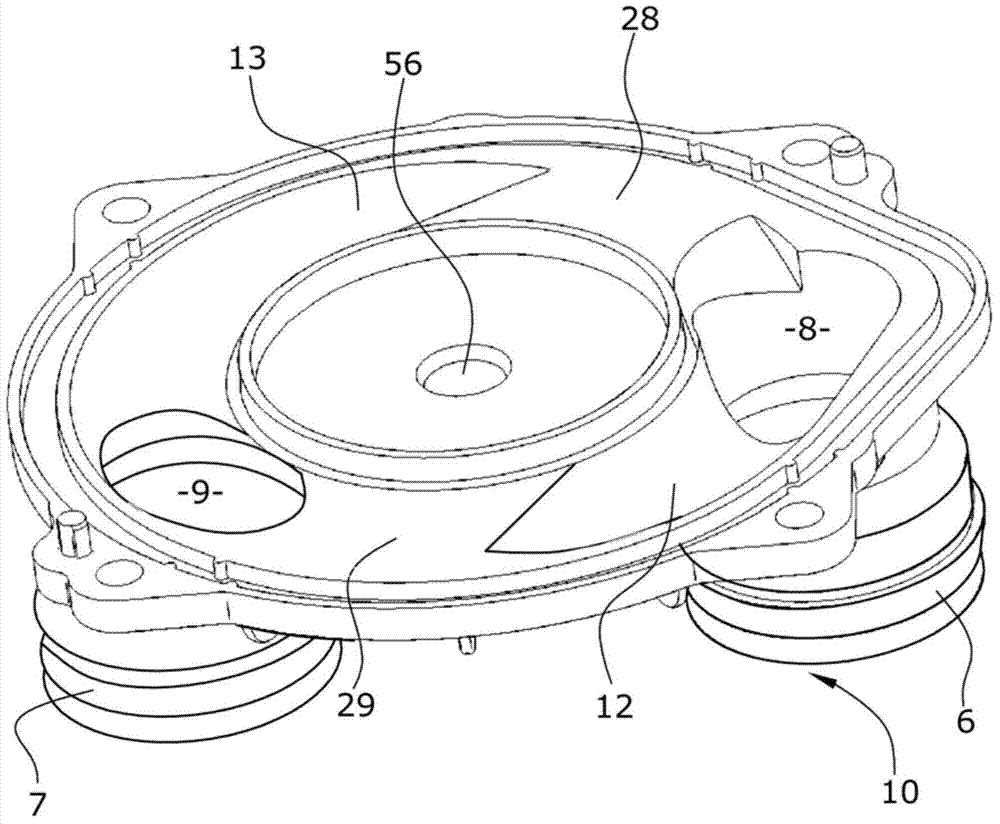

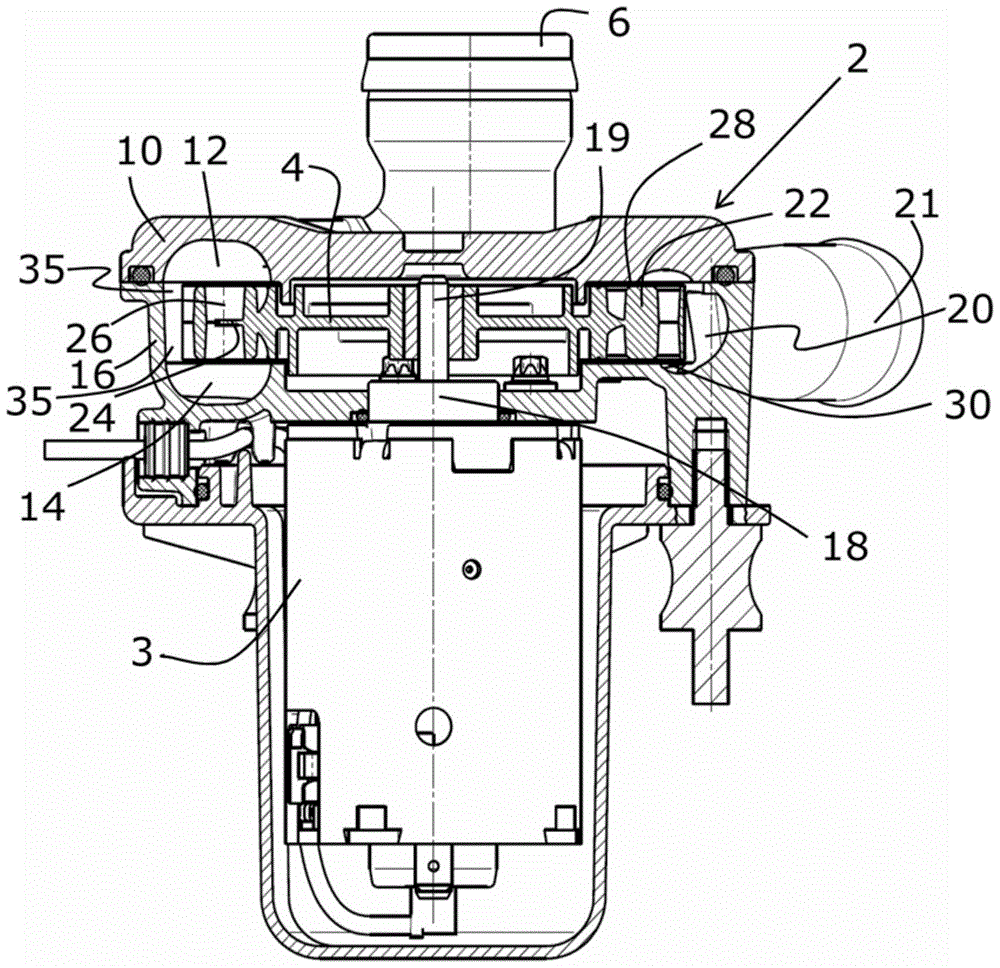

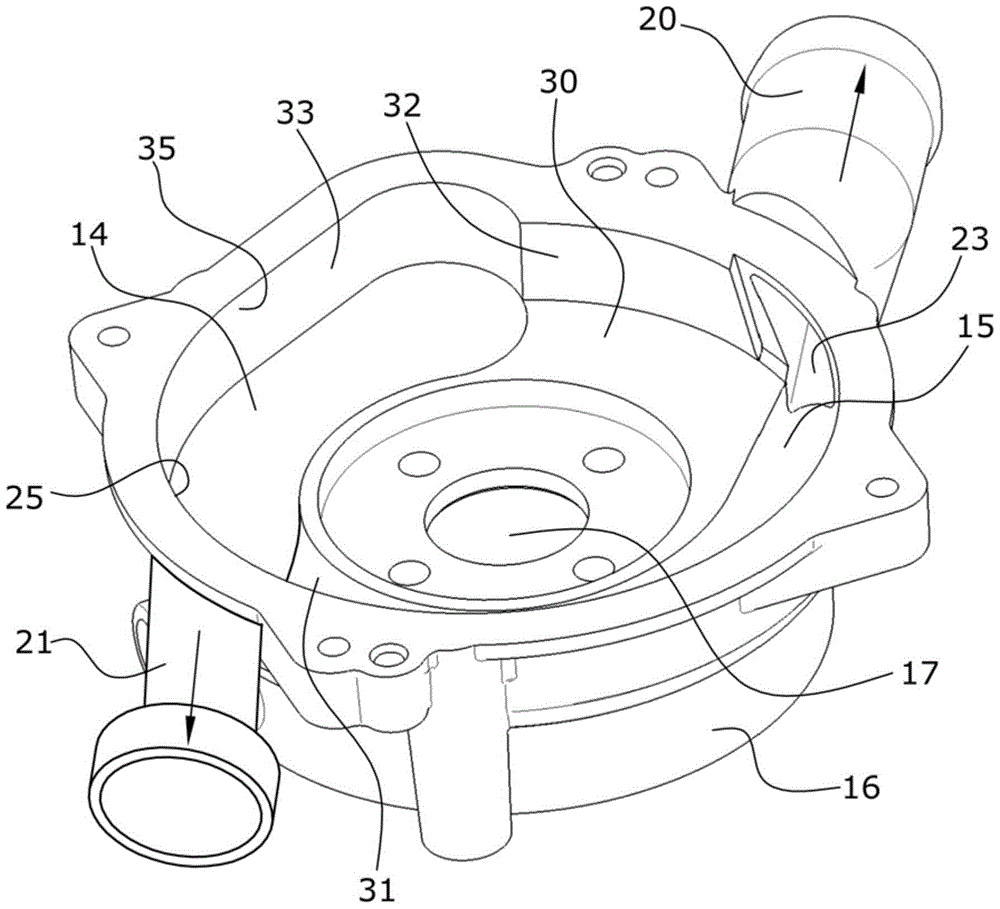

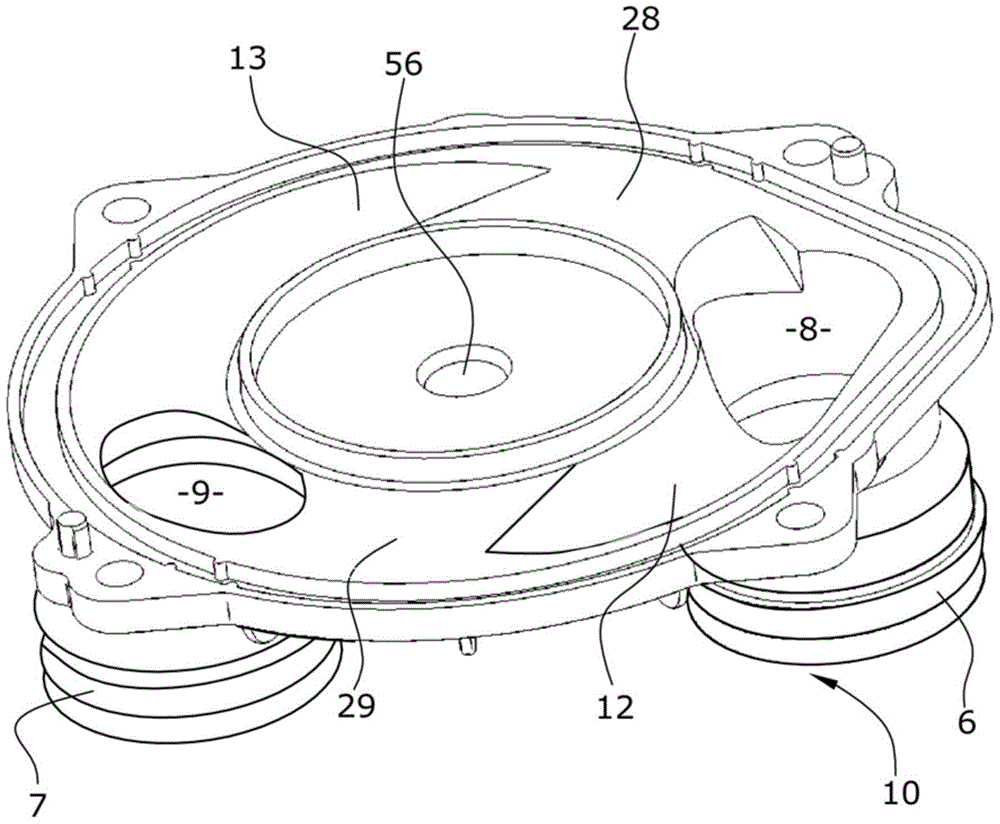

Side channel blower having a plurality of feed channels distributed over the circumference

ActiveCN103717905AIncrease the maximum pressureSave spacePump componentsRotary non-positive displacement pumpsImpellerEngineering

The invention relates to a side channel blower, in particular a secondary air pump for an internal combustion engine, comprising a multi-part housing which has at least one inlet (6, 7) and at least one outlet (20, 21) and has substantially one first and one second housing part (10, 16), wherein the inlet (6, 7) and the outlet (20, 21) are fluidically connected via at least one inlet region (8, 9), extending over at least one at least partially annular feed channel (12, 14) formed in the first and / or second housing part (10, 16) and via at least one outlet region (23, 25), comprising an impeller (4) which is rotatably mounted in the housing (2) and can be driven via a drive unit (3), wherein the impeller (4) has conveying blades (22) which interact with the opposite feed channel and comprising at least one interruption region (28, 30) between the inlet region (8); and in the outlet region (23, 25), in which the at least one feed channel (12, 14) is interrupted in the circumferential direction, wherein there is at least one feed channel (12, 14) which has a circumferential angle of 300 DEG.

Owner:PIERBURG GMBH & CO KG NEUSS

A submersible vehicle high-pressure case and a method of manufacturing that same

PendingCN109050784AImprove pressure resistanceIncrease the maximum pressureVessel partsEngineeringHigh pressure

Owner:QINZHOU UNIV

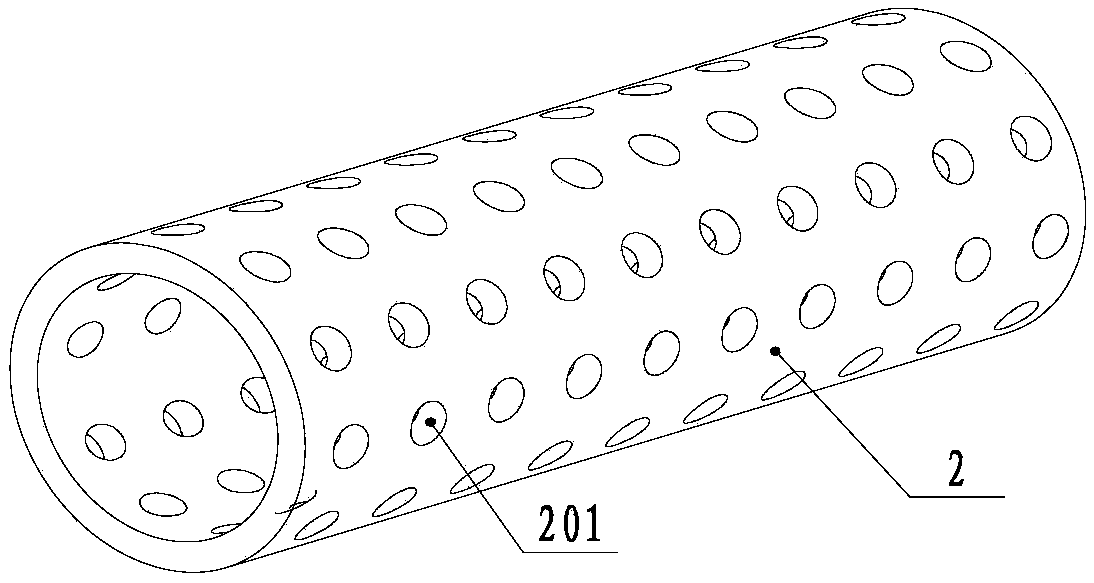

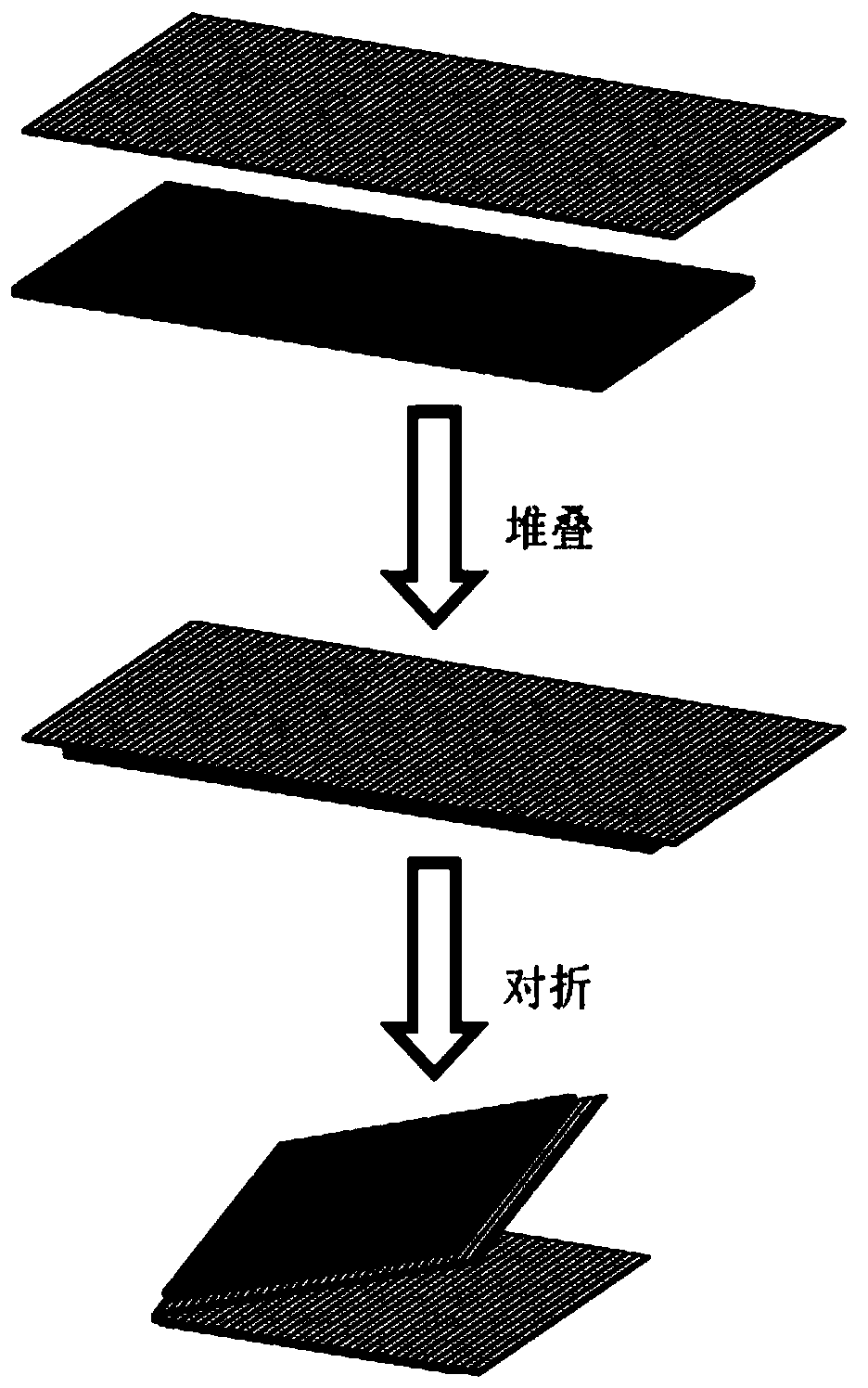

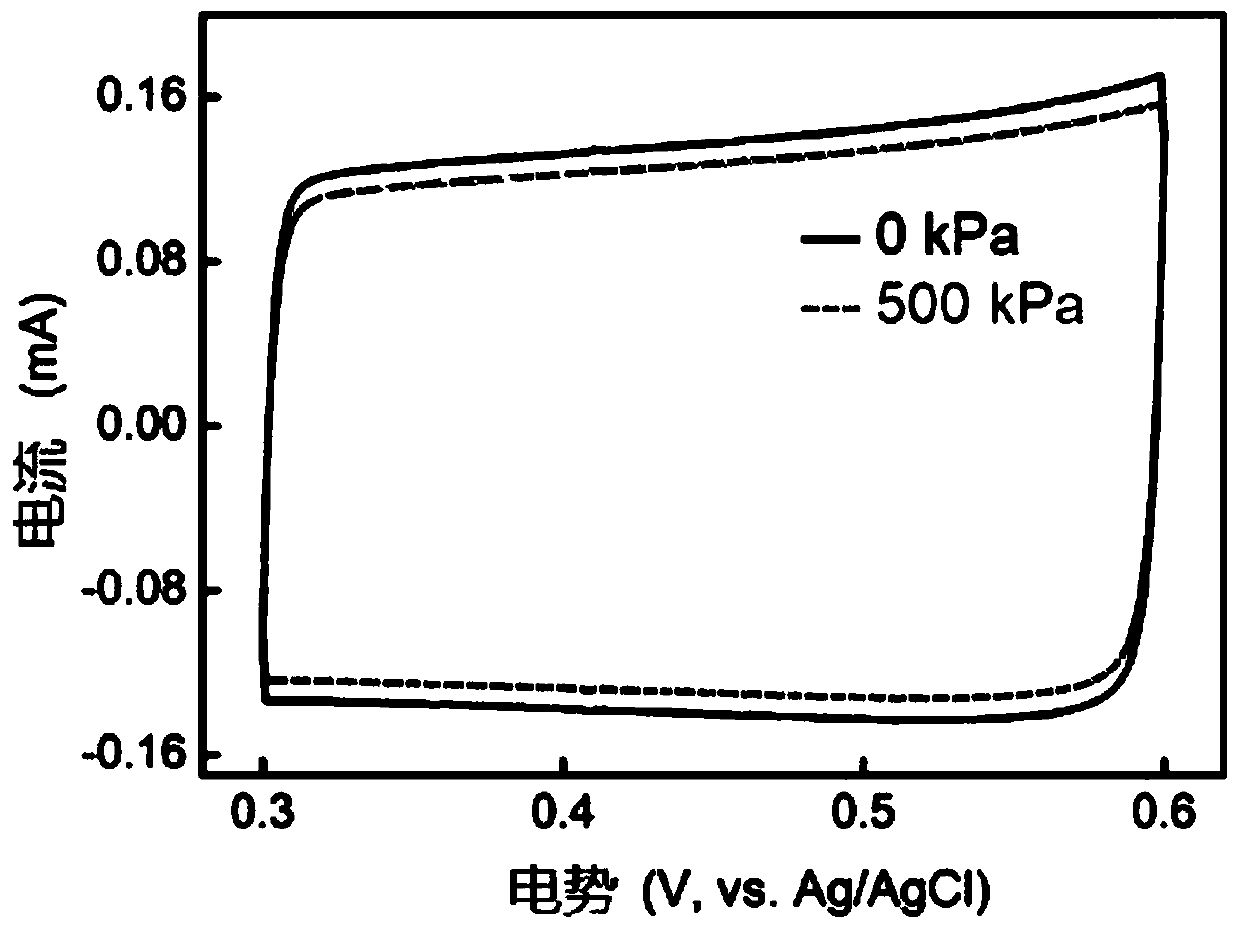

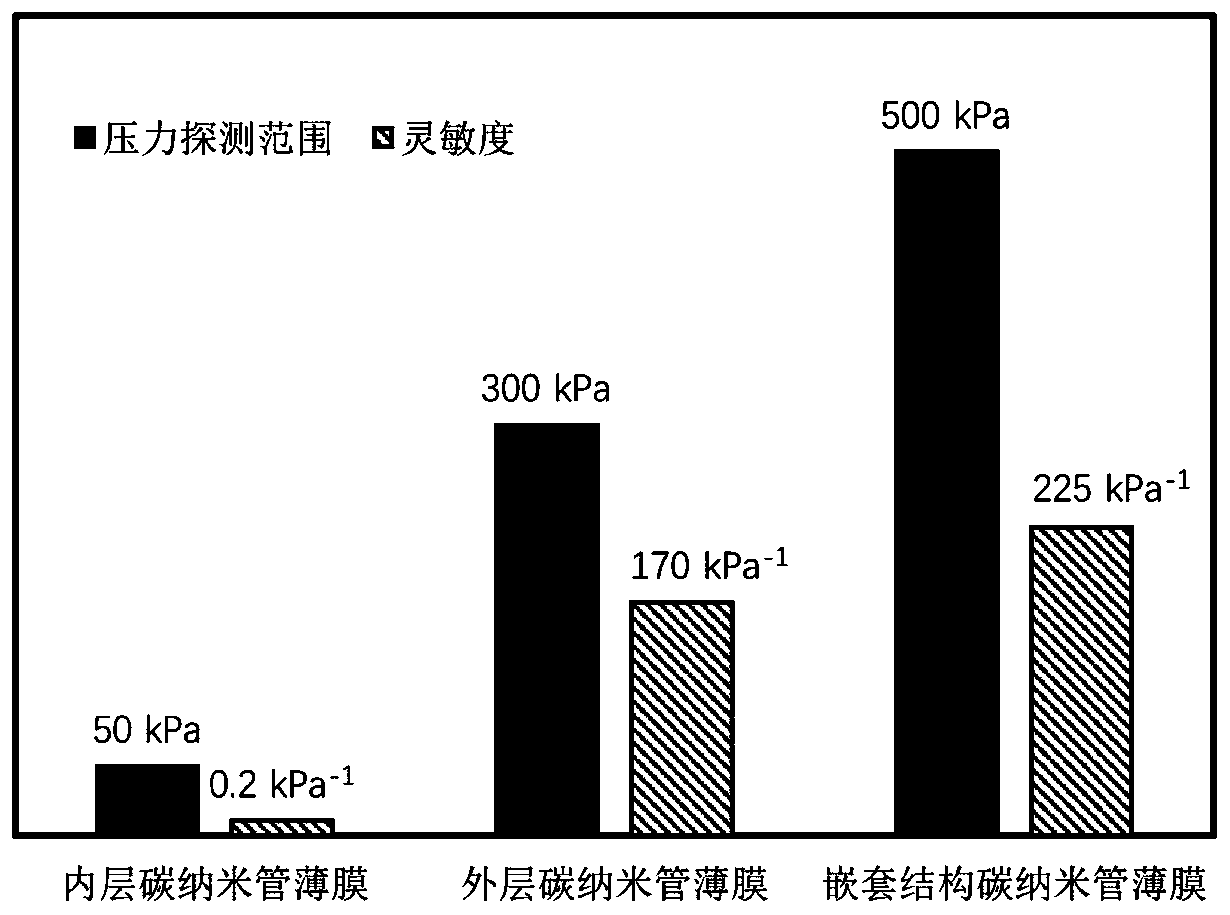

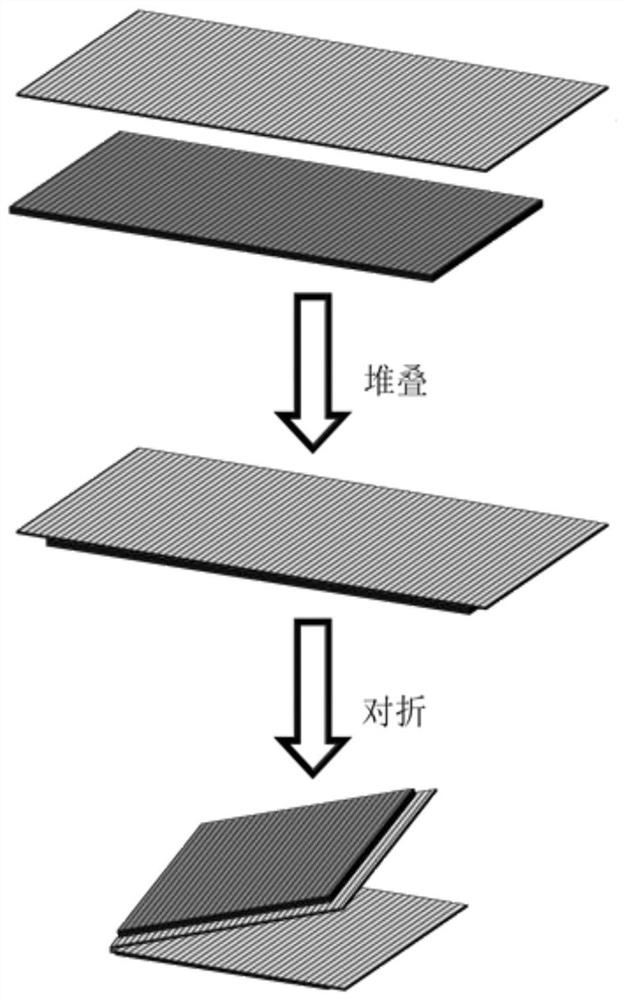

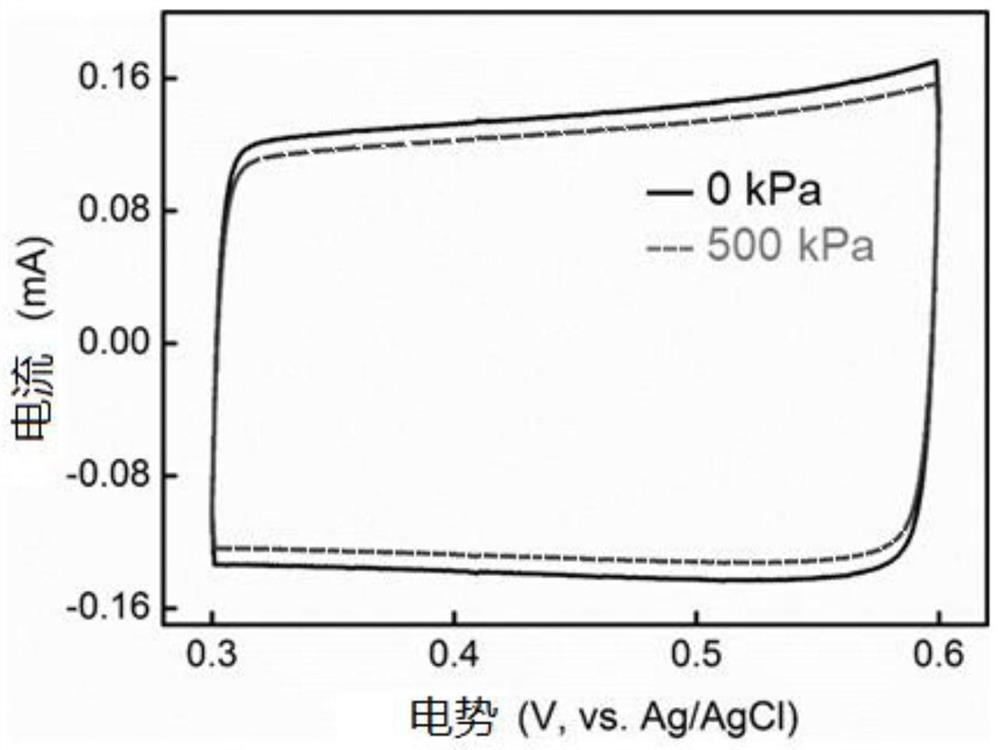

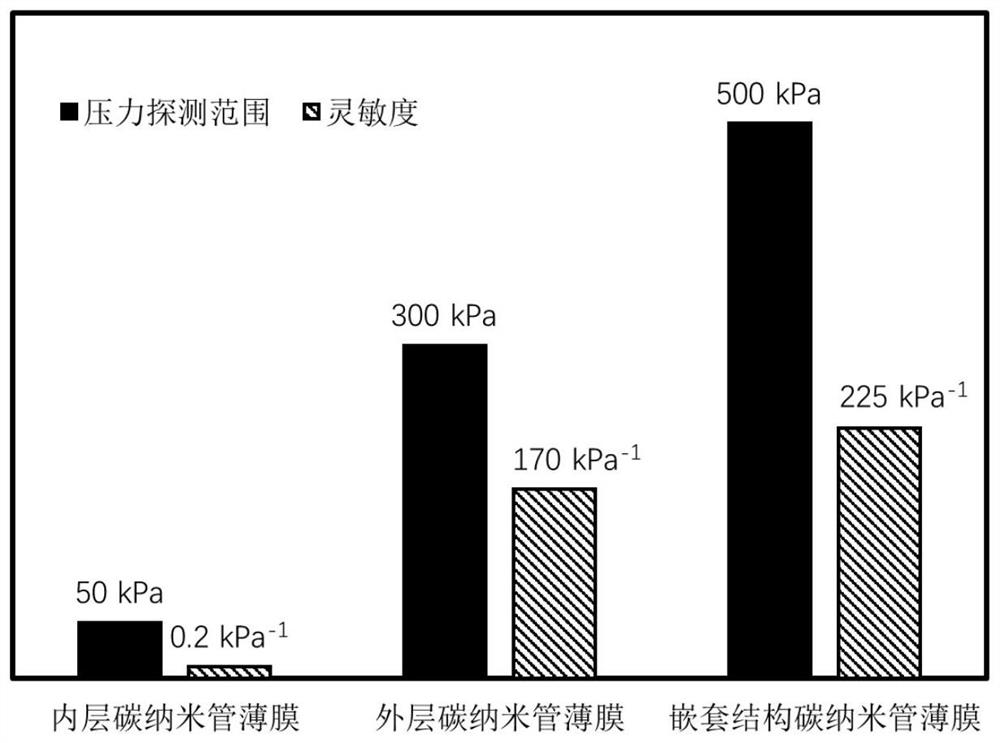

Working electrode based on film nested structure and electrochemical pressure sensor

ActiveCN111524715AHigh pressure detection range and sensitivityHigh specific capacitanceHybrid capacitor electrodesDouble layer capacitorsPhysicsThin membrane

The invention belongs to the related technical field of electrochemical pressure sensing, and discloses a working electrode based on a film nested structure and an electrochemical pressure sensor. Theworking electrode comprises a first thin film material and a second thin film material, and the first thin film material and the second thin film material are stacked. The first thin film material and the second thin film material are both materials capable of forming double electric layers together with electrolyte in a working environment, and the surface density of one of the first thin film material and the second thin film material and the specific capacitance of the double electric layers formed by the electrolyte are both larger than those of the other thin film material and the electrolyte. The working electrode can be used for assembling an electrochemical pressure force sensor, pressure energy is converted into electric energy through the pressure-induced electrochemical potential change characteristic of a two-dimensional film, high-sensitivity pressure detection in a wide range can be achieved due to the structural advantages, and then real-time distribution monitoring ofmulti-point pressure is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

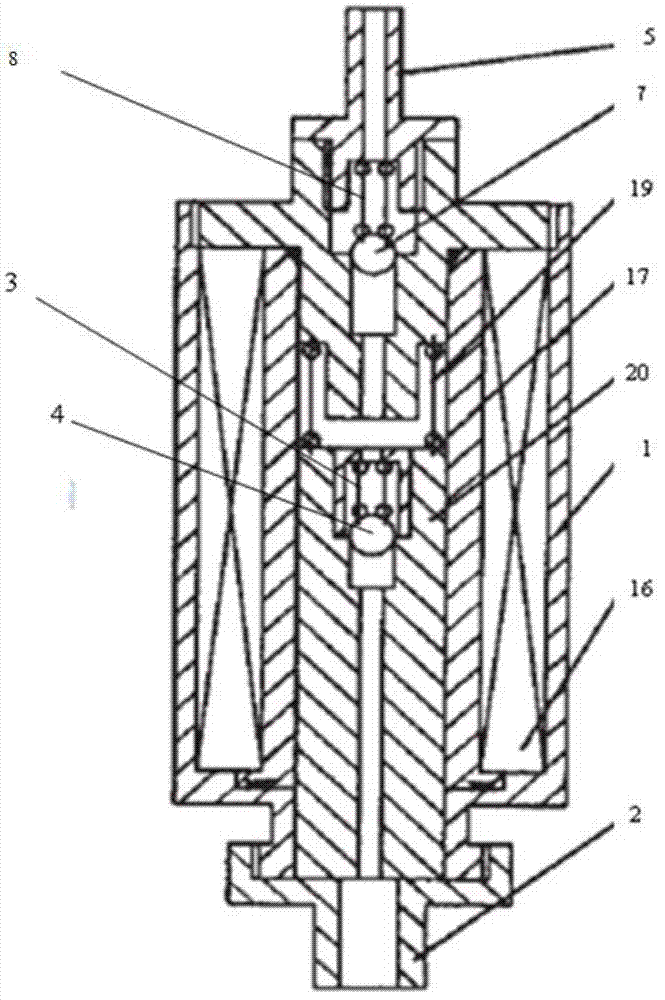

Thrust bearing, rotor system and control method of thrust bearing

PendingCN108869542AImprove dynamic performanceImprove stabilityBearing assemblyGas cushion bearingsMagnetic bearingThrust bearing

The invention provides a thrust bearing, a rotor system and a control method of the thrust bearing. The thrust bearing comprises a thrust disc, firsts stators and second stators, wherein the thrust disc is fixedly connected to a rotating shaft, the first stators and the second stators are arranged on the rotating shaft in a penetrating mode, and the first stators and the second stators are arranged on the two opposite sides of the thrust disc; each stator comprises a magnetic bearing and a foil bearing, a plurality of first magnetic parts are arranged on the magnetic bearings in the circumferential direction, and second magnetic parts are arranged on the foil bearings; and the foil bearings are arranged between the magnetic bearings and the thrust disc, bearing gaps are formed between thefoil bearings and the thrust disc, and the foil bearings can move in the axial direction of the rotating shaft under the action of magnetic force. According to the thrust bearing, the bearing gaps andthe magnetic bearings are arranged in the thrust bearing, so that the thrust bearing forms a gas and magnetic hybrid thrust bearing, and the dynamic performance and the stability of the thrust bearing under a high-speed running state can be improved due to the fact that gas bearings and the magnetic bearings can work cooperatively.

Owner:靳普

Linear electromagnetic driving plunger pump

InactiveCN102808712AAvoid excessive pressureIncrease the maximum pressureFuel injection apparatusMachines/enginesPressure stabilizationSpring force

The invention discloses a linear electromagnetic driving plunger pump, belongs to volumetric fluid conveying pumps and is applicable to pressure pumping, pressure accumulation, pressure stabilization and overflow protection of the fuel of an electronic fuel injection system of an internal combustion engine. The linear electromagnetic driving plunger pump comprises a pump body, an upper cover, a lower cover, an electromagnetic coil, an armature, a return spring, an inlet joint, an outlet joint, a sleeve, a valve core, a supporting pipe, a diaphragm, a nut, an overflow port joint, a plunger rod and a leakage flow port joint. Under the action of electromagnetic force and spring force, the plunger rod reciprocates, gasoline pumping is realized, the total pressure of a pressure accumulating cavity is low in fluctuation, the linear electromagnetic driving plunger pump has pressure accumulation, pressure stabilization and overflow functions, accurate control can be realized, and an operating period of an electromagnet can be shortened, so the reliability is improved. The linear electromagnetic driving plunger pump which serves as an oil sprayer is applicable to an internal combustion engine system, and great significance is provided for realization of accurate and reliable oil spraying control over the internal combustion engine.

Owner:HUAZHONG UNIV OF SCI & TECH

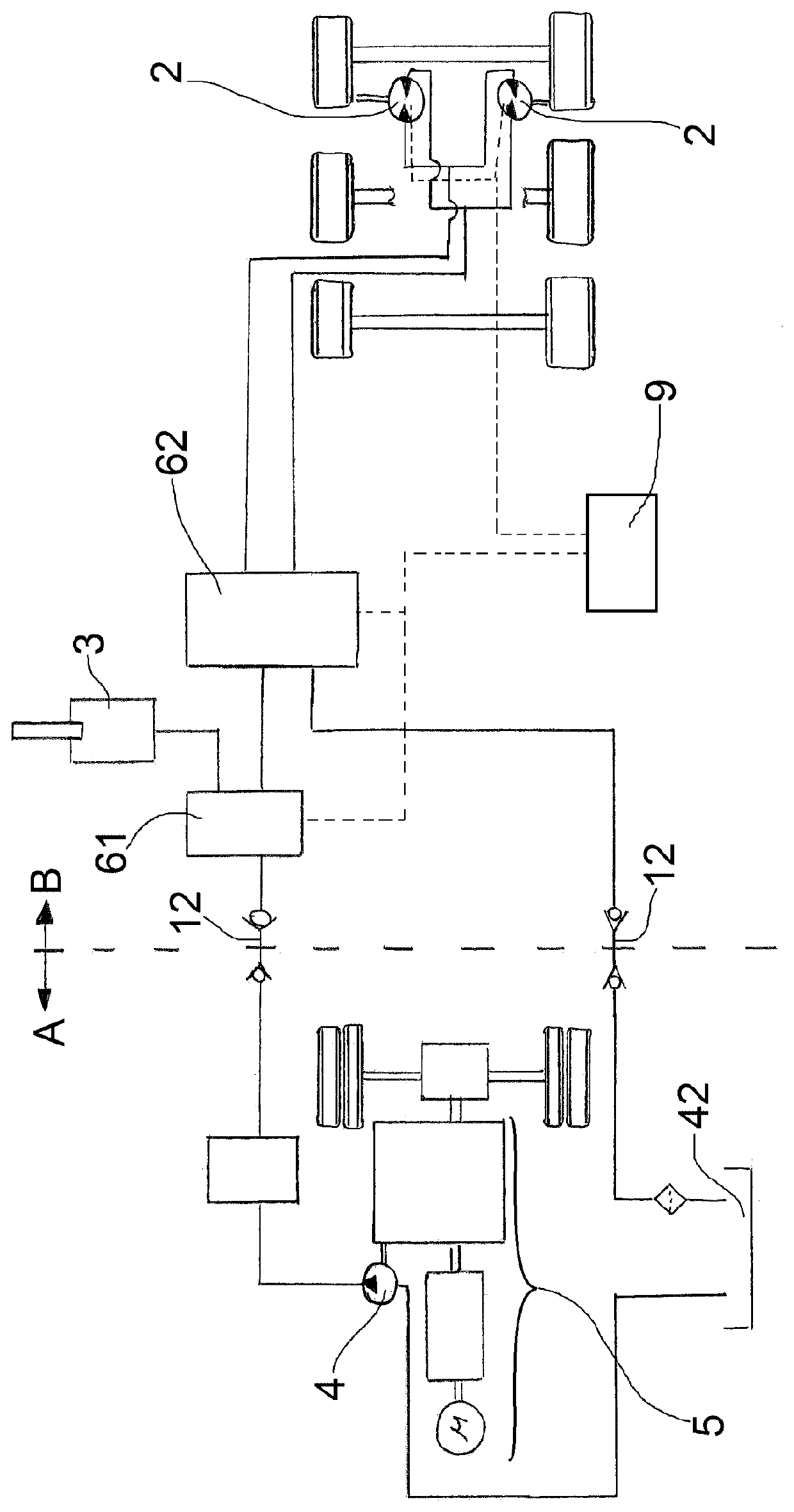

Hydraulic system

ActiveUS10654354B2Increase the maximum pressureEasy to adaptMotor depositionTowing devicesHydraulic pumpEngineering

A hydraulic system for utility vehicles includes an auxiliary drive, a hydraulic pump and a first valve arrangement, wherein, in an operating mode, the auxiliary drive is supplied with hydraulic energy by the hydraulic pump via the first valve arrangement, wherein, in addition to the auxiliary drive, the hydraulic pump supplies at least one further hydraulically operated system with hydraulic energy, wherein the hydraulic pump is arranged on a tractor vehicle, and wherein the auxiliary drive is arranged on a trailer, which is able to be coupled to the tractor vehicle.

Owner:SAF HOLLAND GMBH

Working electrode and electrochemical pressure sensor based on thin film nested structure

ActiveCN111524715BHigh sensitivityReduce capacitanceHybrid capacitor electrodesDouble layer capacitorsCapacitanceElectrolytic agent

Owner:HUAZHONG UNIV OF SCI & TECH

Blower with side channel with several delivery channels distributed around the circumference

ActiveCN103717905BIncrease the maximum pressureSave spacePump componentsRotary non-positive displacement pumpsEngineeringInternal combustion engine

The invention relates to a blower with side channels, in particular a secondary air pump for an internal combustion engine, comprising a multi-part housing with at least one inlet (6, 7) and at least one outlet (20, 21), and generally has a first and a second housing part (10, 16), wherein the inlets (6, 7) pass through at least one inlet area (8, 9), are designed to extend at least one arc itself at least in the first and / or the delivery channel (12, 14) in the second housing part (10, 16), and is fluidly connected to said outlet (20, 21) with each other via at least one outlet region (23, 25); The blower with side channel comprises an impeller (4), which is rotatably mounted in the housing (2) and can be driven by a drive unit (3), wherein the impeller (4) has conveying blades (22), which Conveyor vanes cooperate with opposite conveying channels; and also include at least one discontinuity (28, 30) between the inlet zone (8) and the outlet zone (23, 25), within the discontinuity (28, 30) At least one conveying channel ( 12 , 14 ) is cut in the circumferential direction, wherein at least one conveying channel ( 12 , 14 ) is provided with a circumferential angle of <300°.

Owner:PIERBURG GMBH & CO KG NEUSS

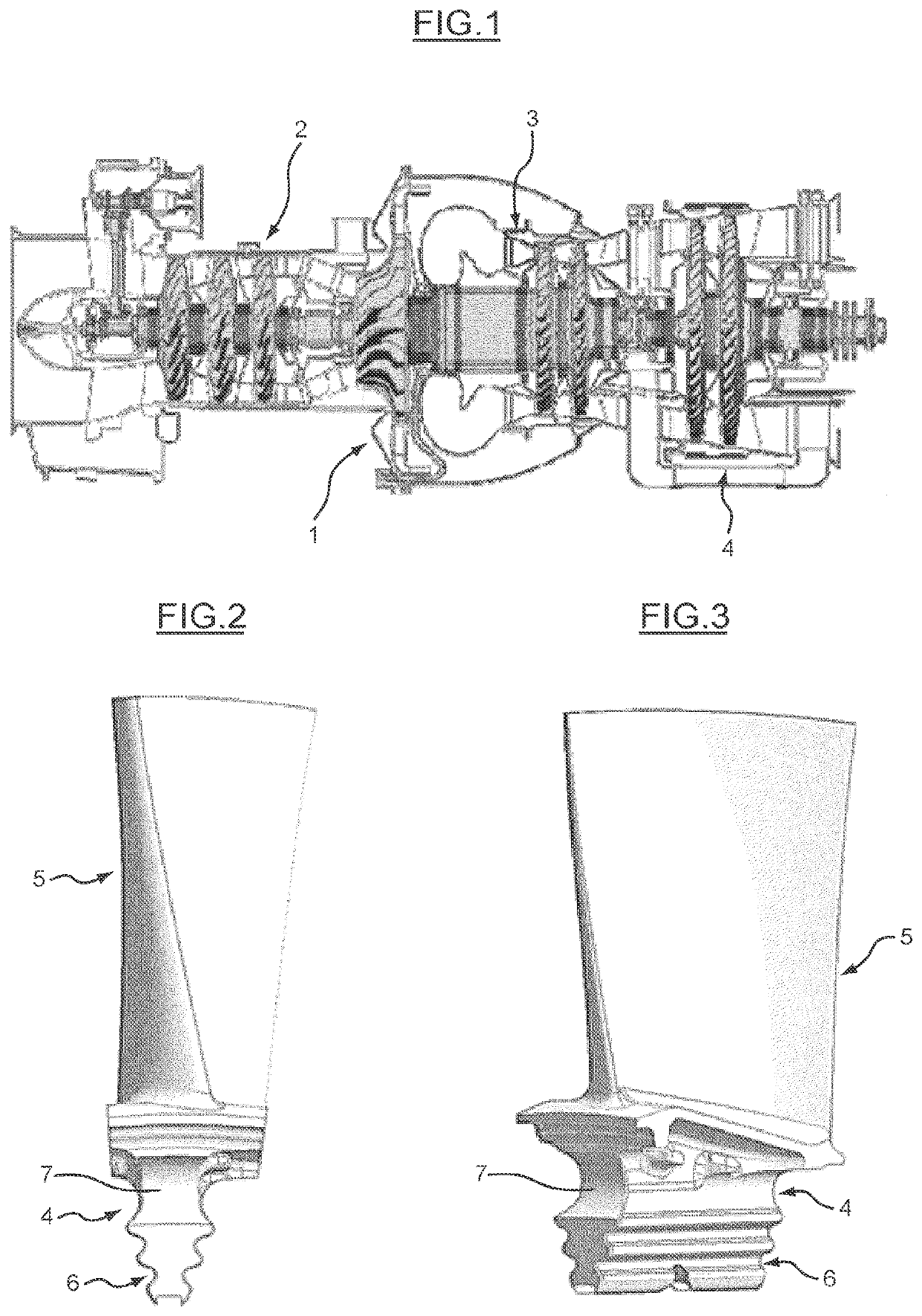

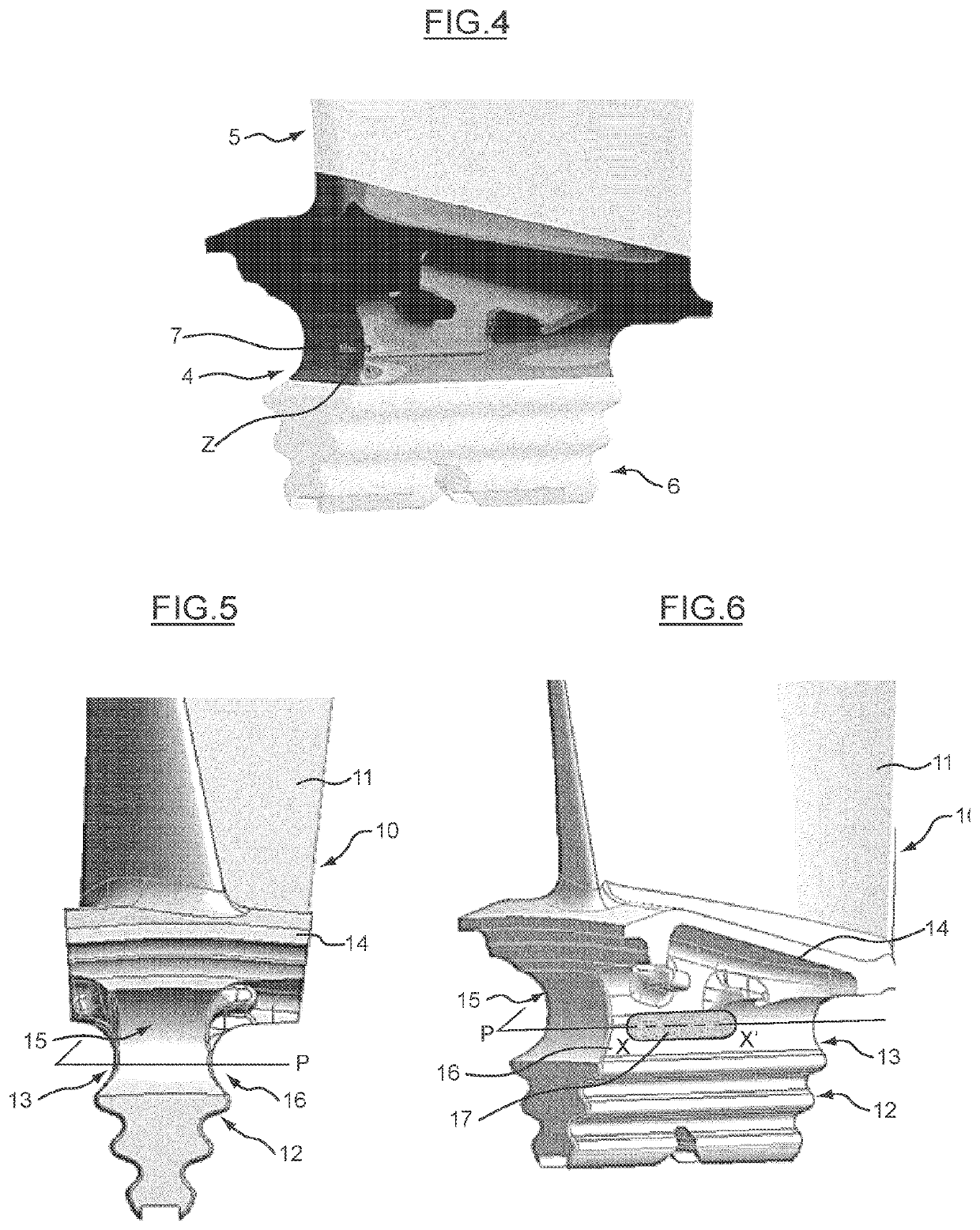

Turbine vane provided with a recess for embrittlement of a frangible section

PendingUS20220235665A1Increase pressureOptimise setting of limit speedEngine manufactureEngine fuctionsTurbine bladeStructural engineering

A turbine vane of a turbine engine is described. The turbine vane includes a blade and a root. The root includes a stilt having lateral flanks with a curvilinear profile. The stilt includes a frangible zone suitable for undergoing a breakage of the stilt if radial forces higher than a threshold are exerted on the vane, in particular centrifugal forces during an overspeed state of the turbine. The frangible zone includes at least one oblong frangibility recess formed on at least one of the lateral flanks of the stilt, the oblong recess extending in an axial direction of the stilt along a longitudinal axis parallel to or included in a minimum cross-sectional plane which contains a minimum cross-section of the stilt.

Owner:SAFRAN HELICOPTER ENGINES

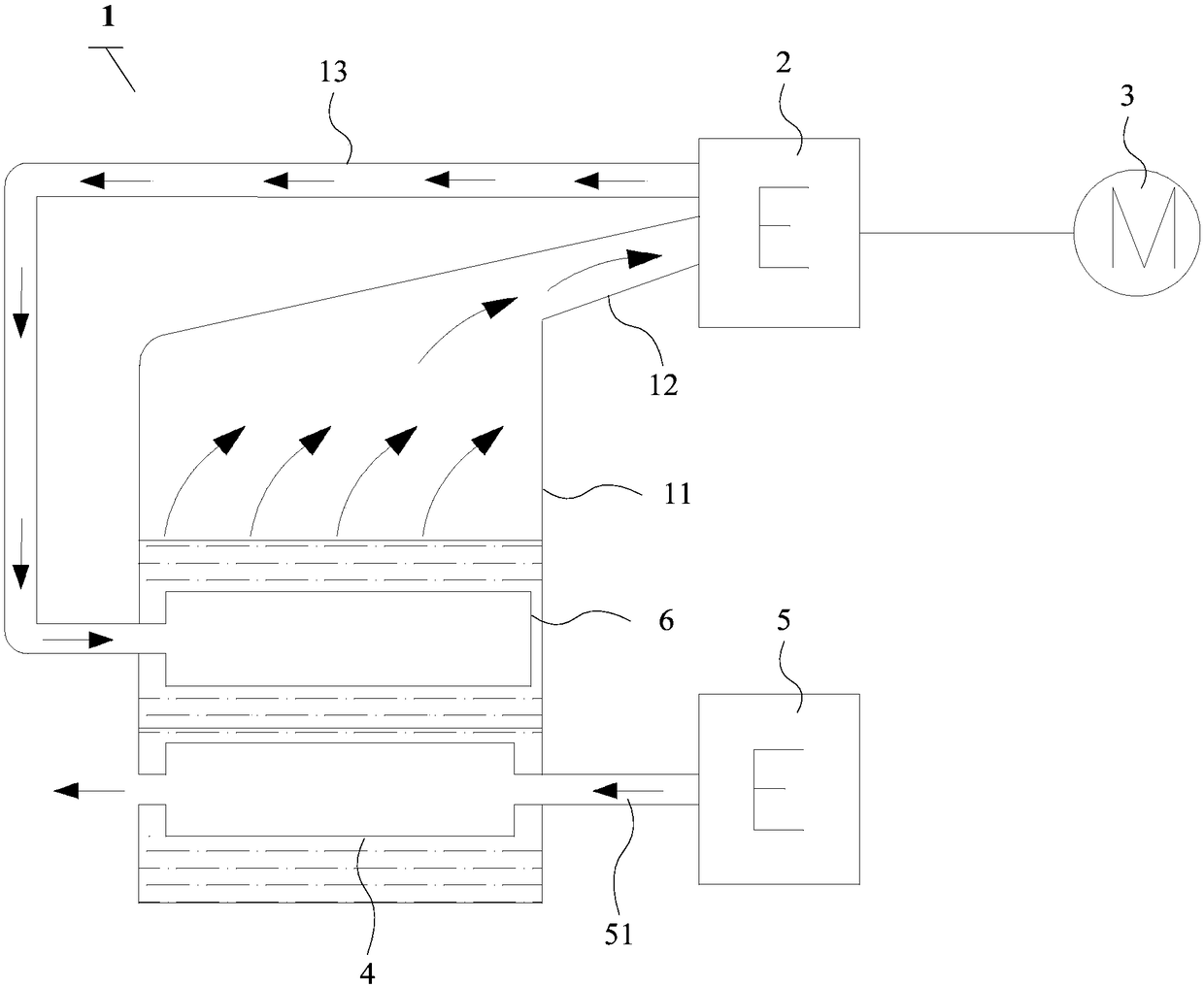

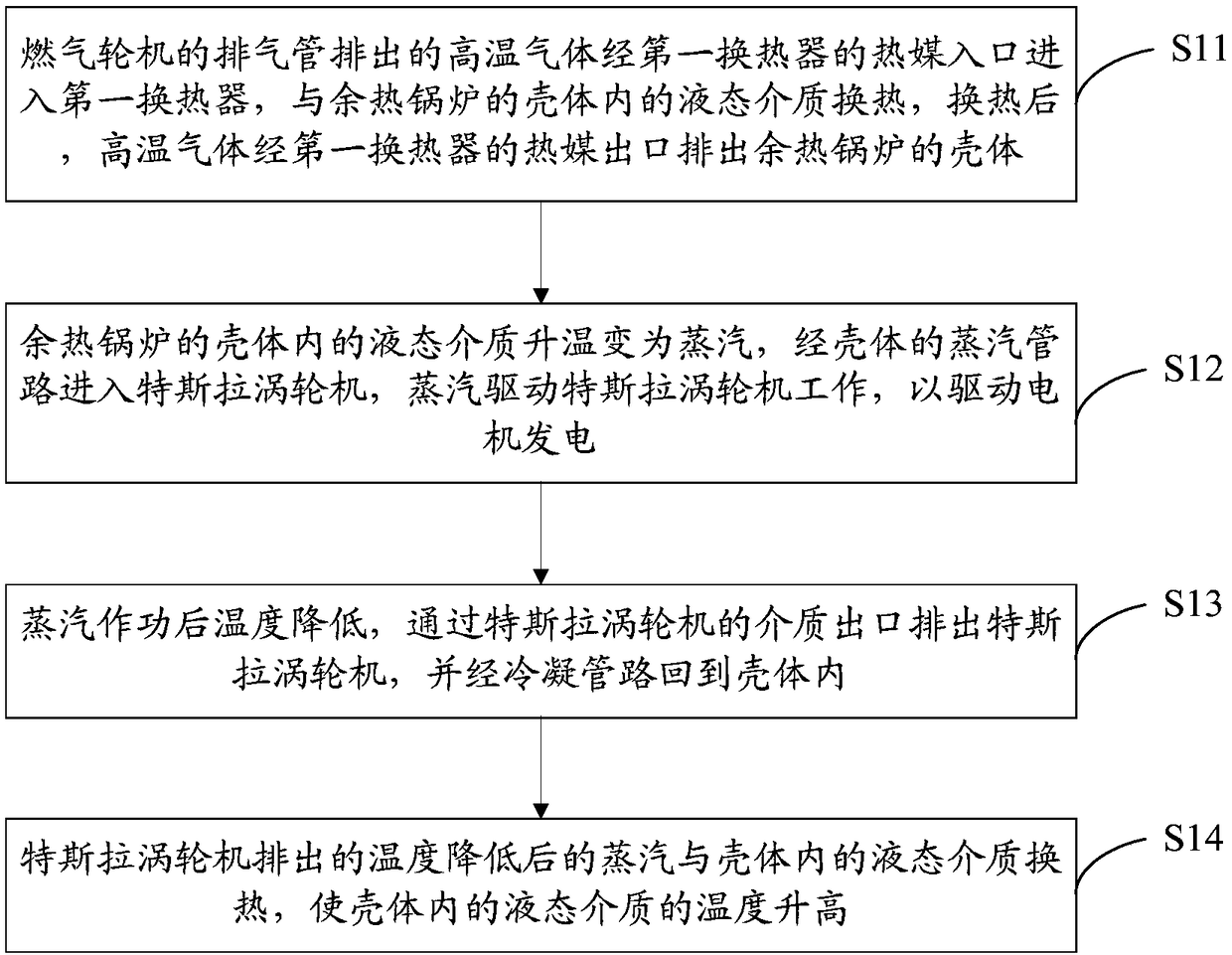

Power generation system and control method thereof

PendingCN108868911AImprove efficiencyImproved dynamic performance and stabilityBearing assemblyEngine componentsLiquid mediumEngineering

The invention provides a power generation system and a control method thereof. The power generation system comprises a waste heat boiler, a Tesla turbine and a motor, wherein the Tesla engine is connected with the motor, the Tesla turbine is used for driving the motor to work, and the Tesla turbine is provided with a medium inlet and a medium outlet; the waste heat boiler comprises a shell body, aliquid medium is filled in the shell body, at least one heat exchanger used for converting the liquid medium into a vapor state medium is further arranged inside the shell body, and the heat exchanger is immersed in the liquid medium; and a steam pipeline and a condensation pipeline are arranged on the shell body, wherein the steam pipeline communicating with the medium inlet is arranged on the shell body, and the condensation pipeline communicates with the medium outlet; and the at least one heat exchanger comprises a first heat exchanger, a heat medium inlet of the first heat exchanger communicates with an exhaust pipe of a gas turbine, and the heat medium outlet of the first heat exchanger is located outside the shell body. According to the system and the method, the high-efficiency Tesla turbine is used as a steam turbine, so that the efficiency of the fuel gas and steam combined cycle power generation system is improved.

Owner:刘慕华

High voltage electromagnetic induction device

ActiveUS9672969B2Reduce the overall diameterIncrease the maximum pressureTransformers/inductances casingsLead-in/lead-through insulatorsElectricityHigh pressure

A high voltage electromagnetic induction device including: a lead-through device-receiving structure having an opening for receiving a lead-through device, a lead-through device extending through the opening, wherein an internal portion is tapering in a direction along the central axis of the lead-through device away from the opening, and an electrical insulation barrier which is arranged in the lead-through device-receiving structure, arranged around and distanced from the internal portion, and which electrical insulation barrier is tapering in the direction, whereby a duct is formed between the internal surface of the electrical insulation barrier and the external surface of the internal portion of the lead-through device, wherein the electrical insulation barrier is tapering relative to the lead-through device such that the distance between the internal surface of the electrical insulation barrier and the external surface of the lead-through device increases in the direction.

Owner:HITACHI ENERGY LTD

A method for preparing polycrystalline diamond microspheres by hydrothermally synthesizing carbon spheres

ActiveCN106582448BThe size is easy to controlUniform sizeUltra-high pressure processesCarbon preparation/purificationRheniumPolymer science

The invention discloses a method of preparing polycrystalline diamond microspheres by hydro-thermal synthesis of carbon spheres and belongs to the field of material preparation. The method comprises the steps: by taking a 0.1-0.2mol / L glucose solution as a raw material, synthesizing carbon microspheres at constant temperature 2-4 hours in an oven at 200 DEG C by virtue of a hydrothermal method; dispersing the prepared carbon microspheres to ball-milled sodium chloride superfine powder to form a mixture as a raw material, filling a mould with the raw material and performing compression moulding, filling a magnesium oxide pot after demoulding, forming an assembly block with a pressure transmitting medium magnesium oxide, a rhenium tube furnace, a lanthanum chromite ring and an aluminum oxide column, and putting the assembly block in the oven at constant temperature of 120 DEG C in the oven 3-4 hours; and taking out the assembly block and putting the assembly block in a high-temperature high-pressure device, and performing a high-temperature reaction at an ultrahigh pressure to obtain the polycrystalline diamond microspheres. According to the method disclosed by the invention, no catalysts are added, and the obtained diamond microspheres are uniform in size and compact in block, and the Vickers hardness reaches 60-80 GPa.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com