Rotor system and control method thereof and gas turbine generator set and control method thereof

A technology of generators and rotors, used in gas turbine installations, machines/engines, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

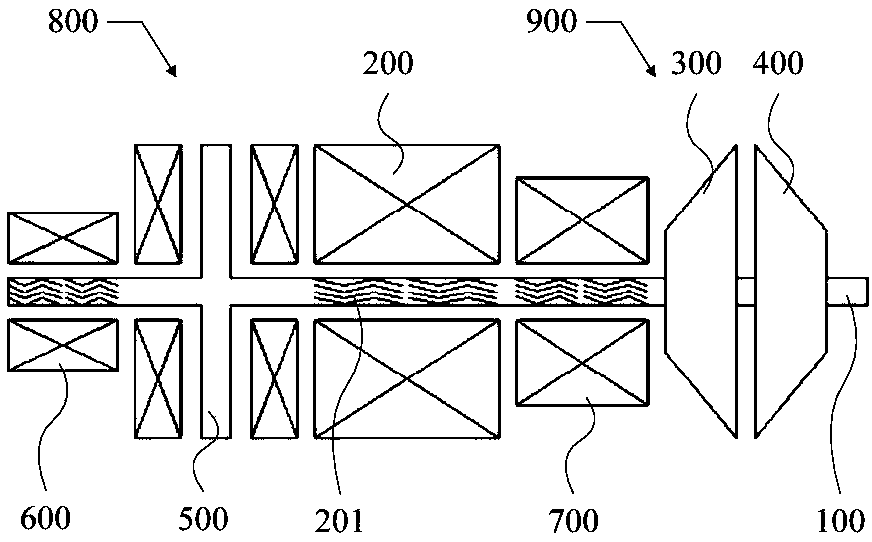

[0174] like Figure 1 to Figure 3 As shown, the rotor system includes:

[0175] The rotating shaft 100, the shaft body of the rotating shaft 100 has an integrated structure, and the rotating shaft 100 is arranged horizontally;

[0176] Motor 200, compressor 300, turbine 400, thrust bearing 500, first radial bearing 600 and second radial bearing 700 arranged on rotating shaft 100, thrust bearing 500, first radial bearing 600 and second radial bearing The bearings 700 are non-contact bearings;

[0177] And the first casing 800 and the second casing 900, the first casing 800 is connected with the second casing 900, wherein, the motor 200, the thrust bearing 500, the first radial bearing 600 and the second radial bearing 700 are all set In the first casing 800 , the compressor 300 and the turbine 400 are both arranged in the second casing 900 ;

[0178] The first radial bearing 600 is disposed on a side of the motor 200 away from the second casing 900 , and the second radial be...

Embodiment 2

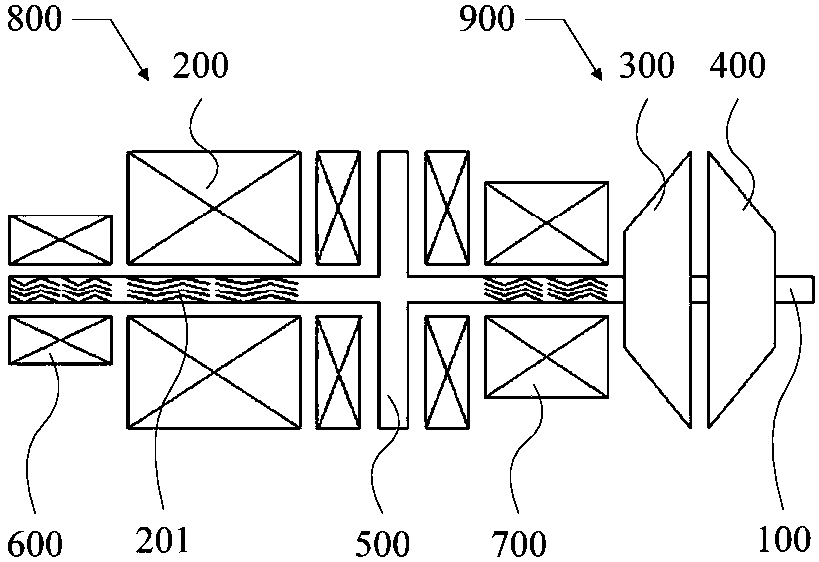

[0189] like Figure 4 to Figure 6 As shown, the rotor system includes:

[0190] The rotating shaft 100, the shaft body of the rotating shaft 100 is an integral structure, and the rotating shaft 100 is vertically arranged;

[0191] Motor 200, compressor 300, turbine 400, thrust bearing 500, first radial bearing 600 and second radial bearing 700 arranged on rotating shaft 100, thrust bearing 500, first radial bearing 600 and second radial bearing The bearings 700 are non-contact bearings;

[0192] And the first casing 800 and the second casing 900, the first casing 800 is connected with the second casing 900, wherein, the motor 200, the thrust bearing 500, the first radial bearing 600 and the second radial bearing 700 are all set In the first casing 800 , the compressor 300 and the turbine 400 are both arranged in the second casing 900 ;

[0193] The first radial bearing 600 is disposed on a side of the motor 200 away from the second casing 900 , and the second radial bearing...

Embodiment 3

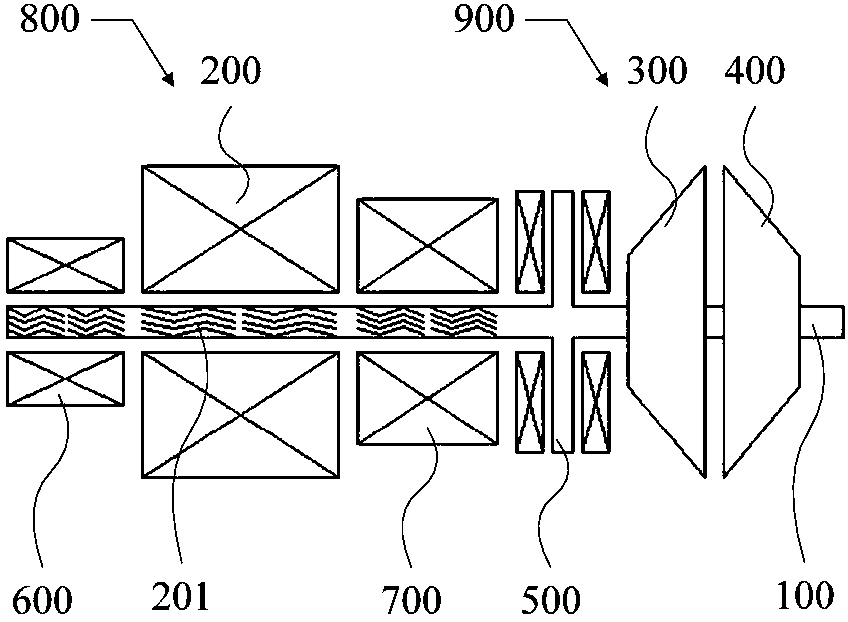

[0197] When the rotor system of the present application is used in a mobile device, such as an extended-range electric vehicle, when the rotor system is not working, the rotating shaft is in direct contact with the bearing. During the driving process of the car, the radial or axial movement of the rotating shaft relative to the bearing is caused by bumps or vibrations, causing wear between the rotating shaft and the bearing, which in turn affects the accuracy and life of the bearing.

[0198] Therefore, in order to solve the above problems, on the basis of other embodiments of the present invention, the rotor system of the embodiment of the present invention is provided with a locking device, and the locking device is used to lock the rotating shaft when the rotor system is not working.

[0199] In the embodiment of the present invention, the structural form and arrangement of the locking device are not unique. For ease of understanding, two implementations will be described in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com