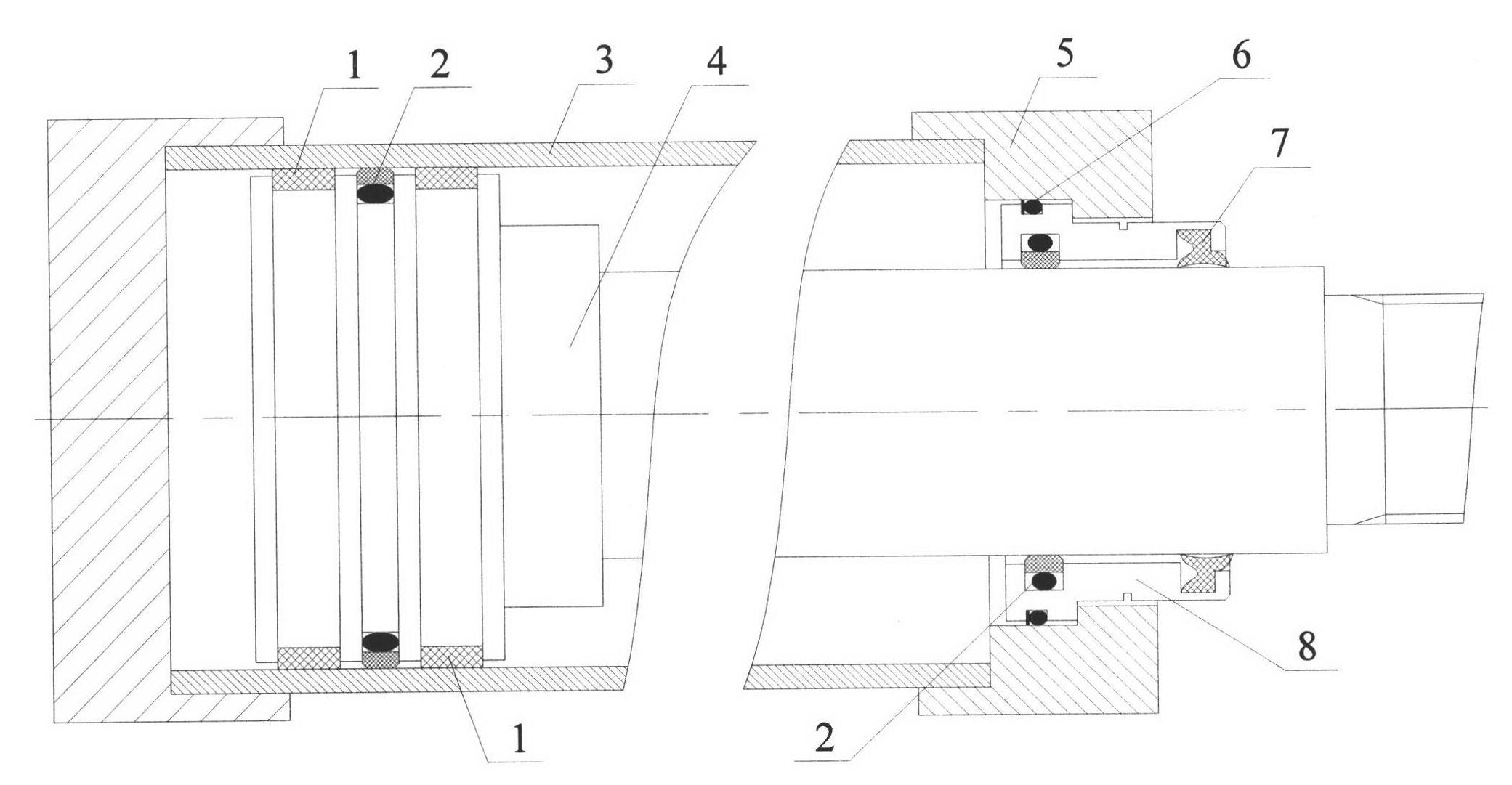

Y type sealing unit

A technology of sealing unit and sealing ring, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of reducing the sealing compensation effect, small movement speed, poor sealing of hydraulic cylinders, etc., to achieve enhanced sealing effect and increased service life , Eliminate the effect of poor oil passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

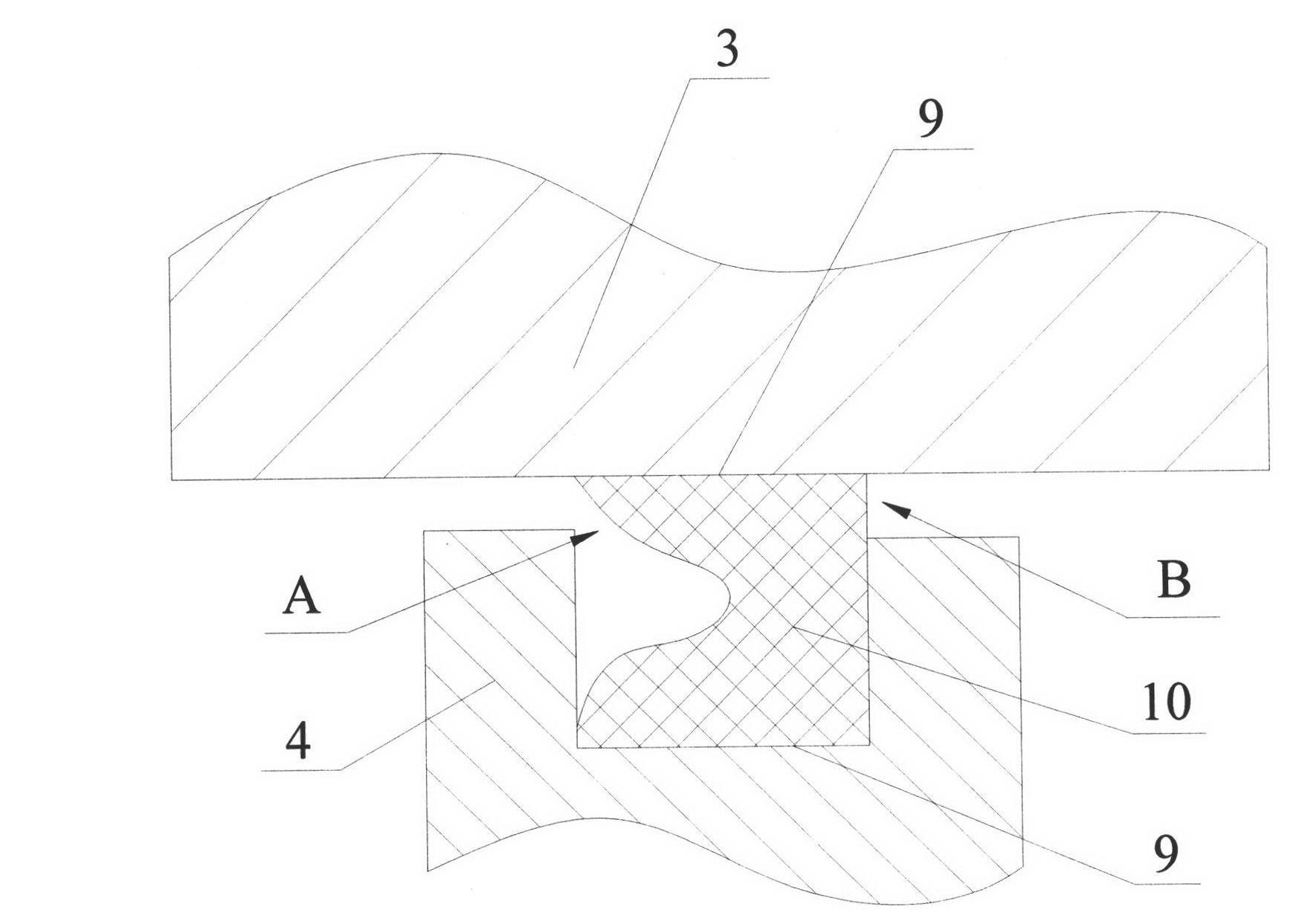

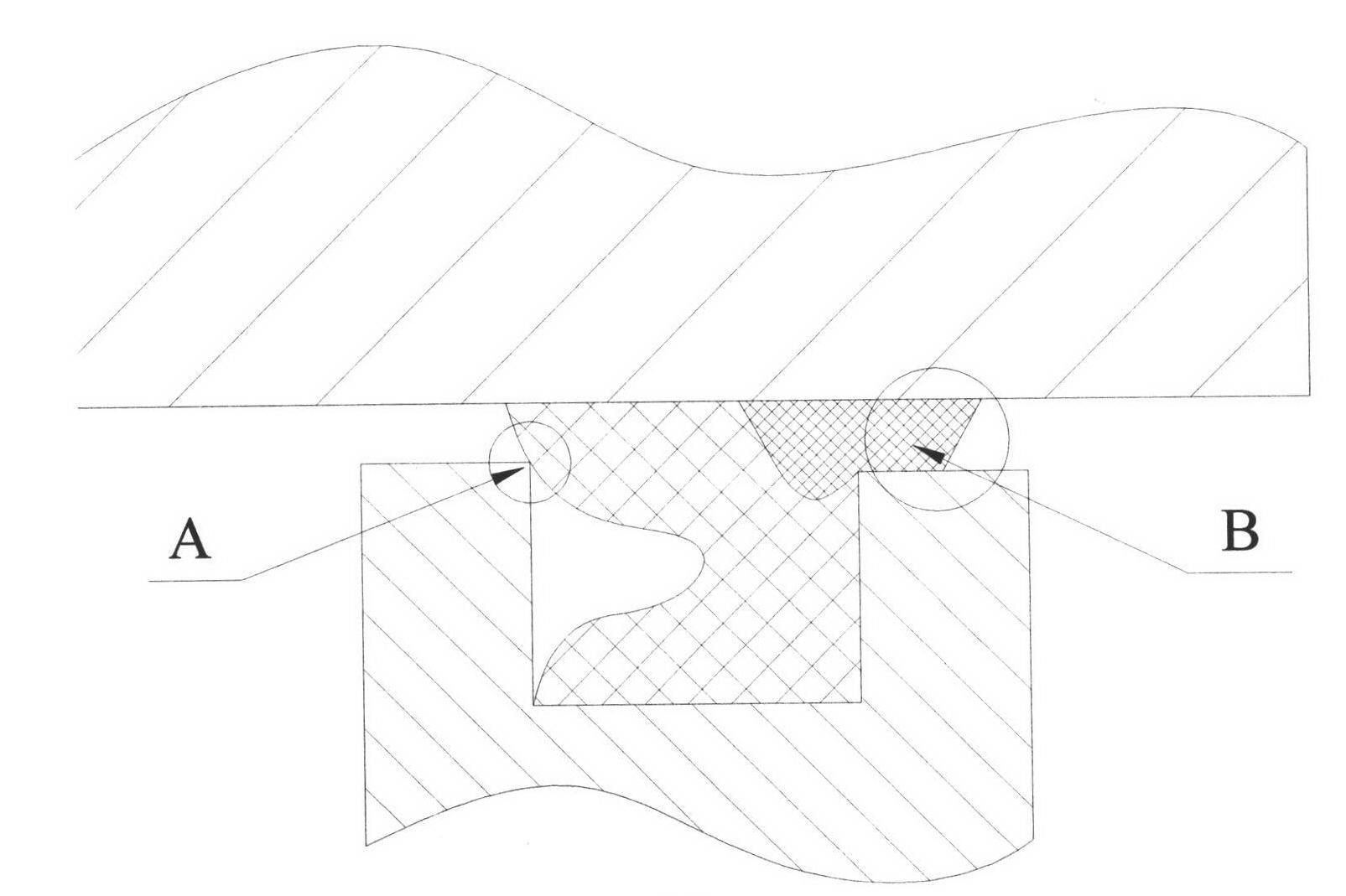

Embodiment Construction

[0042] See Figure 4 , Figure 5 , Put the retaining ring 12 and the Y-shaped sealing ring 13 into the seal groove of the guide sleeve 8 (or piston), the Y-shaped sealing unit 13 is assembled, after injecting hydraulic oil, even if the Y-shaped sealing ring 13 and the guide sleeve 8 The gap between them is small, and the hydraulic oil will also smoothly enter the inner cavity of the Y-shaped sealing ring through the oil inlet hole of the guide sleeve, so that the inner and outer lips of the Y-shaped sealing ring are close to the inner and outer sealing surfaces 9. At this time, the sealing surface is The effective sealing pressure is equal to the sum of the pre-pressure of the sealing ring due to elastic deformation and the hydraulic oil pressure: when there is no internal pressure, the contact pressure with the sealing surface 9 is equal to the pre-pressure of elastic deformation; when there is internal pressure, the bottom of the lip ring will be affected Axial compression,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com