Method of preparing polycrystalline diamond microspheres by hydro-thermal synthesis of carbon spheres

A technology of polycrystalline diamond and hydrothermal synthesis, applied in the direction of carbon preparation/purification, application of ultra-high pressure process, etc., can solve the problem that it is difficult to meet the requirements of the diamond secondary anvil and affect the hardness and heat of artificial polycrystalline diamond. Stability, large particle size and other issues, to achieve the effect of uniform size, compact block, and controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

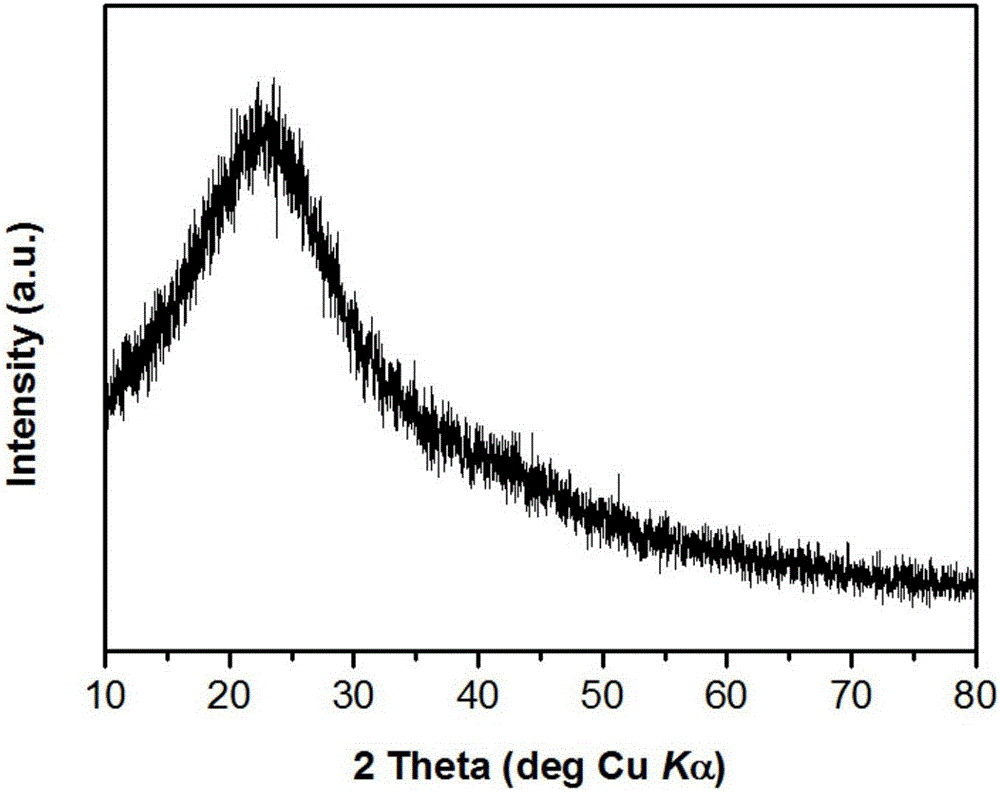

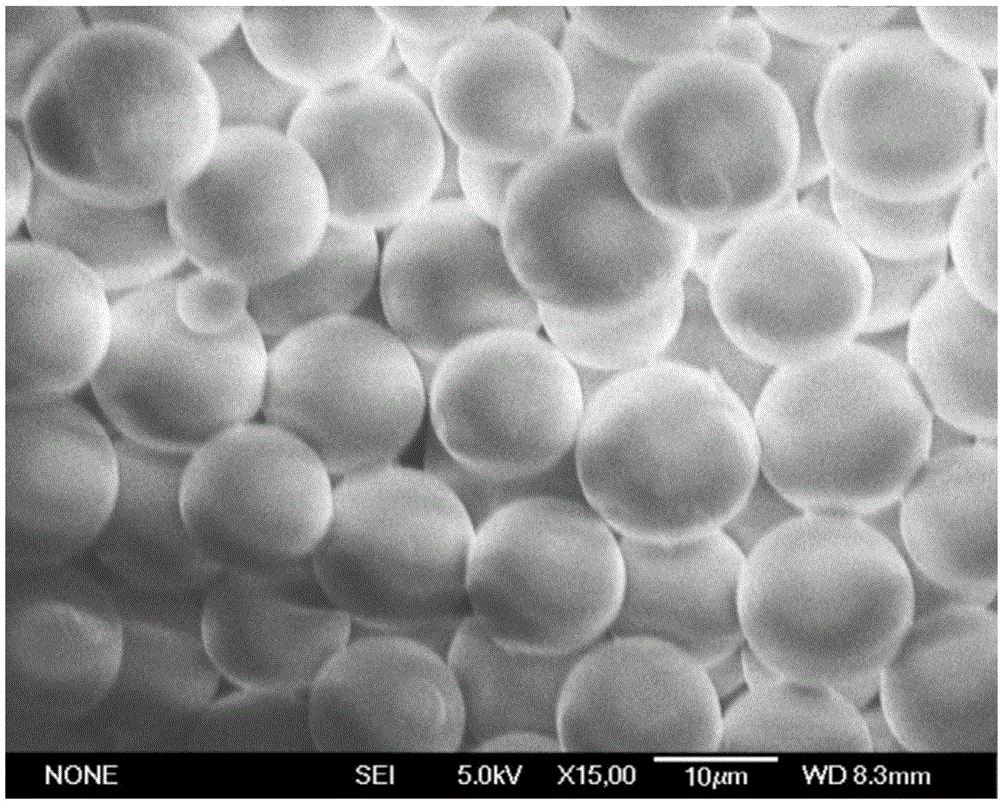

[0028] Take 0.01mol of glucose and dissolve it into 100ml of deionized water to make a 0.1mol / L glucose solution. Take 16ml of the above solution and put it into a 20ml reactor. Tighten and seal the reactor. Keep the temperature at 200°C for 24 hours, then take out the reaction kettle from the oven, and let it cool down to room temperature naturally. Open the reaction kettle, remove the solution in the reaction kettle, wash the solid product with water and ethanol, centrifuge three times, put it in a 60°C oven and dry it for 10 hours to obtain carbon microspheres. X-ray diffraction tests show that the material contains only carbon, such as figure 1 Shown; Scanning electron microscopy test shows that the material is uniform carbon microspheres with a diameter of about 10‐15 microns, such as figure 2 shown.

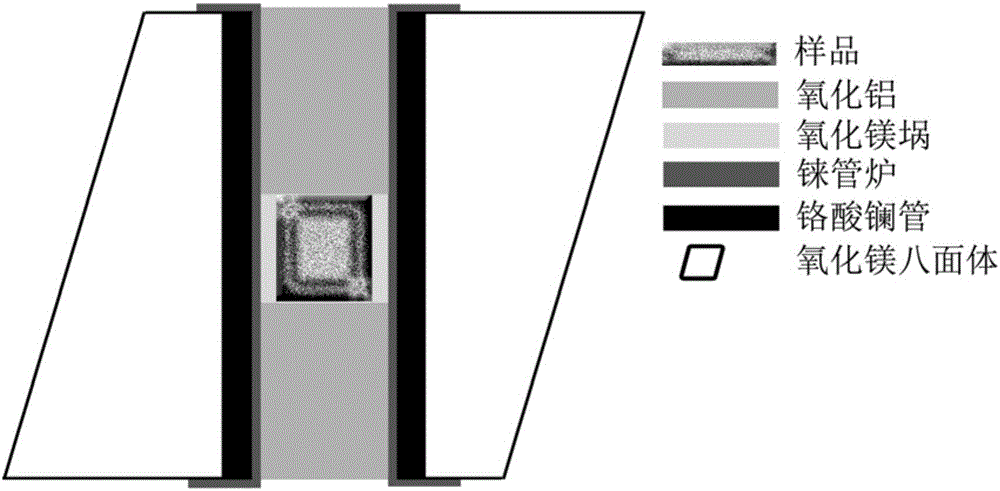

[0029] Put 4g of sodium chloride into a silicon carbide ball mill tank with a capacity of 20ml, add silicon carbide grinding balls with a diameter of 5mm, the mass ratio...

Embodiment 2

[0032] Put 3g of sodium chloride into a 20ml silicon carbide ball mill tank, add silicon carbide grinding balls with a diameter of 5mm, the mass ratio of silicon carbide grinding balls to sodium chloride is 20:1, set the speed at 800 rpm, and pause after 15 minutes of ball milling 15 minutes, accumulative ball milling for 4 hours, to obtain sodium chloride powder

[0033] Mix 0.05 g of carbon microspheres synthesized in Example 1 with 1 g of sodium chloride powder by shaking, so that the carbon microspheres are evenly distributed in the sodium chloride powder. Take a certain amount of the above-mentioned mixture and put it into a prefabricated mold, repeat the operation method of Example 1 to form an assembly block, put the assembly block into an oven, and keep the temperature at 120° C. for 4 hours. Take out the assembly block from the drying oven and put it into a high-temperature and high-pressure device. First, raise the pressure to 20GPa, keep it under this pressure, and ...

Embodiment 3

[0035] Take 0.02 mol of glucose and dissolve it into 100 ml of deionized water to form a 0.2 mol / L glucose solution, and repeat the operation method of Example 1 to obtain carbon microspheres. X-ray diffraction tests show that the material contains only carbon; scanning electron microscope tests show that the size of carbon microspheres is 1‐5 microns.

[0036]0.05 g of carbon microspheres and 1 g of sodium chloride powder milled according to Example 2 were shaken and mixed, so that the carbon microspheres were uniformly distributed in the sodium chloride powder. Take a certain amount of the above-mentioned mixture and put it into a prefabricated mold. Take a certain amount of the above-mentioned mixture and put it into a prefabricated mold, and repeat the operation method of Example 1 to form an assembly block. Hour. Take out the assembly block from the drying oven and put it into a high-temperature and high-pressure device. First, raise the pressure to 20GPa, keep it under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com