Thrust bearing, rotor system and control method of thrust bearing

A thrust bearing and rotor technology, applied in the field of bearings, can solve the problems of high energy consumption, inapplicability, and shaft collision of magnetic bearings, and achieve the effect of improving bearing capacity and strong anti-disturbance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

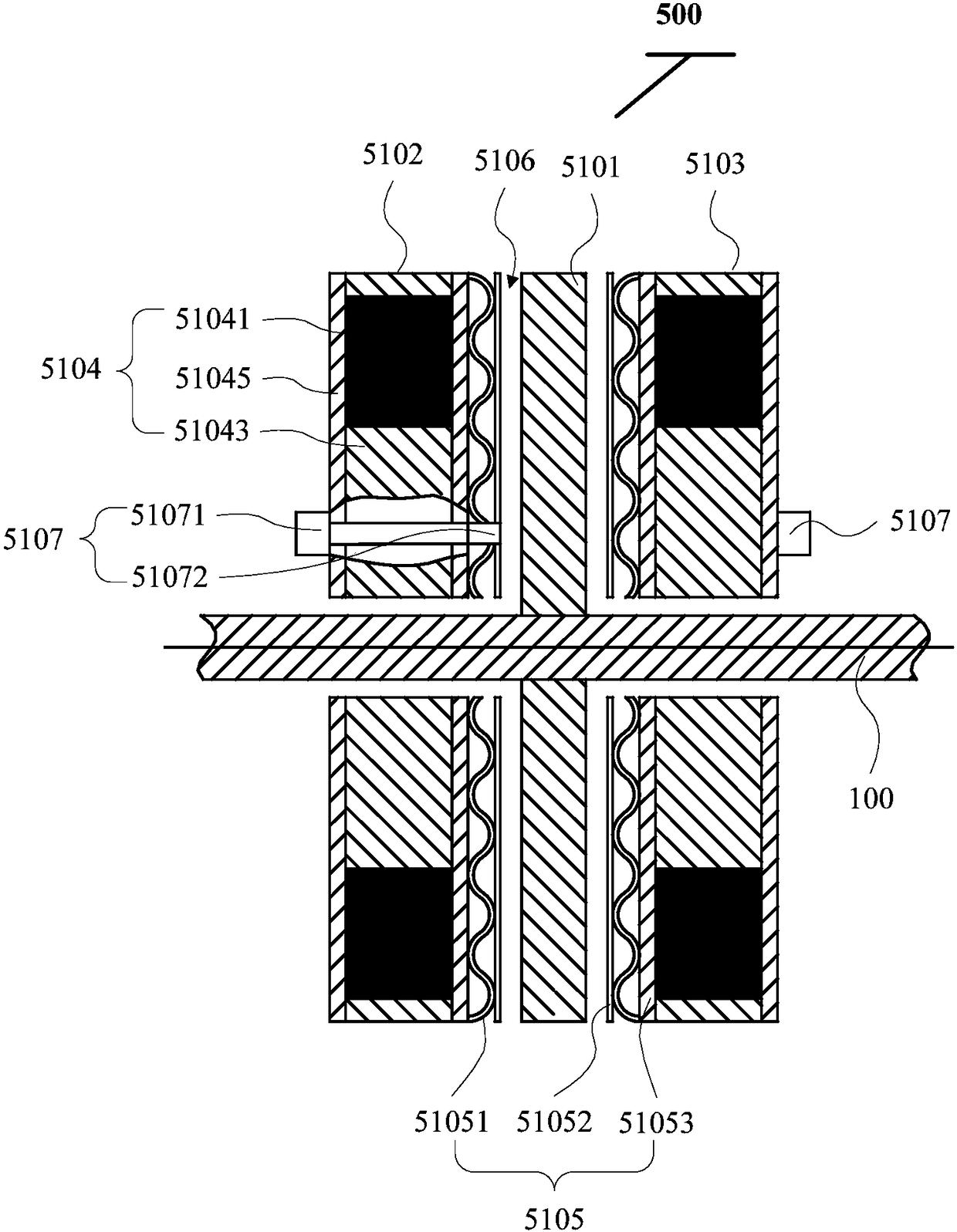

[0089] Such as Figure 1 to Figure 4 As shown, the thrust bearing 500 is used to be installed on the rotating shaft 100, and the thrust bearing 500 includes:

[0090] Thrust plate 5101, the thrust plate 5101 is fixedly connected to the rotating shaft 100;

[0091] And, the first stator 5102 and the second stator 5103 passing through the rotating shaft 100, the first stator 5102 and the second stator 5103 are respectively arranged on opposite sides of the thrust plate 5101;

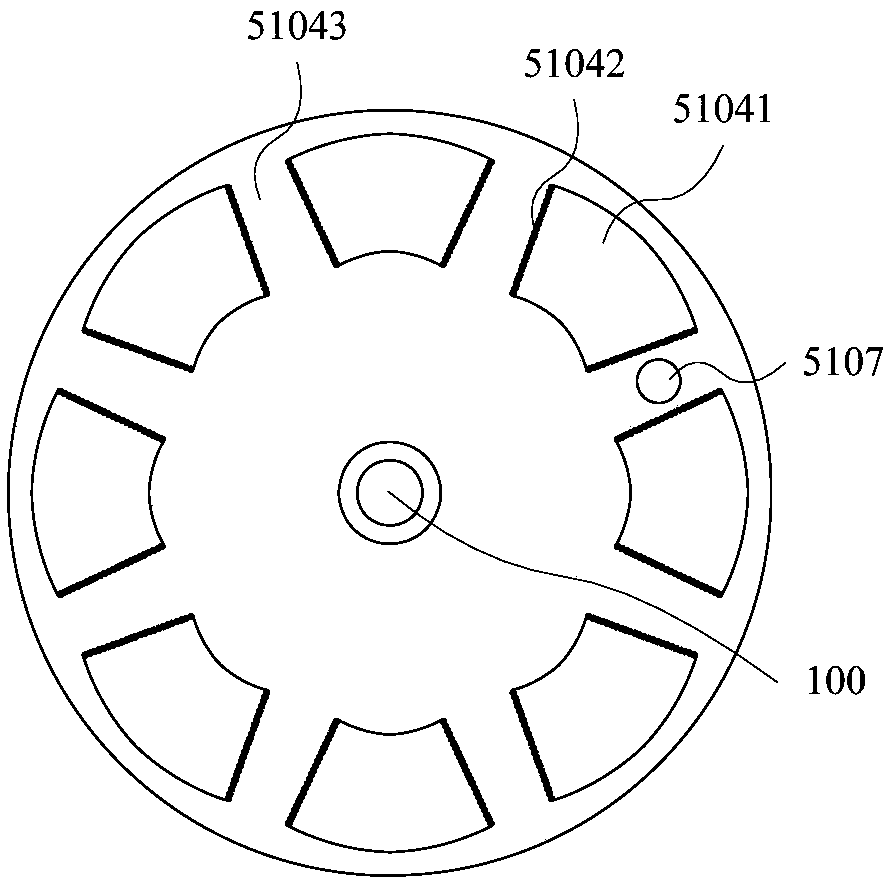

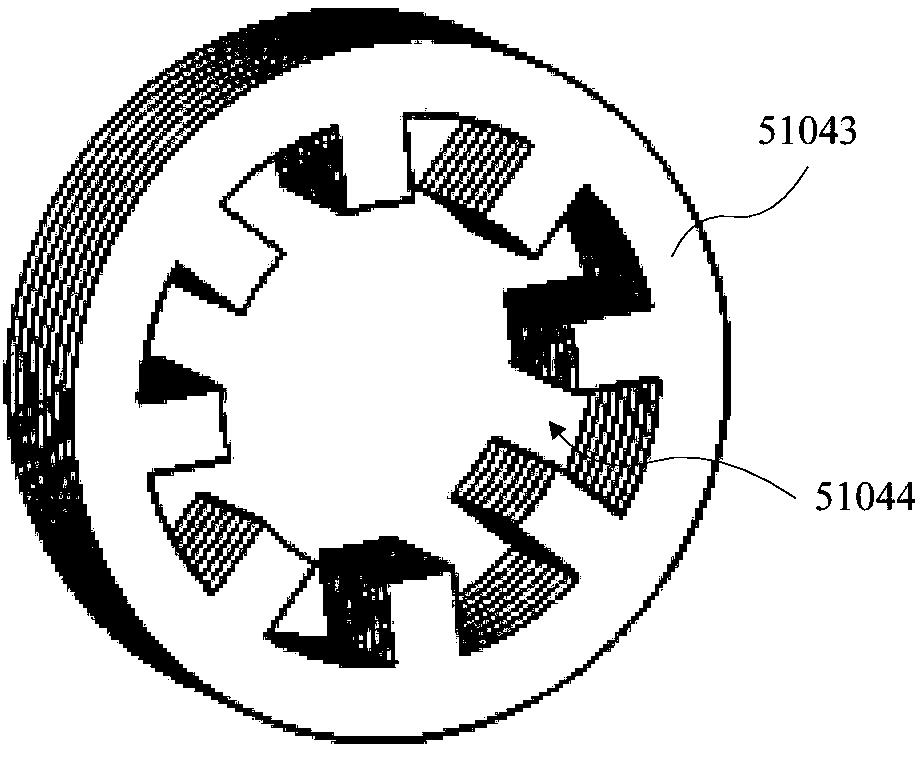

[0092] In the first stator 5102 and the second stator 5103, each stator includes a magnetic bearing 5104 and a foil bearing 5105, the magnetic bearing 5104 is provided with a plurality of first magnetic components along the circumferential direction, and the foil bearing 5105 is provided with multiple A second magnetic component that generates a magnetic force between the first magnetic components;

[0093] Wherein, the foil bearing 5105 is arranged between the magnetic bearing 5104 and the thrust plate ...

Embodiment 2

[0135] An embodiment of the present invention provides a rotor system, including:

[0136] A rotating shaft, the shaft body of which is an integrated structure, and the rotating shaft is arranged horizontally;

[0137] A motor, a compressor and a turbine arranged on the rotating shaft in sequence;

[0138] And, a thrust bearing and at least two radial bearings arranged on the rotating shaft;

[0139] Wherein, the thrust bearing is arranged at a preset position on the side of the turbine close to the compressor, and the preset position is such that the center of gravity of the rotor system is located at the at least two radial bearings The position between the two radial bearings that are farthest apart.

[0140] In the embodiment of the present invention, the thrust bearing is the thrust bearing provided in this application.

[0141] In the embodiment of the present invention, the thrust bearing is a bearing used to limit the movement of the rotating shaft in the axial dire...

Embodiment 3

[0157] An embodiment of the present invention provides a rotor system, including:

[0158] A rotating shaft, the shaft body of the rotating shaft is an integrated structure, and the rotating shaft is arranged vertically;

[0159] A motor, a compressor and a turbine arranged on the rotating shaft in sequence;

[0160] And, a thrust bearing and at least two radial bearings arranged on the rotating shaft;

[0161] Wherein, the thrust bearing is arranged at a preset position on the side of the turbine close to the compressor, and the preset position is such that the center of gravity of the rotor system is located at the at least two radial bearings The position between the two radial bearings that are farthest apart.

[0162] In the embodiment of the present invention, the thrust bearing is the thrust bearing provided in this application.

[0163] In the embodiment of the present invention, the thrust bearing is a bearing used to limit the movement of the rotating shaft in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com