Electromagnetically enabled active hydrodynamic gas-lubricated bearing

A technology of dynamic pressure gas bearings and electromagnetic bearings, which is applied in the direction of air cushion bearings, magnetic bearings, sliding contact bearings, etc., can solve the problems of bearing disturbance eccentricity, low precision requirements, and low bearing capacity at low speeds, and achieve high rotor damping and precision High requirements and the effect of improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

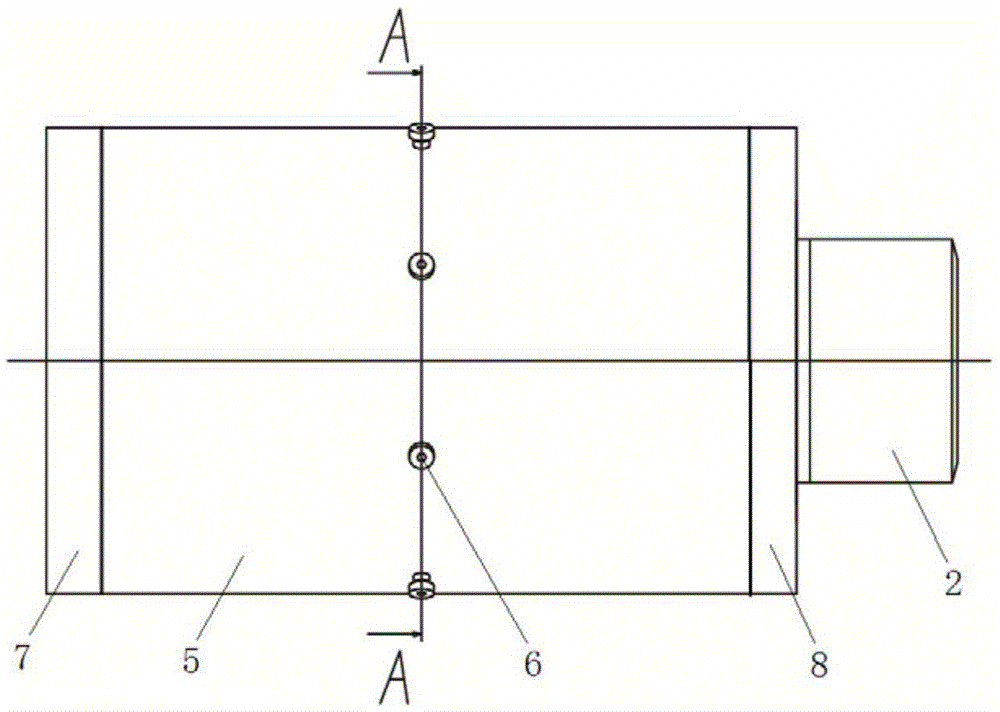

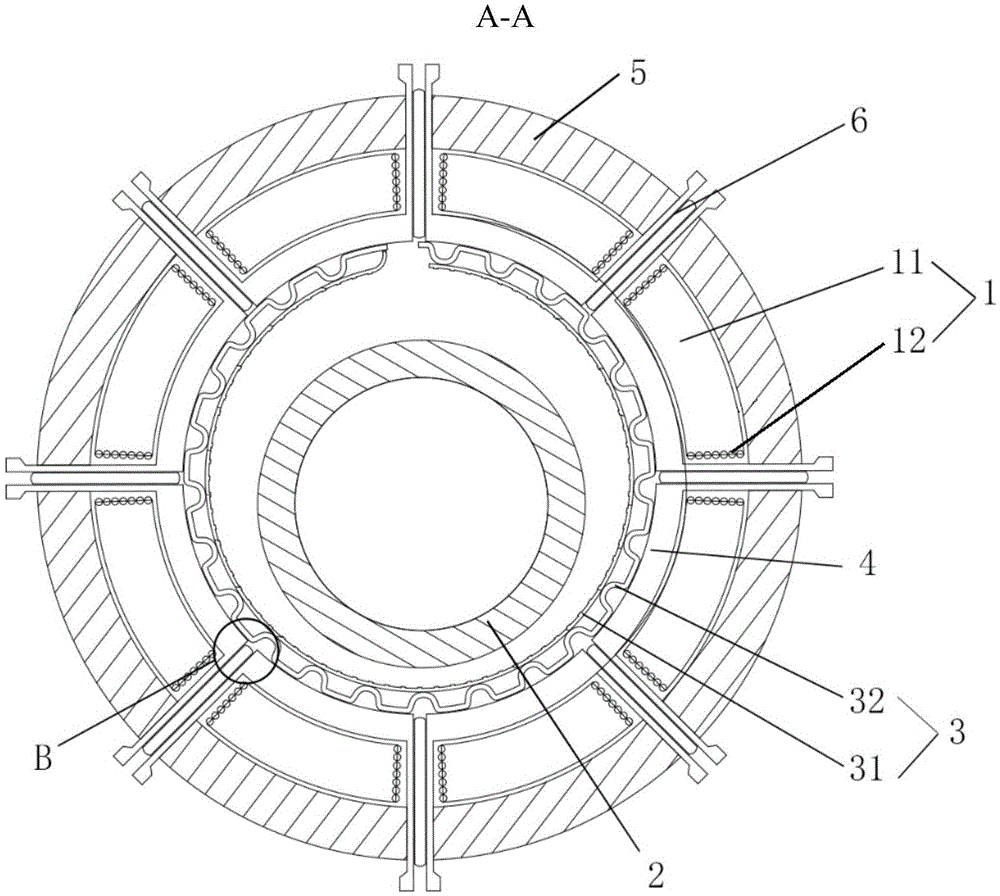

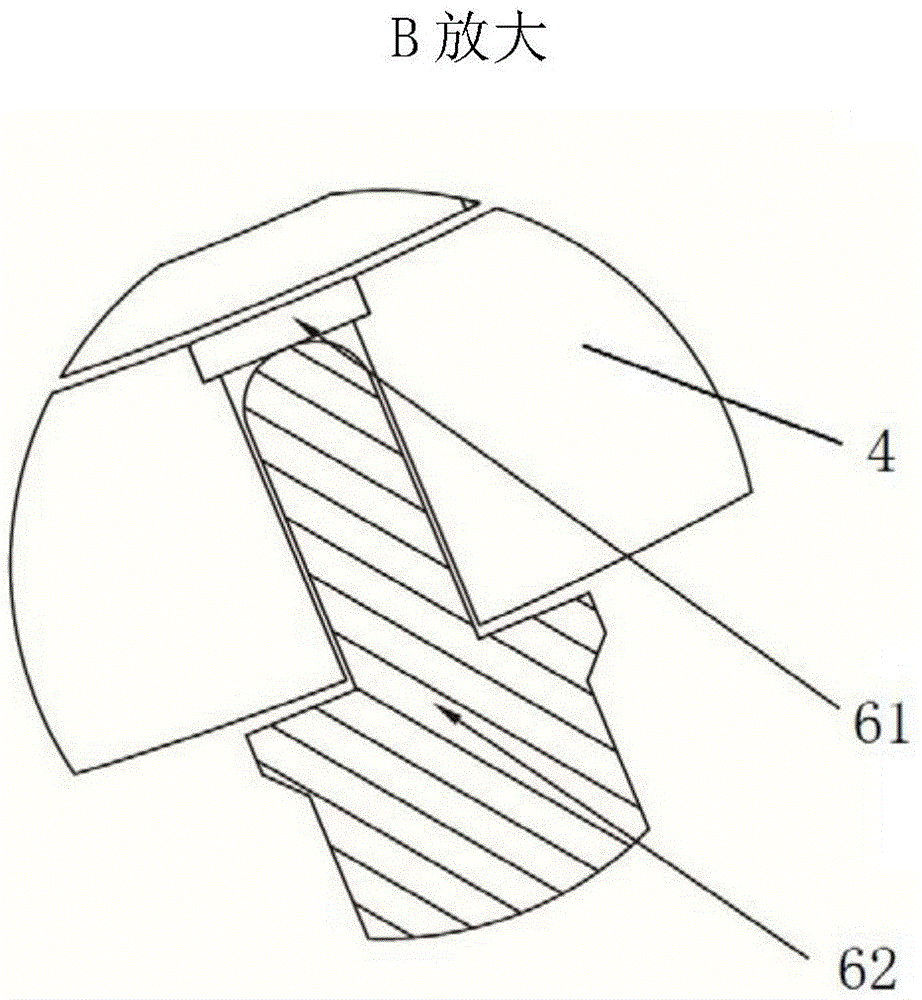

[0029] like Figure 1-2 As shown, an electromagnetically enabled active dynamic pressure gas bearing of the present invention includes an electromagnetic bearing 1, an elastic foil bearing 3 nested between the electromagnetic bearing 1 and the rotor shaft 2, an elastic foil bearing seat 4, The bearing housing 5, the pressure sensor 6, the left end cover 7 and the right end cover 8 are characterized in that the elastic foil bearing 3 includes a top elastic foil 31 and a bottom elastic foil 32, and the top elastic foil 31 It is a non-magnetic material, and a plurality of independent magnetic material regions are distributed on the surface of the top elastic foil 31 .

[0030] The electromagnetic bearing 1 is located between the elastic foil bearing seat 4 and the bearing housing 5, the elastic foil bearing seat 4 is used to install the underlyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com