4004 aluminum alloy containing bismuth and tellurium for brazing and production method of 4004 aluminum alloy

A production method and aluminum alloy technology, applied in welding equipment, welding medium, metal processing equipment, etc., can solve the problem of not being able to significantly increase the wettability of the alloy during brazing, increasing the incidence of welding leaks, and the low pass rate of heat exchangers To achieve the effect of reducing the incidence of welding leaks, improving degassing efficiency and quality, and increasing wettability and spreadability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

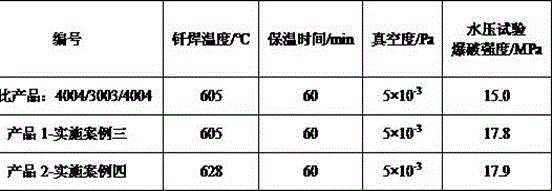

Examples

Embodiment 1

[0025] (1) Raw material and weight:

[0026] Its chemical composition is: Si: 9.0%, Mg: 1.0%, Fe≤0.8%, Cu≤0.25%, Mn≤0.1%, Zn≤0.20%, Sr: 0.02%, Bi: 0.02%, Te : 0.01%, individual content of other impurity elements ≤0.05%, total content of other impurity elements ≤0.15%, and the balance is Al.

[0027] (2) Production method:

[0028] (1) Smelting: Put aluminum ingots with a purity of 99.75% or more into the melting furnace, weigh the alloy elements according to the ratio and put them in the furnace, and then smelt them at a temperature of 720°C. During the smelting process, use electromagnetic stirring to accelerate the smelting speed , and use a slag removal truck to remove slag from the molten aluminum, and the molten aluminum stays in the smelting furnace for 8 hours;

[0029] (2) Degassing and slag removal: the smelted aluminum alloy melt is refined in the furnace and online degassing and slag removal; the online degassing uses argon as the covering gas to prevent secondary...

Embodiment 2

[0036] (1) Raw material and weight:

[0037]Its chemical composition is: Si: 9.5%, Mg: 1.5%, Fe≤0.8%, Cu≤0.25%, Mn≤0.1%, Zn≤0.20%, Sr: 0.1%, Bi: 0.1%, Te : 0.1%, individual content of other impurity elements ≤0.05%, total content of other impurity elements ≤0.15%, and the balance is Al.

[0038] (2) Production method:

[0039] (1) Melting: put aluminum ingots with a purity of 99.75% or more into the melting furnace, weigh the alloy elements according to the ratio and put them in the furnace, and then melt them at a temperature of 740°C. During the melting process, electromagnetic stirring is used to accelerate the melting speed , and use a slag removal truck to remove slag from the molten aluminum, and the molten aluminum stays in the smelting furnace for 7.5 hours;

[0040] (2) Degassing and slag removal: the smelted aluminum alloy melt is refined in the furnace and online degassing and slag removal; the online degassing uses argon as the covering gas to prevent secondary o...

Embodiment 3

[0047] (1) Raw material and weight:

[0048] Its chemical composition is: Si: 10.0%, Mg: 1.8%, Fe≤0.8%, Cu≤0.25%, Mn≤0.1%, Zn≤0.20%, Sr: 0.15%, Bi: 1.0%, Te : 0.5%, the single content of other impurity elements ≤0.05%, the total content of other impurity elements ≤0.15%, and the balance is Al.

[0049] (2) Production method:

[0050] (1) Melting: put aluminum ingots with a purity of 99.75% or more into the melting furnace, weigh the alloy elements according to the ratio and put them in the furnace, and then melt them at a temperature of 760 ° C. During the melting process, electromagnetic stirring is used to accelerate the melting speed , and use a slag removal truck to remove slag from the molten aluminum, and the molten aluminum stays in the smelting furnace for 7 hours;

[0051] (2) Degassing and slag removal: the smelted aluminum alloy melt is refined in the furnace and online degassing and slag removal; the online degassing uses argon as the covering gas to prevent seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com