A submersible vehicle high-pressure case and a method of manufacturing that same

A technology of high pressure resistance and submersibles, applied in the field of submersibles, can solve the problems of low compressive strength and achieve the effects of enhanced compressive strength, improved production efficiency, and increased pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

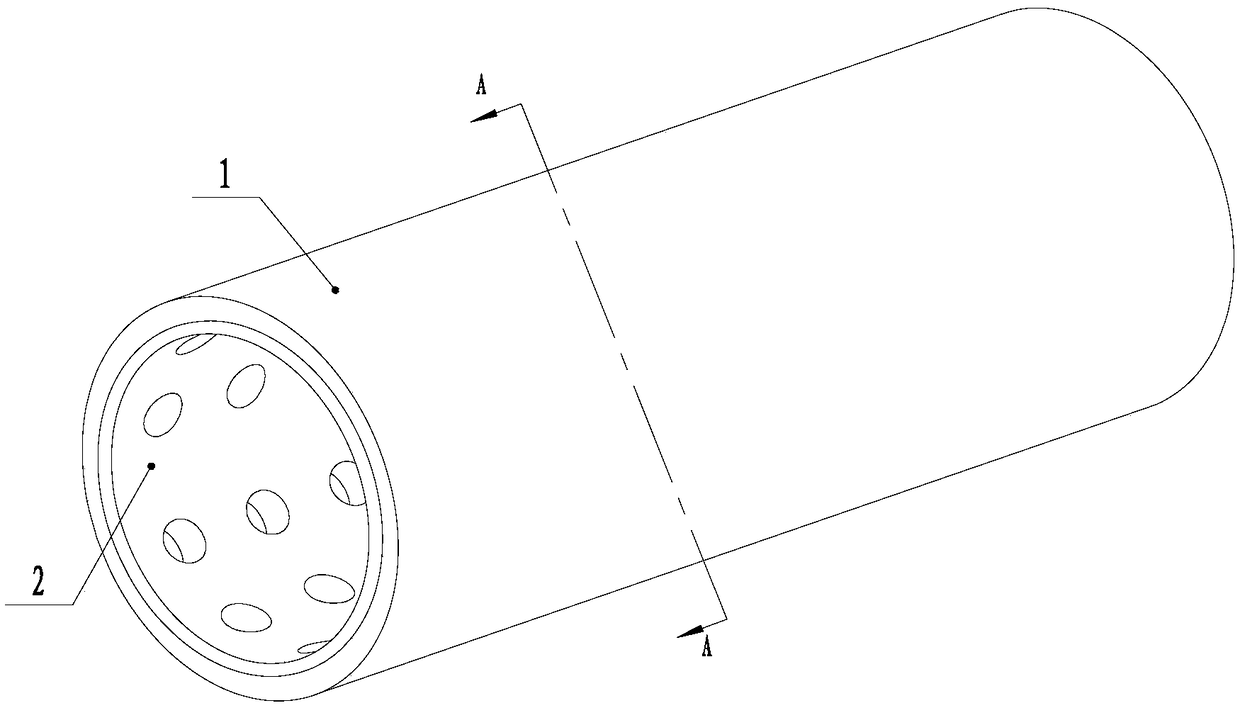

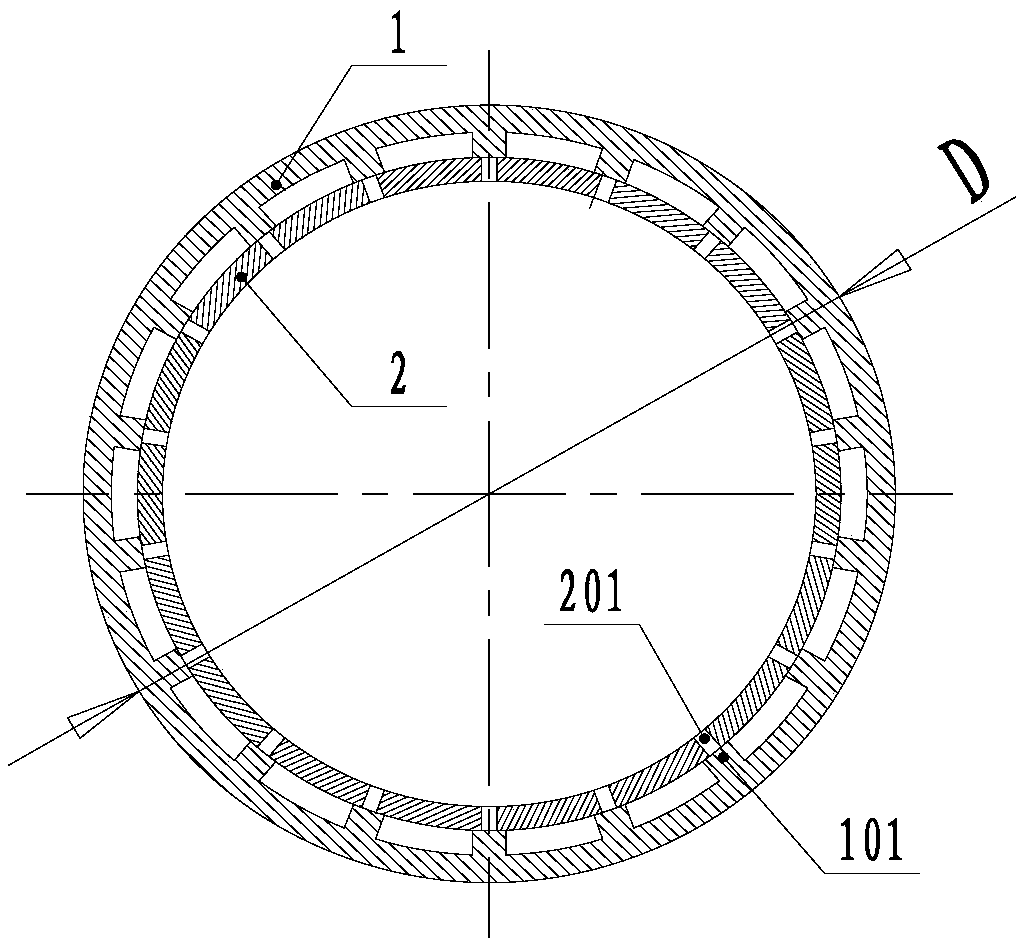

[0032] Such as Figure 1 to Figure 4 As shown, a high-pressure-resistant shell of a submarine includes an outer shell 1 and an inner shell 2, the outer shell 1 and the inner shell 2 are both cylindrical, and the outer shell 1 is sleeved outside the inner shell 2. A number of supporting rib rings 102 are arranged between the outer shell 1 and the inner shell 2. The supporting rib rings 102 are evenly spaced along the axial direction of the outer shell 1. The outer diameter of the outer shell 1 is D, and the distance between the supporting rib rings 102 is L, and 2D≤L≤5D.

[0033] Between the inner side wall of the outer casing 1 and the outer side wall of the inner casing 2, there are uniformly arranged support grids. In this embodiment, the supporting grid is a regular hexagon, and the inner surface of the outer shell 1 is formed with a honeycomb-like hexagonal supporting grid to differentiate the shell, and the regular structure greatly enhances the local pressure bearing ca...

Embodiment 2

[0035] Such as Figure 5 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the supporting grid is a trapezoidal grid, and the trapezoidal grid is alternately arranged in front and back.

[0036] The manufacturing method of the high-pressure-resistant casing of the above-mentioned submarine comprises the following steps:

[0037] 1) The outer casing 1 is processed by precision casting or numerical control machining, and the inner side wall of the outer casing 1 is provided with a supporting rib ring 102 and a supporting grid;

[0038] 2) machining the inner casing 2 by means of precision casting or numerical control machining,

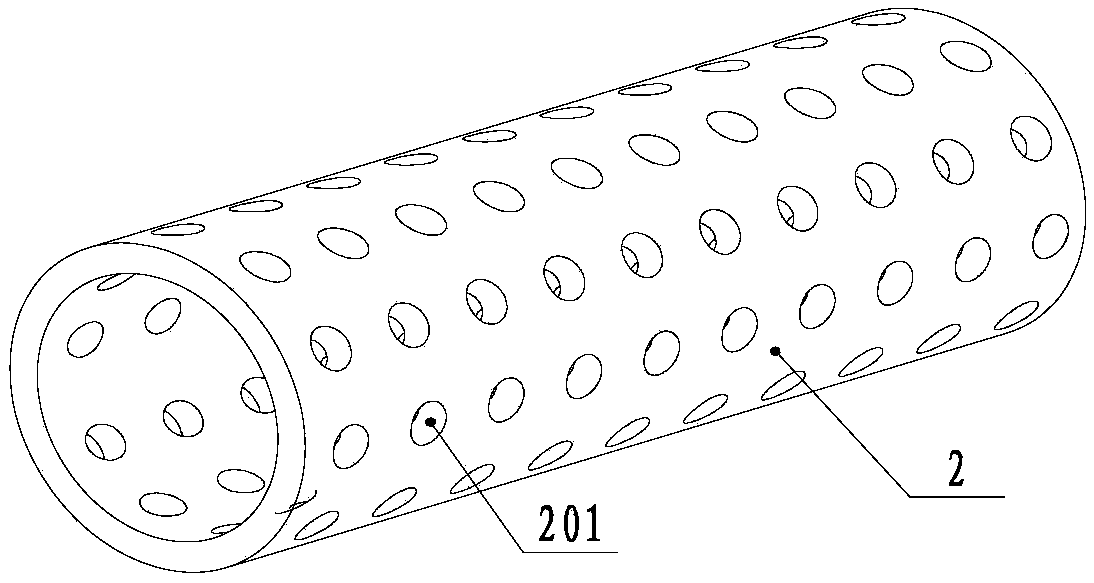

[0039] 3) Put the inner casing 2 inside the outer casing 1 , and weld and fix the inner casing 2 on the outer casing 1 through the plug welding hole 201 on the inner casing 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com