Side channel blower having a plurality of feed channels distributed over the circumference

A technology of conveying channels and blowers, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve problems such as high cost and limited degree of freedom, and achieve low manufacturing cost and space saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

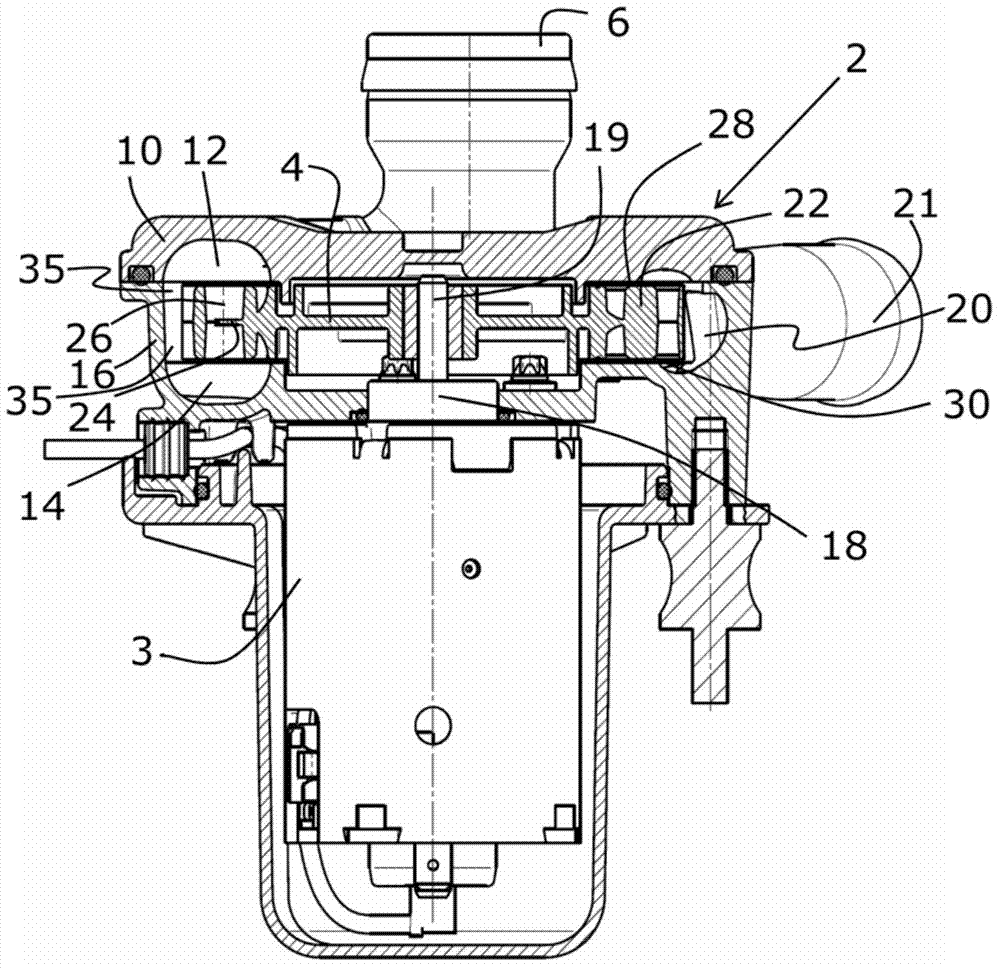

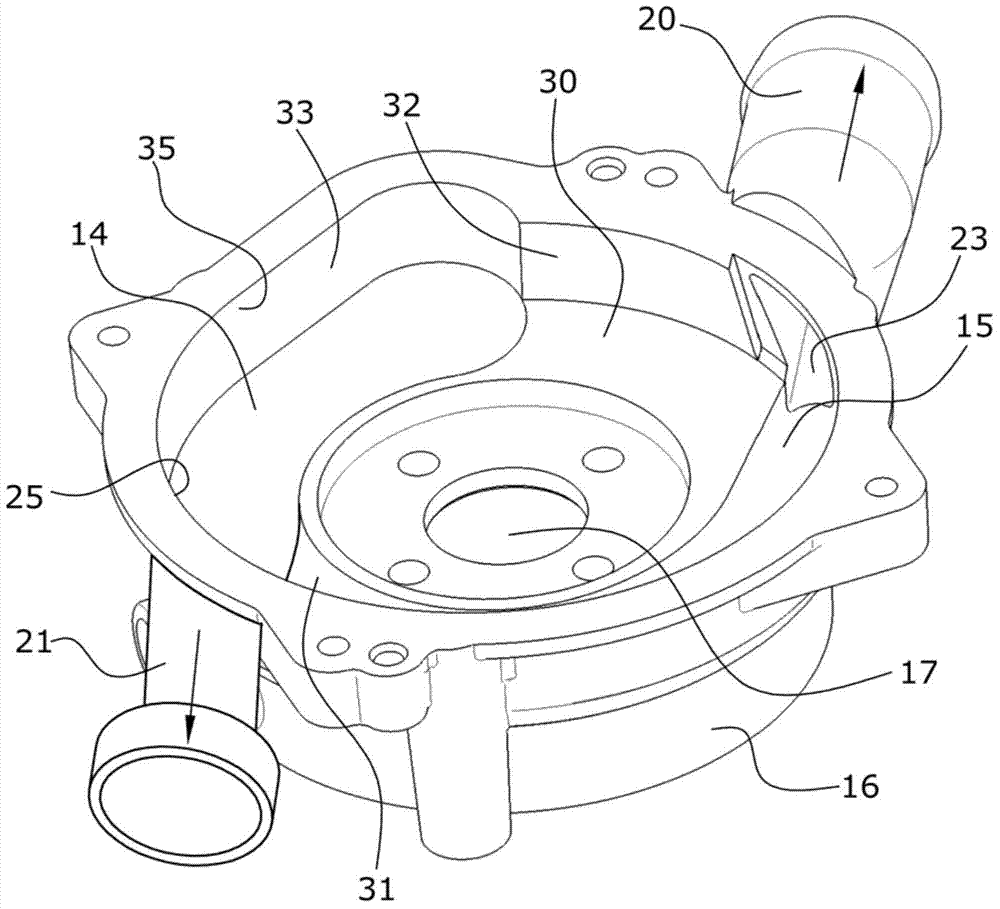

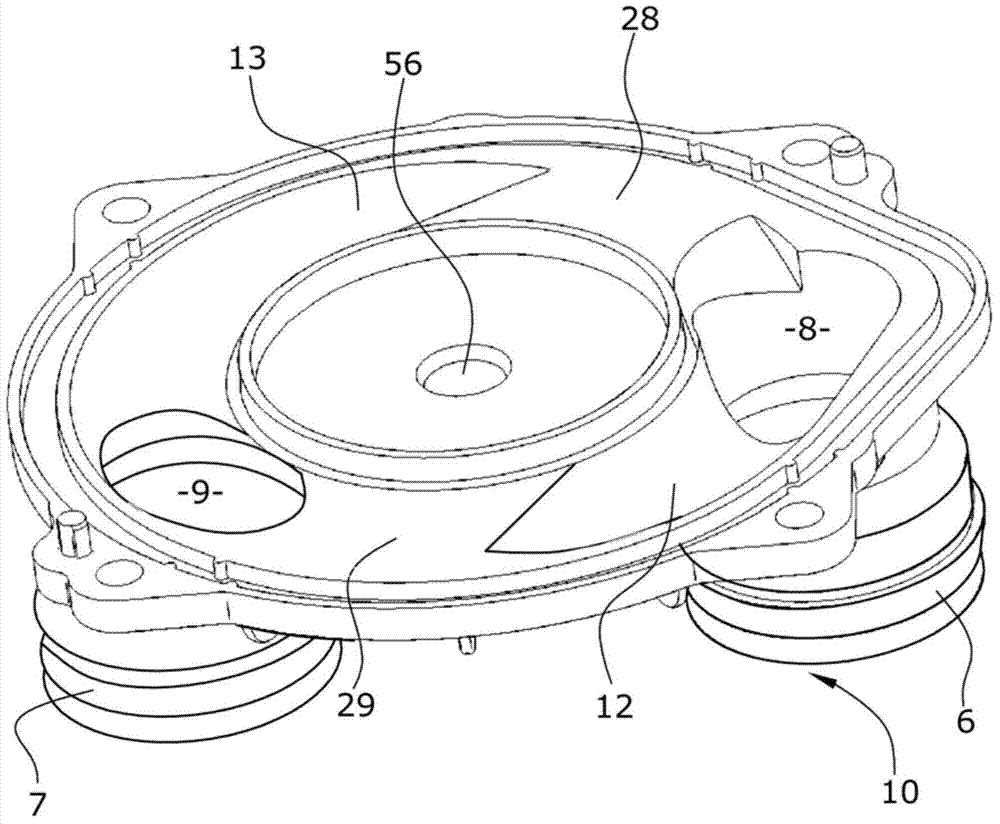

[0017] The embodiment of the blower with side channels shown in the figure is a so-called double helix design, in which not only in the first but also in the second housing part, there are two conveying channels which follow each other in the circumferential direction, here Conveyor channels extending axially parallel to one another each have an outlet region, which merge into a common outlet. figure 1 The section in is chosen to extend through a delivery channel. exist figure 1 The blower with side channel shown in , consists of a housing 2 divided into two parts and an impeller 4 which is rotatably mounted in the housing 2 and which can be driven by a drive unit 3 , for example for conveying air. The air passes through the axial inlet 6 into the inlet region 8 of the first housing part 10 which in this embodiment serves as a cover for a blower with side channels. From the outlet area 8, the air then flows into two substantially arc-shaped delivery channels 12, 14, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com