A method for preparing polycrystalline diamond microspheres by hydrothermally synthesizing carbon spheres

A polycrystalline diamond and hydrothermal synthesis technology, which is applied in the preparation/purification of carbon and the process of applying ultra-high pressure, can solve the requirements that it is difficult to meet the requirements of the secondary diamond anvil, the particle size is large, and the artificial polycrystalline Diamond hardness, thermal stability and other issues, to achieve the effect of uniform size, controllable size, and dense block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

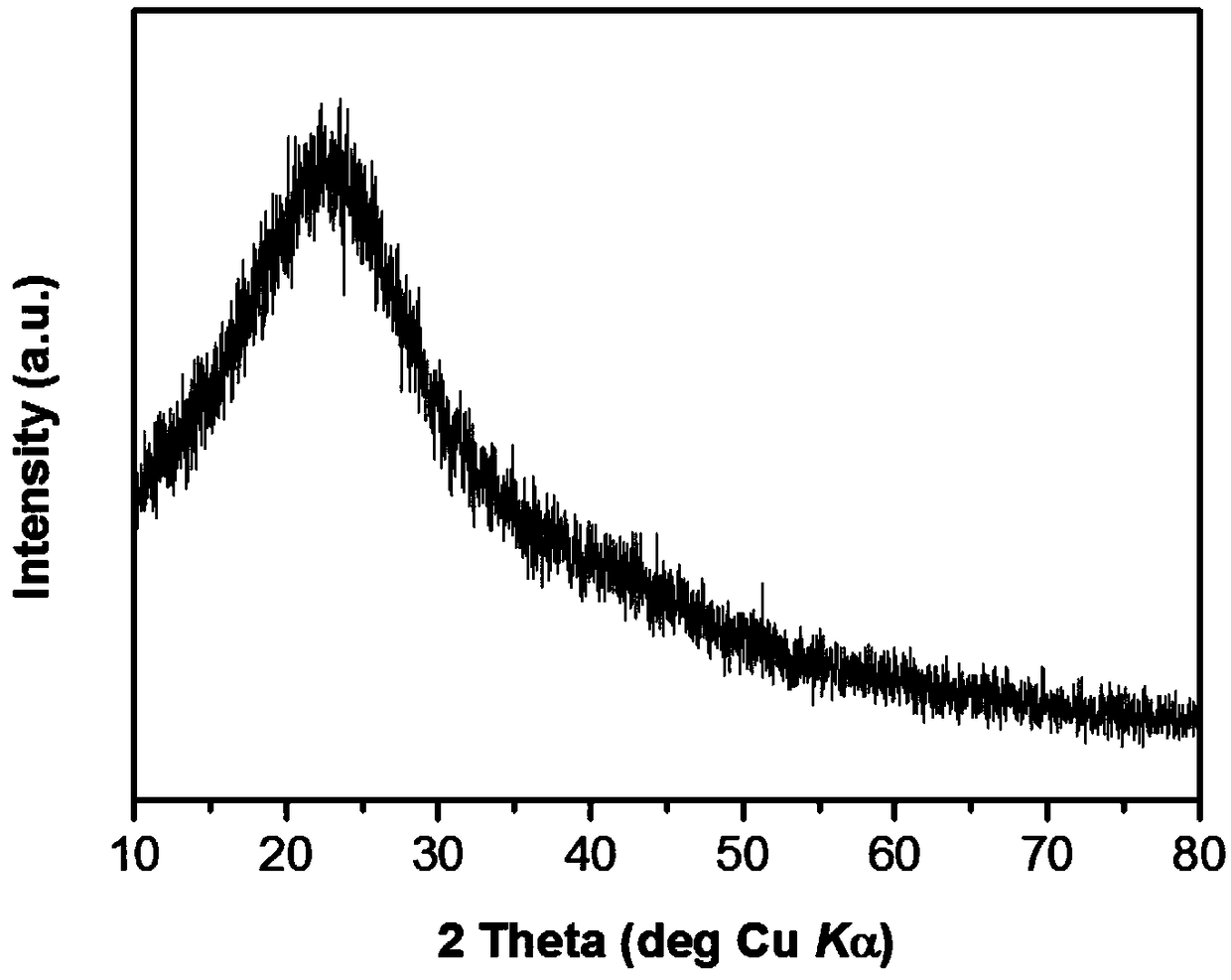

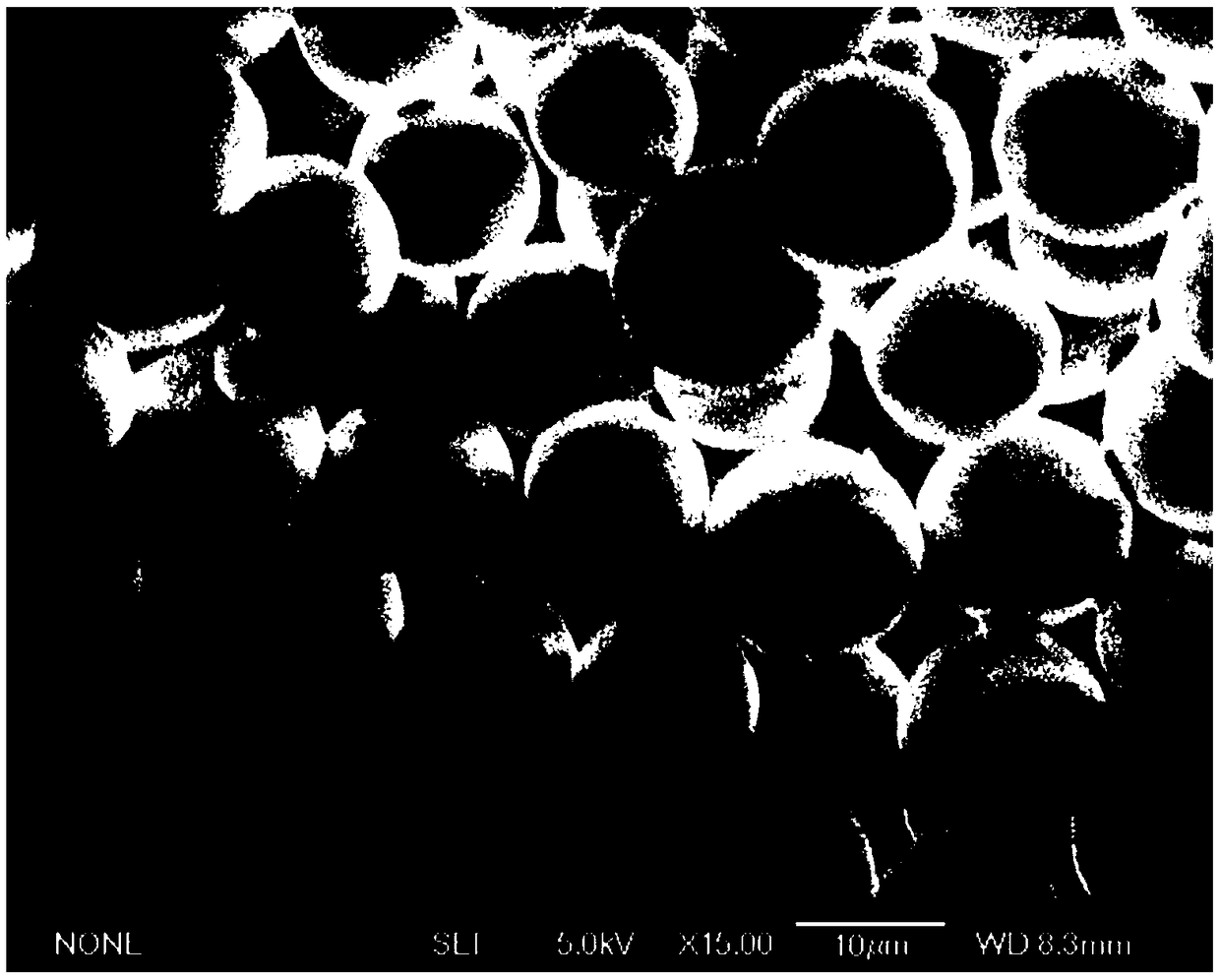

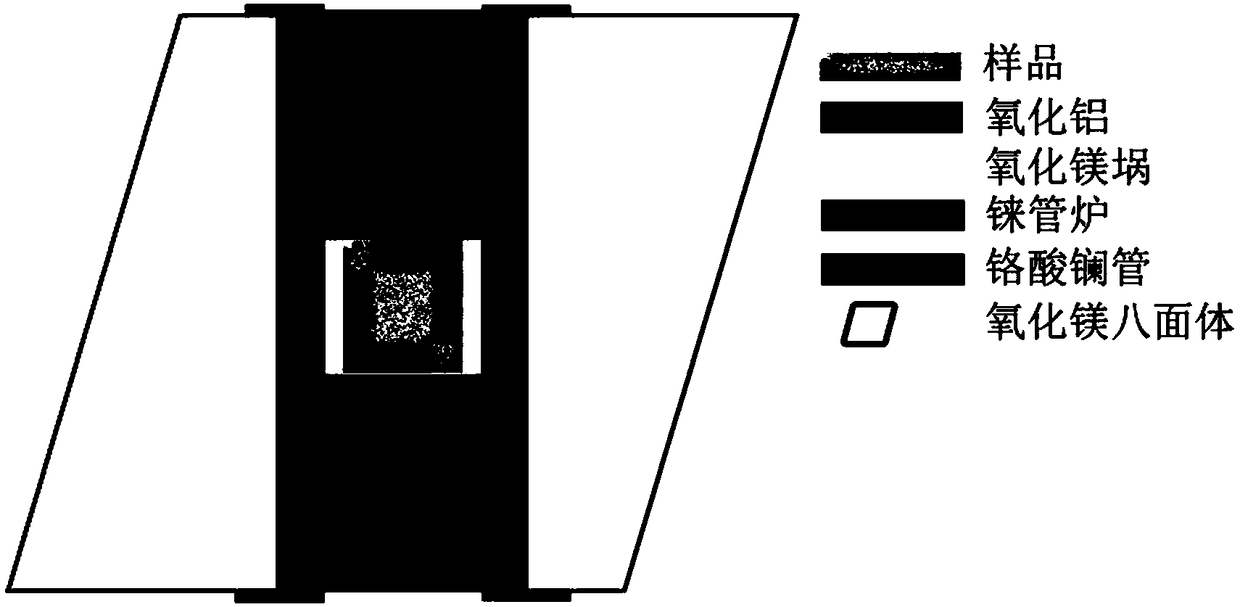

[0028] Take 0.01mol of glucose and melt it into 100ml of deionized water to make a 0.1mol / L glucose solution, take 16ml of the above solution and put it into a 20ml reaction kettle, tighten and seal the reaction kettle, place it in an oven at room temperature, and the oven heating rate is 200°C / h, 200 ℃ constant temperature for 24 hours, then take out the reaction kettle from the oven, and naturally cool to room temperature. The reaction kettle was opened, the solution in the reaction kettle was removed, the solid product was washed with water and ethanol, centrifuged three times, and then placed in a 60° C. oven for drying for 10 hours to obtain carbon microspheres. X-ray diffraction tests show that the material contains only carbon, such as figure 1 shown; scanning electron microscopy tests showed the material to be uniform carbon microspheres, approximately 10-15 microns in diameter, as in figure 2 shown.

[0029] Put 4g of sodium chloride into a 20ml silicon carbide bal...

Embodiment 2

[0032] Put 3g of sodium chloride into a 20ml silicon carbide ball mill, add silicon carbide grinding balls with a diameter of 5mm, the mass ratio of silicon carbide grinding balls to sodium chloride is 20:1, set the rotation speed to 800 rpm, and stop after 15 minutes of ball milling. 15 minutes, ball milling for 4 hours, to obtain sodium chloride powder

[0033] 0.05 g of carbon microspheres synthesized in Example 1 and 1 g of sodium chloride powder were shaken and mixed, so that the carbon microspheres were evenly distributed in the sodium chloride powder. A certain amount of the above mixture was loaded into a prefabricated mold, and the operation method of Example 1 was repeated to form an assembled block. The assembled block was placed in an oven and kept at 120° C. for 4 hours. Take out the assembly block from the drying box and put it into a high temperature and high pressure device. First, raise the pressure to 20GPa, keep it under this pressure, and raise the temperat...

Embodiment 3

[0035] Take 0.02mol glucose into 100ml deionized water to make 0.2mol / L glucose solution, repeat the operation method of Example 1 to obtain carbon microspheres. X-ray diffraction testing showed that the material contained only carbon; scanning electron microscopy testing showed carbon microspheres ranging in size from 1-5 microns.

[0036]0.05 g of carbon microspheres and 1 g of the sodium chloride powder ball-milled according to Example 2 were shaken and mixed, so that the carbon microspheres were evenly distributed in the sodium chloride powder. Get a certain amount of the above-mentioned mixture and put it into a prefabricated mold. Take a certain amount of the above-mentioned mixture and put it into a prefabricated mold. Repeat the operation method of Example 1 to form an assembly block. Hour. Take out the assembly block from the drying box and put it into a high temperature and high pressure device. First, raise the pressure to 20GPa, keep it under this pressure, and ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com