Flexible display panel and preparation method thereof

A flexible display and flexible substrate technology, which is used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., and can solve problems such as large differences in bending ability, increased maximum strain, and difficulty in ensuring film shear force. , to avoid film separation, increase adhesion, improve bendability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the embodiments shown in the drawings. However, these embodiments do not limit the present invention, and the structural, method, or functional changes made by those skilled in the art based on these embodiments are all included in the protection scope of the present invention.

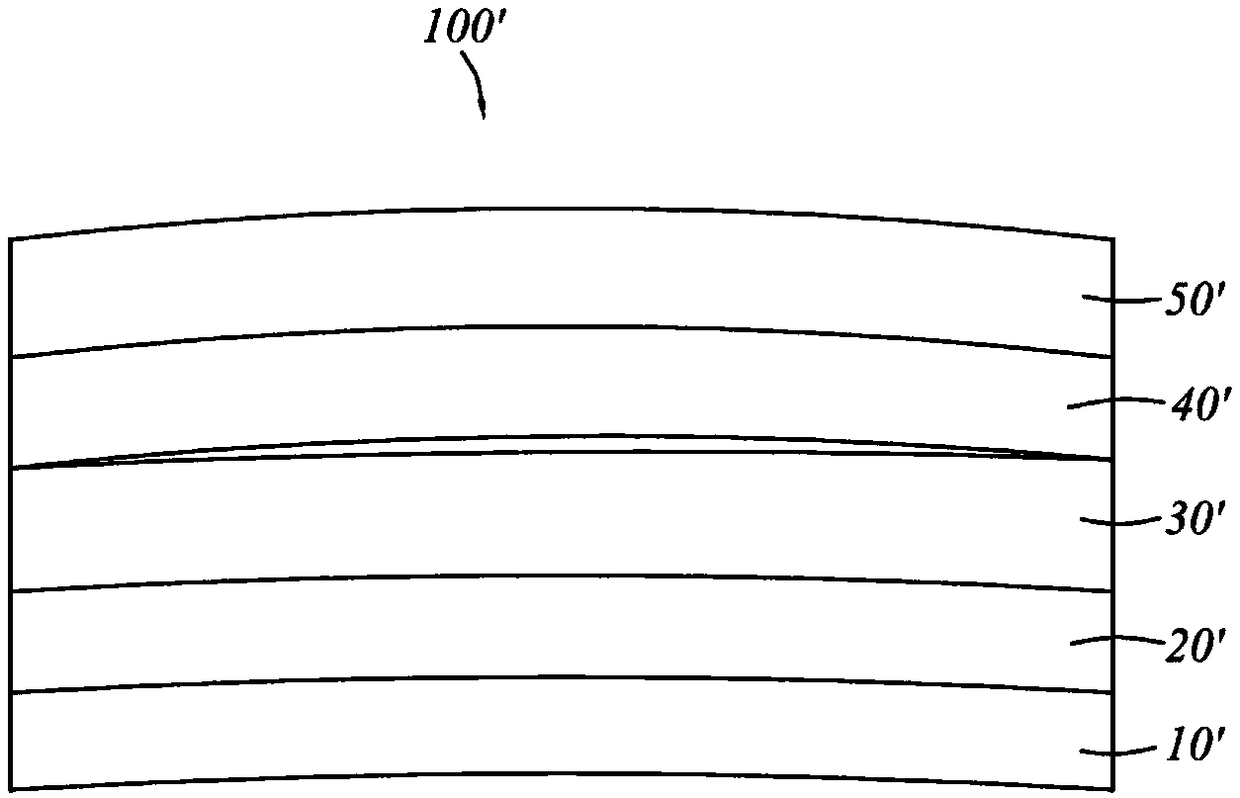

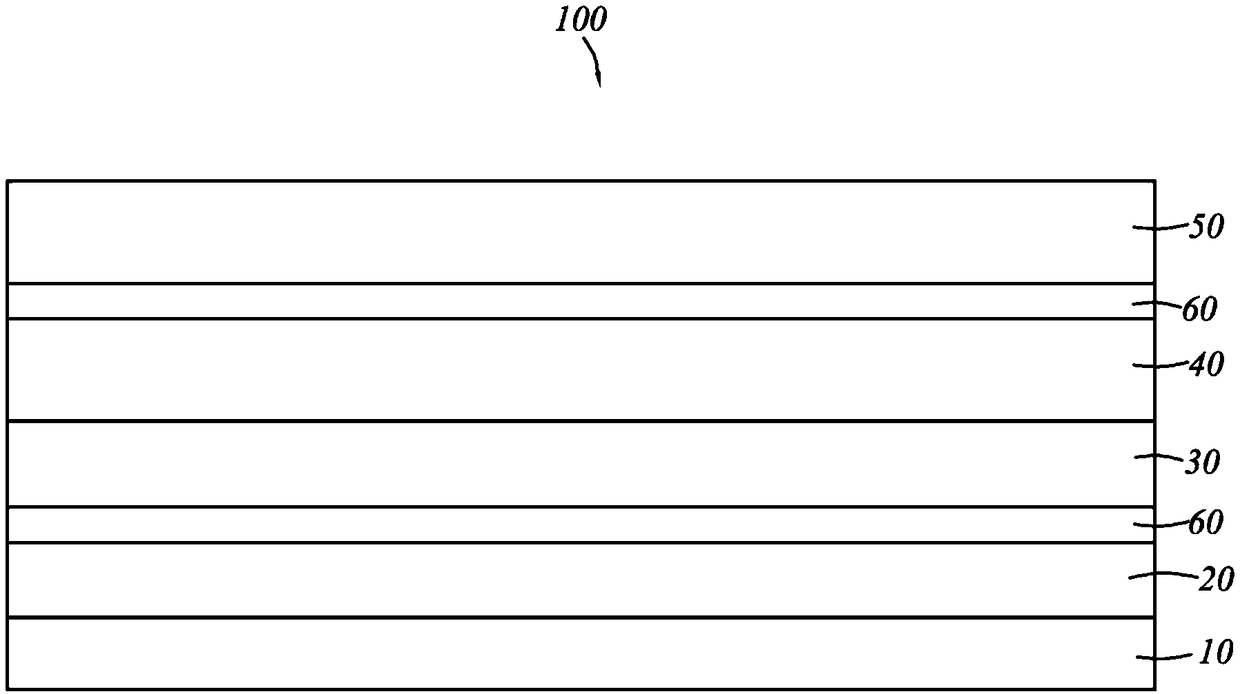

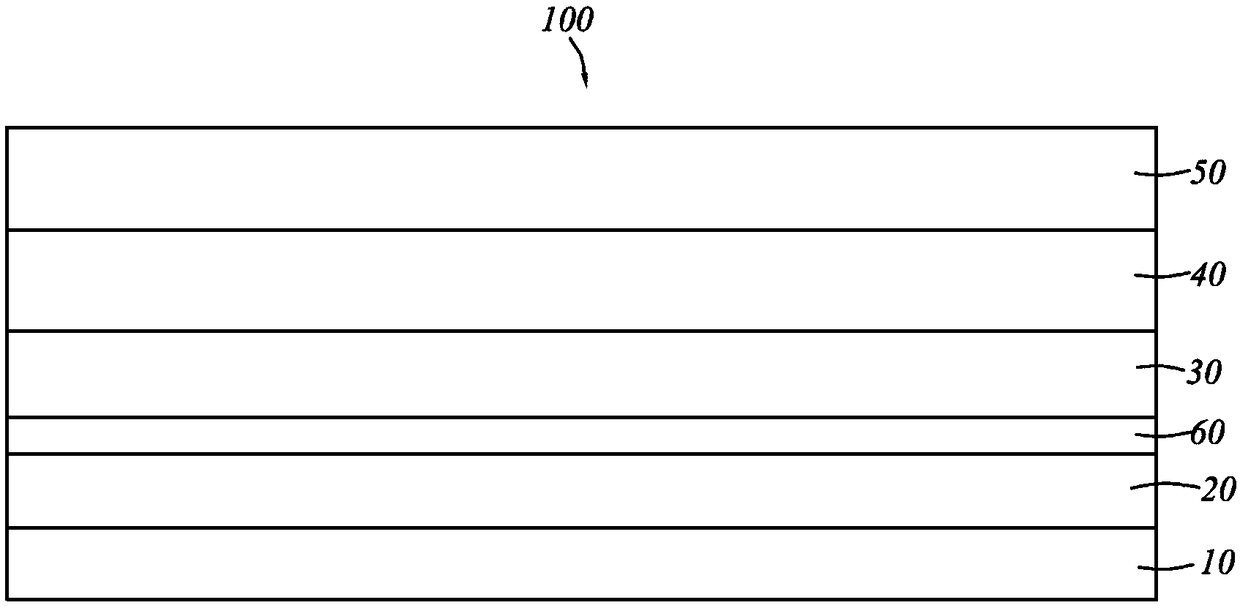

[0035] Please refer to Figure 2 to Figure 4 As shown, the flexible display panel 100 of the present invention includes a flexible substrate 10, a light emitting device layer 20 disposed on the flexible substrate 10, a touch layer 30 located on the upper side of the light emitting device layer 20, and a touch layer 30 located on the touch layer 30. An additional layer 60 is attached to the upper side of the polarizing layer 40 and the cover 50, the lower side of the touch layer 30 and / or the upper side of the polarizing layer 40, and the Poisson's ratio of the additional layer 60 is negative.

[0036] In the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com