Method for preventing and controlling rock burst of stope roadway for unequal-width entry protection coal pillar

A rock burst and roadway technology, applied in ground mining, earthwork drilling, underground mining, etc., can solve problems such as strong impact, rock burst, large static and dynamic stress field of the working face, etc., and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

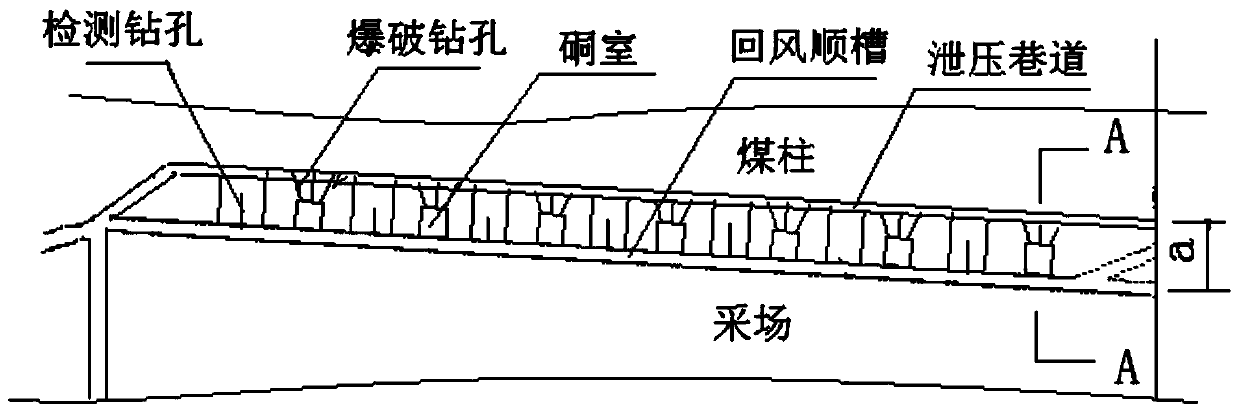

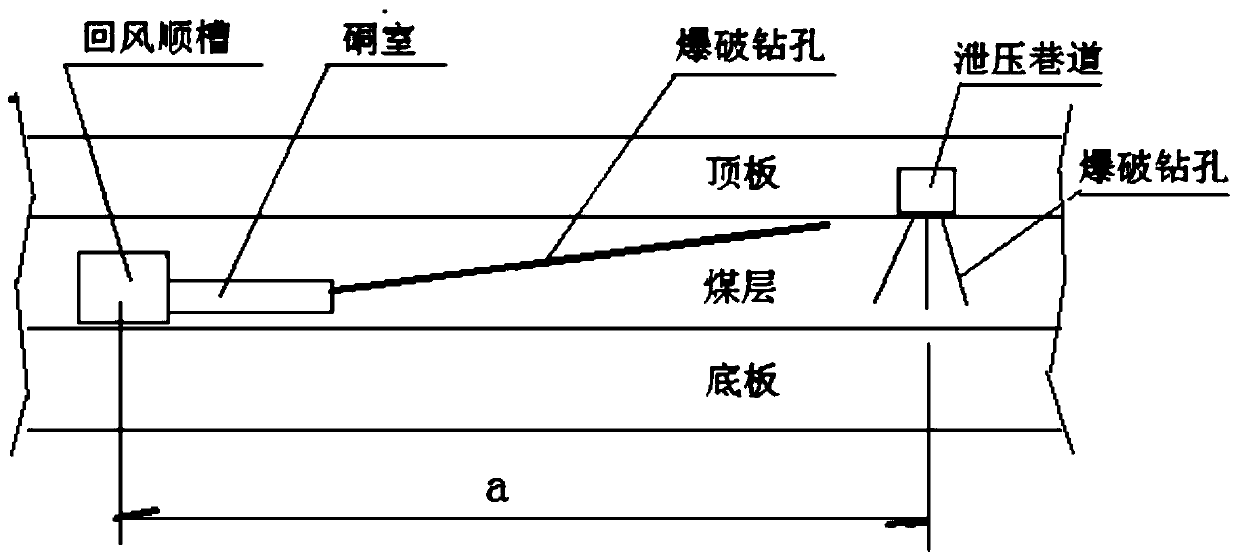

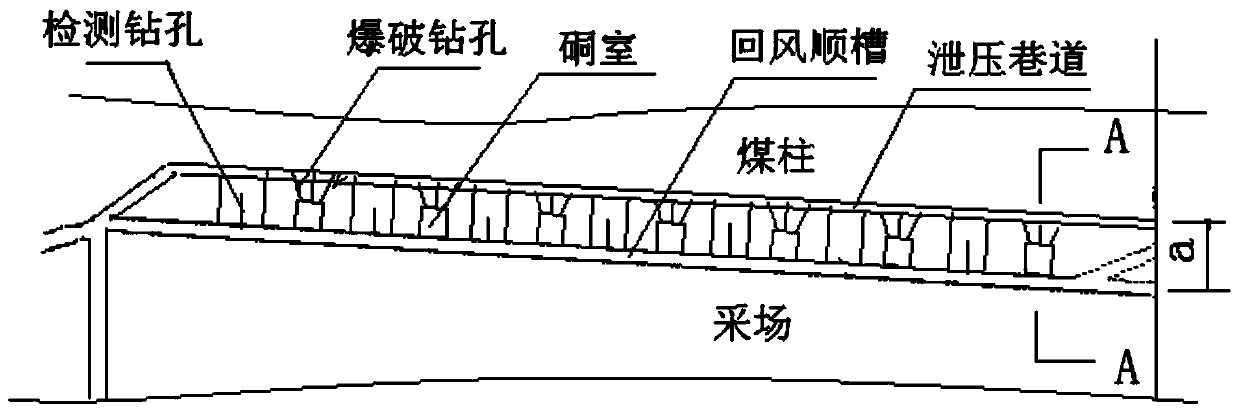

[0016] A mine exploits coal pillar stopes with unequal width protection roadways. Before mining, the stope working face is arranged, and the stope roadway is excavated. The stope roadway includes tunneling return air chute and transportation chute. Below, the technical solution of the present invention will be further described in conjunction with the accompanying drawings by taking the excavation return wind trough as an example.

[0017] Such as figure 1 , 2 As shown, the prevention and control methods for roadway rockburst in coal pillar stope roadway with unequal width are as follows:

[0018] 1. Excavating roof breaking and pressure relief roadway

[0019] Before excavation along the wind return channel in the stope, the pressure relief roadway is firstly arranged on the roof of the coal pillar with unequal width. The pressure relief roadway is arranged in parallel with the wind return channel (stope roadway), and the horizontal distance a=12-15m Then, drill blast hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com