Patents

Literature

77results about How to "Stress stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exhaust-gas purification catalyst to be used close to the engine and process for its production

InactiveUS6875725B2High activityOptimize dataNitrogen compoundsInternal combustion piston enginesTemperature stressCombustion

A starter catalyst for the purification of the exhaust gases from internal combustion engines, which include palladium on aluminum oxide and of barium oxide, as well as a process for its production. The barium oxide and palladium are together deposited in a finely divided state on the supporting material aluminum oxide and the average particle size of the palladium crystallites is between 3 and 7 nm. The small crystallite size of palladium and the barium oxide likewise deposited in finely divided state on the supporting material impart to the catalyst a high activity and long-term stability to high temperature stresses.

Owner:UMICORE AG & CO KG +1

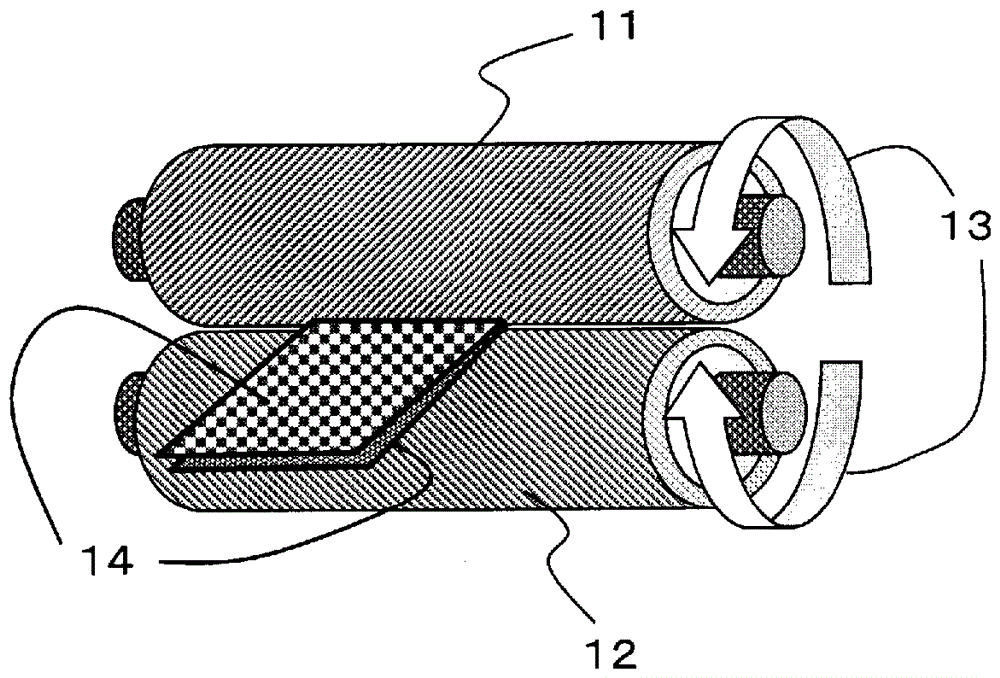

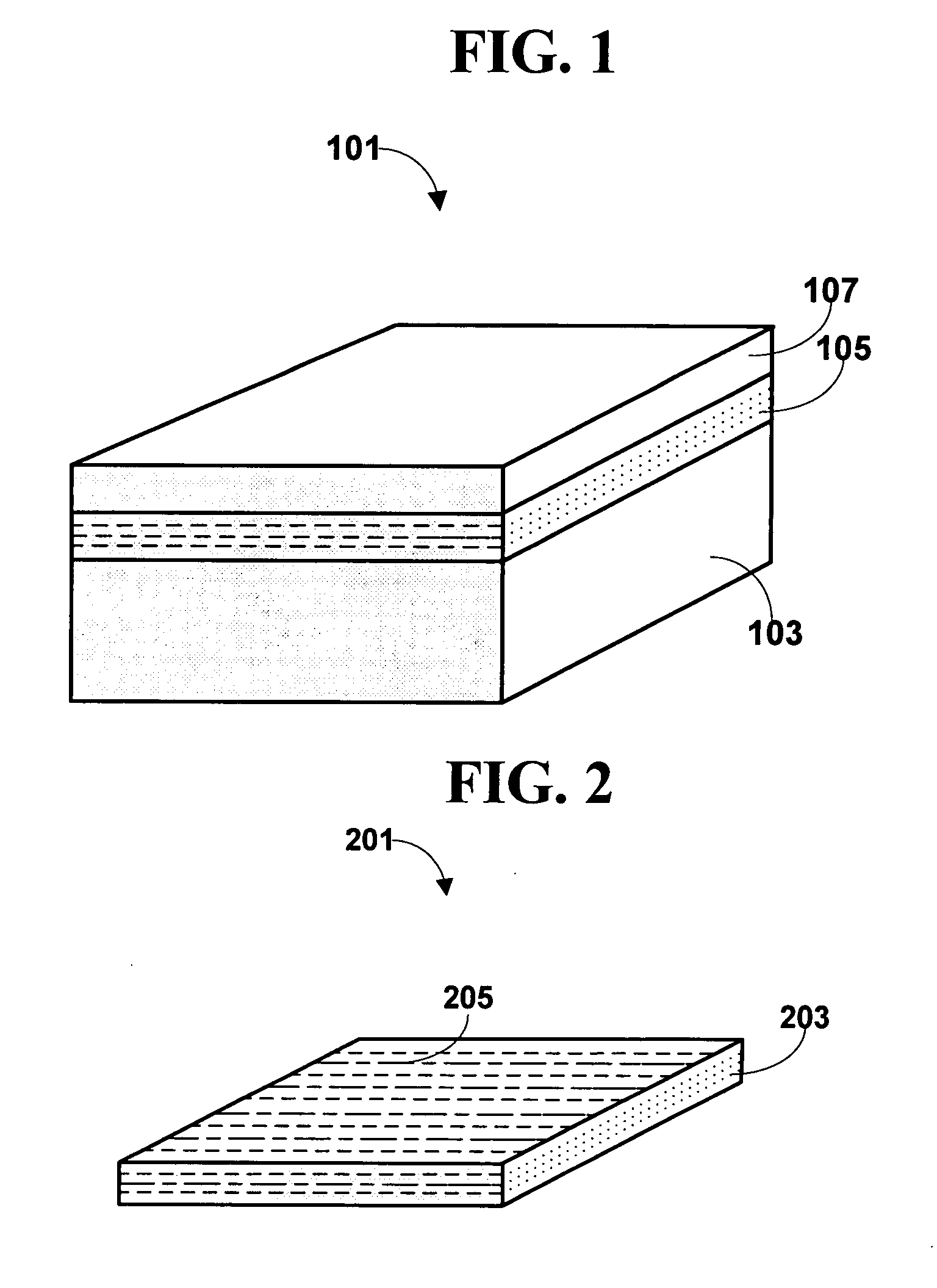

Light-polarizing article and process for making same

InactiveUS20090059367A1Easy alignmentStress stabilizationPolarising elementsPolarizerChemical composition

A process wherein a polymer, such as DNA, having a defined chemical composition and size is used to template the alignment of polarizing species, such as optically active organic dyes or metal nanoparticles having defined compositional characteristics and / or size and shape characteristics, on a surface to manufacture a thin film polarizer; a process where metal nanorods are aligned on a substrate surface or inside a substrate to make a polarizer; and a polarizer thus made. Multi-layered polarizing structure can be created by using the process of the present invention.

Owner:CORNING INC

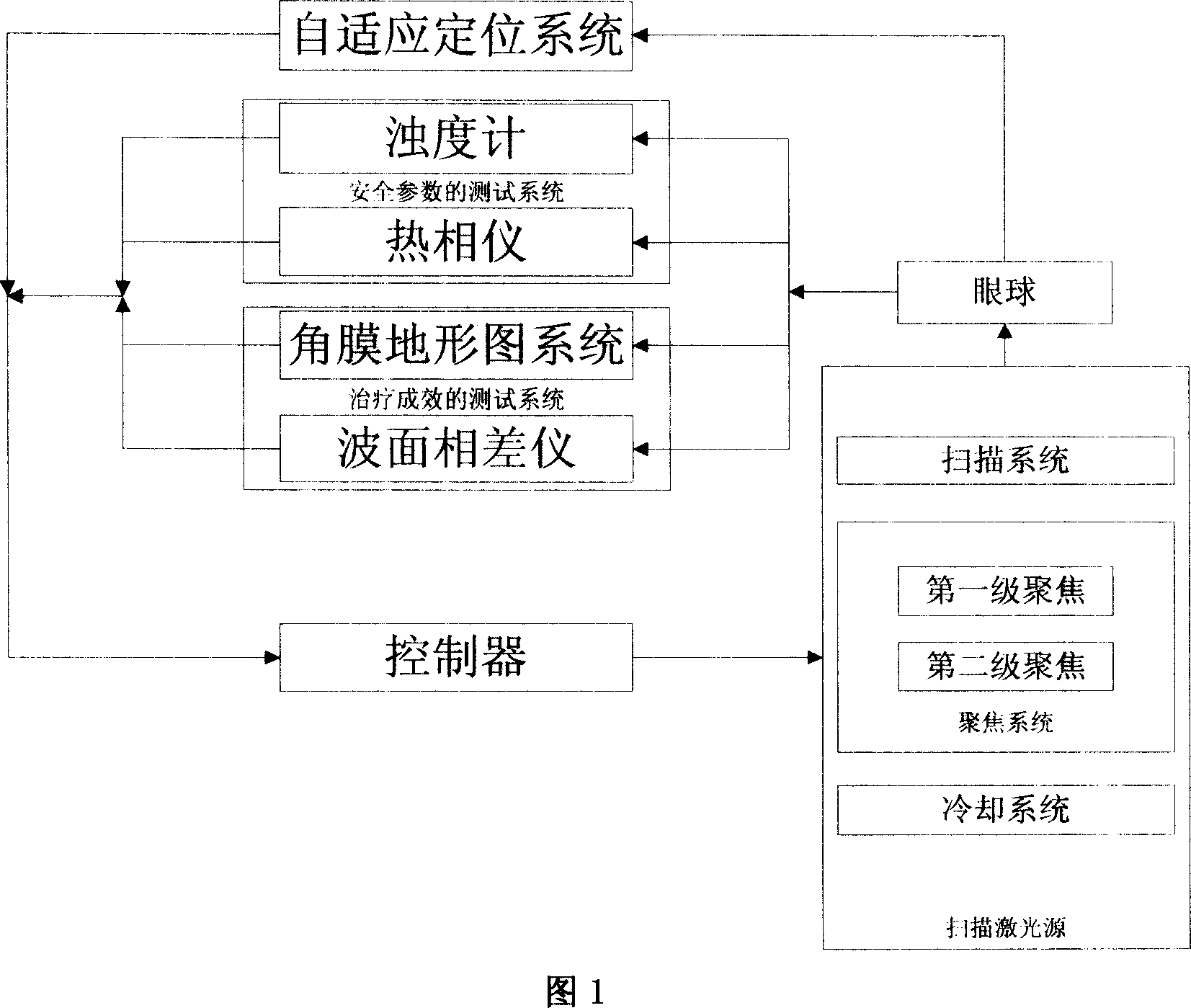

Intravital surgery system for scanning type laser operation of hot forming cornea

InactiveCN1957867AImprove stabilityImprove predictabilityLaser surgeryTherapeutic effectUnexpected therapeutic effect

A scanning laser operation system for the thermo-shaping operation of cornea on living body is composed of a scanning laser source, an adaptive locating system, a safte parameter testing system, a therapeutic effect testing system, and a controller.

Owner:SHANGHAI JIAO TONG UNIV

Exhaust-gas purification catalyst to be used close to the engine and process for its production

InactiveUS20020039549A1High activityOptimize dataNitrogen compoundsInternal combustion piston enginesTemperature stressCombustion

A starter catalyst for the purification of the exhaust gases from internal combustion engines, which include palladium on aluminum oxide and of barium oxide, as well as a process for its production. The barium oxide and palladium are together deposited in a finely divided state on the supporting material aluminum oxide and the average particle size of the palladium crystallites is between 3 and 7 nm. The small crystallite size of palladium and the barium oxide likewise deposited in finely divided state on the supporting material impart to the catalyst a high activity and long-term stability to high temperature stresses.

Owner:UMICORE AG & CO KG +1

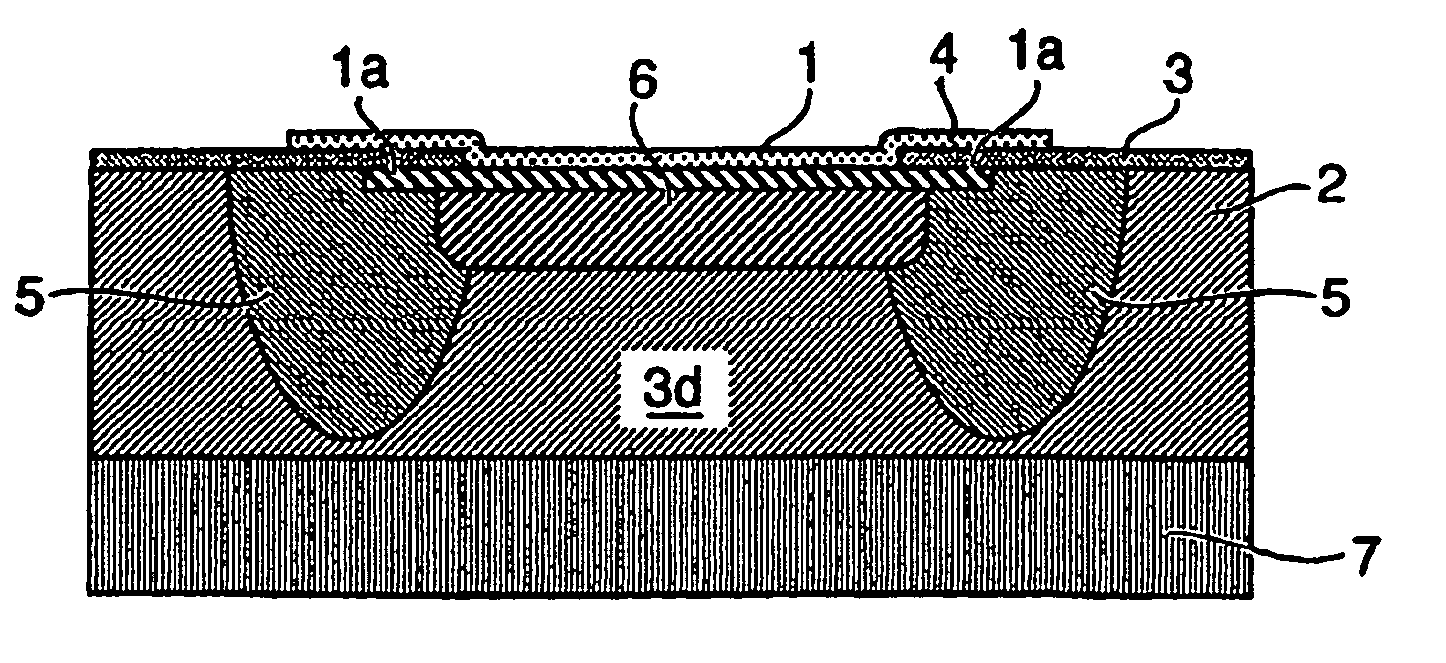

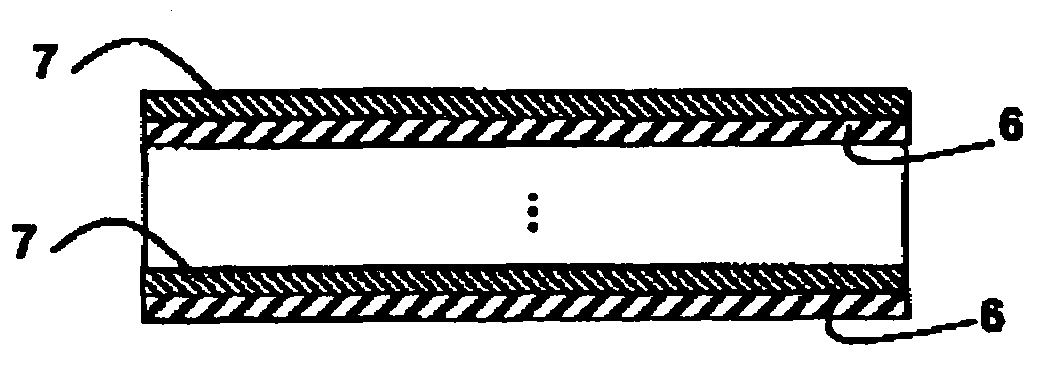

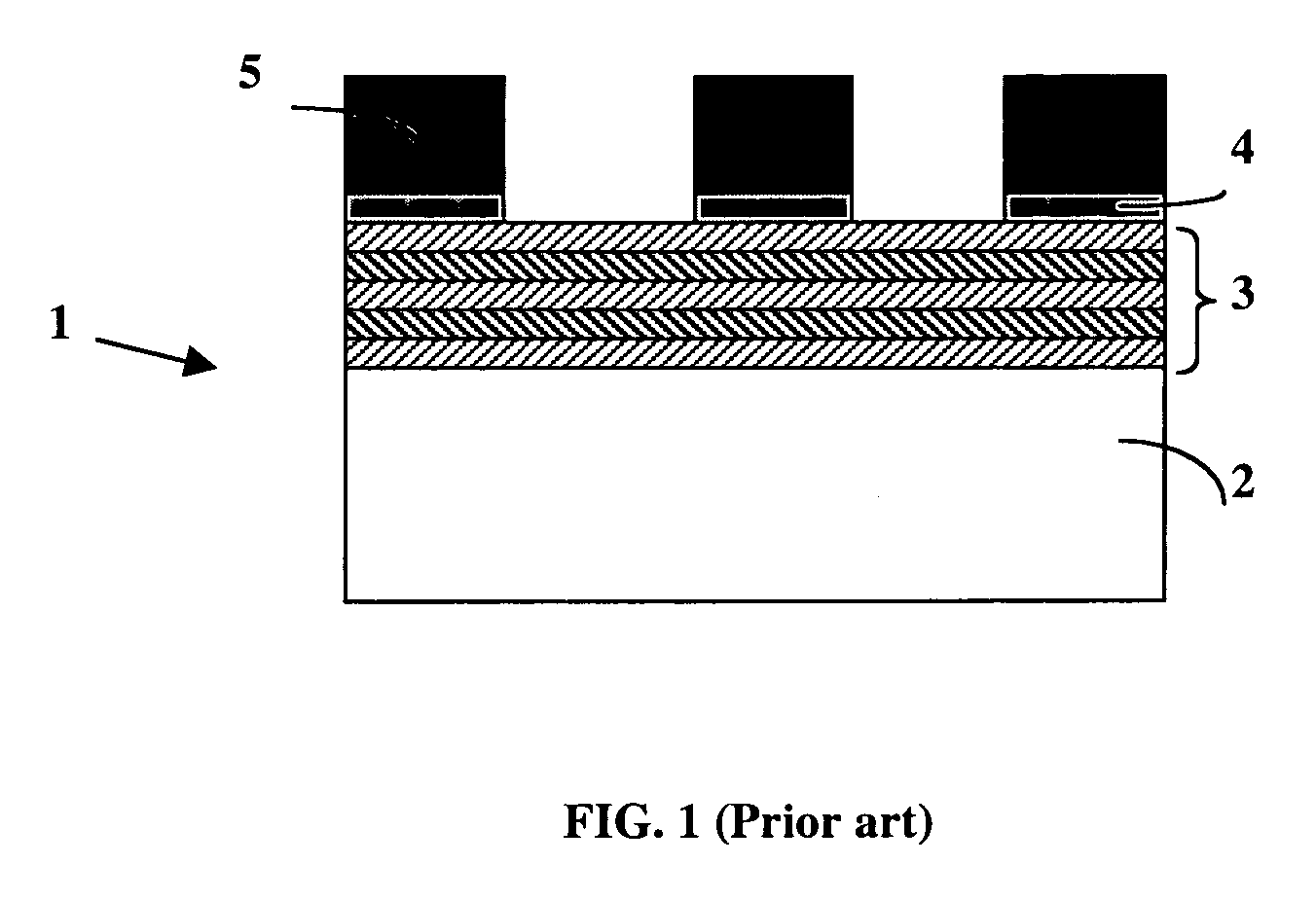

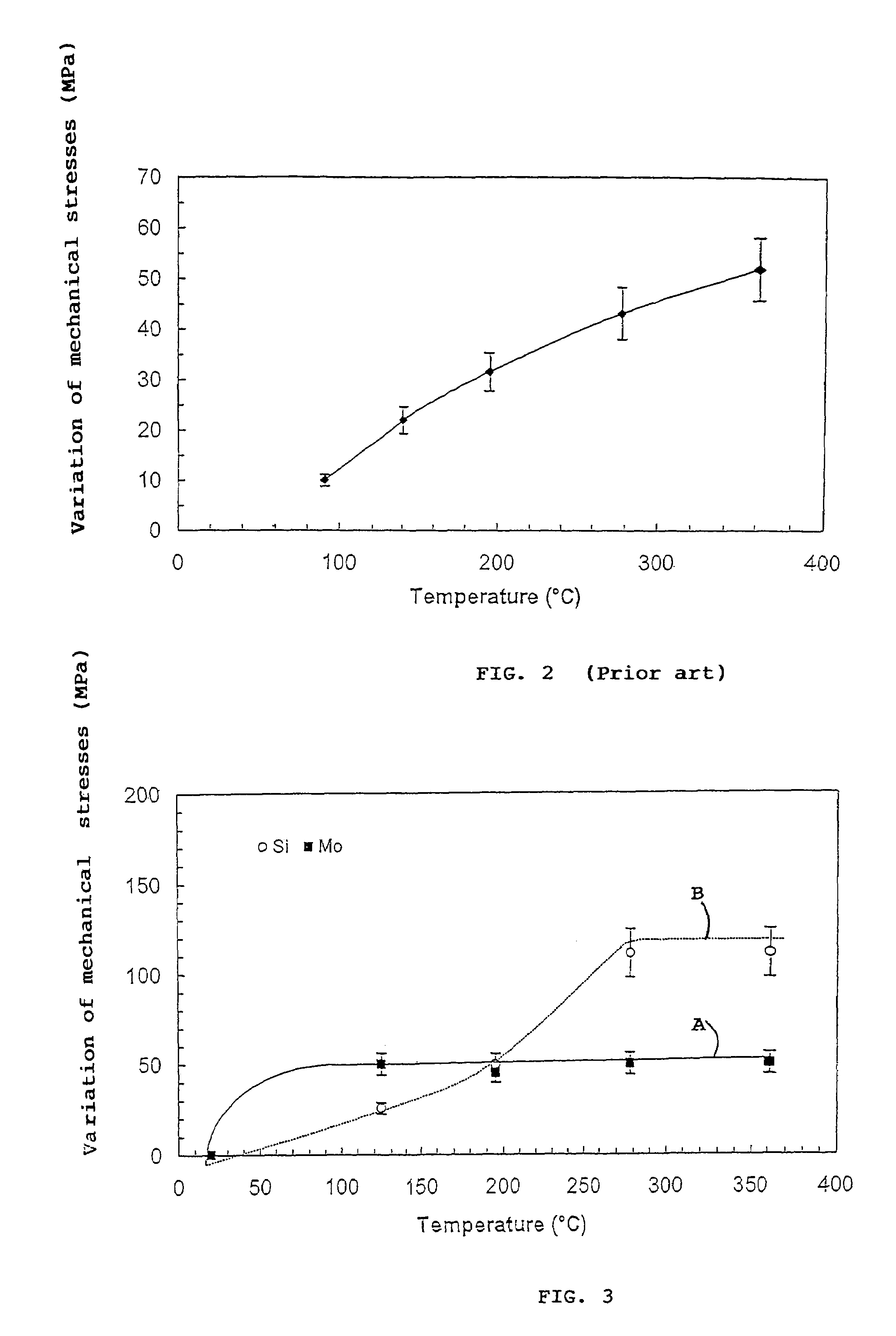

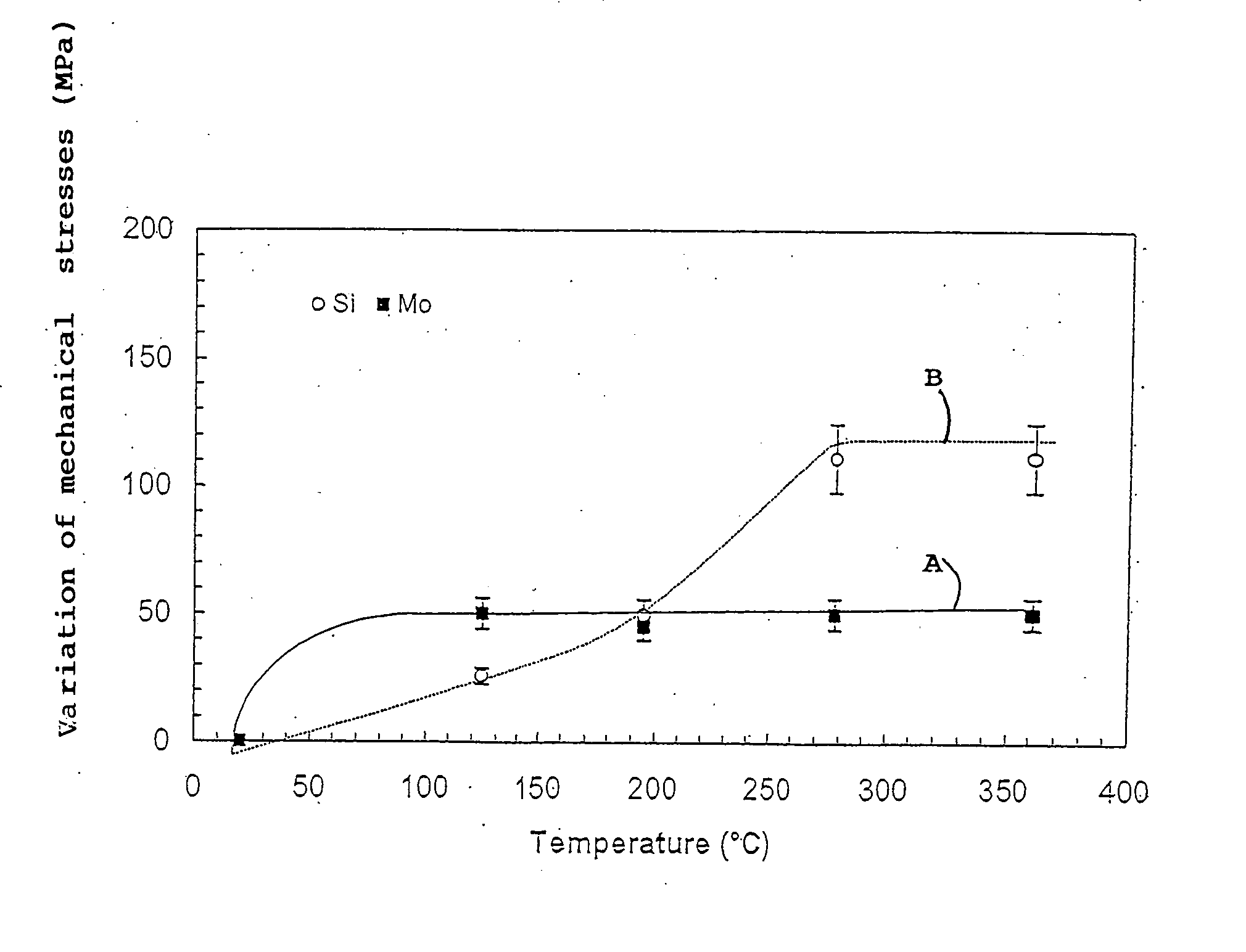

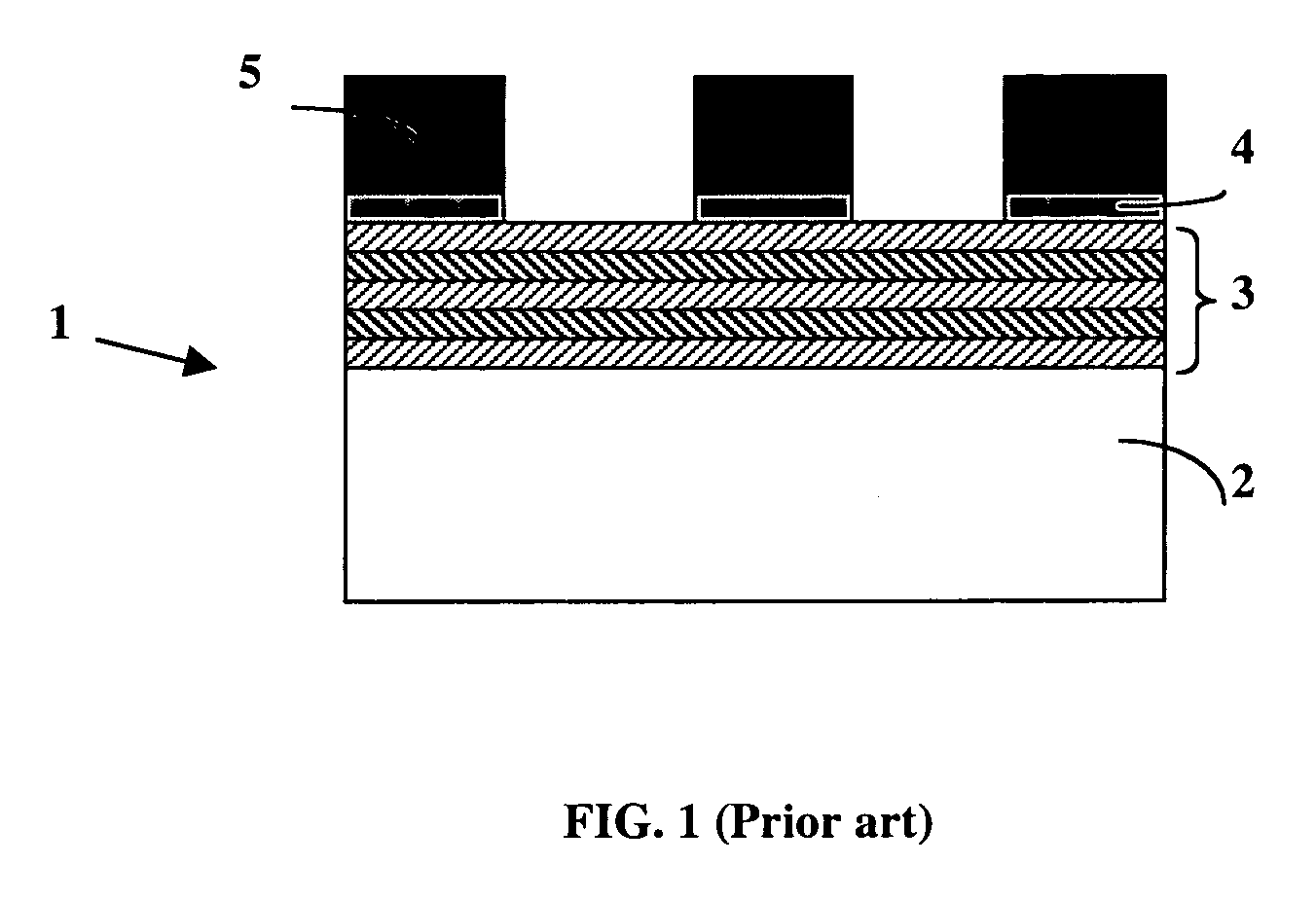

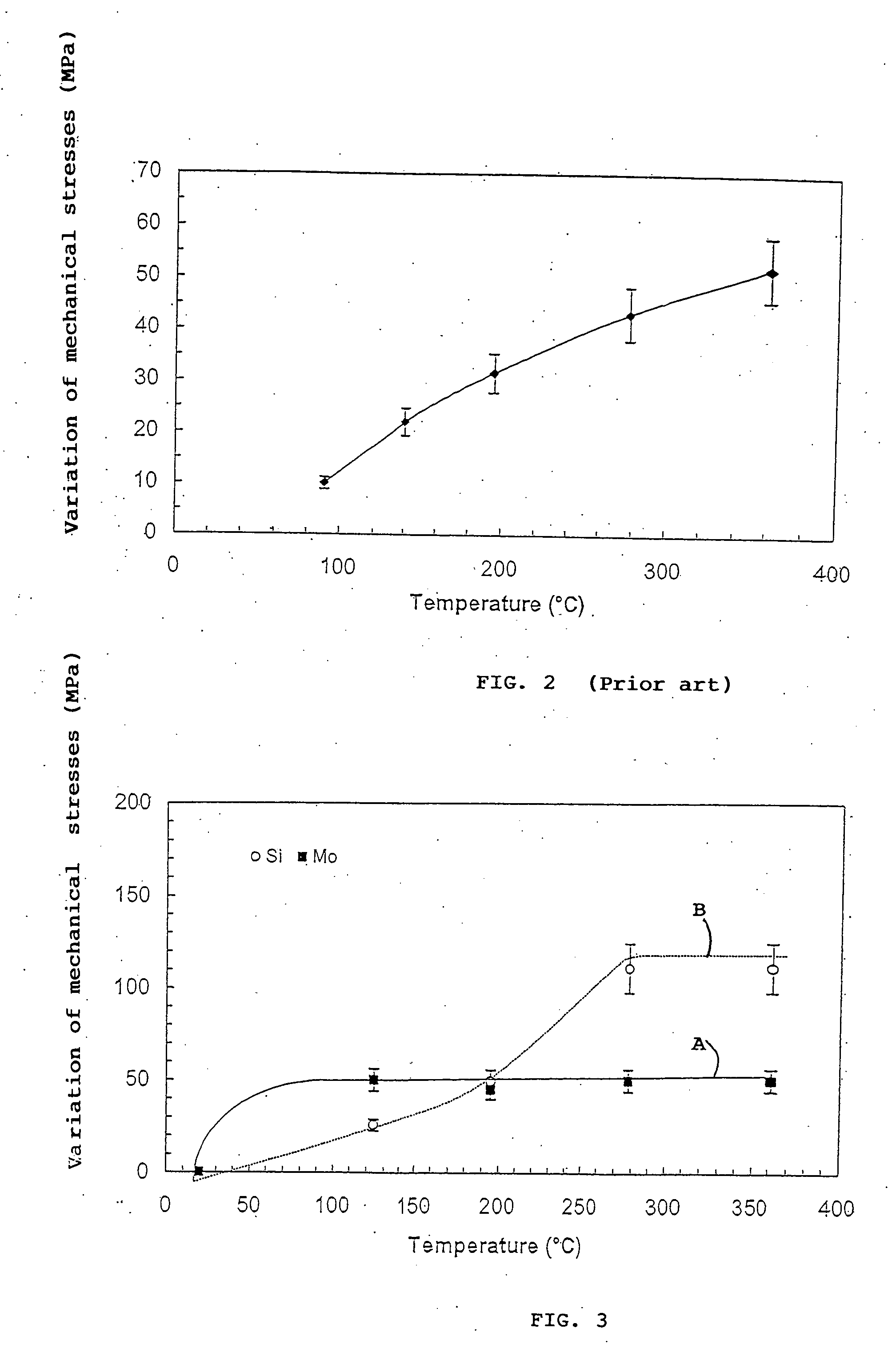

Optical device with enhanced mechanical stability operating in the extreme ultraviolet and lithography mask comprising such a device

InactiveUS7012753B2Stress stabilizationMirrorsNanoinformaticsLithographic artistMechanical stability

An optical device reflecting a range of wavelengths comprised between 10 nm and 20 nm comprises alternate superposed first and second layers. The first layers are made of metal or metallic compound and the second layers are formed by an amorphous silicon compound chosen from a-Si—Hx, a-Si—CHx, a-Si—Cx, a-Si—OHx, a-Si—Fx, a-Si—FHx, a-Si—Nx, a-Si—NHx, x being comprised between 0.01 and 0.3. The use of second layers of amorphous silicon compound enables the mechanical stresses of the optical device to be stabilized up to at least 200° C. The optical device is preferably used as reflector for a lithography mask in the extreme ultraviolet (EUV).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

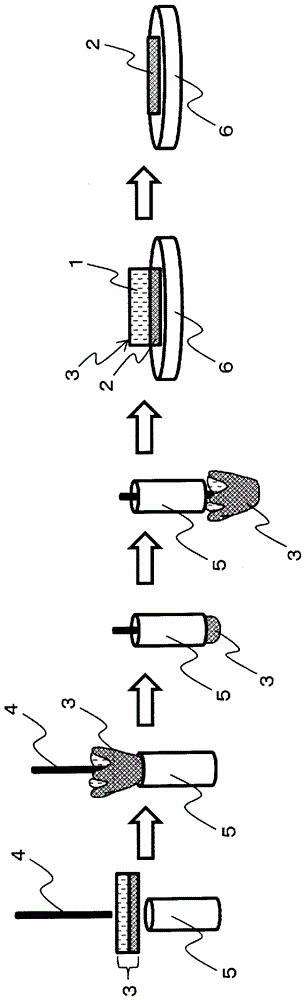

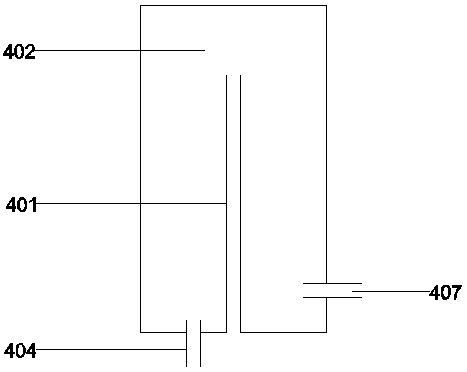

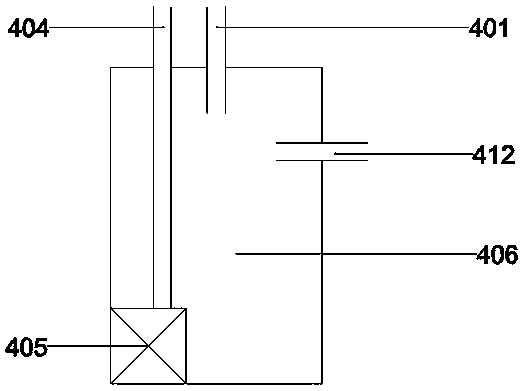

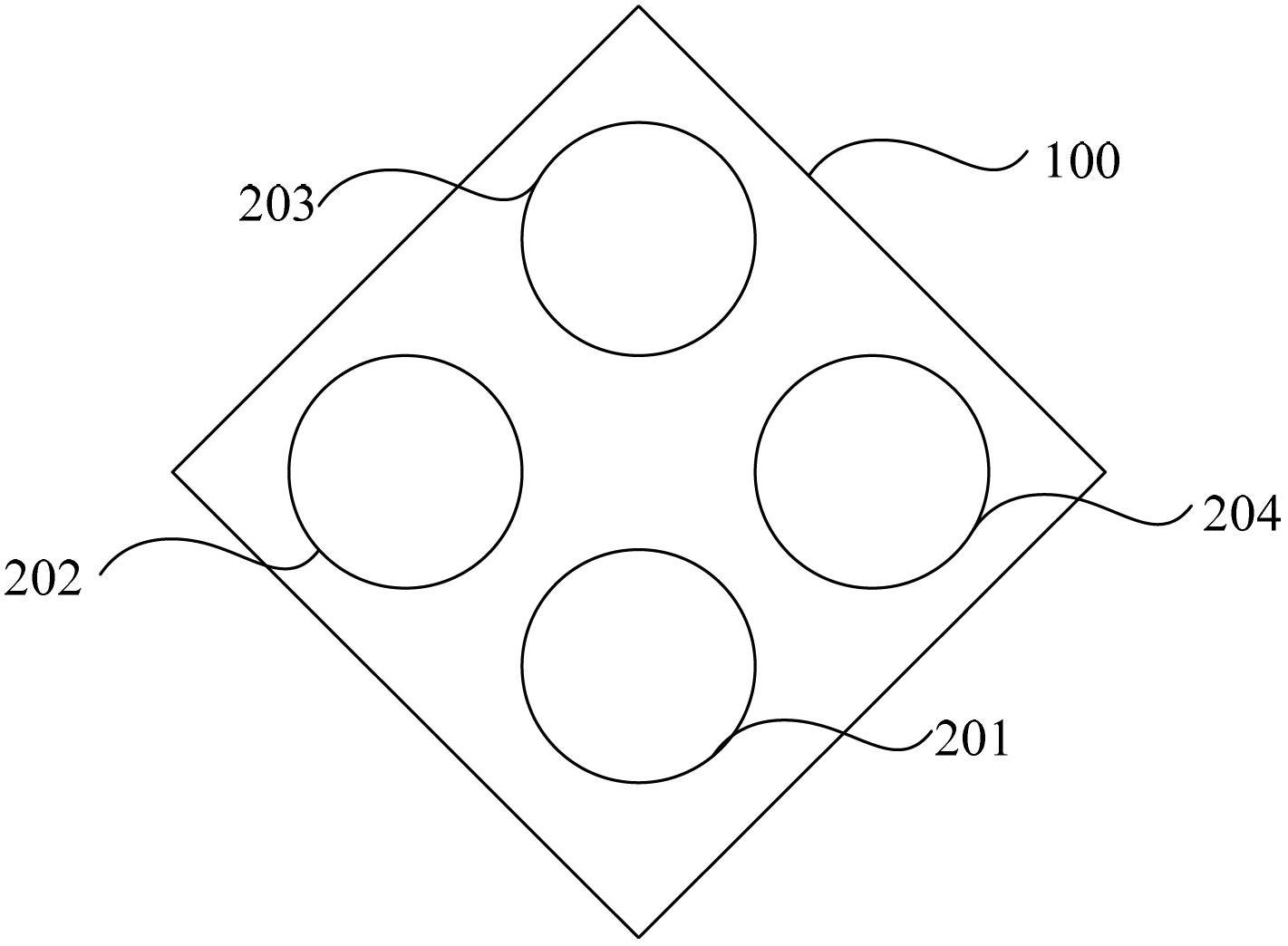

N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-n'-(5-methyl-3-isoxazolyl)urea salt in crystalline form

The present invention provides a crystal of a pharmaceutically acceptable salt of N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-N′-(5-methyl-3-isoxazolyl) urea. This crystal of salt is usable for the therapy of a disease selected from the group consisting of tumors, diabetic retinopathy, chronic rheumatism, psoriasis, atherosclerosis, Kaposi's sarcoma, and exudation type age-related maculopathy, and has characteristics suitable for applications of oral pharmaceutical preparations.

Owner:KYOWA HAKKO KIRIN CO LTD

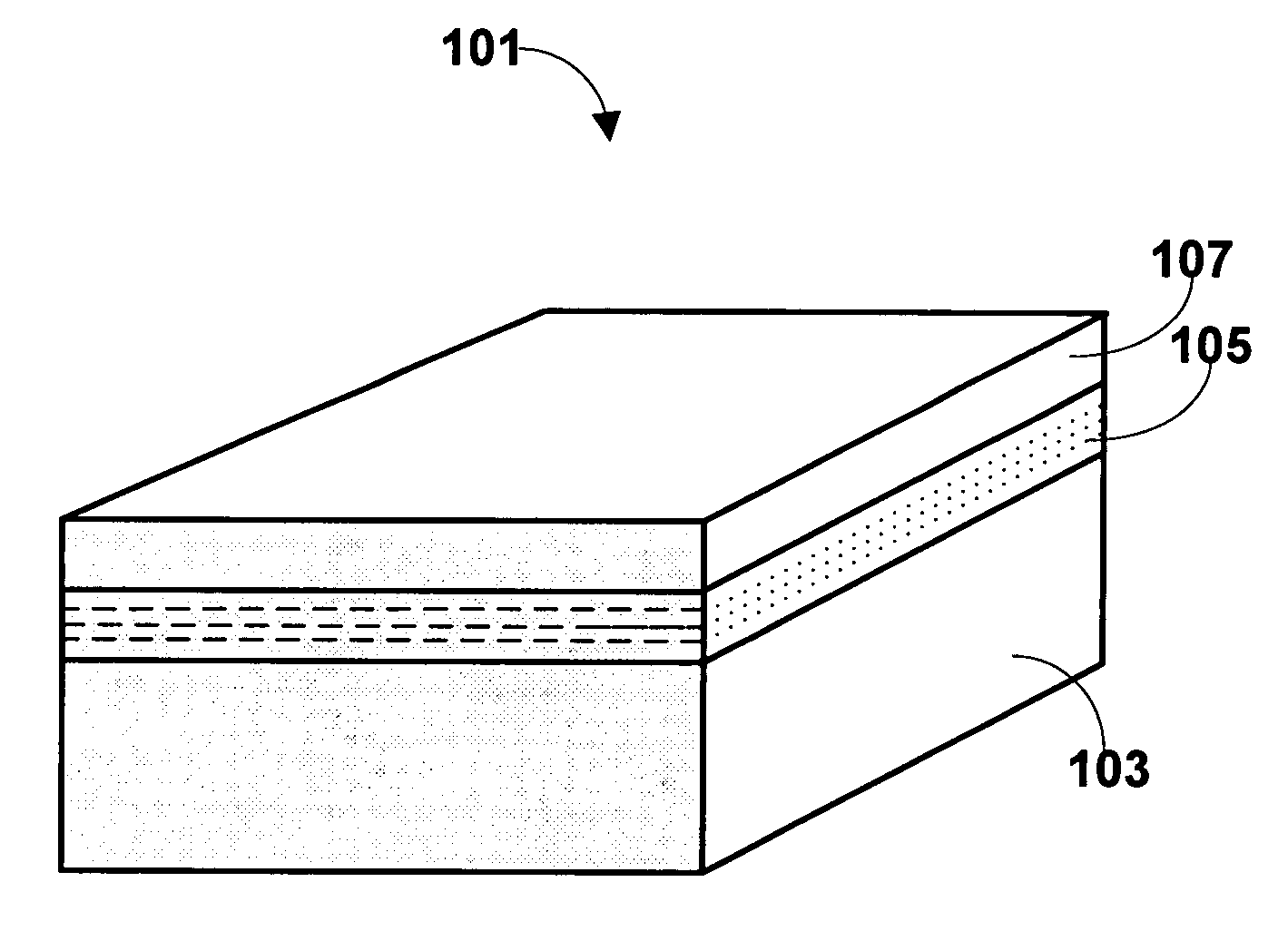

Optical device with enhanced mechanical stability operating in the extreme ultraviolet and lithography mask comprising such a device

InactiveUS20040233535A1Stress stabilizationMirrorsNanoinformaticsLithographic artistAmorphous silicon

An optical device reflecting a range of wavelengths comprised between 10 nm and 20 nm comprises alternate superposed first and second layers. The first layers are made of metal or metallic compound and the second layers are formed by an amorphous silicon compound chosen from a-Si-Hx, a-Si-CHx, a-Si-Cx, a-Si-OHx, a-Si-Fx, a-Si-FHx, a-Si-Nx, a-Si-NHx, x being comprised between 0.01 and 0.3. The use of second layers of amorphous silicon compound enables the mechanical stresses of the optical device to be stabilized up to at least 200° C. The optical device is preferably used as reflector for a lithography mask in the extreme ultraviolet (EUV).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-n'-(5-methyl-3-isoxazolyl)urea salt in crystalline form

ActiveUS20060052415A1Stable stress physical stressStable thermal stress stressBiocideSenses disorderDrugPsoriasis

The present invention provides a crystal of a pharmaceutically acceptable salt of N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-N′-(5-methyl-3-isoxazolyl) urea. This crystal of salt is usable for the therapy of a disease selected from the group consisting of tumors, diabetic retinopathy, chronic rheumatism, psoriasis, atherosclerosis, Kaposi's sarcoma, and exudation type age-related maculopathy, and has characteristics suitable for applications of oral pharmaceutical preparations.

Owner:KYOWA HAKKO KIRIN CO LTD

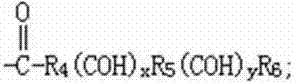

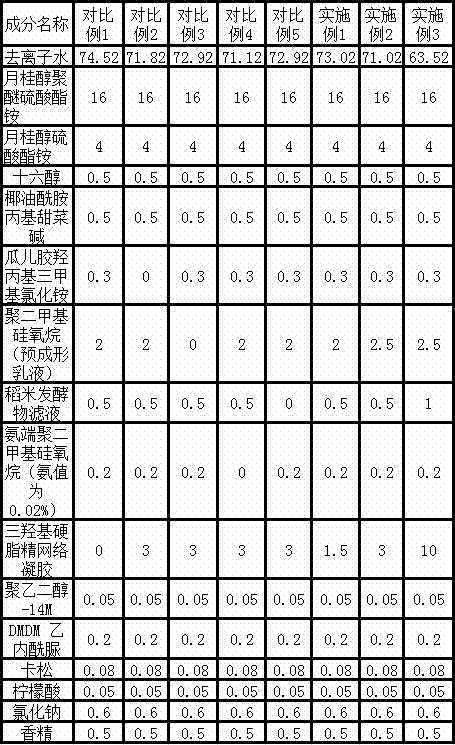

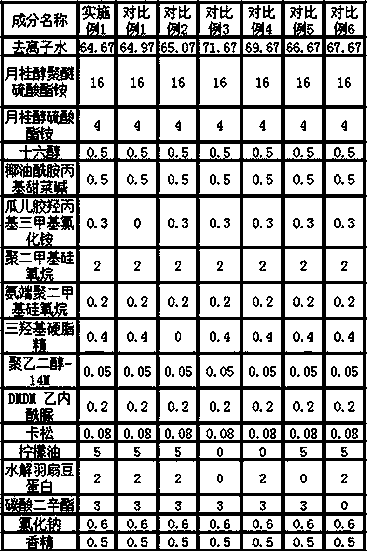

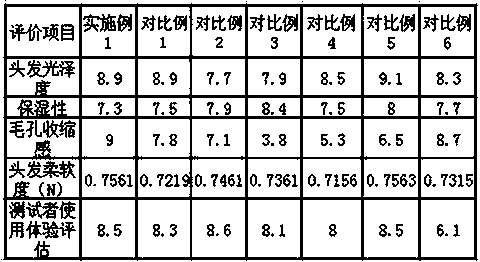

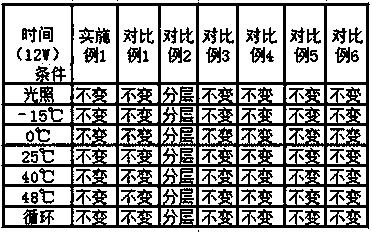

Hair composition containing rice leavening filtrate and preparation method thereof

ActiveCN107496296AStable storageNot perishableCosmetic preparationsHair cosmeticsPersonal careSilicone oil

The invention relates to the field of personal care and discloses a hair composition containing rice leavening filtrate. The invention further discloses a preparation method of the hair composition. By means of reasonable construction of a composition framework, synergistic interaction among raw materials and limit of key parameters of the raw materials, a use amount of silicone oil is reduced under the premises of achieving good stable performance and crystallization stability and cooperating with a cationic polymer to enhance a conditioning property, and excessive accumulation sedimentation is avoided. The composition has the advantages of moderate components, applicability to all kinds of hair quality, obvious effect, low cost and convenience in application.

Owner:OPAL COSMETICS HUIZHOU

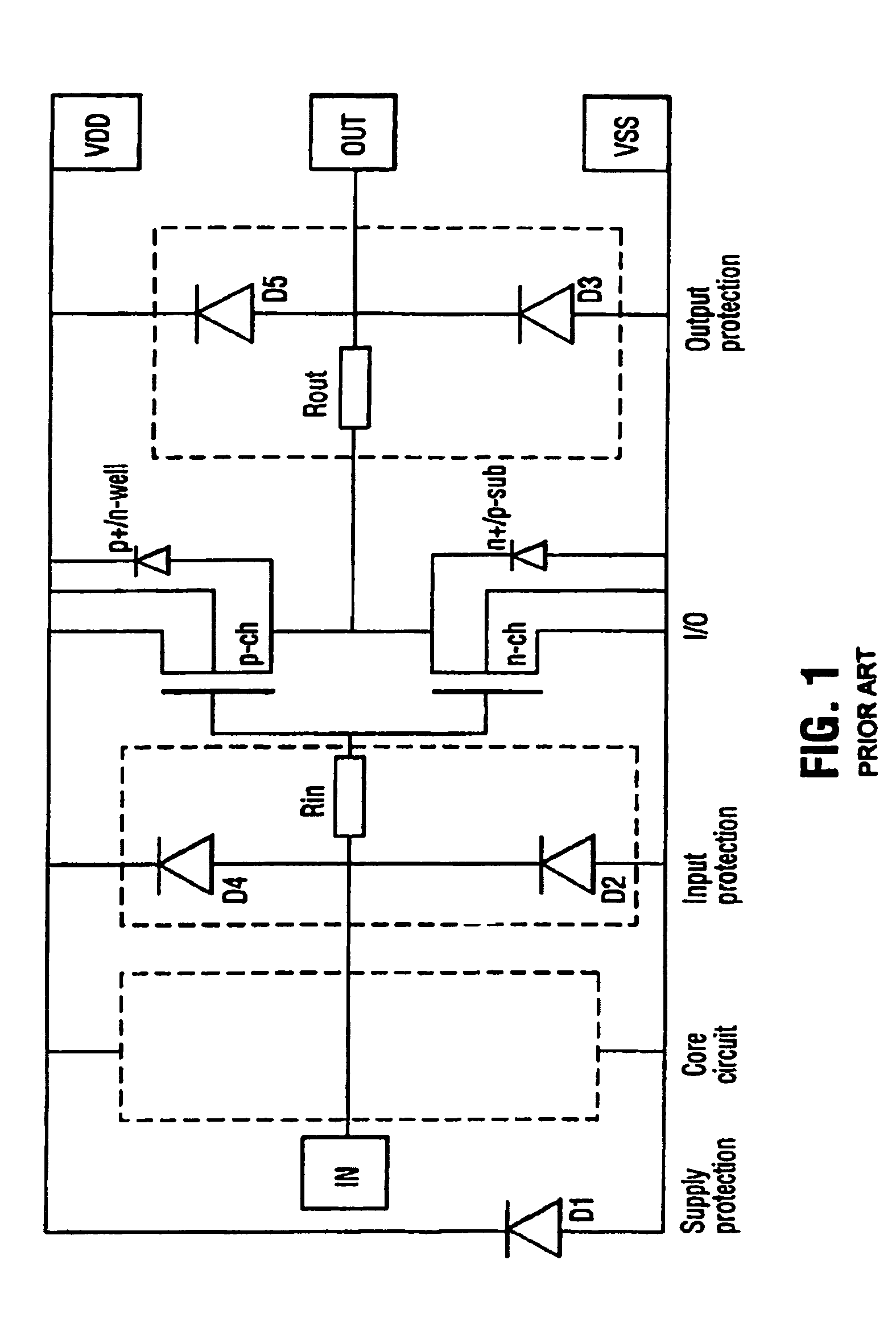

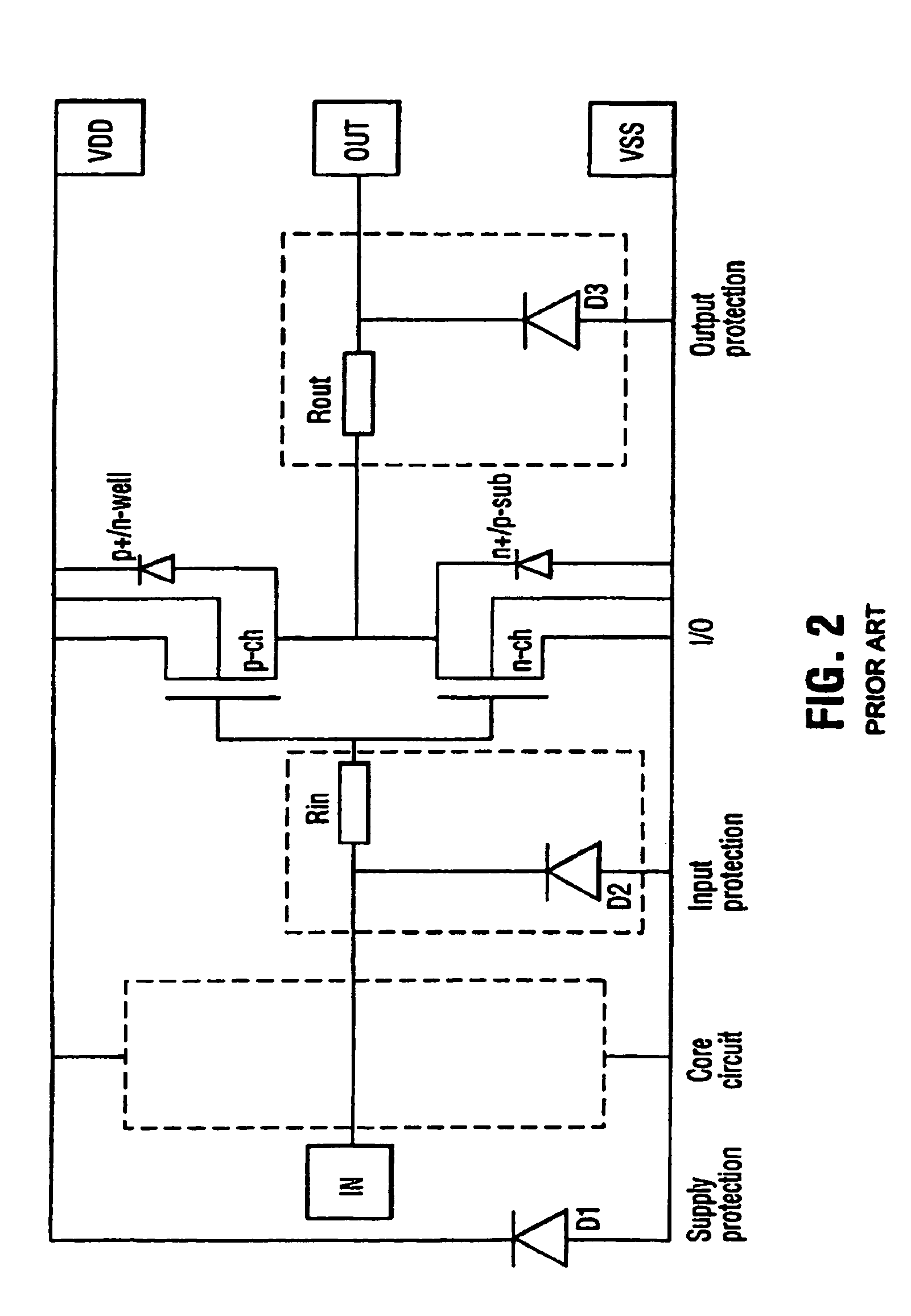

Compact high voltage ESD protection diode

InactiveUS6972462B2Reduced series resistanceLarge energyTransistorOrganic active ingredientsPower flowEngineering

A protection device provides to integrated circuits against high voltages. The diode includes a diode connected to provide a safe discharge path for the high voltage currents. The diode is configured so that in reverse bias breakdown occurs across an area portion of its active junction. The device can dissipate a large amount of ESD energy in a minimal area.

Owner:TELEDYNE DIGITAL IMAGING INC

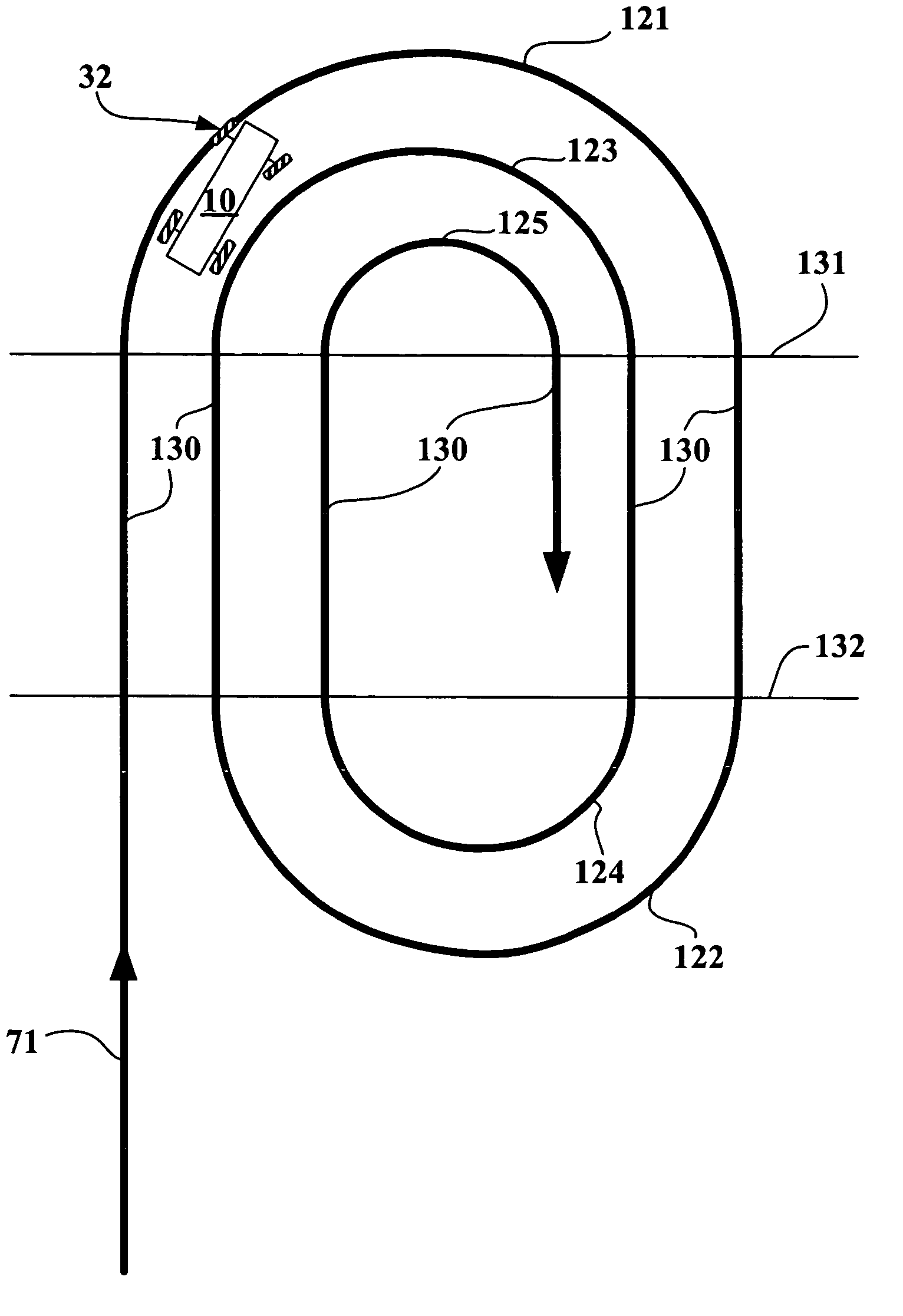

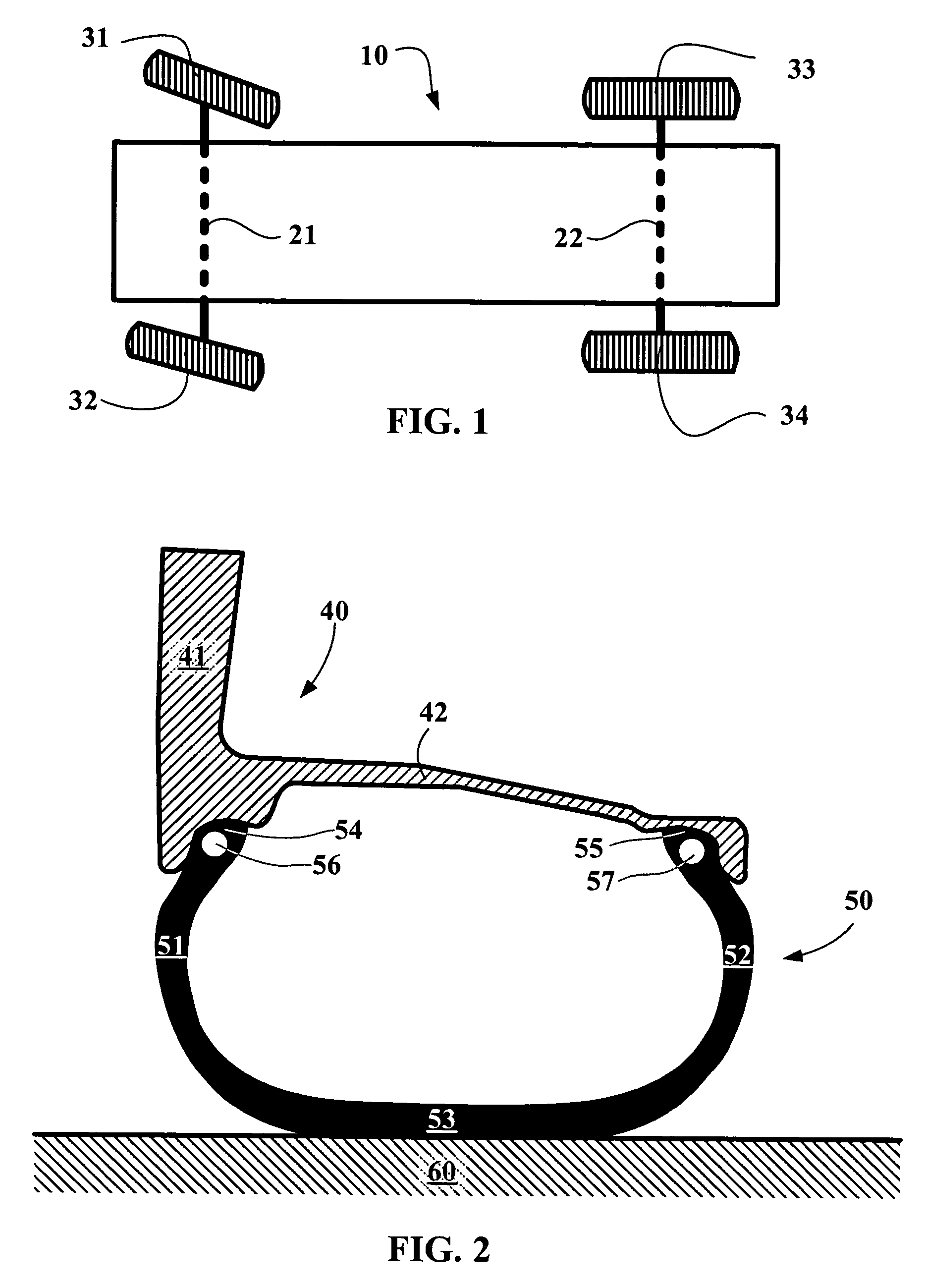

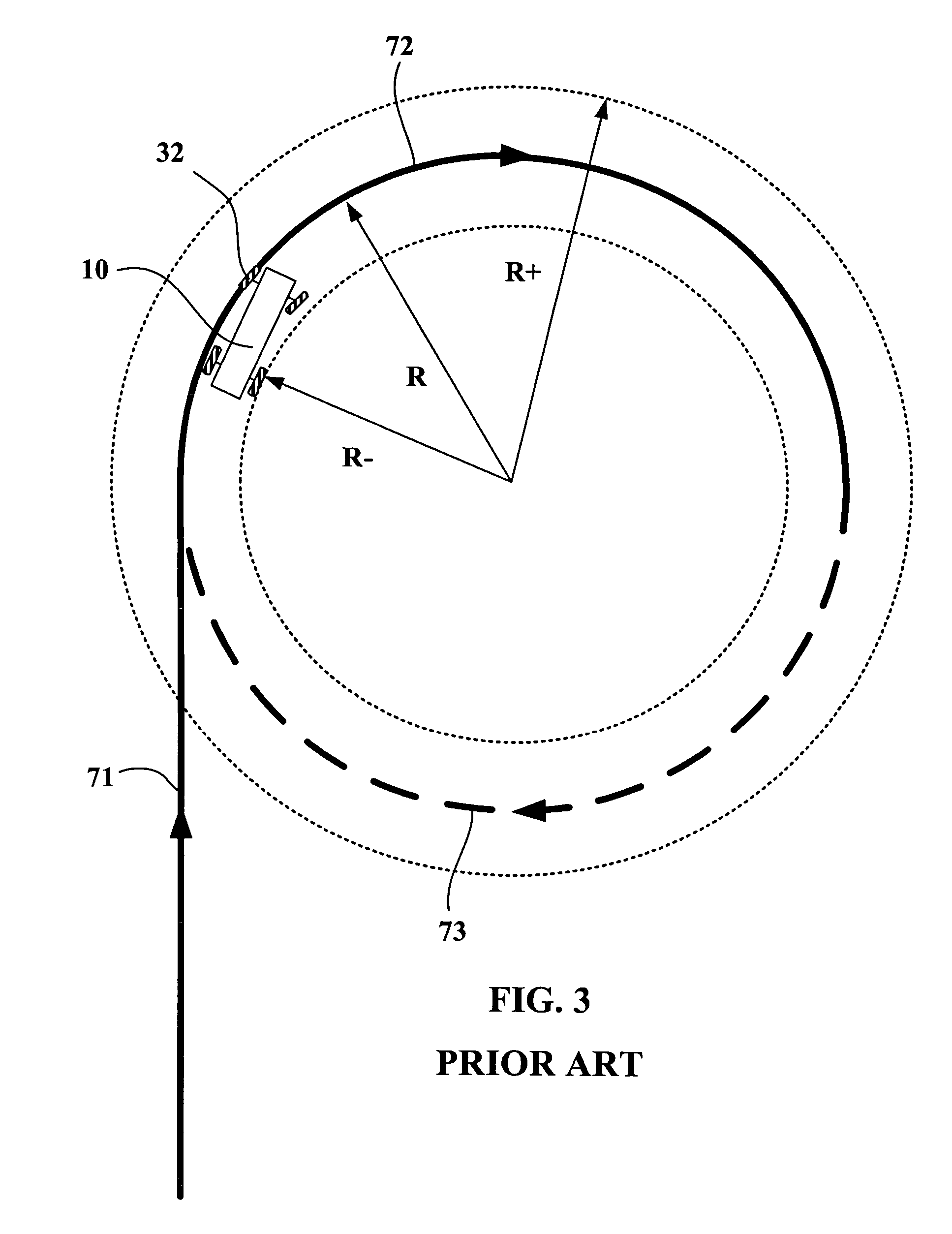

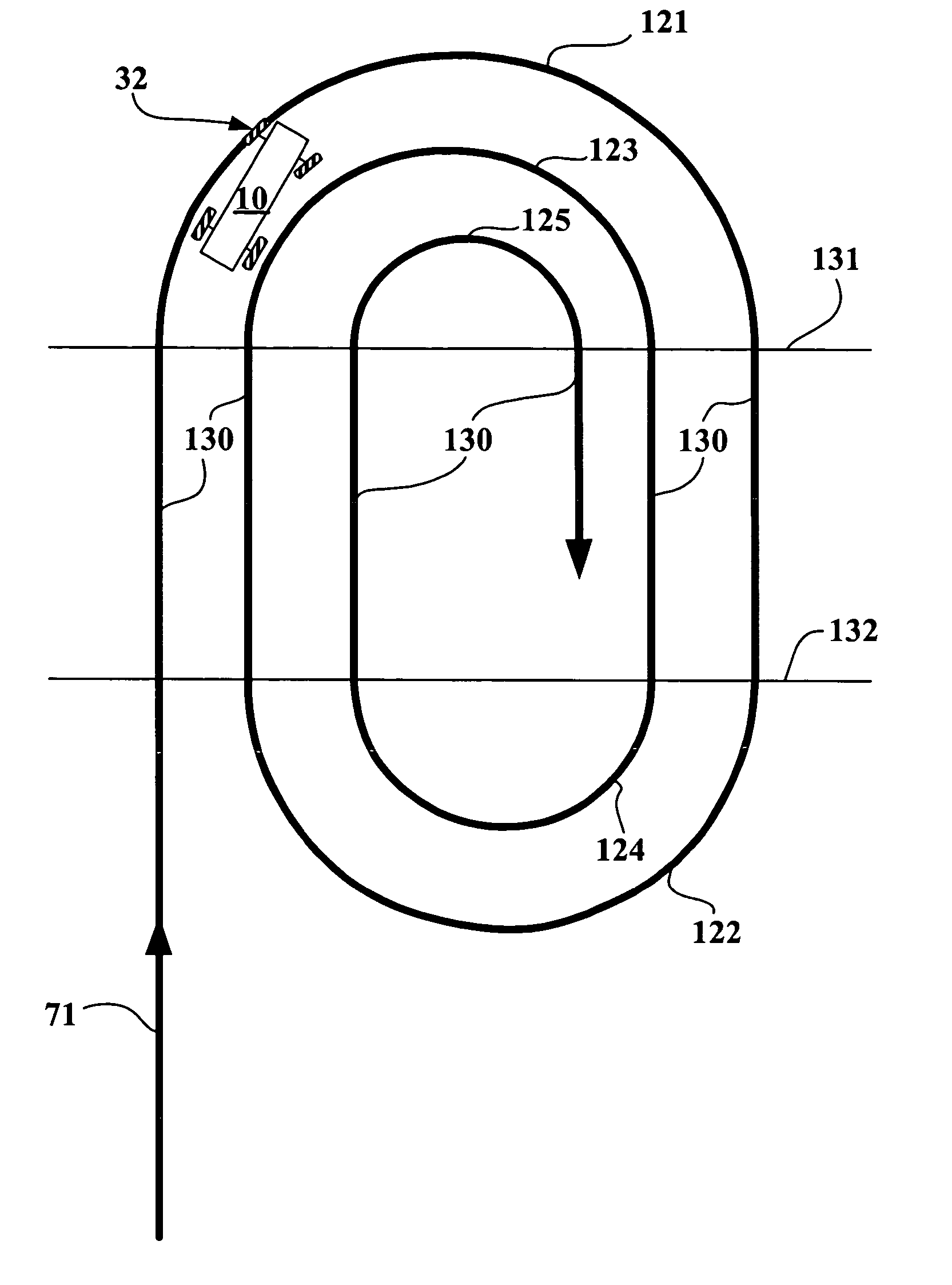

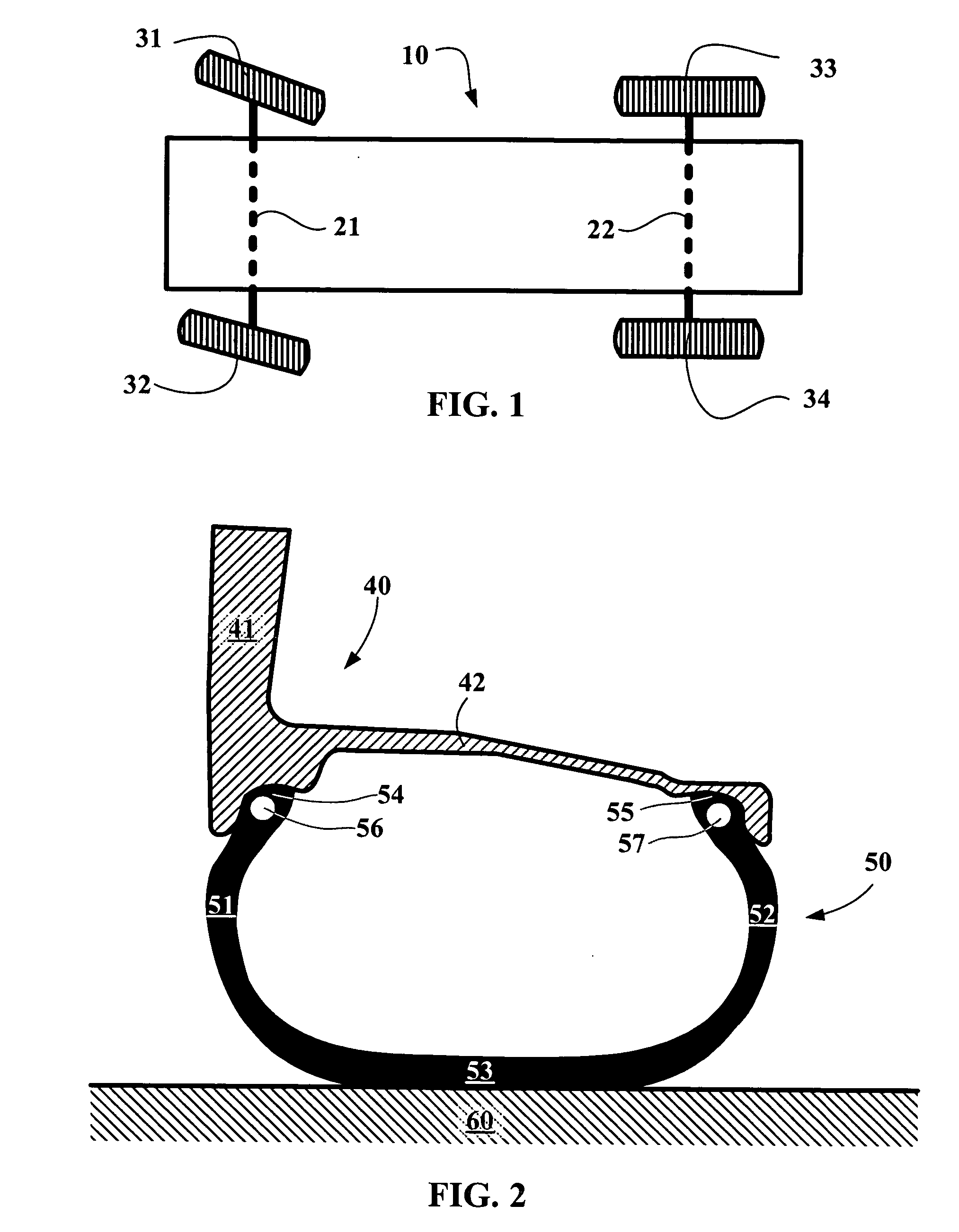

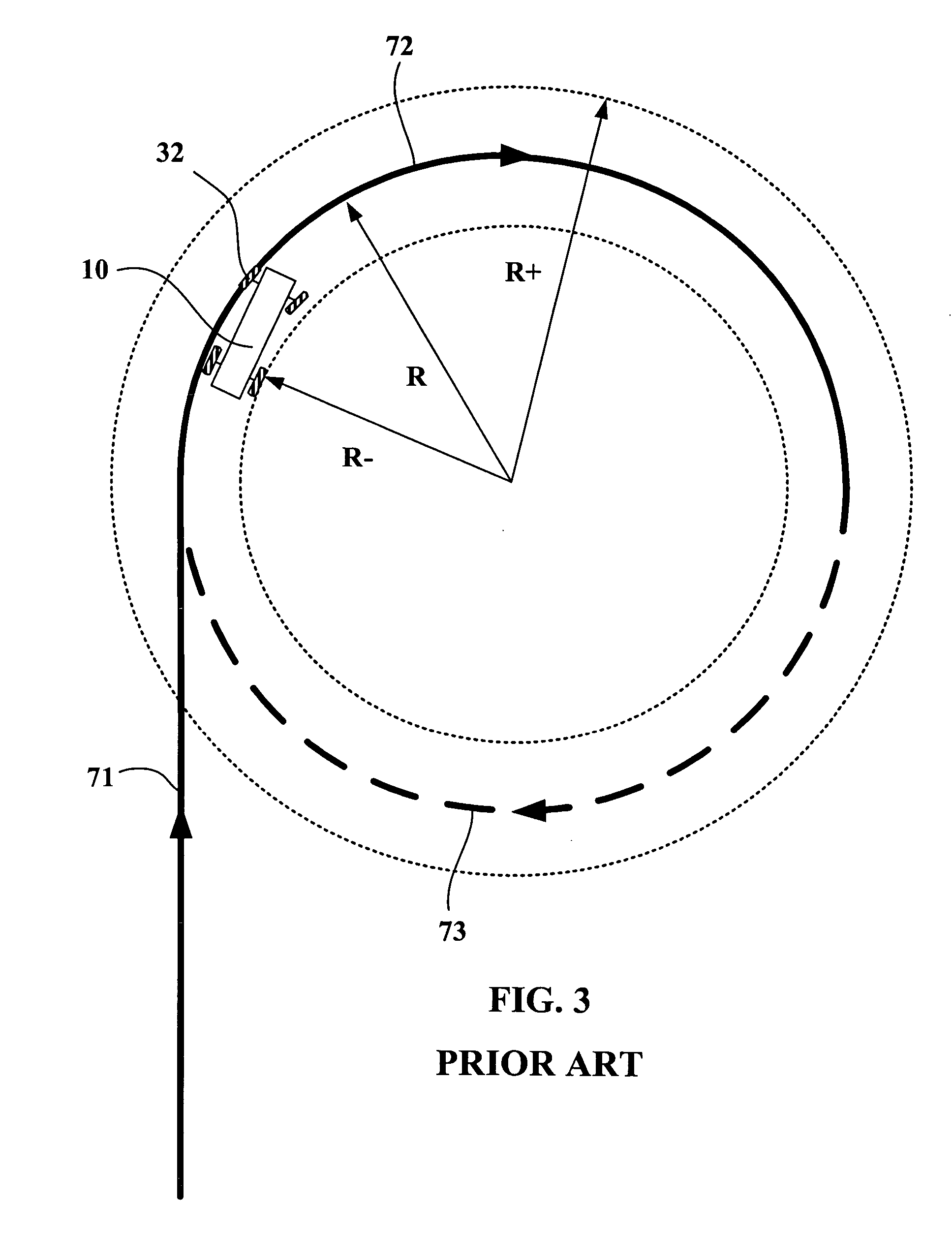

Method of unseating a tire

InactiveUS7159454B2Small surface areaShorten the construction periodRoads maintainenceVehicle tyre testingSteering angleSteering wheel

The resistance to unseating of at least one tire mounted on a mounting rim and inflated to a predetermined pressure is determined by mounting the tire / rim unit on a vehicle in a steering axle position. The vehicle is set in motion in a straight path and stabilized at a predetermined speed. The steering wheel is then rotated to impose a steering angle which is maintained so that the vehicle travels along a circular trajectory arc. If the tire does not unseat, increases in the steering angle are made periodically so that the vehicle travels in progressively tighter circular trajectory arcs until either the tire becomes unseated or the steering wheel reaches its terminal stop.

Owner:MICHELIN RECH & TECH SA

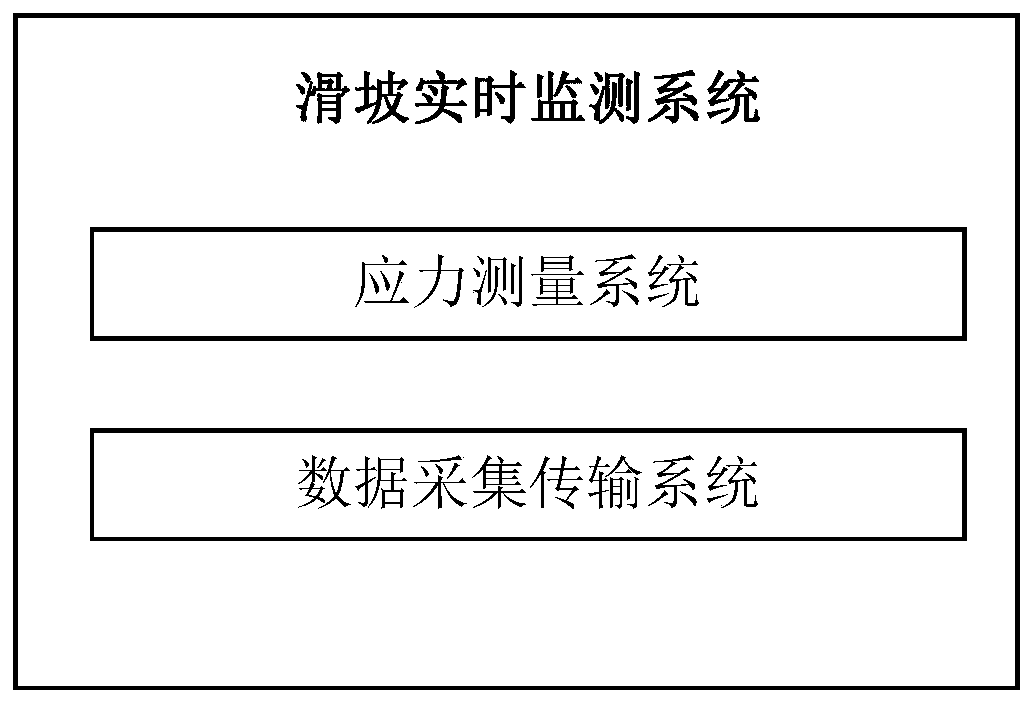

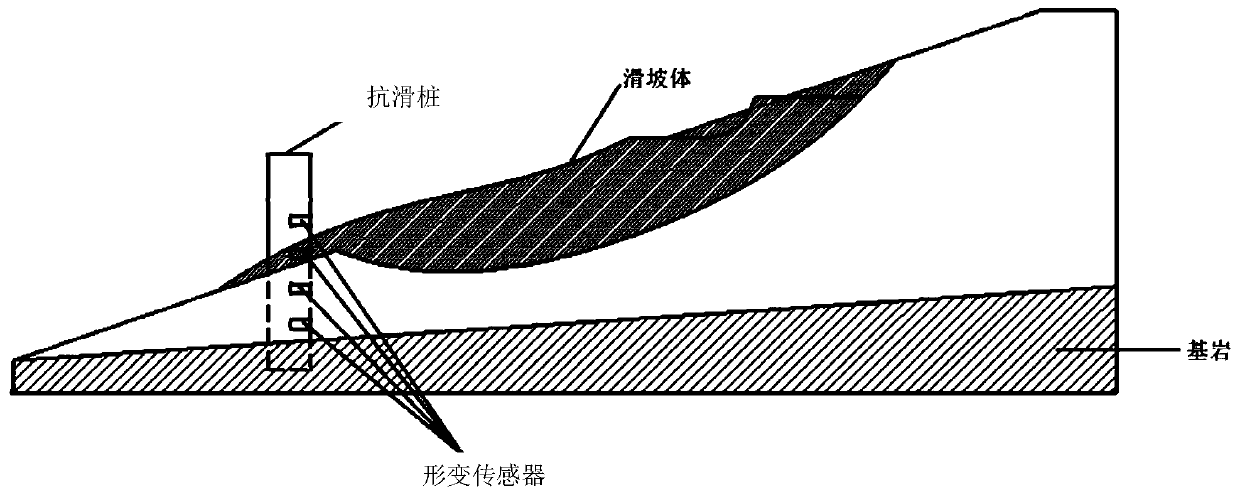

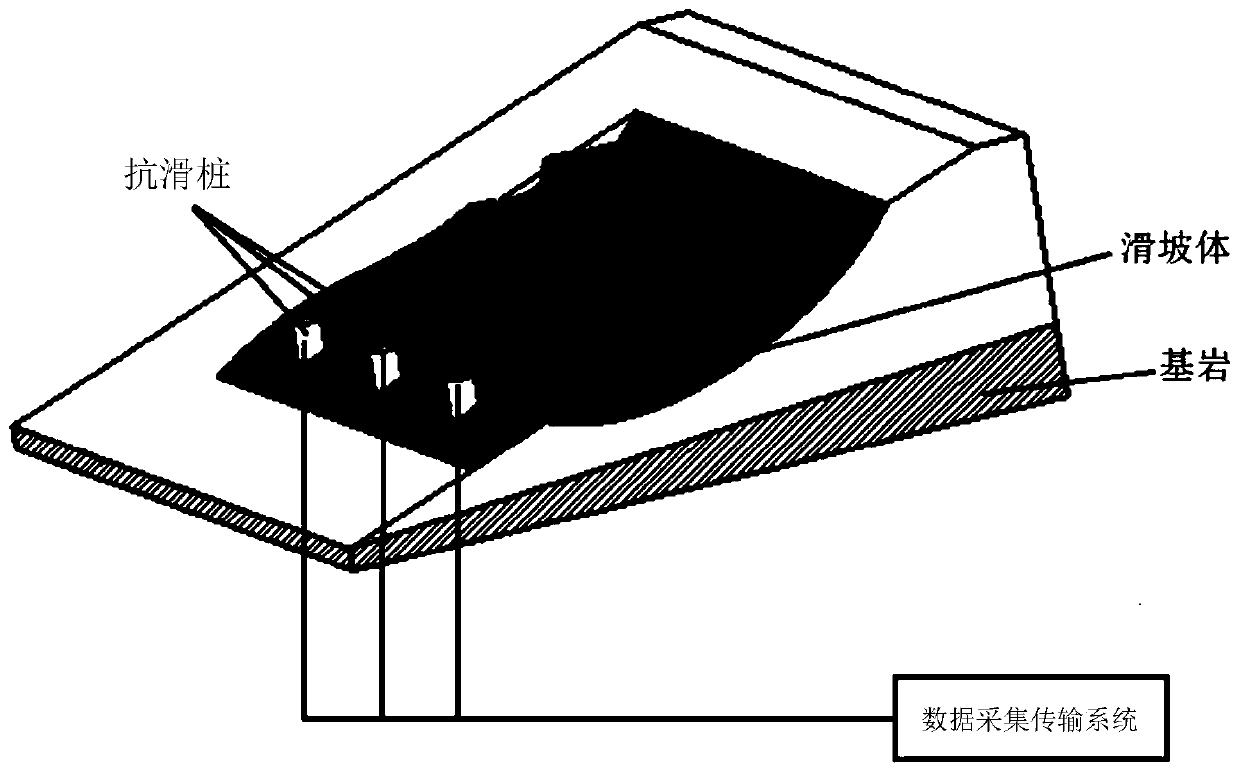

Landslide real-time monitoring system and method

InactiveCN110487449AAchieve observationStable stateForce measurementStress measurementData acquisition

The invention belongs to the technical field of landslide monitoring, and particularly relates to a landslide real-time monitoring system and method. The system comprises a stress measurement system and a data collection and transmission system. The stress measurement system comprises an anti-slide pile and a deformation sensor fixed on the anti-slide pile, and the anti-slide pile is fixed in an area, which does not slide, of the lower part of a landslide body; and the data collection and transmission system is connected with a deformation sensor and is used for acquiring and transmitting dataoutput by the deformation sensor. The deformation sensor is fixed on the anti-slide pile; the anti-slide pile is fixed in a relatively stable area which does not slide, the movement along with the landslide body is avoided, the landslide real-time monitoring system and method can stably monitor the state and stress change of a landslide body, the deformation sensor is connected with the data collection and transmission system, real-time transmission and observation of data can be achieved, the real-time monitoring of the landslide body and the safety of data acquisition personnel are ensured,and compared with a traditional optical fiber monitoring system, the monitoring cost is greatly reduced.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

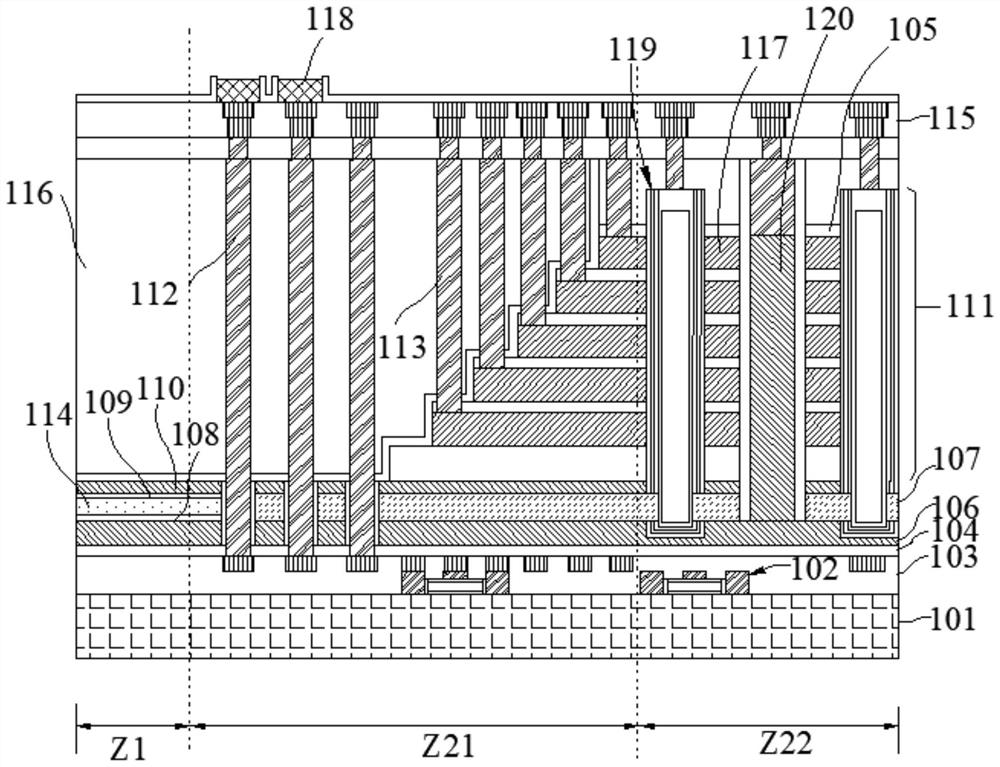

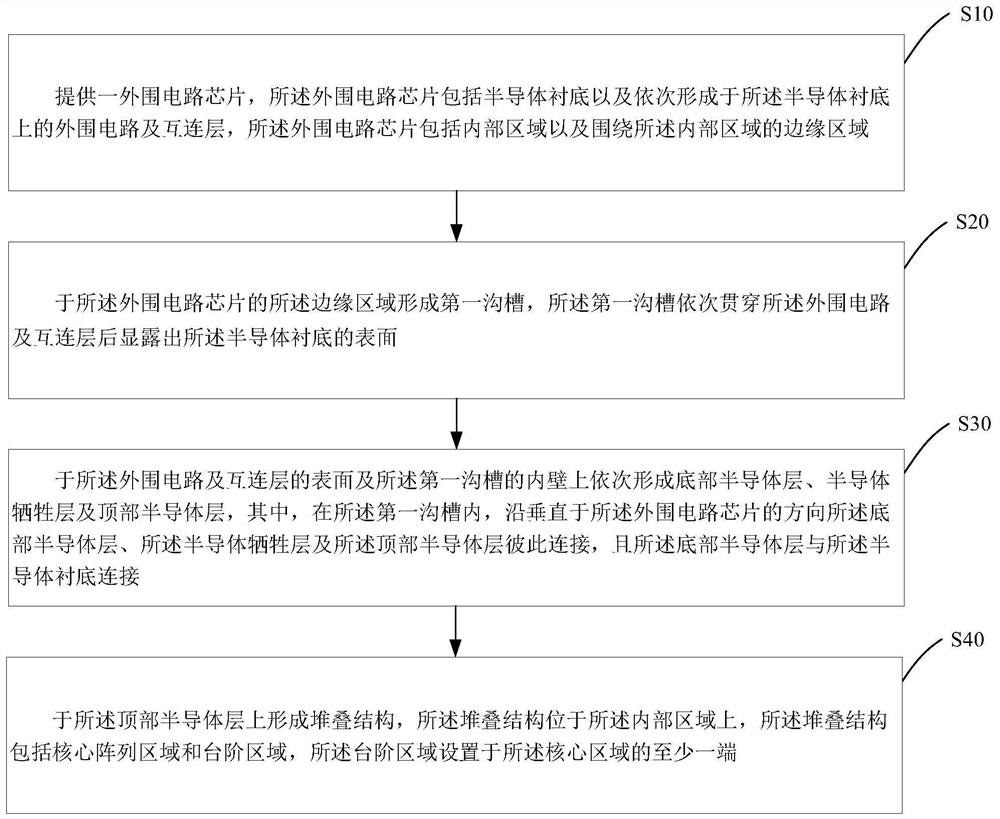

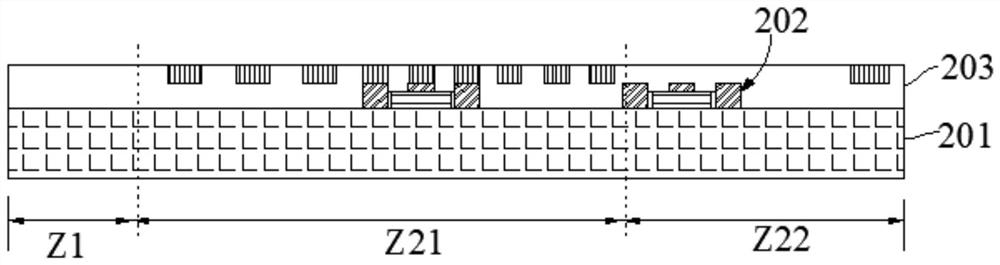

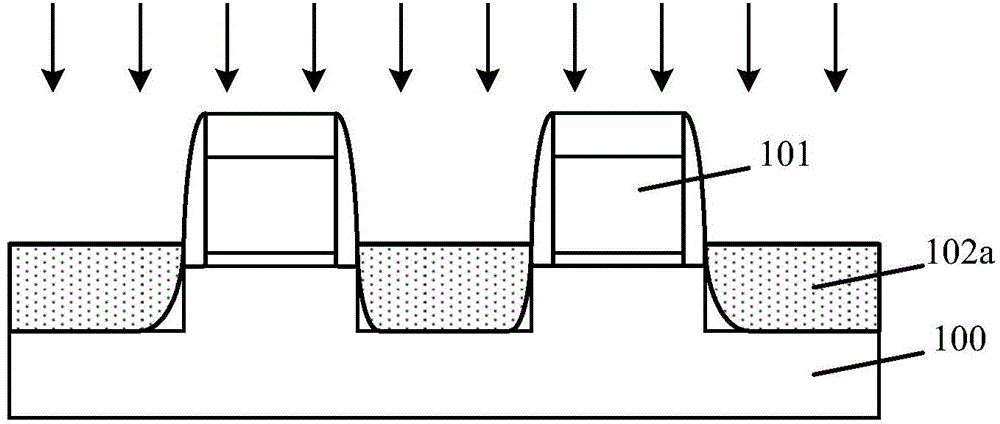

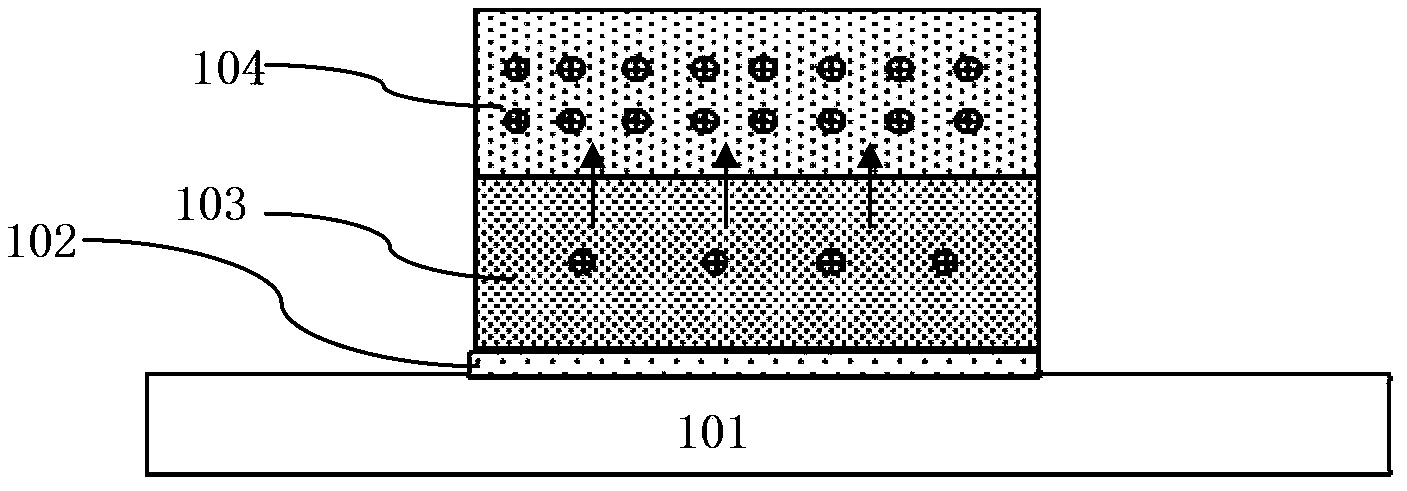

Three-dimensional memory and preparation method thereof

PendingCN112466881AStable structureStress stabilizationSolid-state devicesSemiconductor devicesPhysicsEngineering

The invention provides a three-dimensional memory and a preparation method thereof, and the three-dimensional memory comprises a peripheral circuit chip which comprises a semiconductor substrate, a peripheral circuit and an interconnection layer, wherein the peripheral circuit and the interconnection layer are sequentially formed on the semiconductor substrate, and a trench exposing the semiconductor substrate is formed in the edge region of the peripheral circuit chip; a bottom semiconductor layer, a middle semiconductor layer and a top semiconductor layer which are sequentially arranged on the groove, the peripheral circuit and the interconnection layer, wherein the middle semiconductor layer is composed of a middle layer main body part arranged in the internal area and a middle layer connecting part arranged in the first groove; in the trench, the bottom semiconductor layer, the intermediate semiconductor layer, and the top semiconductor layer are electrically connected to the semiconductor substrate. The trench is formed in the edge area of the peripheral circuit chip, the bottom semiconductor layer, the semiconductor sacrificial layer and the top semiconductor layer are electrically connected with the semiconductor substrate through the groove, and charged plasma generated in the array etching process can be guided away through the semiconductor substrate.

Owner:YANGTZE MEMORY TECH CO LTD

On-line Method for Stabilizing Surface Compressive Stress of Chemically-tempered Glass

ActiveUS20180057402A1Reduce replacement frequencyIncrease profitGlass tempering apparatusChemical reactionMolten salt

The present invention provides an on-line method for stabilizing surface compressive stress of chemically-tempered glass, which comprises the steps of: placing glass to be tempered together with a stabilizer in a tempering furnace containing a molten salt bath for glass tempering; and after reacting at a temperature for a period of time, removing the glass and the stabilizer from the tempering furnace. The stabilizer is capable of chemically reacting with impurity ions in the molten salt bath for glass tempering, to remove the impurity ions in the molten salt bath. Therefore, the presence of the stabilizer allows the impurity ion content in the molten salt bath for glass tempering to be stable without gradual accumulation.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

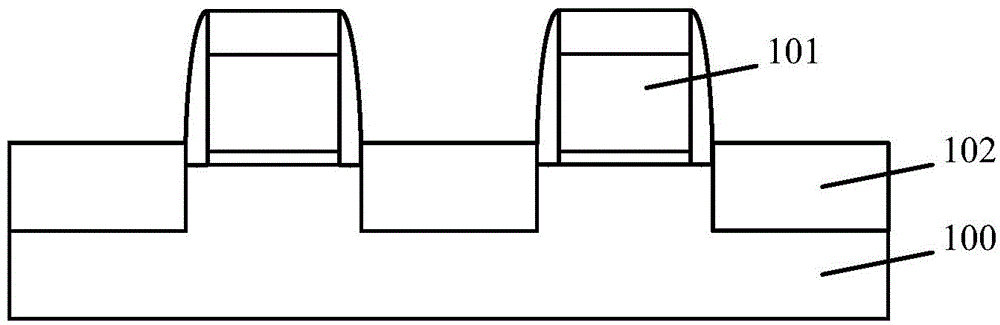

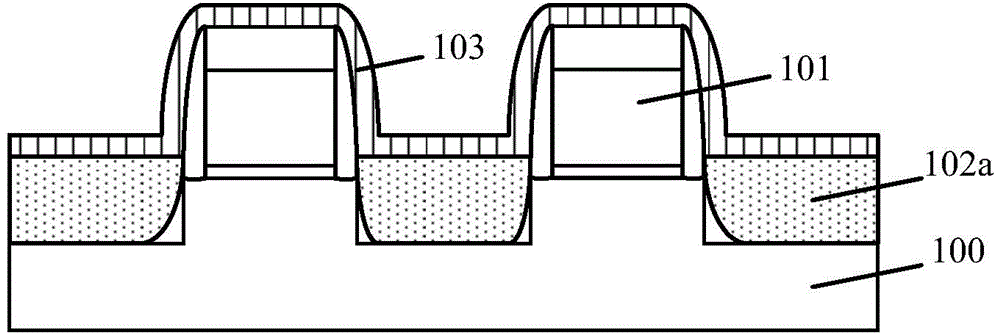

Method for forming semiconductor structure

ActiveCN105575808AGood lookingSmall sizeSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureCrystalline materials

A method for forming a semiconductor structure comprises the following steps: providing a substrate; forming gate structures on the surface of the substrate; forming an initial stress layer on the surface of the substrate on the two sides of the gate structures, wherein the material of the initial stress layer is amorphous; forming a cover stress layer on the surface of the initial stress layer; and after the cover stress layer is formed, converting the material of the initial stress layer into a crystalline material through a solid-phase process, and forming a source and drain stress layer. The morphology and the performance of the formed semiconductor structure are improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Laminate and production method therefor

InactiveCN106457811AGood followabilityExcellent adhesionAdhesive articlesSurgeryWater solubleAqueous solution

Provided is a laminate characterized by having at least one polylactic acid resin-containing layer (C) with a thickness of 10-500 nm on at least one surface of a fibrous structure (B) containing a water-soluble resin (A). Also provided is a production method for the laminate, said method being characterized in that water or an aqueous solution is applied to the joining surface of the fibrous structure (B) and the polylactic acid resin-containing layer (C). A laminate according to the present invention exhibits superior tracking, adhesion and coating properties relative to flexible, curved objects, exhibits superior compatibility to organs such as skin and internal organs, and, because the fibrous structure (B) containing a water-soluble resin (A) can easily be removed from the polylactic acid resin-containing layer (C) by means of the aqueous solution, is optimal for use in materials for external use on the skin, such as wound-covering materials, adhesion-preventing materials, and skin care products.

Owner:TORAY IND INC

Normal-temperature plastic deformation-rapid solidification magnesium alloy anode material as well as preparation method and application thereof

ActiveCN110492094ADissolve fastIncrease discharge voltageFuel and secondary cellsCell electrodesHigh energyElectrochemistry

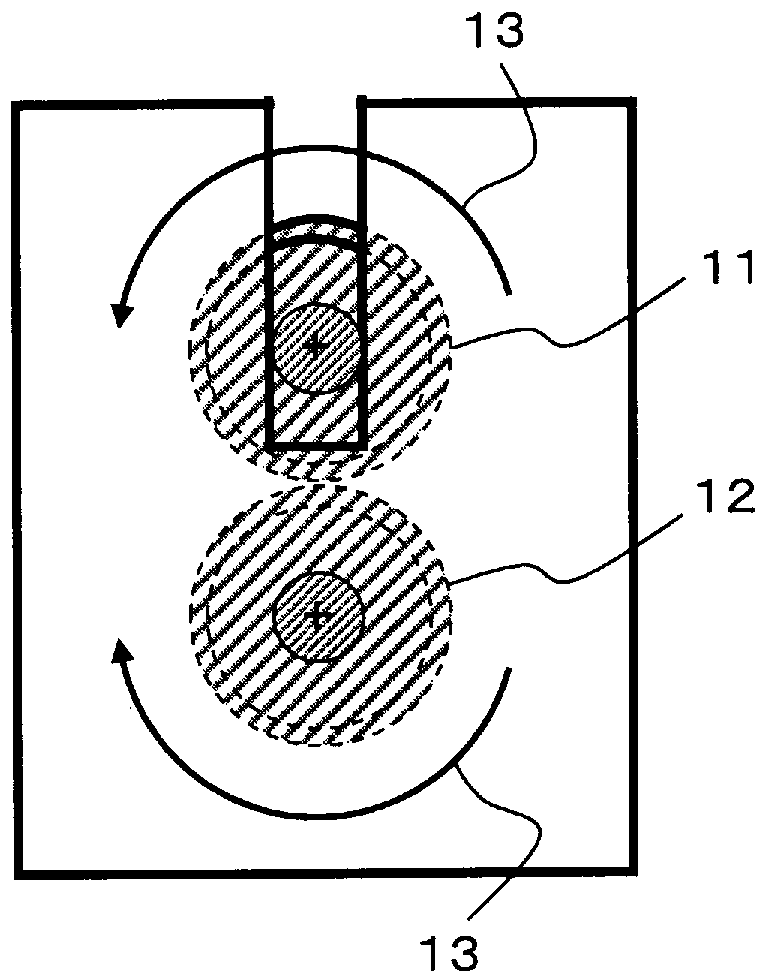

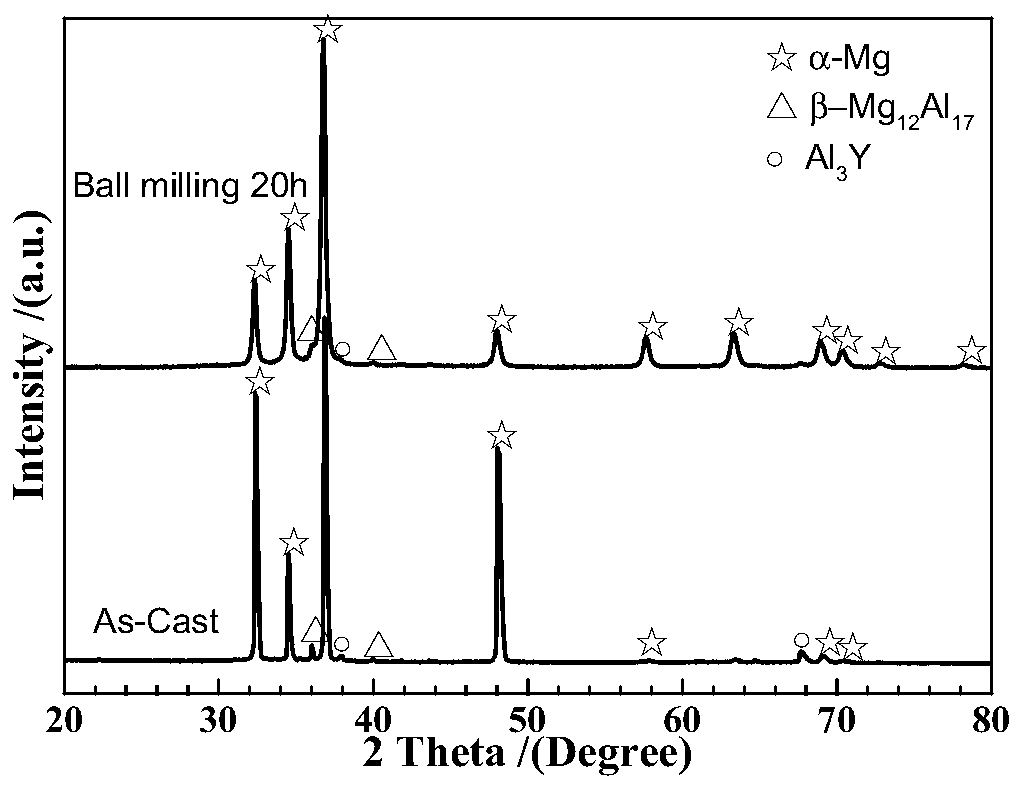

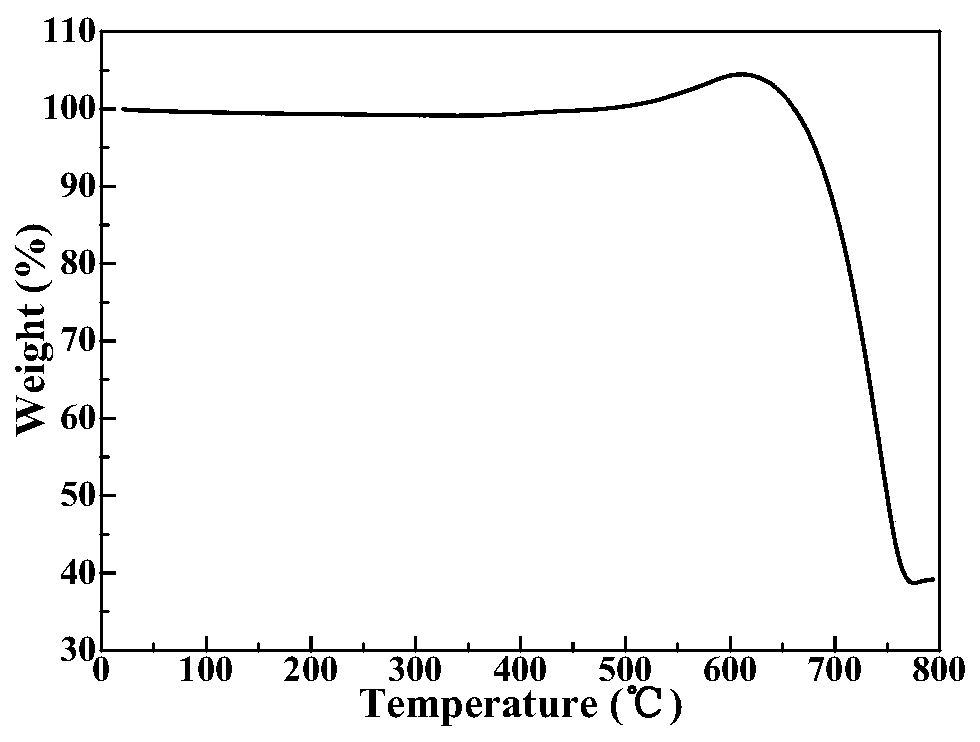

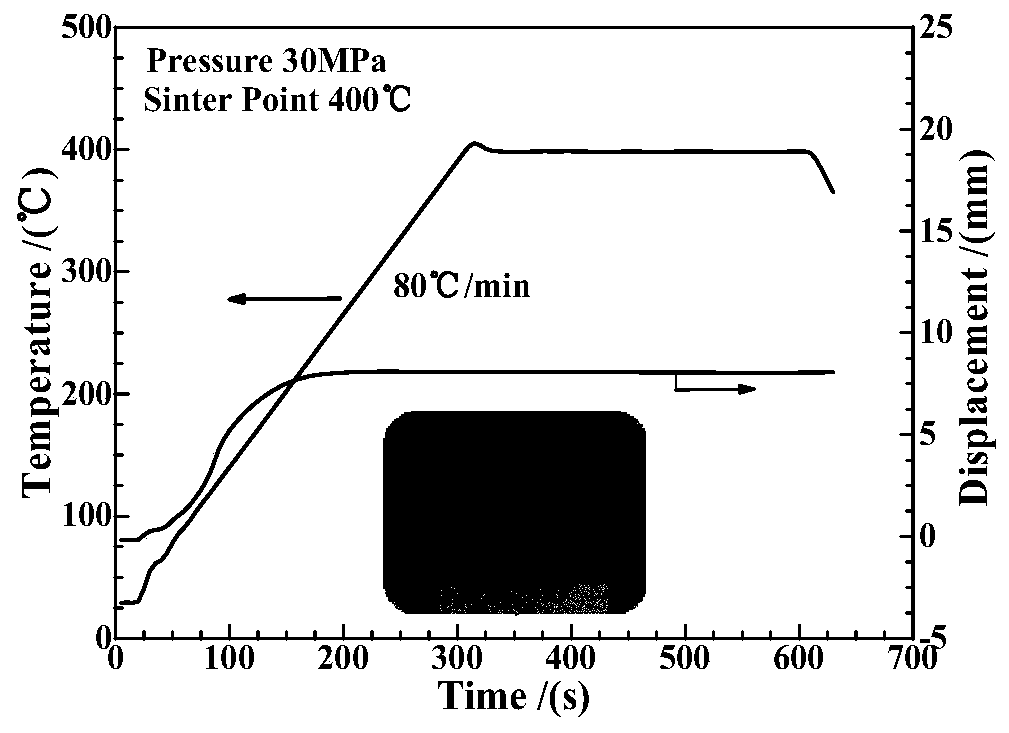

The invention relates to a normal-temperature plastic deformation-rapid solidification magnesium alloy anode material as well as a preparation method and application thereof. The preparation method comprises the following steps that S101, as-cast AP65 magnesium alloy is treated into magnesium chips, grains are refined through high-energy ball milling, and powder is obtained and ground; S102, in avacuum environment, spark plasma sintering is carried out after pretreatment, and the material is obtained, or S201, the as-cast AP65 magnesium alloy is treated into magnesium chips, grains are refined through high-energy ball milling, powder is obtained and ground; and S202, after spark plasma sintering is conducted, heat treatment is conducted under the vacuum condition, and the material is obtained. According to the invention, high-energy ball milling, spark plasma sintering and consolidation technology and the like are adopted, the magnesium alloy anode material is promoted to be rapidly and uniformly dissolved under low current density, and peeling off of a corrosion product is accelerated, so that the discharge voltage of the magnesium alloy is improved, the voltage fluctuation is reduced, stable work of an electric appliance is facilitated, and the comprehensive electrochemical performance of the magnesium alloy anode material is further improved.

Owner:GUANGDONG UNIV OF TECH

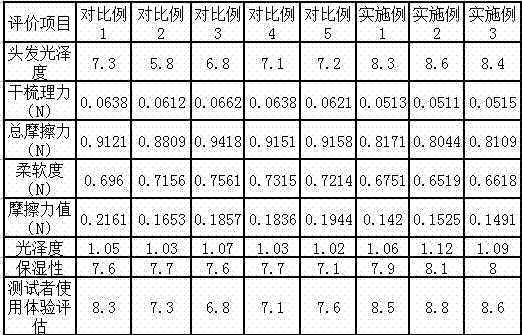

Silicone-compatible photoiniators

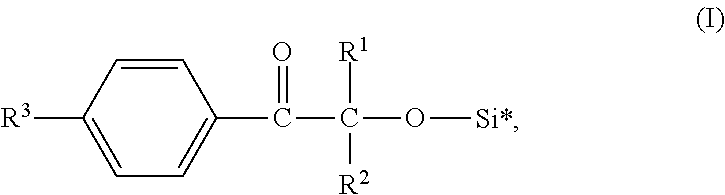

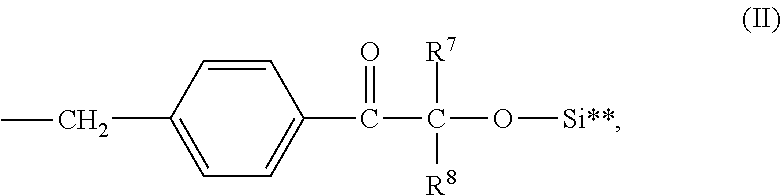

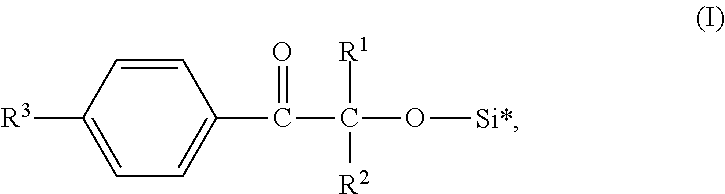

InactiveUS20150266907A1Avoid yellowingHighly solubleSilicon organic compoundsGroup 3/13 element organic compoundsPhotosensitizerHydrogen atom

The present invention provides a compound represented by the following formula (I):whereinR1 and R2 each independently designates an alkyl group of 1 to 12 carbon atoms or a cycloalkyl group of 5 or 6 carbon atoms or R1 and R2 form together with the carbon atom to which they are attached a cycloaliphatic ring of 5 or 6 carbon atoms,Si* represents an organopolysiloxane residue bonded via a silicon atom of this residue to the oxygen shown in formula (I), or a silane group SiR4R5R6, wherein R4, R5 and R6 each independently designates an alkyl group of 1 to 12 carbon atoms, a cycloalkyl group of 5 or 6 carbon atoms or an aryl group of 6 to 10 carbon atoms, andR3 designates a hydrogen atom or a group represented by the following formula (II)whereinR7 and R8 each independently designates an alkyl group of 1 to 12 carbon atoms or a cycloalkyl group of 5 or 6 carbon atoms or R7 and R8 form together with the carbon atom to which they are attached a cycloaliphatic ring of 5 or 6 carbon atoms, andSi** represents an organopolysiloxane residue bonded via a silicon atom of this residue to the oxygen shown in formula (II), or a silane group SiR9R10R11, wherein R9, R10 and R11 each independently designates an alkyl group of 1 to 12 carbon atoms, a cycloalkyl group of 5 or 6 carbon atoms or an aryl group of 6 to 10 carbon atoms,a method to produce this compound and the use thereof as photoinitiator and / or photosensitizer.

Owner:HENKEL KGAA +1

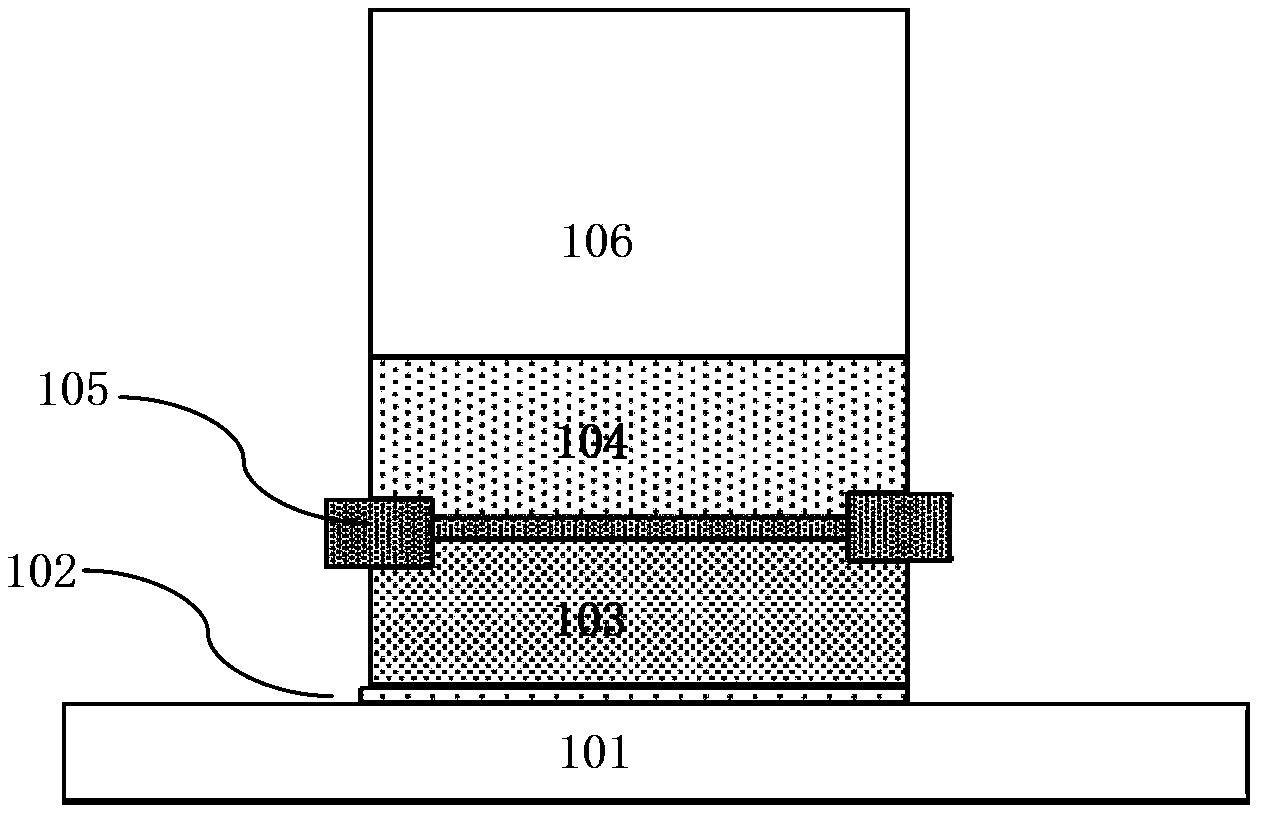

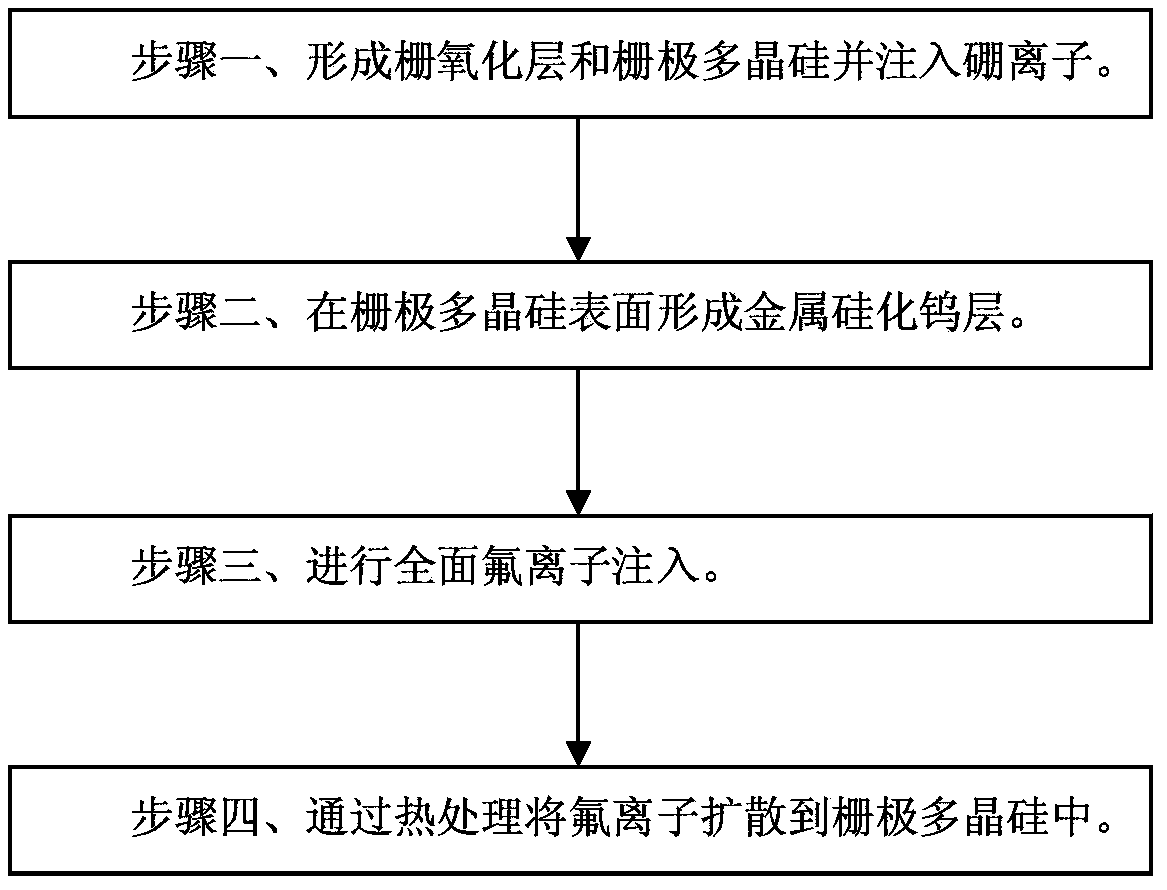

Method for improving negative bias temperature stability of grid of PMOS device

ActiveCN104347370AReduced Threshold Voltage DriftImproved Negative Bias Temperature StabilitySemiconductor/solid-state device manufacturingSemiconductor devicesHydrogenSilicon oxide

The invention discloses a method for improving the negative bias temperature stability of the grid of a PMOS device. The method comprises the following steps: forming a grid oxide layer and grid polysilicon, and injecting boron ions; forming a metal tungsten silicide layer on the surface of the grid polysilicon; performing comprehensive fluorinion injection; and diffusing fluorinions into the grid polysilicon through thermal treatment. According to the invention, the stress at the interface of silicon and silicon oxide of the grid can be decreased, the interface state generated due to the existence of hydrogen bonds is reduced, the stability of the interface of the silicon and the silicon oxide can be enhanced, the threshold voltage drift of the PMOS device can be effectively reduced, and the negative bias temperature stability of the grid of the PMOS device is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

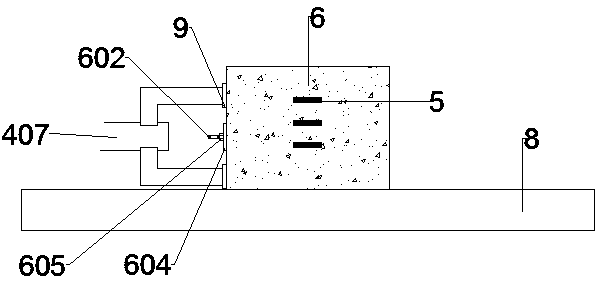

Bolted rock mass long-term strength test system based on stress-seepage coupling effect

PendingCN111189692AReduce mistakesSimple system structureMaterial strength using tensile/compressive forcesTunnel engineeringCreepmeter

The invention provides a bolted rock mass long-term strength test system based on a stress-seepage coupling effect. The system is used to solve the technical problems that a bolted rock mass long-termstrength test cannot meet the actual physical state of a bolted rock mass, the constitutive relation of the bolted rock mass long-term strength in a stress-seepage coupling environment is not clear and the like. The system comprises a pressurizing device, a hydraulic system and a strain detection device, the pressurizing device comprises a creepmeter, and a containing box used for containing a bolted rock mass sample is arranged in the middle of a workbench of the creepmeter. The hydraulic system comprises a water tank, the strain detection device comprises a computer, a strain gauge and a strain gauge, and the strain gauge is connected with the strain gauge and the computer. The system utilizes the characteristics that the stress provided by the creepmeter is stable, the error is small,etc., is combined with an autonomously designed hydraulic system, simulates the occurrence environment of the bolted rock mass in a tunnel engineering, provides a stress seepage coupling test environment, is high in test accuracy, good in effect, simple in structure, clear in working principle and low in cost, and is easy to operate.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Laser leveling method of thin wall slide plate

ActiveCN104250683ADoes not affect heat treatment performanceShorten the processing cycleFurnace typesHeat treatment furnacesLaser quenchingLaser scanning

The invention relates to a laser leveling method of a thin wall slide plate, which comprises the following steps: A)treating surface of the thin wall slide plate, detecting; B)using laser for scanning a lug boss of the thin wall slide plate, taking central section of a highest point and a lowest point as an origin, taking a deformed length direction as a scan direction for scanning, performing laser quenching; while laser scanning, employing an auxiliary water cooling mode on a non-quenching position, and preventing heat diffusion while scanning; and C)detecting. The laser leveling method employs specific advantage of a laser surface technology, employs a reasonable laser back pull correction action, special processing is not required on parts, secondary processing is required, flatness can be recovered at one time, original heat treatment performance of the slide plate is not influenced, correction position and scope can be controlled in a flexible mode, high point can be corrected in a target mode, stress is smooth, local bending due to local point-like stress is not generated, good correction effect can be reached, and the method saves processing period, economic cost and manpower resource for enterprise.

Owner:淮南市启迪电子有限公司

Hair cleaning composition and preparation method thereof

ActiveCN107753319AEasy to wrapReduces friction on wet hairCosmetic preparationsHair cosmeticsNatural sourceWater insoluble

The invention relates to the field of daily chemicals and discloses a hair cleaning composition which is prepared from the following components in percentage by weight: 1-10% of water-insoluble silicone oil combination, 0.1-1% of natural source cationic polymer, 0.01-10% of crystalline hydroxyl-containing stabilizer, 4-20% of surfactant, 0.1-5% of lemon oil, 0.1-2% of hydrolyzed lupin protein andthe balance of deionized water. The invention also discloses a preparation method of the hair cleaning composition, wherein a relatively good effect of improving the health of hair and scalp is realized through reasonable establishment of the composition framework, synergism among the raw materials and limitation of key parameters of the raw materials.

Owner:OPAL COSMETICS HUIZHOU

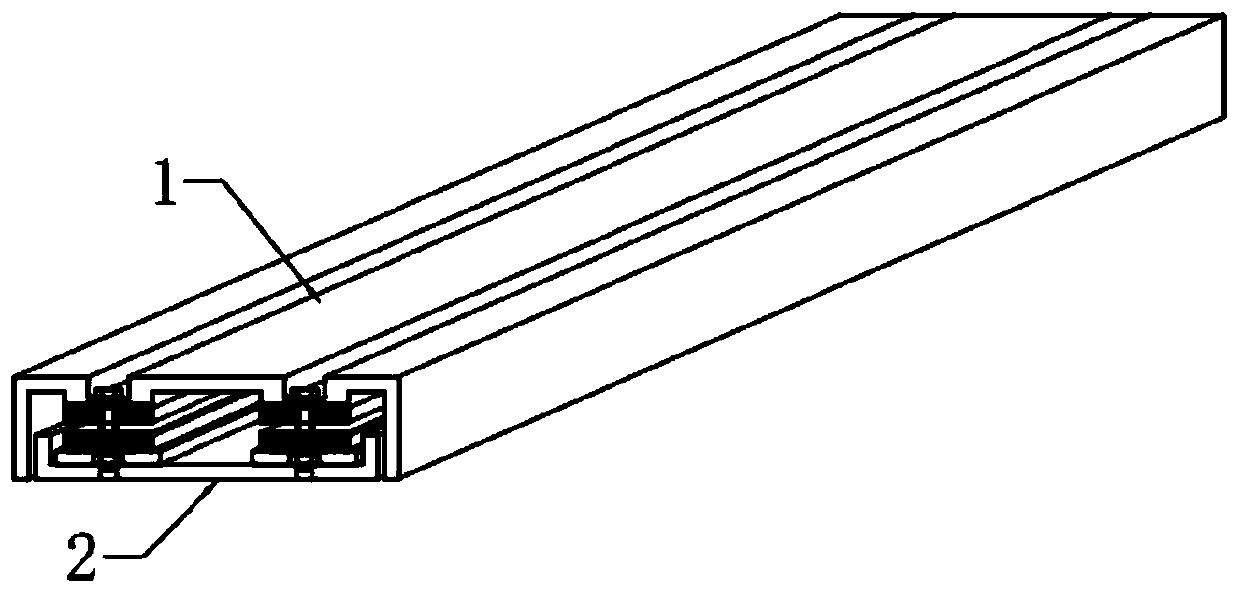

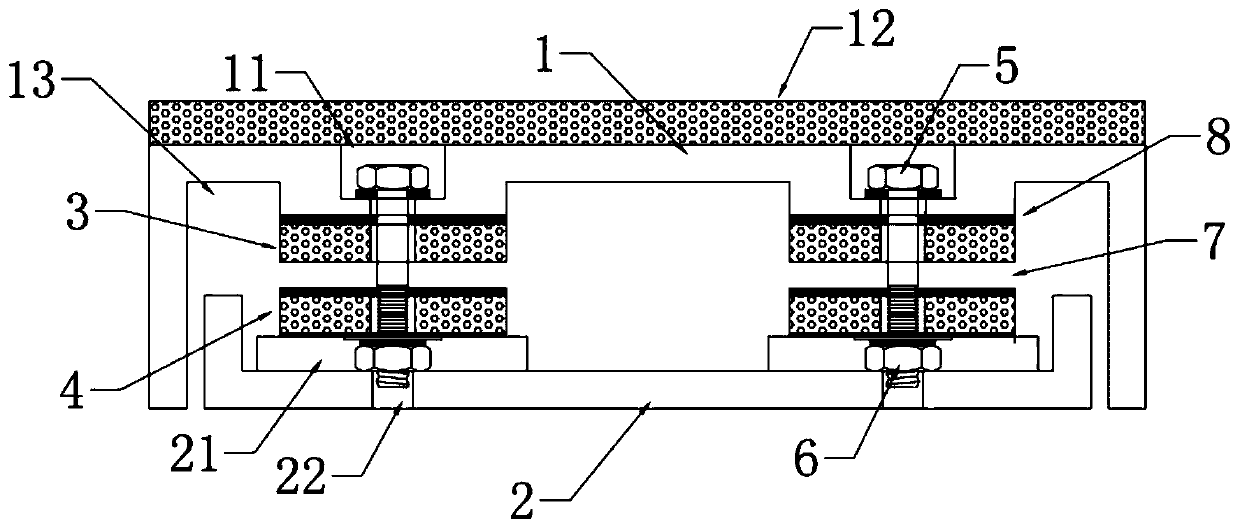

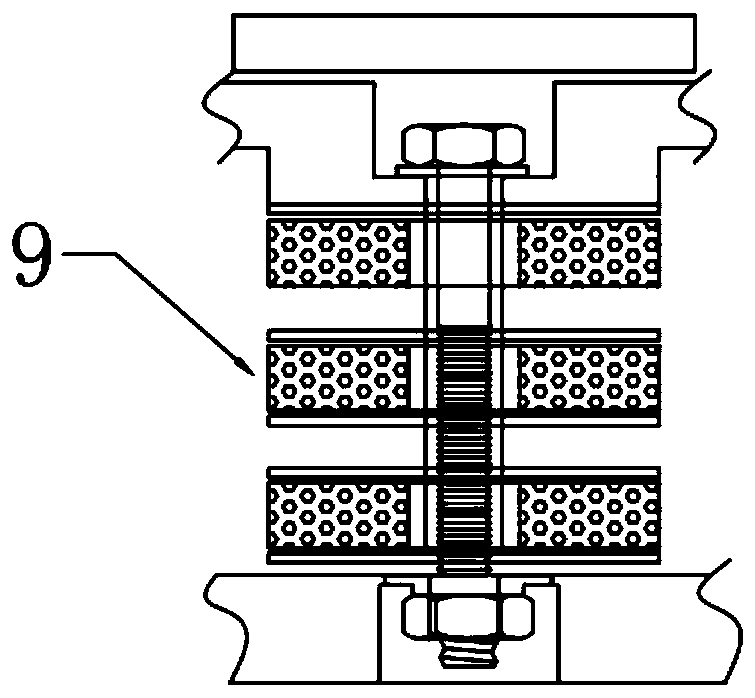

Magnetic force buffer device

InactiveCN110748103AAvoiding Metal Fatigue ProblemsThe overall stress is stableTreadsEngineeringMagnetic tension force

The invention relates to the technical field of building facilities, in particular to a magnetic force buffer device. The magnetic force buffer device comprises a top pressing block, a bottom supporting plate, a plurality of sets of first magnetic stripes, second magnetic stripes, positioning screw rods and positioning nuts. The top pressing block is located above the bottom supporting plate. Thecross section of the top pressing block and the cross section of the bottom supporting plate are both in a U shape. The top pressing block and the bottom supporting plate are arranged in a matched mode. The first magnetic stripes and the second magnetic stripes are fixed into a recessed cavity of the top pressing block and a recessed cavity of the bottom supporting plate correspondingly. The samemagnetic poles of the first magnetic stripes and the second magnetic stripes are opposite, and thus magnetic repulsive force is formed. The first magnetic stripes and the second magnetic stripes are fixed into the device through the positioning screw rods. The top pressing block is suspended on the bottom supporting plate under the lifting action of the magnetic repulsive force and the limiting action of the positioning screw rods. A lifting space area is formed between the first magnetic stripes and the second magnetic stripes. According to the magnetic force buffer device, the magnetic stripes with the same magnetic poles being opposite are evenly arranged, the magnetic repulsive force is used for replacing elastic force, stable fixation is conducted, the problem of metal fatigue causedby using of elastic parts is avoided, and the stress of the device is stable on the whole.

Owner:FOSHAN YIGO HARDWARE LTD

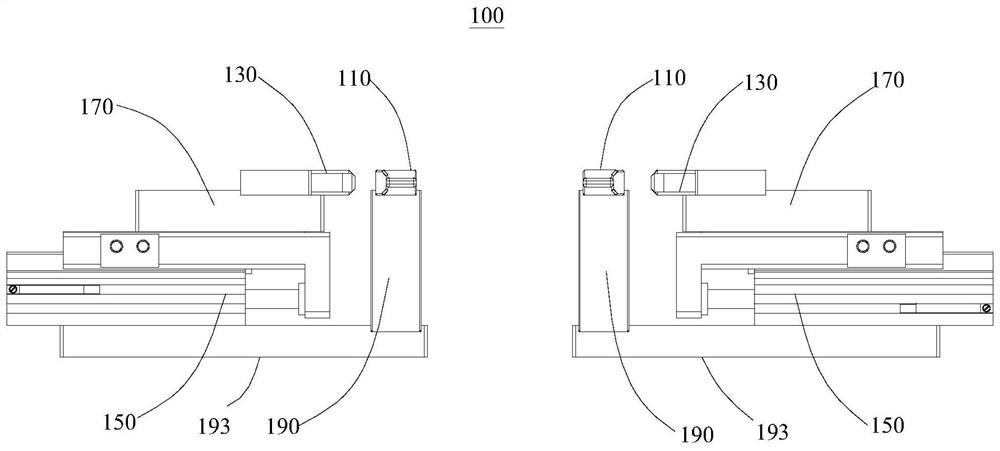

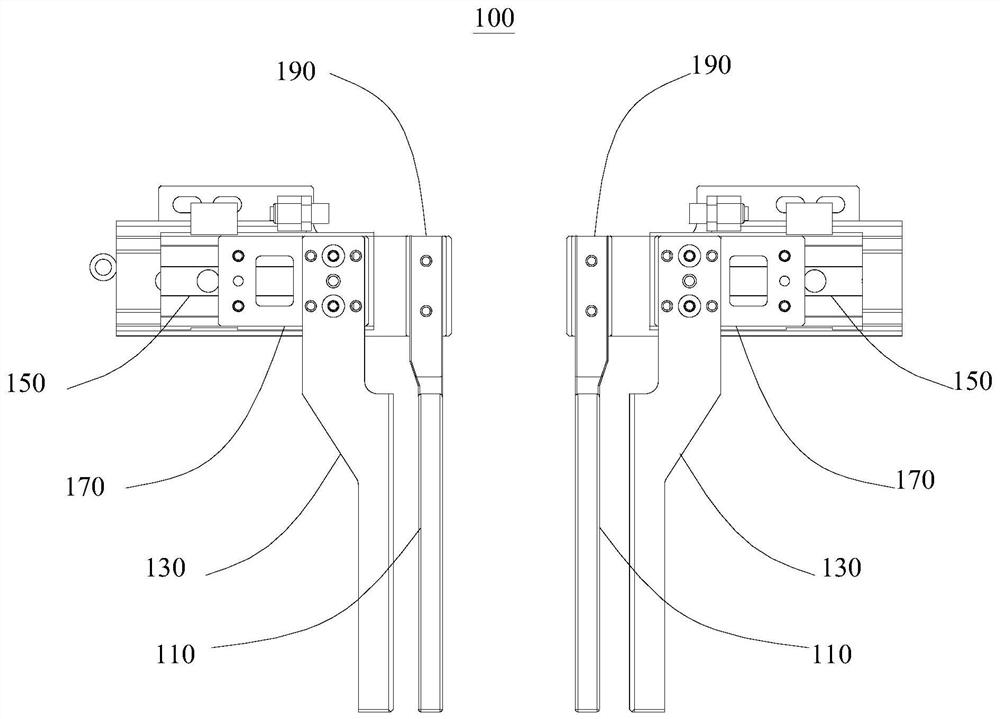

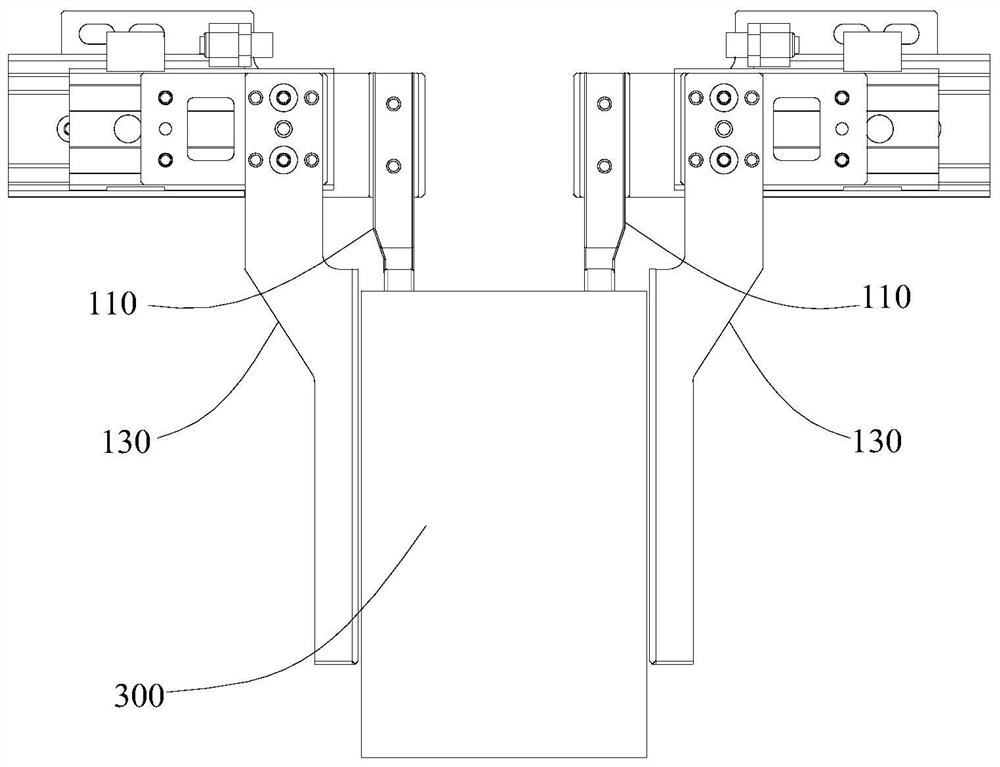

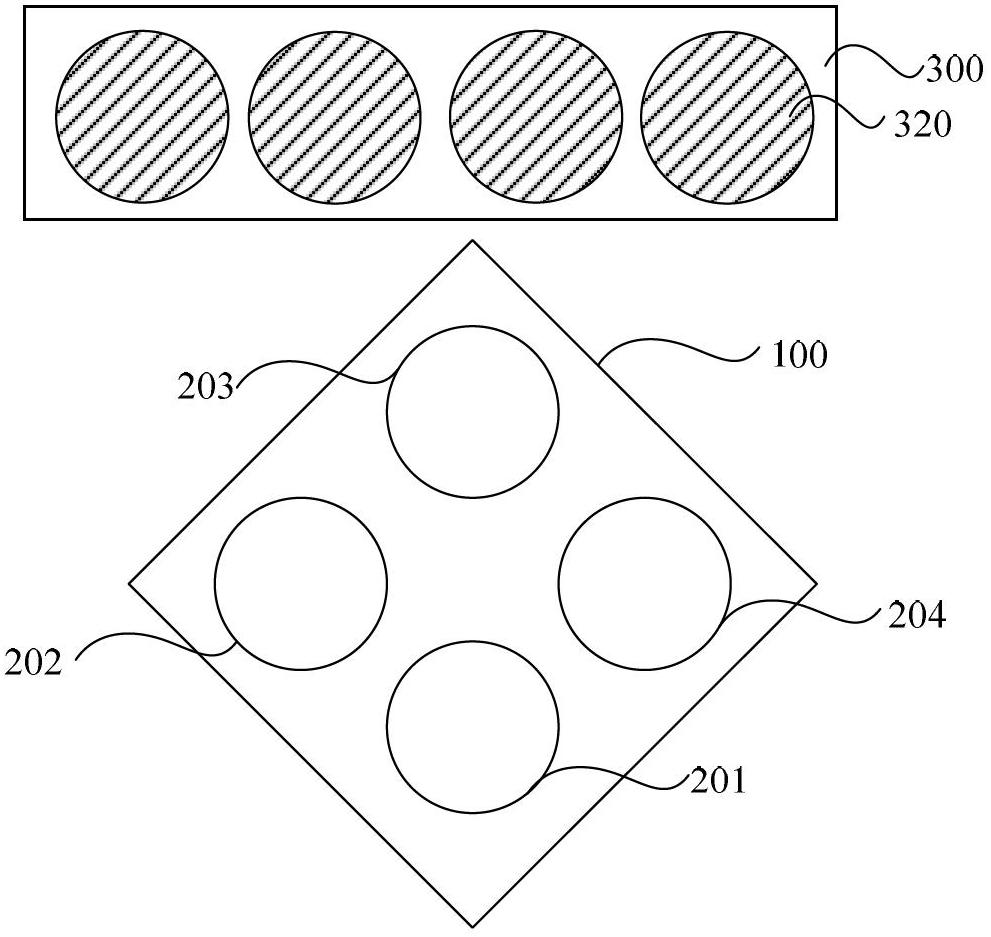

Battery cell blanking clamping mechanism

PendingCN111824765ASmall footprintStress stabilizationFinal product manufactureSecondary cellsCell fabricationStructural engineering

The embodiment of the invention provides a battery cell blanking clamping mechanism, and relates to the field of lithium battery manufacturing equipment. The battery cell blanking clamping mechanism comprises an inner side clamping plate, an outer side clamping plate and a clamping driving mechanism, wherein the inner side clamping plate and the outer side clamping plate are oppositely arranged; the clamping driving mechanism is simultaneously in transmission connection with the inner side clamping plate and the outer side clamping plate and is used for driving the inner side clamping plate and the outer side clamping plate to be mutually close to each other or mutually separated; and the cross sections of the inner side clamping plate and the outer side clamping plate are rectangular. Through the adoption of the inner side clamping plate and the outer side clamping plate of rectangular and plate-shaped structures, the occupied space of the clamping plates is smaller; the probability of battery cell inner side collapse is reduced; meanwhile, the clamping plates are more stable when being stressed in the horizontal direction; deformation cannot easily occur, so that the deformationand wrinkling of the battery cell can be avoided; the contact area between the clamping plates and the battery cell is smaller; the clamping force is greater; the clamping effect is good; and the corepulling risk due to driving of an inner layer diaphragm during the needle coiling and needle pulling can be reduced.

Owner:GEESUN AUTOMATION TECH

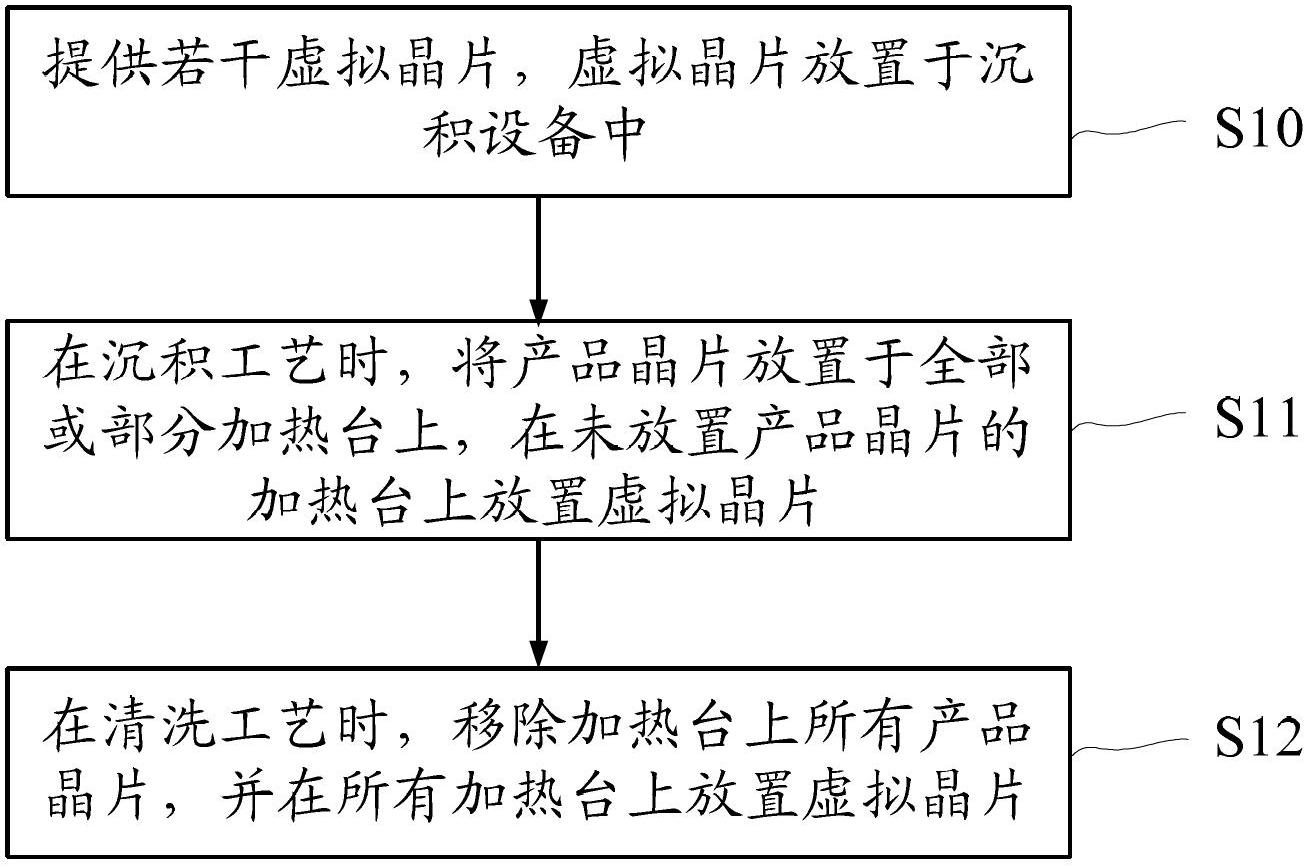

Method for eliminating load effect of multi sequence single deposition device

InactiveCN102664146AStable thicknessStress stabilizationSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

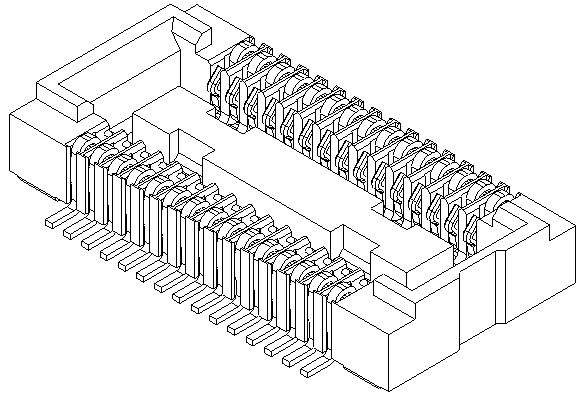

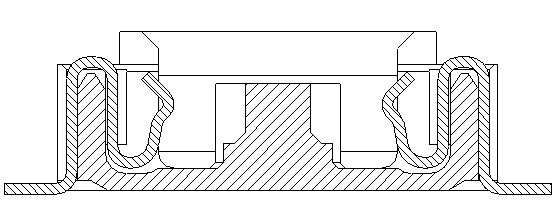

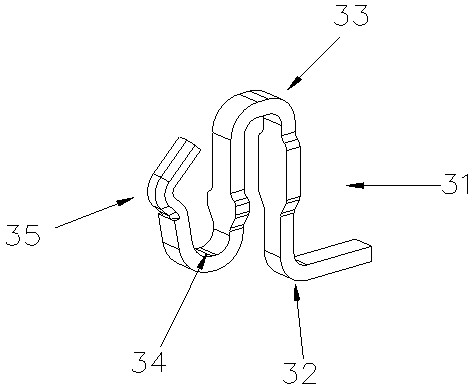

Board-to-board connectors with dropout socket contacts

InactiveCN102290657AStress stabilizationSimple preparation processCoupling contact membersFixed connectionsState of artBoard-to-board connector

The invention discloses a board-to-board connector with a blanking socket terminal, which includes a socket connector and a plug connector capable of being inserted into the socket connector. The socket connector includes a second insulating body and several The socket terminal on both sides of the second insulating body is characterized in that: the socket terminal includes a contact head, a positioning column and a welding foot, and the positioning column of the socket terminal is inserted into an insertion hole in the second insulating body for fixing, and the The bottom of the positioning column extends backward for soldering feet, and the front end of the positioning column is connected with a contact head for electrical connection with the plug terminal. The invention solves the problem in the prior art that the board-to-board connector socket terminal and the plug terminal are not in good contact, which easily causes the board-to-board connector to fail to conduct, and provides a simple-to-manufacture, convenient-to-use, and relatively stable conduction effect. Board-to-board connectors with drop-type socket terminals.

Owner:KUSN DLK ELECTRONICS TECH

Method of unseating a tire

InactiveUS20060086183A1Shorten the construction periodAccurate measurementRoads maintainenceVehicle tyre testingSteering wheelSteering angle

The resistance to unseating of at least one tire mounted on a mounting rim and inflated to a predetermined pressure is determined by mounting the tire / rim unit on a vehicle in a steering axle position. The vehicle is set in motion in a straight path and stabilized at a predetermined speed. The steering wheel is then rotated to impose a steering angle which is maintained so that the vehicle travels along a circular trajectory arc. If the tire does not unseat, increases in the steering angle are made periodically so that the vehicle travels in progressively tighter circular trajectory arcs until either the tire becomes unseated or the steering wheel reaches its terminal stop.

Owner:MICHELIN RECH & TECH SA

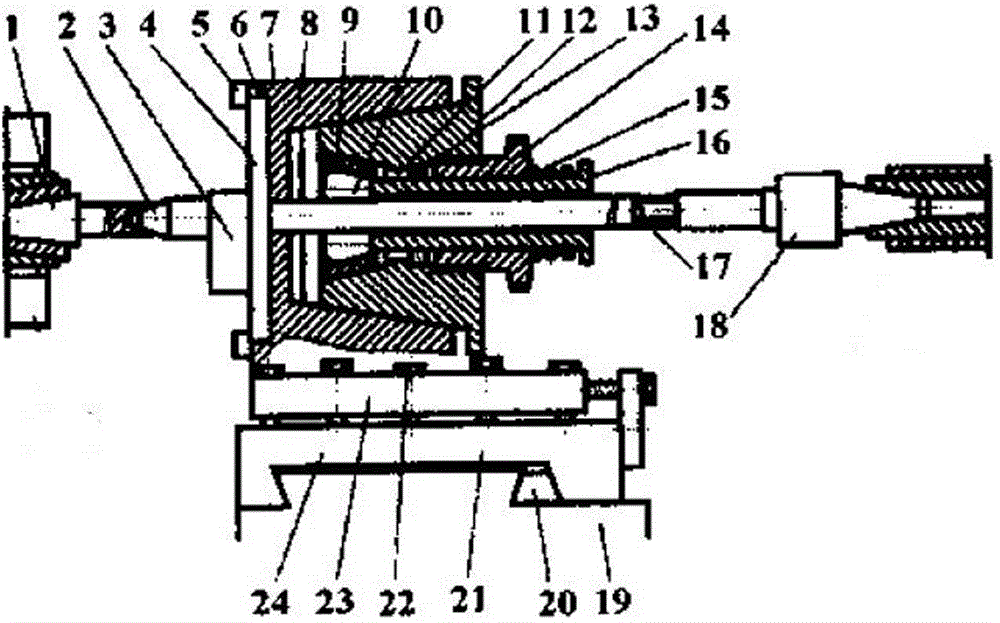

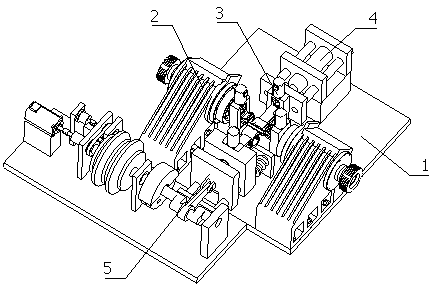

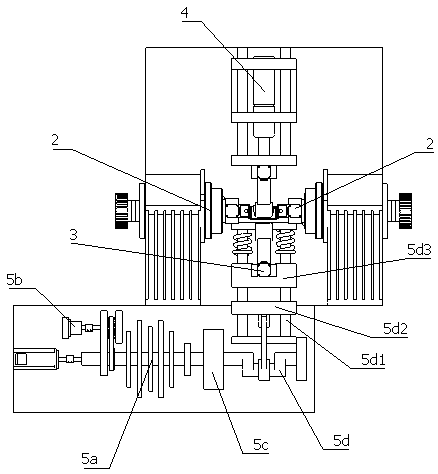

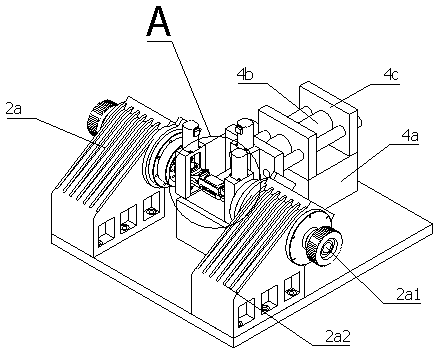

Non-rigid shaft combined machining device

InactiveCN104625113AHigh precisionIncrease productivityTailstocks/centresAuxillary equipmentMachined surfaceEngineering

The invention relates to the field of machining, in particular to a non-rigid shaft combined machining device. The non-rigid shaft combined machining device comprises a bottom plate which is fixed on a lathe carriage through a wedge, and the bottom plate is fixedly connected with a bottom plate body through a fastening screw and an adjusting screw. The bottom plate body is connected with a machining head and a machine body. The two end faces corresponding to the machining head are each provided with a center, and the centers comprise the front center and the rear center. The front center and the rear center are each provided with a guide sleeve, and the guide sleeves comprise the front guide sleeve and the rear guide sleeve. A guide rail is arranged at one end of the machine body, and the guide rail is connected with a tool apron through a presser. The other end of the machine body 8 is provided with a taper hole. According to the non-rigid shaft combined machining device, the microcosmic uneven degree height can be reduced, the product surfaces can be enhanced, the dispersive range of product dimension and geometrical shape tolerances is reduced, the surface residual stress and microcosmic structure variation is stable, and the machined surface precision and the production efficiency are improved.

Owner:王树林

Stress testing device for car suspension control arm bushing stiffening piece

ActiveCN109269898AThe experimental structure is close to the realClose to the actual driving situationMachine part testingMaterial strength using tensile/compressive forcesMomentumControl arm

The invention relates to the technical field of automobile parts, in particular to a stress testing device for a car suspension control arm bushing stiffening piece. The device comprises a fixing table, bushing and stiffing piece fixtures, a stability stress testing device and an instantaneous momentum testing device, the bushing and stiffing piece fixtures are fixedly mounted on both sides of thefixing table, a bushing and a stiffing piece are assembled in one piece, the two sides are respectively mounted on working ends of the two bushing and stiffing piece fixtures, the bushing and stiffing piece fixtures are located on both sides of the bushing in the axial direction, the stability stress testing device and the instantaneous momentum testing device are respectively located on both sides in the radial direction of the bushing and fixedly mounted on the fixing table, and the working ends of the stability stress testing device and the instantaneous momentum testing device are provided with the bushing fixtures. The device applies stress through a simulation control arm, a test result is close to a real situation, the bushing and the stiffing piece can perform stability stress testing and instantaneous momentum testing, and the result is closer to an actual driving situation.

Owner:浙江羿凡汽车配件有限公司

On-line method for stabilizing surface compressive stress of chemically-tempered glass

ActiveUS10618841B2Lowered CS valueStress stabilizationGlass tempering apparatusChemical reactionTempering

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-n'-(5-methyl-3-isoxazolyl)urea salt in crystalline form N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-n'-(5-methyl-3-isoxazolyl)urea salt in crystalline form](https://images-eureka.patsnap.com/patent_img/8400b924-c92b-4129-ae50-afc08a5ed0ad/US07166722-20070123-D00001.png)

![N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-n'-(5-methyl-3-isoxazolyl)urea salt in crystalline form N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-n'-(5-methyl-3-isoxazolyl)urea salt in crystalline form](https://images-eureka.patsnap.com/patent_img/8400b924-c92b-4129-ae50-afc08a5ed0ad/US07166722-20070123-D00002.png)

![N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-n'-(5-methyl-3-isoxazolyl)urea salt in crystalline form N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-n'-(5-methyl-3-isoxazolyl)urea salt in crystalline form](https://images-eureka.patsnap.com/patent_img/8400b924-c92b-4129-ae50-afc08a5ed0ad/US07166722-20070123-D00003.png)

![N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-n'-(5-methyl-3-isoxazolyl)urea salt in crystalline form N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-n'-(5-methyl-3-isoxazolyl)urea salt in crystalline form](https://images-eureka.patsnap.com/patent_img/99fe836a-c7b0-446b-bdcd-625d9849cbcb/US20060052415A1-20060309-D00000.png)

![N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-n'-(5-methyl-3-isoxazolyl)urea salt in crystalline form N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-n'-(5-methyl-3-isoxazolyl)urea salt in crystalline form](https://images-eureka.patsnap.com/patent_img/99fe836a-c7b0-446b-bdcd-625d9849cbcb/US20060052415A1-20060309-D00001.png)

![N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-n'-(5-methyl-3-isoxazolyl)urea salt in crystalline form N-{2-chloro-4-[(6,7-dimethoxy-4-quinolyl)oxy]phenyl}-n'-(5-methyl-3-isoxazolyl)urea salt in crystalline form](https://images-eureka.patsnap.com/patent_img/99fe836a-c7b0-446b-bdcd-625d9849cbcb/US20060052415A1-20060309-D00002.png)