Battery cell blanking clamping mechanism

A clamping mechanism and cell technology, used in circuits, electrical components, secondary batteries, etc., can solve the problems of large circumferential space for rolling needles, easy to drive the inner diaphragm, and small clamping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

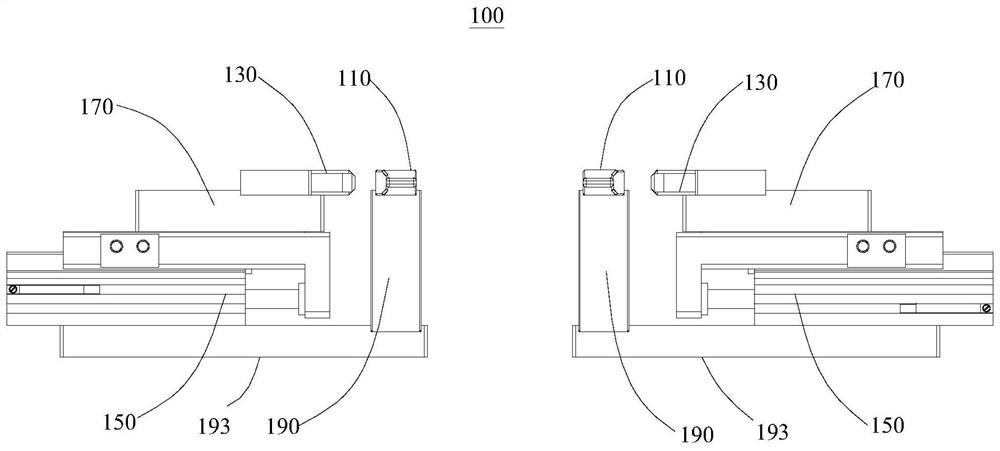

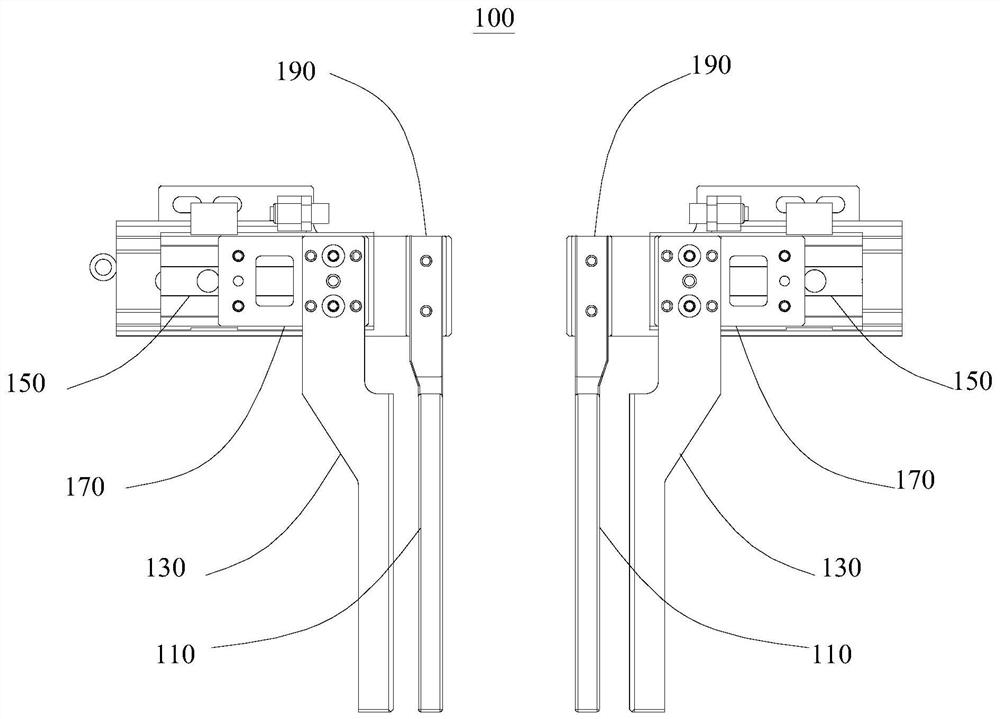

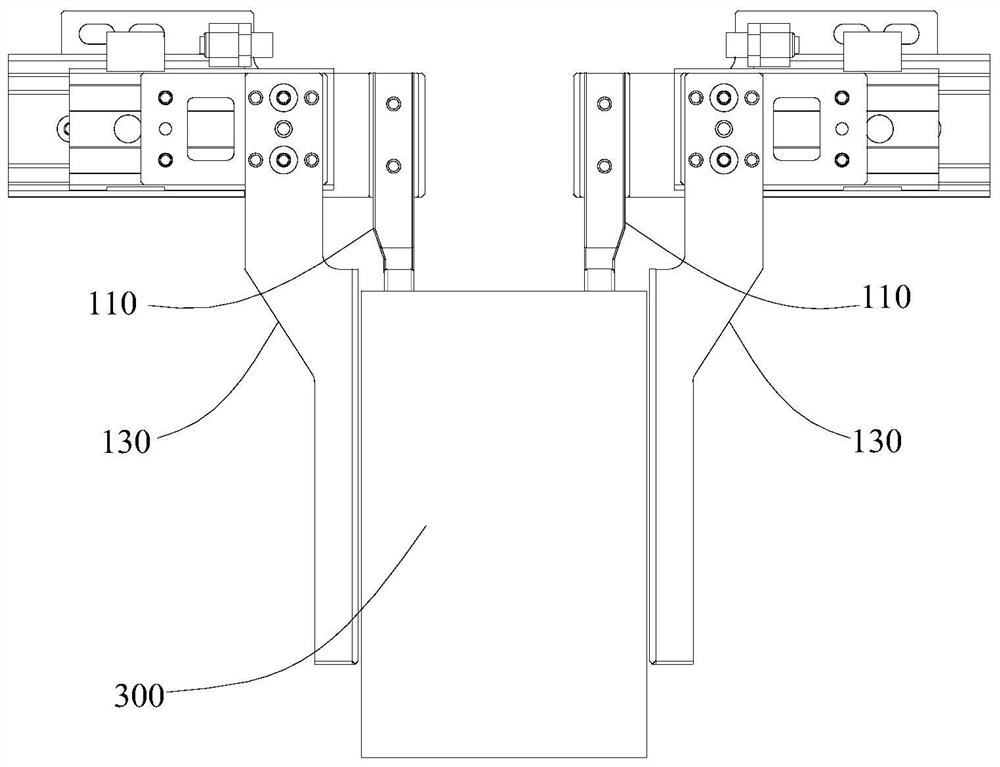

[0034] Join in Figure 1 to Figure 6 , this embodiment provides a cell blanking clamping mechanism 100, which has good clamping effect, is not easily deformed, and occupies a small space, so that the space reserved on the needle winding mechanism 210 is relatively small, so that the cell 300 can be wound. During the cutting process, the inner diaphragm pole piece is not easy to collapse, and the contact area between the clamping roller and the arc surface of the battery cell 300 is relatively small, and the clamping force per unit area is large.

[0035] The cell blanking and clamping mechanism 100 provided by the present invention includes an inner clamping plate 110, an outer clamping plate 130 and a clamping driving mechanism 150. The inner clamping plate 110 and the outer clamping plate 130 are arranged opposite to each other, and the clamping driving mechanism 150 is simultaneously connected with the inner clamping plate 110 and the outer clamping plate 150. The splint 13...

no. 2 example

[0056] see Figure 7 , this embodiment provides a winding device 200, including a needle rolling mechanism 210 and a cell blanking and clamping mechanism 100, wherein the cell blanking and clamping mechanism 100, wherein the basic structure of the cell blanking and clamping mechanism 100 and The principle and the resulting technical effects are the same as those of the first embodiment. For a brief description, for the parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0057] In this embodiment, the cell blanking and clamping mechanism 100 includes an inner clamping plate 110, an outer clamping plate 130 and a clamping driving mechanism 150. The inner clamping plate 110 and the outer clamping plate 130 are disposed opposite to each other, and the clamping driving mechanism 150 is simultaneously connected with the inner clamping plate 110. It is drivingly connected with the outer clamping plate 130 to drive the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com