Non-rigid shaft combined machining device

A combined processing, non-rigid technology, applied in the field of mechanical processing, can solve the problems of high requirements for workpiece processing equipment, undemanding processing accuracy, time-consuming and labor-intensive, etc., to achieve stable surface residual stress and microstructure changes, improve accuracy and production efficiency, The effect of reducing the spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

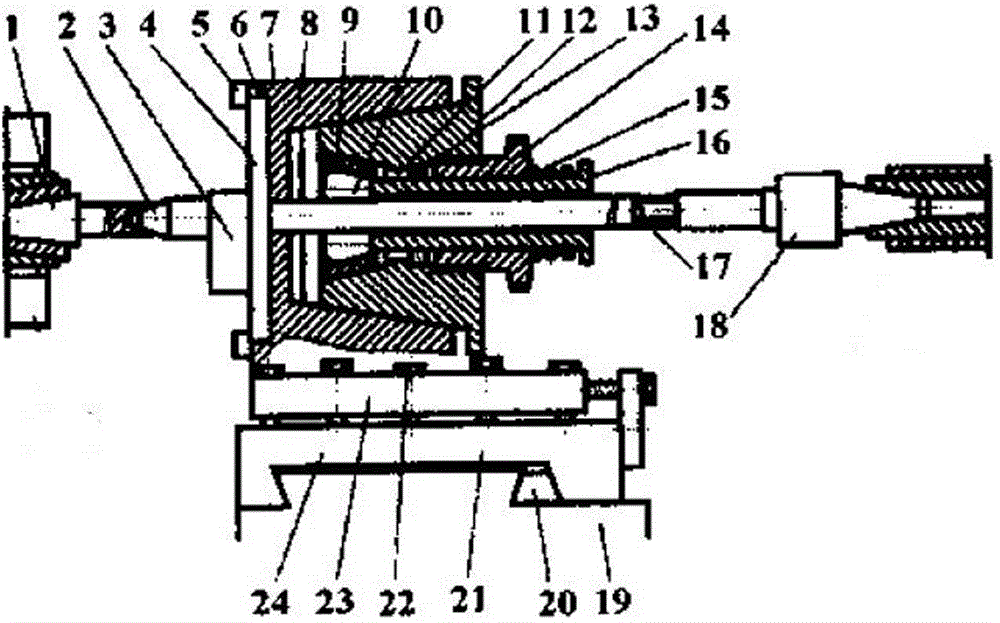

[0010] The non-rigid shaft combination processing device of the present invention includes a base plate 24 fixed on the lathe tool rest 19 through a wedge 20, and a base plate 23 is fixedly connected to the base plate 24 through a fastening screw 22 and an adjustment screw 21. The base plate 23 is connected to There is a processing head 7 and a machine body 8. A top is arranged on the two end faces corresponding to the processing head, which are respectively a front top 1 and a rear top 18. A guide sleeve is arranged on the front top 1 and the rear top 18, respectively. It is the front guide sleeve 2 and the rear guide sleeve 17, one end of the body 8 is provided with a guide rail 6, the guide rail 6 is connected with a knife seat 4 by a compactor 5, and a boss 3 is arranged on the knife seat 4, the The other end of the body 8 is provided with a tapered hole. A deformation device is arranged in the taper hole of the body 8, and the deformation device includes a deformation bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com