Meanwhile, adhesion force and friction force are enhanced

A biomimetic composite structure and friction technology, applied in the field of biomimetic materials, can solve the problems of easy wear and damage, unfavorable strong friction, etc., and achieve the effects of improving applicability, realizing solid-solid contact, and facilitating deformation and bending.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

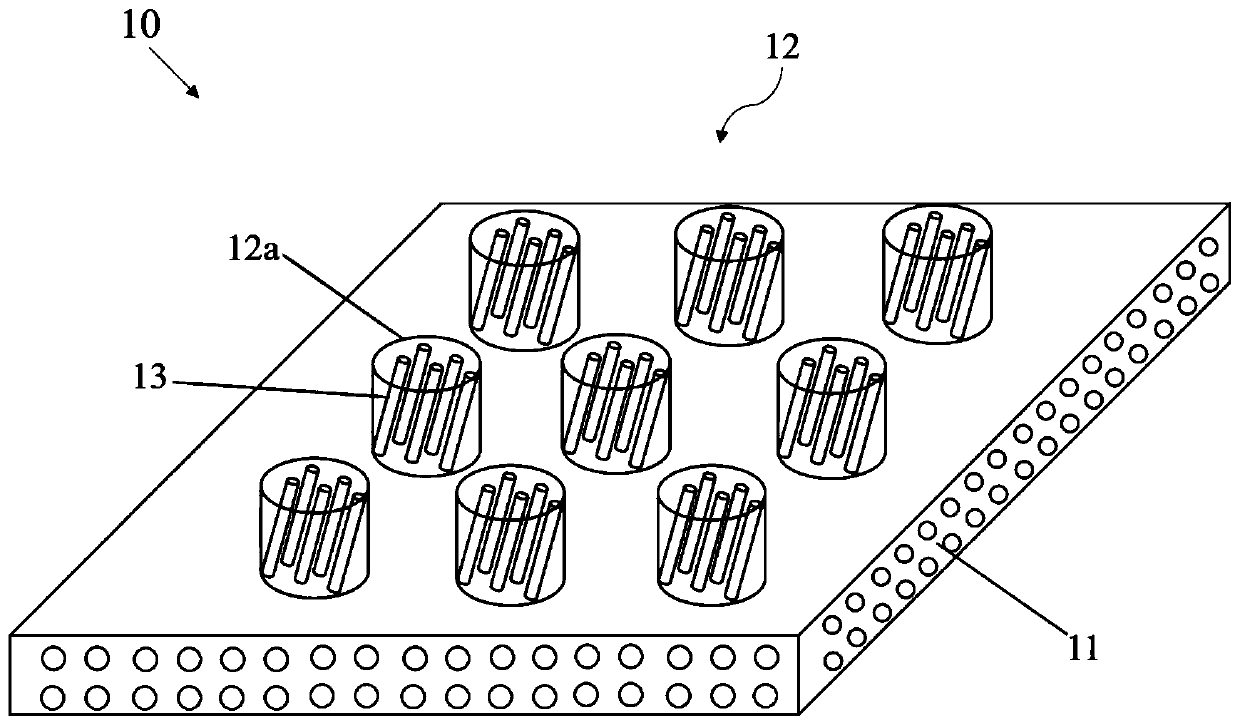

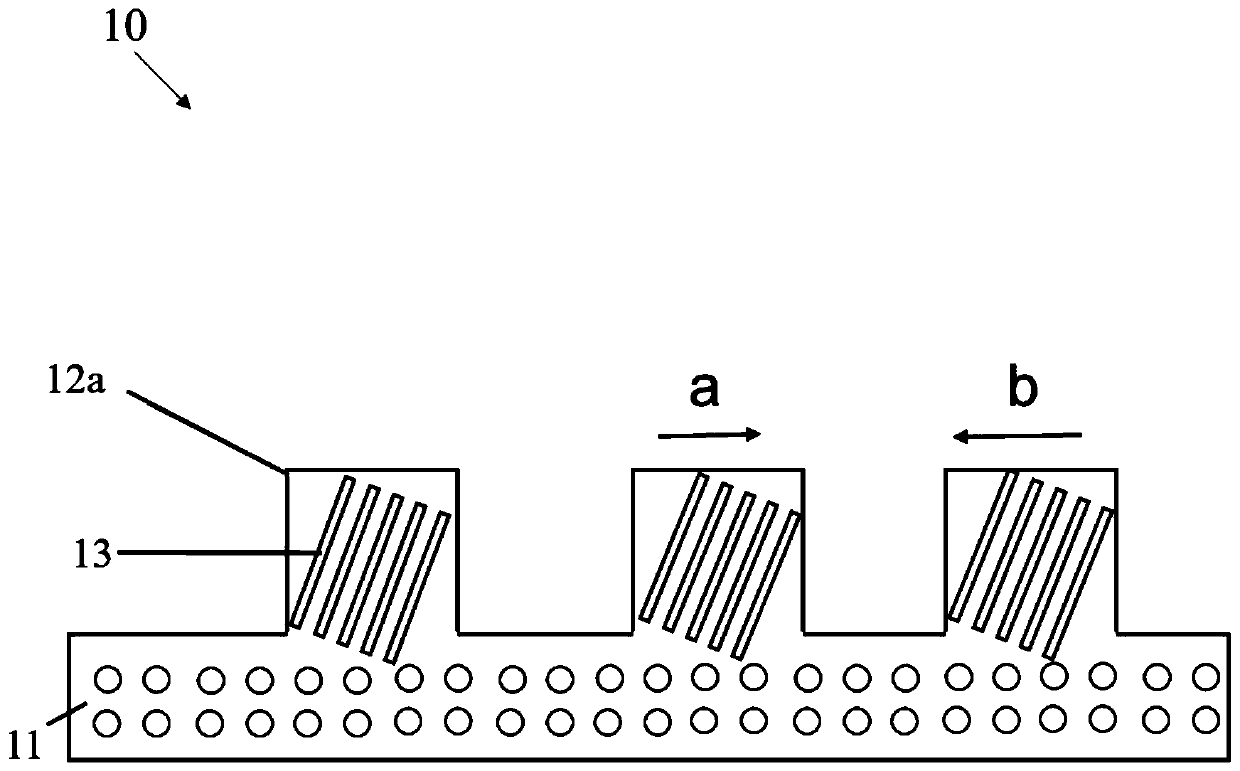

[0033] Such as figure 1 with 2 As shown, the biomimetic composite structure 10 that enhances both adhesion and friction provided by this embodiment includes a support layer 11 , a column array 12 and a micro-nano reinforcement 13 .

[0034] The support layer 11 has a porous structure, and the holes are aligned vertically and horizontally, and each hole is circular with a diameter of about 20 microns. In this embodiment, the supporting layer 11 is made of silicon rubber material.

[0035] The pillar array 12 is formed on the supporting layer 11, and includes pillars 12a arranged in an array and having soft elasticity. In this embodiment, the cylinder array 12 is stacked in a square, and each cylinder 12a has a diameter of 50 microns and a height of 50 microns, and the axial direction of the cylinders 12a is perpendicular to the support layer 11, and the distance between adjacent cylinders 12a is 10. Micron, cylinder 12a adopts silicon rubber material.

[0036] The micro-nan...

Embodiment 2

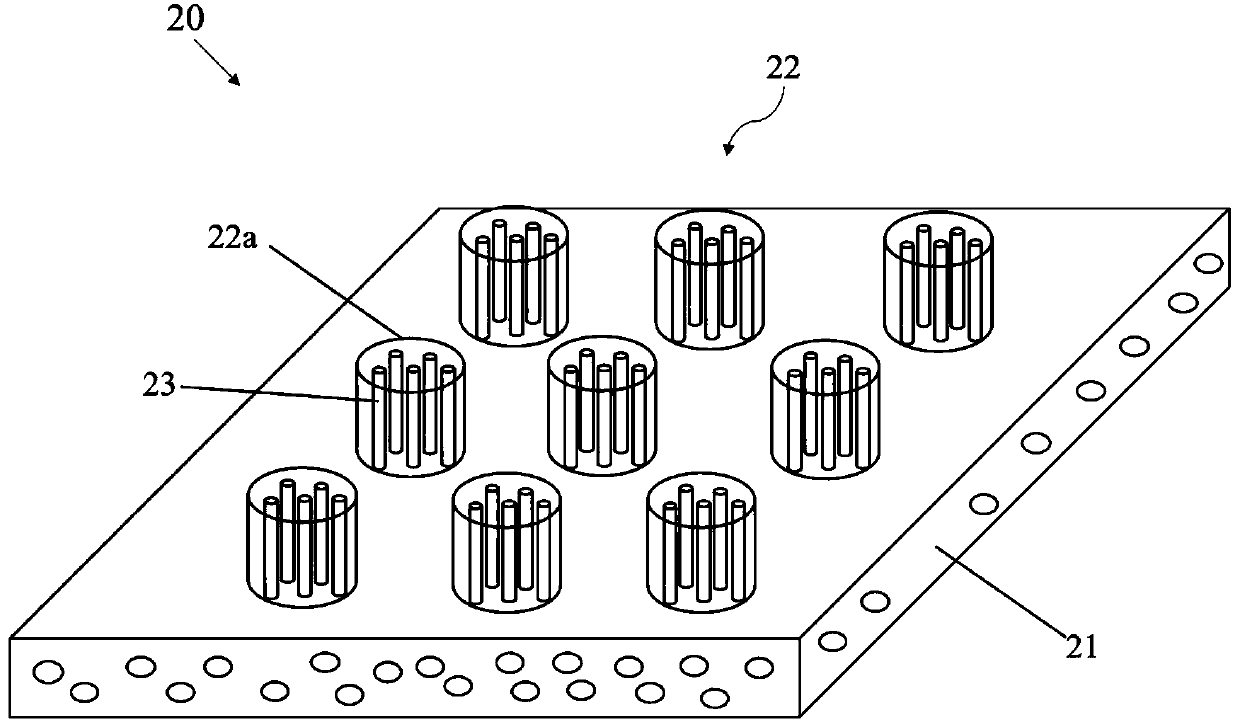

[0046] Such as figure 2 with 3 As shown, the biomimetic composite structure 20 that enhances both adhesion and friction provided by this embodiment includes a support layer 21 , a column array 22 and a micro-nano reinforcement 23 .

[0047] The support layer 21 has a porous structure, and the holes are aligned vertically and horizontally, and each hole is circular with a diameter of about 20 microns. In this embodiment, the supporting layer 21 is made of silicon rubber.

[0048] The pillar array 22 is formed on the supporting layer 21, and includes pillars 22a arranged in an array and having soft elasticity. In this embodiment, the cylinder array 22 is stacked in a square, and each cylinder 22a has a diameter of 50 microns and a height of 50 microns, and the axial direction of the cylinders 22a is perpendicular to the support layer 21, and the distance between adjacent cylinders 22a is 10. Micron, cylinder 22a adopts silicon rubber material.

[0049] The micro-nano reinfo...

Embodiment 3

[0059] Such as Figure 5 with 6 As shown, the biomimetic composite structure 30 that enhances both adhesion and friction provided by this embodiment includes a support layer 31 , a column array 32 and a micro-nano reinforcement 33 .

[0060] The support layer 31 has a porous structure, and the pores are arranged randomly, and each hole is circular with a diameter of about 20 microns. In this embodiment, the supporting layer 31 is made of silicon rubber.

[0061] The post array 32 is formed on the support layer 31 and includes a plurality of soft elastic posts 32a arranged in an array. In this embodiment, the cylinder array 32 is stacked in a square, and each cylinder 32a has a diameter of 50 microns and a height of 50 microns, and the axial direction of the cylinders 32a is perpendicular to the support layer 31, and the distance between adjacent cylinders 32a is 10. Micron, cylinder 32a adopts silicon rubber material.

[0062] The micro-nano reinforcement 33 is embedded in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction | aaaaa | aaaaa |

| friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com