Rotary screw drill tool

A technology of screw drilling tools and casings, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of unsatisfactory use effect of hydraulic impactors, low rock breaking efficiency and mechanical penetration rate, etc. The effect of rock efficiency, improving service life, improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

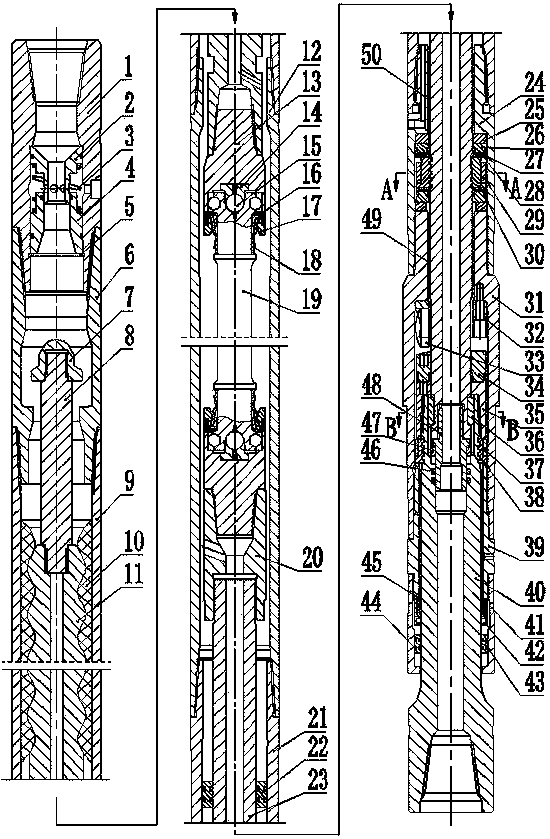

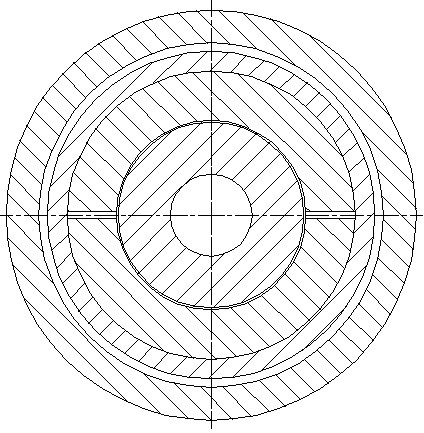

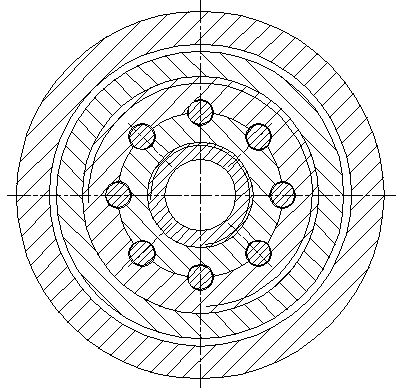

[0013]According to the drawings, a rotary punching screw drilling tool consists of a bypass valve housing, a valve core, a spring, a valve body, a retaining ring, an anti-drop joint, an anti-drop nut, an anti-drop connecting rod, a motor housing, Stator, rotor, cardan shaft housing, living hinge, cardan shaft connecting rod, adapter, outer housing, floating piston, upper shaft body, bearing housing, anti-wear washer, jumping pad, rubber washer, compensation box, upper gear ring, upper sub-ring, cam housing, roller seat, roller, cam, cam seat, spline pin, lower retaining ring, lower sub-ring, bottom piston housing, lower shaft body, lower housing, sealing box, floating ring , an impact plate, and an impact nozzle, and is characterized in that the shell part, the bypass valve housing 1, the anti-drop joint 6, the motor housing 9, the cardan shaft housing 12, the outer housing 21, the bearing housing 24, and the cam housing 31. The bottom piston housing 39 and the lower housing 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com