Self-advancing type high-pressure jet sprayer for radial horizontal well drilling

A high-pressure jet, self-propelled technology, applied in the direction of drilling with liquid/gas jets, etc., can solve the problems of high cost and poor economy of sidetracking horizontal well technology, and achieve the effect of simple structure, reliable operation and reduction of forward resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

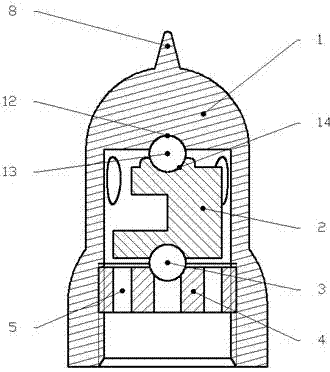

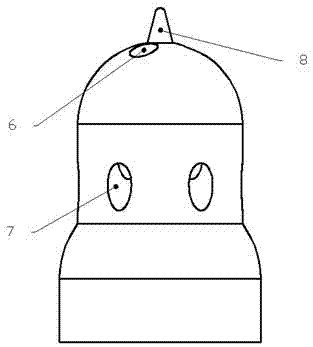

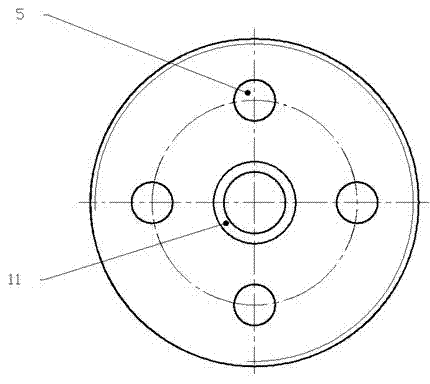

[0012] according to Figure 1~Figure 4 As shown, a self-propelled high-pressure jet nozzle for radial and horizontal well drilling mainly includes a housing 1, a turbine rotor 2, an upper wear-resistant steel ball 13, a lower wear-resistant steel ball 3, and a baffle 4. Its technical features are: the shell 1 is processed with a top 8, 3~6 forward nozzles 6 with a diameter of 3~7mm and 3~6 backward nozzles 7 with a diameter of 3~7mm, of which the forward nozzle 6 The number is less than the number of backward nozzles 7, the front and rear nozzles have the same diameter, and the outer surface of the casing 1 is welded with hard alloy to improve wear resistance; the inside of the casing 1 is equipped with a turbine rotor 2, and the upper end of the turbine rotor 2 is processed with a Spherical groove 14, the lower end is uniformly processed with turbine blade 9 and a spherical groove 10 along the circumference, its body is a semi-cylindrical structure, positioned by two upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com