Method and apparatus for production of homogeneous needle coke

A preparation device and technology of needle coke, which is applied in the field of preparation of high-quality needle coke with uniform quality, can solve the problems of undeveloped small spheres and unfavorable high-quality needle coke, so as to avoid the increase of system viscosity and the promotion of low-viscosity environment , The effect of low CTE

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

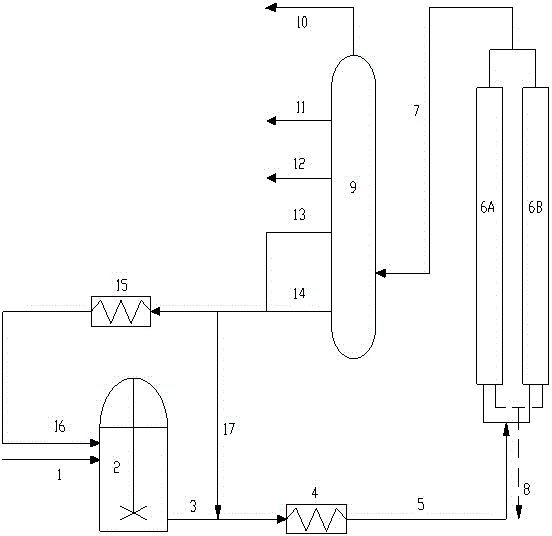

Method used

Image

Examples

Embodiment 1

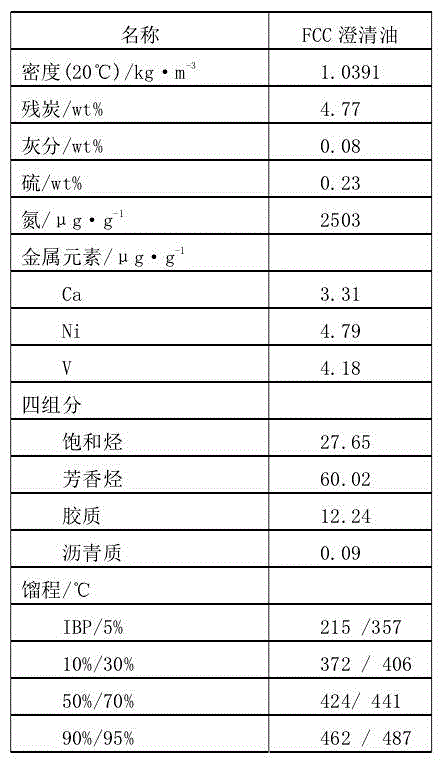

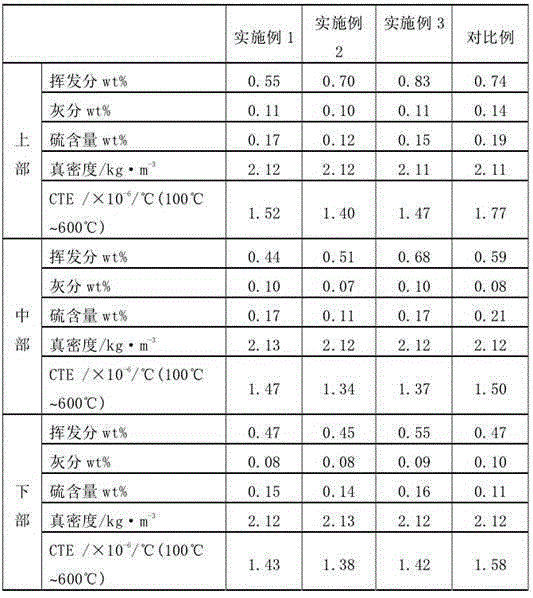

[0042] The operation according to the method provided by the present invention is divided into three steps: (1) Preheat the raw material to 385°C and put it into a stirred pretreatment reactor, which has the functions of weight measurement and display. The pretreatment reaction kettle has a treatment temperature of 385°C, a pressure of 1.2MPa, and a stirring rate of 250r / min. After 1 hour of treatment, the bottom of the kettle starts to discharge materials. The furnace adopts variable temperature control, the initial temperature is 440°C and is maintained for 6 hours, then the temperature is raised to 470°C at a constant speed within 10 hours and maintained for 4 hours, and the pressure of the delayed coking tower is 1.5MPa; (2) When the constant temperature of the coking heating furnace is 440°C, the fractionation system is separated After the heavy distillate oil is heated to 390°C by the preheating furnace, it is injected into the pretreatment reactor at one time. The weight...

Embodiment 2

[0044] Using the same method as in Example 1, changing part of the operating conditions: (1) Preheating the raw materials and putting them into a stirred pretreatment reactor with weight measurement and display functions. The pretreatment reaction kettle has a treatment temperature of 395°C, a pressure of 0.5MPa, and a stirring rate of 250r / min. After 0.5 hours of treatment, the bottom of the kettle starts to discharge materials. The heating furnace adopts variable temperature control, the initial temperature is 425°C and is kept for 8 hours, then the temperature is raised to 475°C at a constant speed within 12 hours and kept for 4 hours, and the pressure of the delayed coking tower is 1.5MPa; (2) When the constant temperature of the coking heating furnace is 425°C, the fractionation system After the separated heavy distillate oil is heated to 400°C by the preheating furnace, it is injected into the pretreatment reactor at one time. The weight ratio of the heavy distillate oil ...

Embodiment 3

[0046] Using the same method as in Example 1, only part of the operating conditions were changed. Among them, the treatment temperature of the pretreatment reactor is 365°C, the pressure is 2.0MPa, and the stirring rate is 400r / min. After 20 hours of treatment, the bottom of the kettle starts to discharge. The operating conditions of the coking furnace are that the first stage of constant temperature is at 420°C for 9 hours; the first stage of temperature rise is at a rate of 2°C / h to 460°C; the second stage of constant temperature is at 460°C for 3 hours ;The second stage of heating adopts a rapid heating method, the heating rate is 60 / h, and the temperature is raised to 490°C; the third stage of constant temperature is 490°C for 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com