Electric automobile chassis calculus battery pack

A technology for electric vehicles and battery packs, applied in battery pack components, secondary batteries, electric power devices, etc., can solve the problems of inconvenient disassembly and assembly of battery packs, increase the difficulty of maintenance, and increase maintenance costs, so as to facilitate the production of modules. The effect of convenient control and management, and convenient final assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

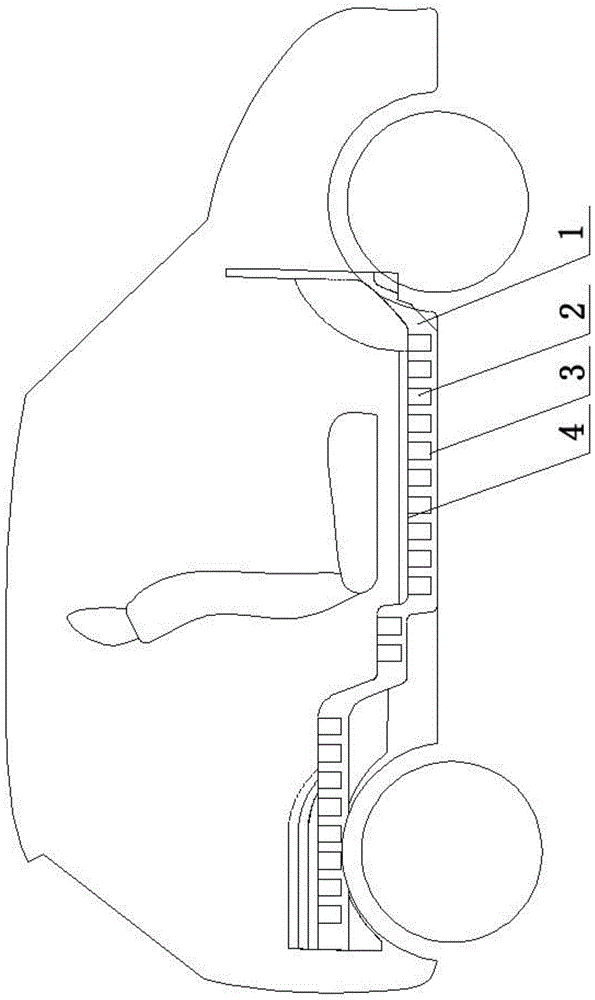

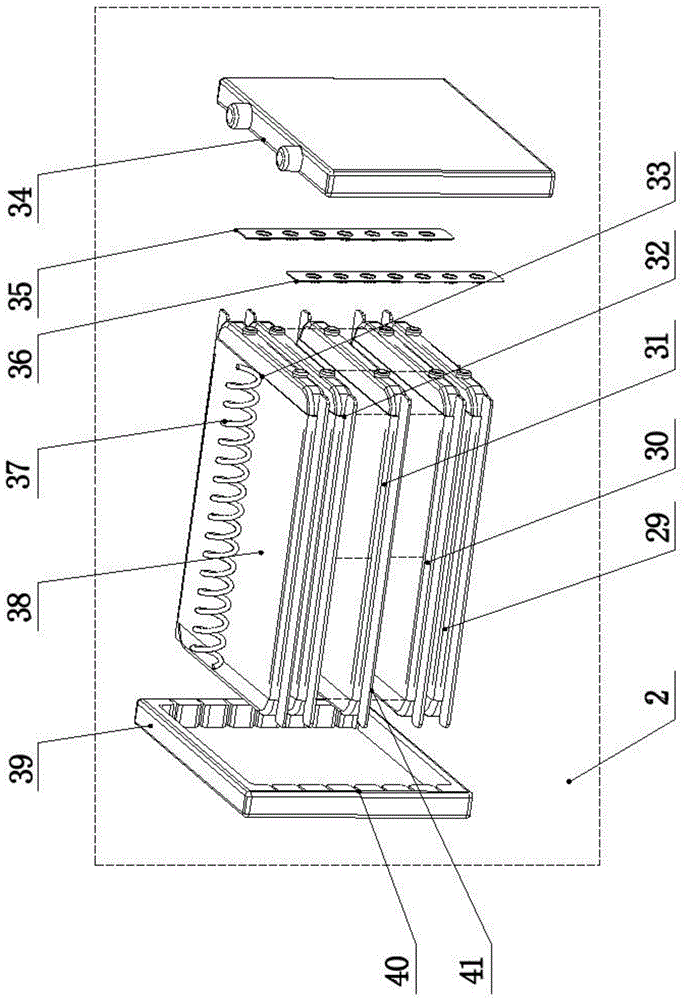

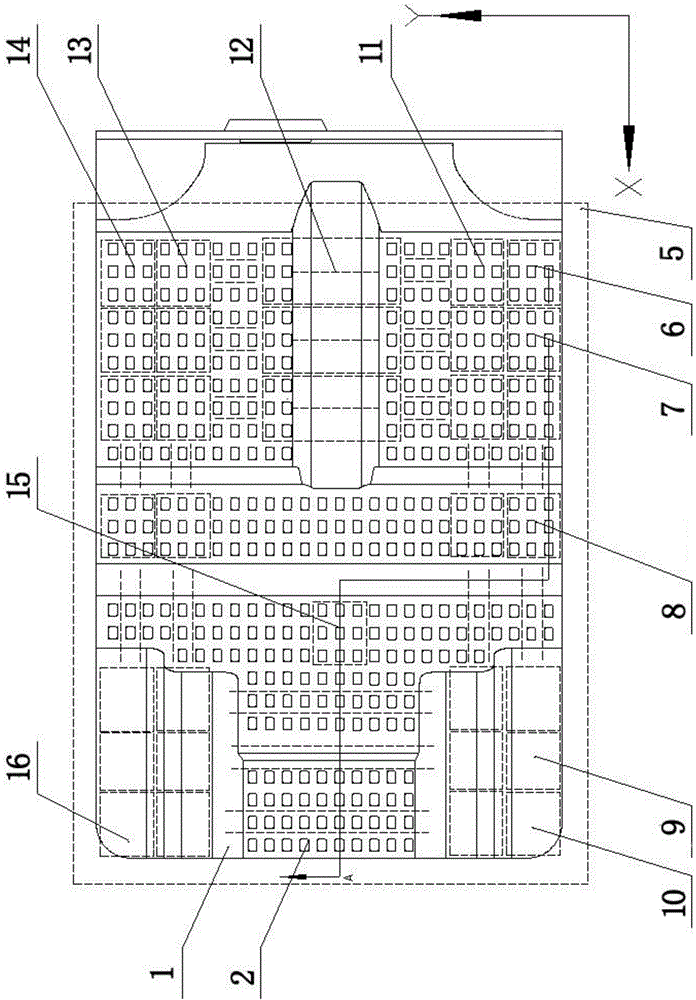

[0021] Now in conjunction with accompanying drawing, the present invention will be further described:

[0022] Such as figure 1 and figure 2 As shown, a kind of electric vehicle chassis 1 calculus battery pack of the present invention comprises chassis 1, and the upper plane of chassis 1 is provided with battery installation groove 3, and battery installation groove 3 is installed with calculus battery monomer 2, and calculus battery Cell 2 consists of overlapping battery cells E 1 29, battery cell E 2 30, ..., battery cell E i 31, ..., battery cell E (n-1) 32, battery cell E n 33 components, each battery cell E i 31 is covered by a heat conduction sheet 38, and each battery cell E i One end of 31 is provided with positive and negative electrodes, and the battery cell E i The positive electrodes of 31 are connected in parallel through the positive electrode plate 35, the negative electrodes are connected in parallel through the negative electrode plate 36, and the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com