Gripper and cross-member having at least one gripper

A technology for grabbers and hanging beams, applied in the field of grabbers and hanging beams with at least one grabber, can solve problems such as heavy load damage, reduce space volume, reduce damage potential, reduce The effect of small shipping costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

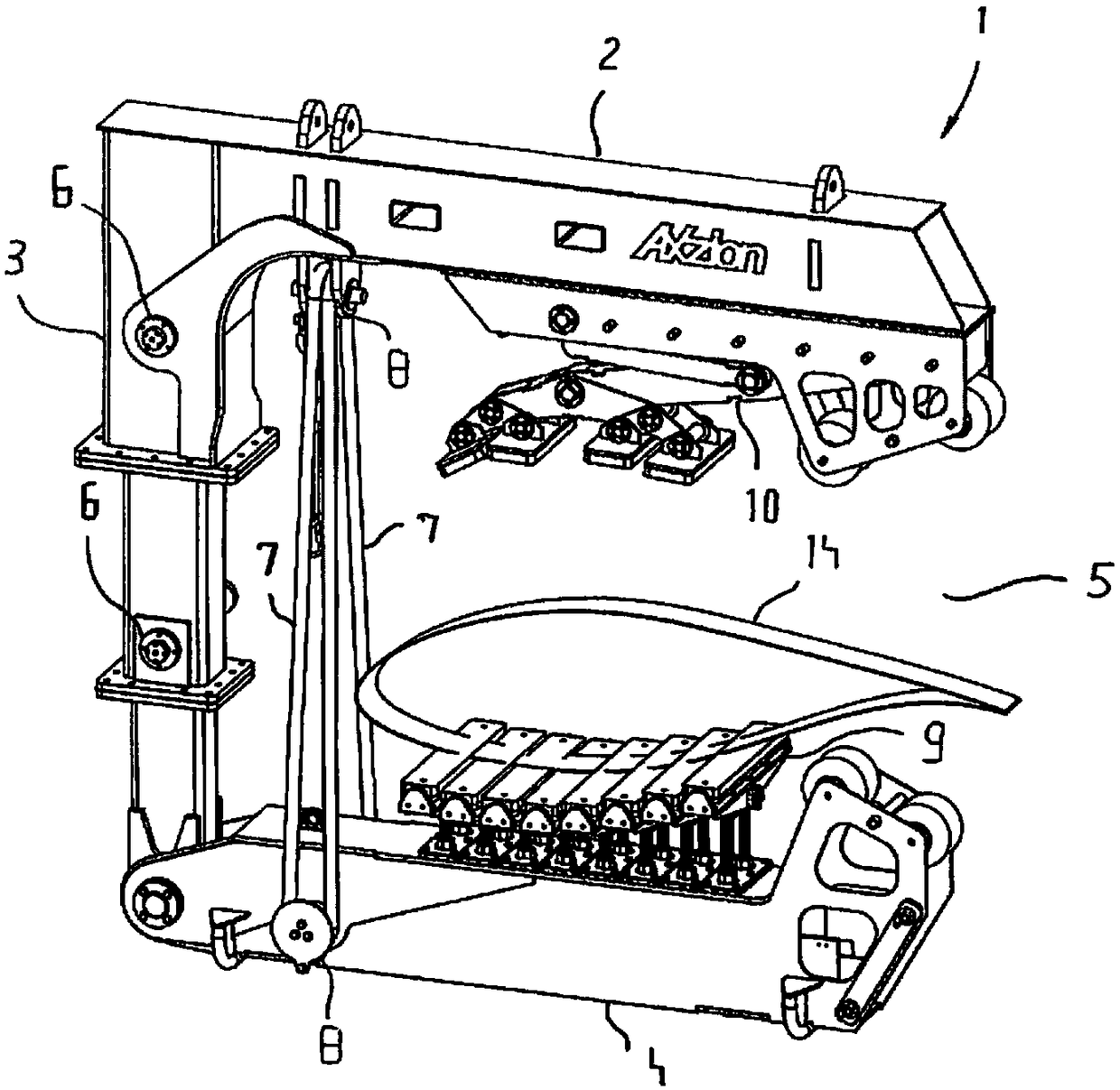

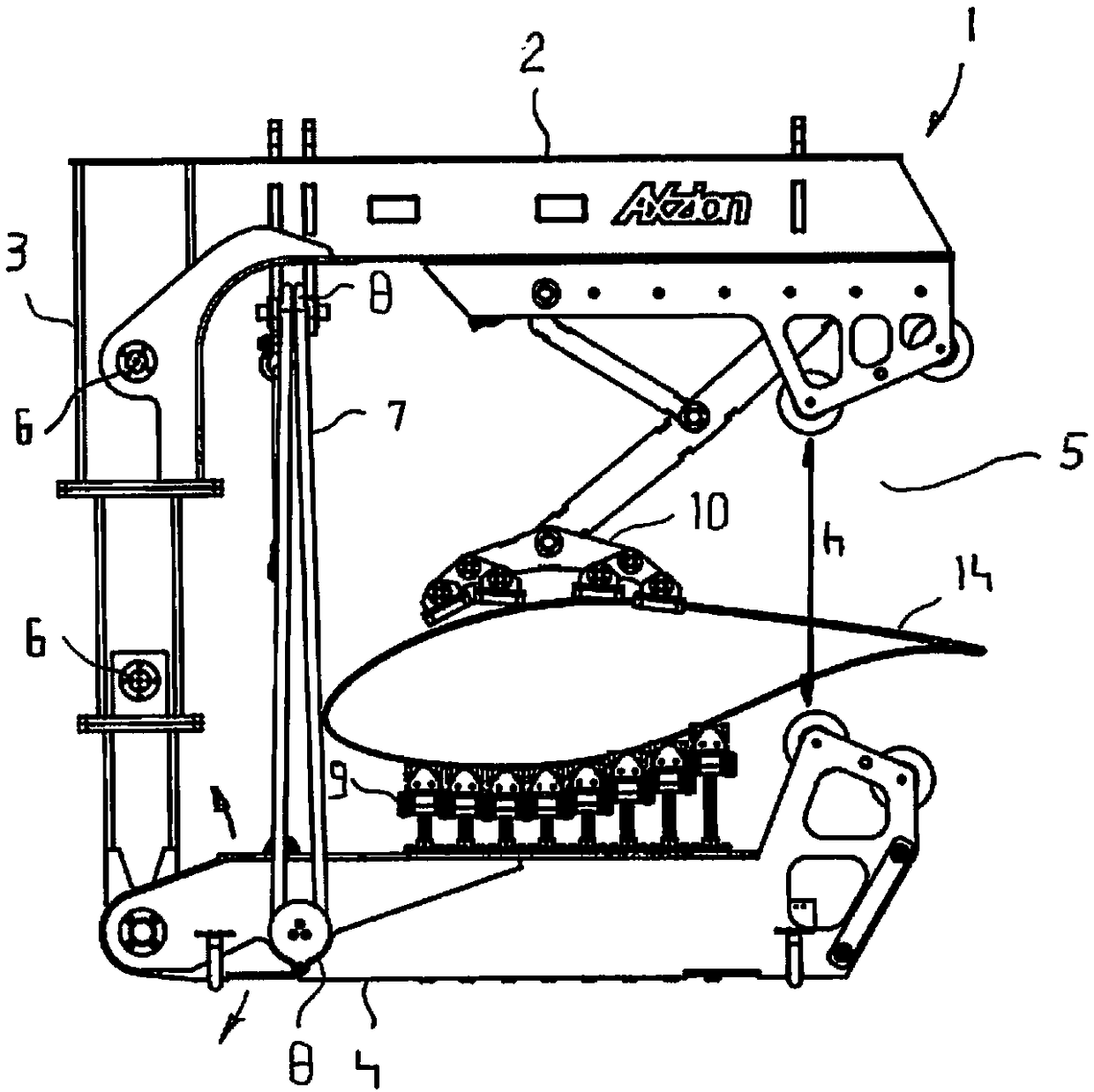

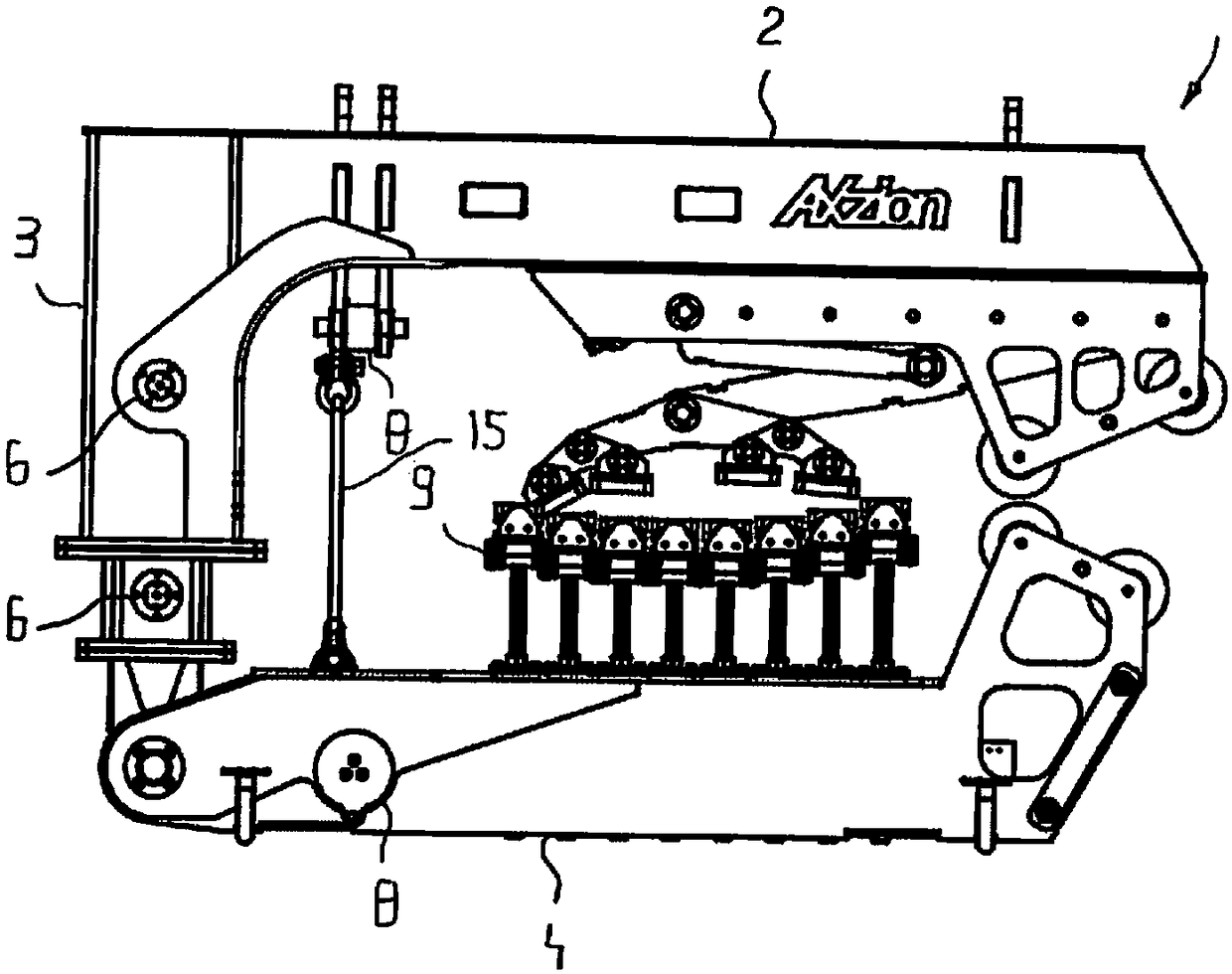

[0025] exist figure 1 The C-shaped gripper 1 is seen in the figure, which can be arranged at the suspension beam 11. The C-grabber 1 consists of an upper support 2 , a vertical support 3 and a brace support 4 . The cradle support 4 has a plurality of cradle sections 9 and forms a so-called hook base onto which a lifting load 14 can be placed. The upper support 2 and the vertical support 3 are rigidly connected to each other as in conventional design structures and are arranged at right angles to each other. The support support 4 is not rigidly connected to the vertical support 3 in a rotatably supported manner, to be more precise in such a way that the opening of the C-shaped gripper 1 has a clean Dimension (h) can be changed, for example can be enlarged or reduced. The brace support 4 is thus pivotable, which in figure 2 identified by arrows. Furthermore, the vertical support 3 is telescopic, in the embodiment double telescopic.

[0026] The locking of the telescoping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com