A three-axis hybrid drive robotic arm

A hybrid drive and robotic arm technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of clumsy movement, complex mechanism, low transmission efficiency, etc., and achieve the effect of dexterous movement, high transmission efficiency, and smooth movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

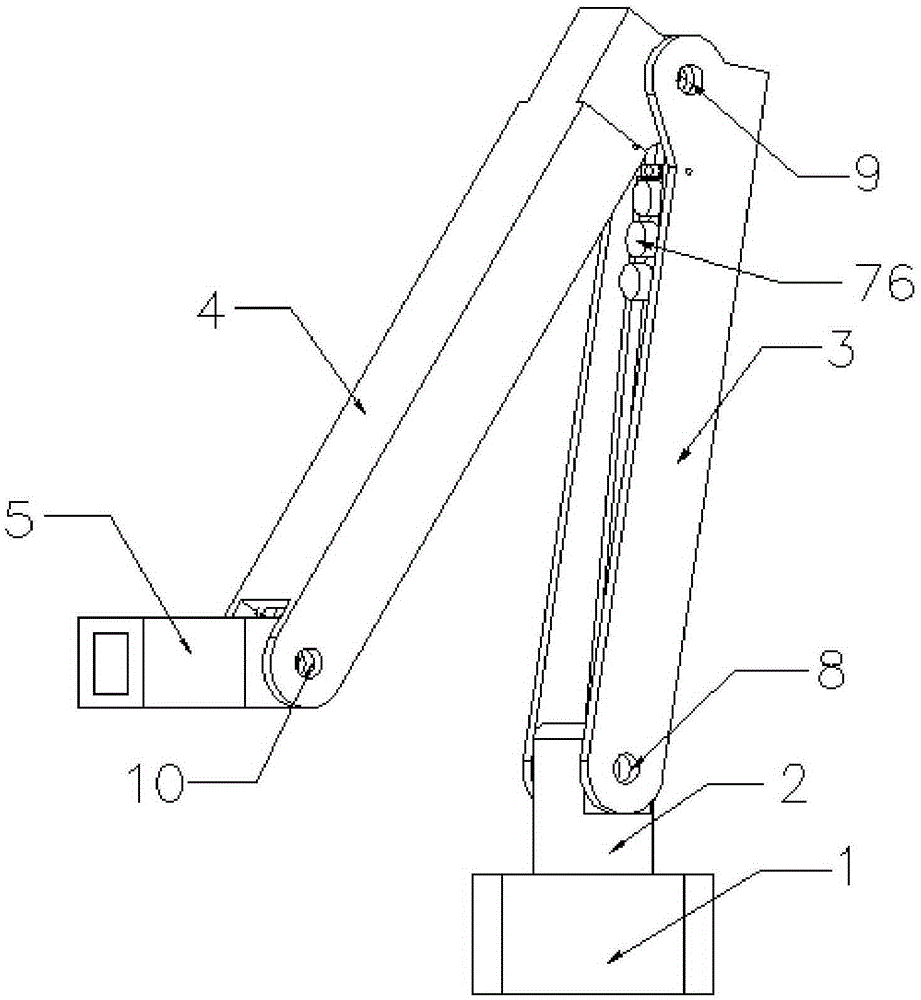

[0020] Refer to the attached figure 1 -5 further illustrate the present invention:

[0021] The three-axis hybrid drive mechanical arm of the present invention includes a base 1, a support 2, a rear arm 3, a forearm 4, and a palm 5, and is characterized in that the support 2 is hinged around the vertically upward first axis On the base 1, the lower end of the rear arm 3 is hinged on the support 2 around the second horizontal axis 8, and the upper end of the front arm 4 is hinged on the rear arm 3 around the third axis 9 , the lower end of the forearm 4 is hinged to the palm 5 around the fourth axis 10, and the second axis 8, the third axis 9, and the fourth axis 10 are parallel to each other;

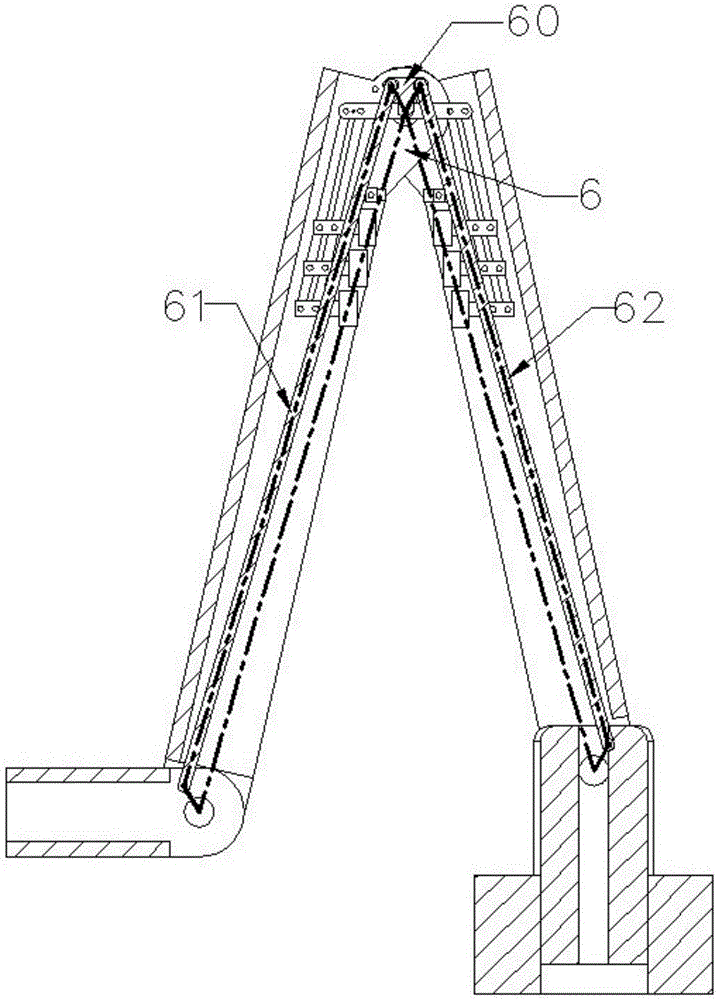

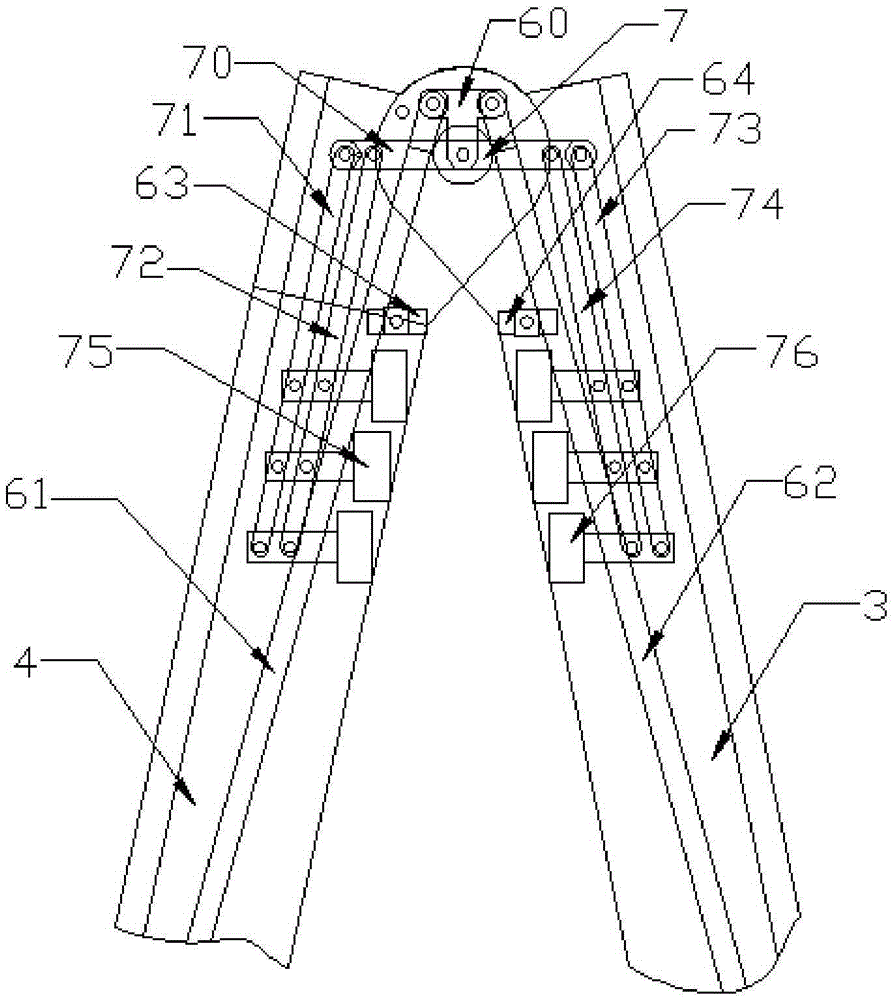

[0022] The palm 5 is connected to the first link mechanism, and the first link mechanism 6 includes a first intermediate link 60 whose middle part is hinged on the third shaft 9, a forearm link 61 extending in the forearm 4, and a forearm link 61 extending in the forearm 4. The rear a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com