Flexible coupling of wind generator set and assembling or replacing method of flexible coupling

A technology for wind turbines and flexible couplings, which is applied in the direction of elastic couplings, couplings, clutches, etc., and can solve problems such as shortening maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

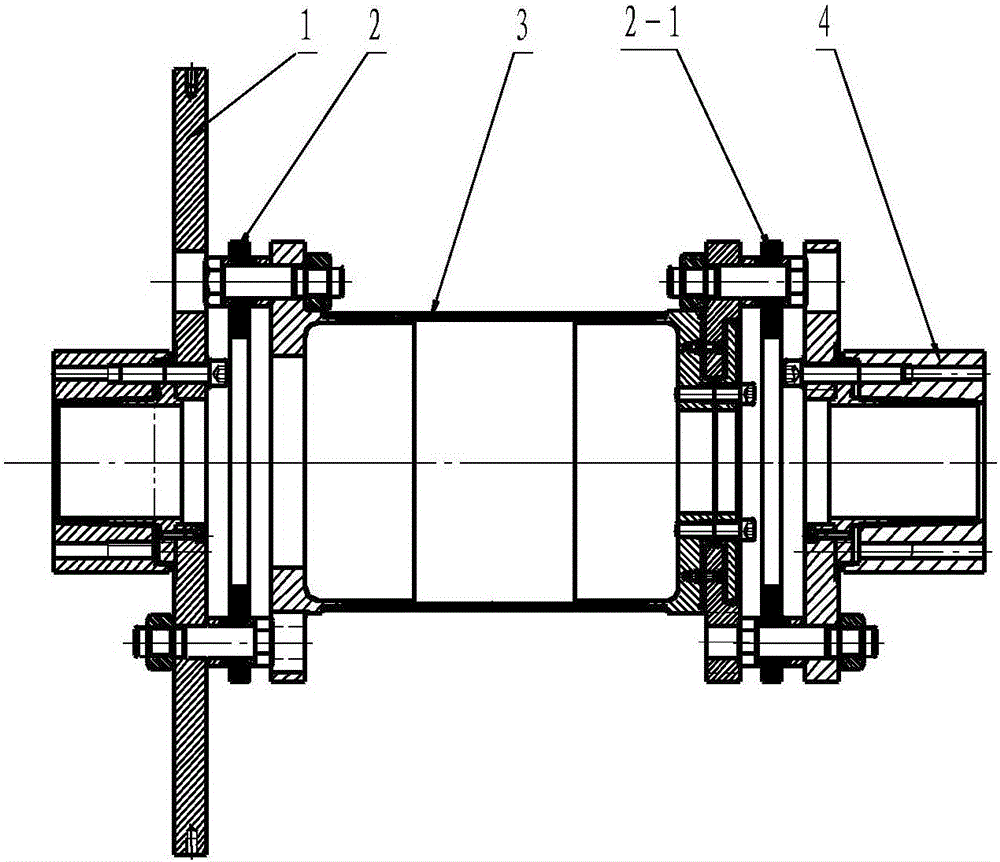

[0052]A flexible coupling for a wind power generating set, comprising a brake disc assembly 1, a left flexible coupling assembly 2, an intermediate coupling body assembly 3, a right flexible coupling assembly 2-1, and a generator side coupling assembly 4 is connected by a set of transmission bolts (see attached figure 1 );

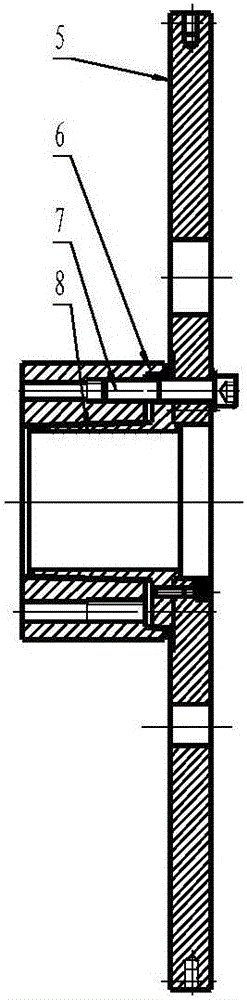

[0053] The brake disc assembly 1 (see attached figure 2 ) consists of brake disc 5, (keyless connection) outer taper sleeve 6, a set of connecting bolts 7, and (keyless connection) inner taper sleeve 8; (keyless connection) inner taper sleeve 8 is sleeved on (keyless connection ) inside the outer taper sleeve 6, a set of connecting bolts 7 fixedly connect the brake disc 5 and the outer taper sleeve 6;

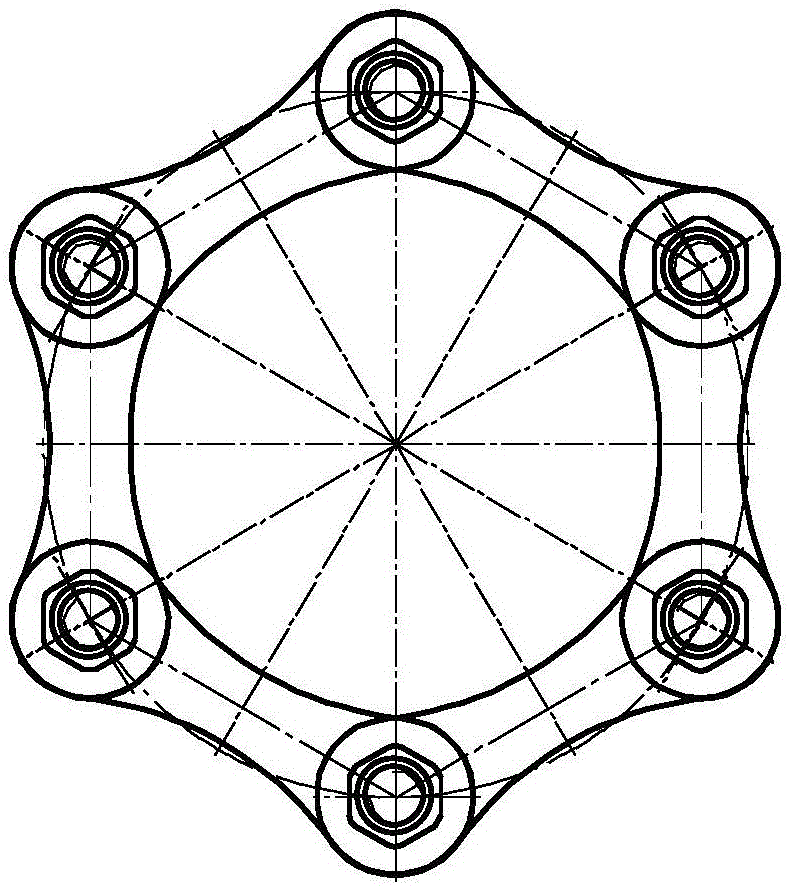

[0054] The left flexible link assembly 2 and the right flexible link assembly 2-1 (see attached image 3 and 4 ) are composed of a set (6 in total) of transmission bolts 9, a washer set 10, and a set of (6 in total) connecting pieces 11; A gasket set...

Embodiment 2

[0060] A flexible coupling for a wind power generating set, in the middle coupling body assembly 3, an annular metal inner friction plate 23 and a The annular non-metallic inner gasket 24 on the outer ring of the annular inner friction plate 23; material), the thickness (axial thickness) of the annular non-metallic inner gasket 24 is preferably greater than the thickness of the annular metal inner friction plate 23;

[0061] In the intermediate coupling body assembly 3, the annular metal inner friction plate 23 is an annular metal inner friction plate coated with lubricating oil (or called grease); the lubricating oil can also be coated on the coupling In the gap between the disc 14 and the right coupling disc 16; the lubricating oil is commercially available lubricating oil (preferably semi-solid lubricating oil) used for lubricating mechanical parts;

[0062] Others are the same as embodiment 1, omitted.

[0063] This embodiment can ensure the reliability and stability of ...

Embodiment 3

[0065] A flexible coupling for a wind power generating set. In the intermediate coupling body assembly 3, an annular metal outer friction plate 25 and a ring-shaped metal outer friction plate 25 are arranged between the coupling disc 14 and the pressure plate 17. An annular non-metallic outer washer 26 on the outer ring of the shaped metal outer friction plate 25; this annular non-metallic outer washer 26 is made of elastic, compressible non-metallic materials (for example: non-metallic materials such as plastics or rubber) material), the thickness (axial thickness) of the annular non-metallic outer gasket 26 is preferably greater than the thickness of the annular metal outer friction plate 25;

[0066] In the intermediate coupling body assembly 3, the annular metal outer friction plate 25 is an annular metal outer friction plate coated with lubricating oil (or grease); the lubricating oil can also be coated on the coupling In the gap between the disc 14 and the pressure plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com