High-pile wharf superstructure integrated construction equipment and construction method thereof

A technology of high-piled wharf and construction method, which is applied in basic structure engineering, water conservancy engineering, marine engineering and other directions, can solve the problems of large size of prefabricated components, difficult erection and low operation accuracy, etc., and achieves increased installation location and convenient transportation. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

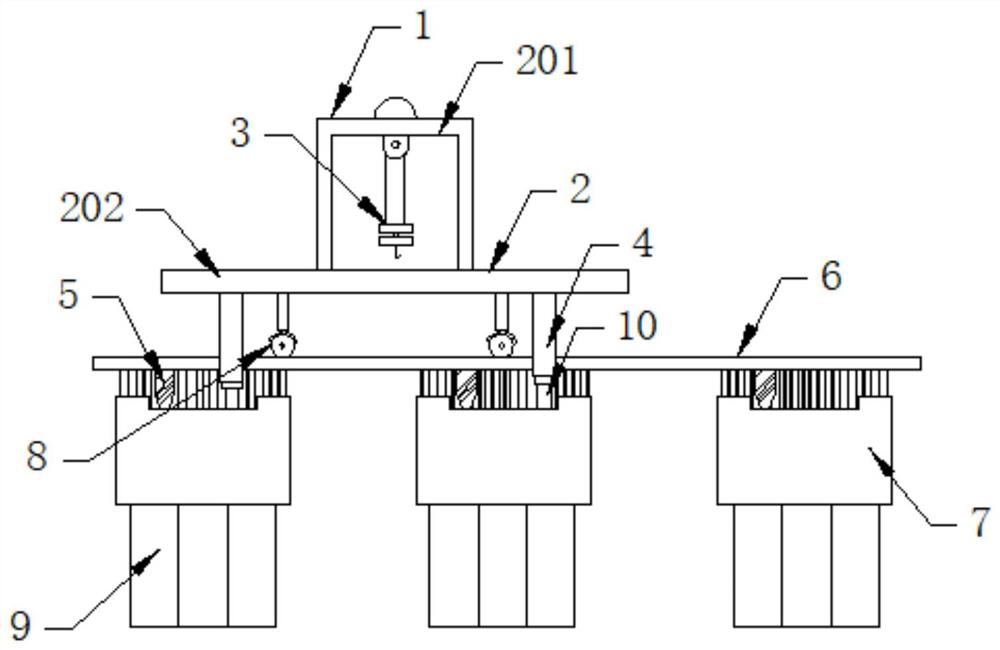

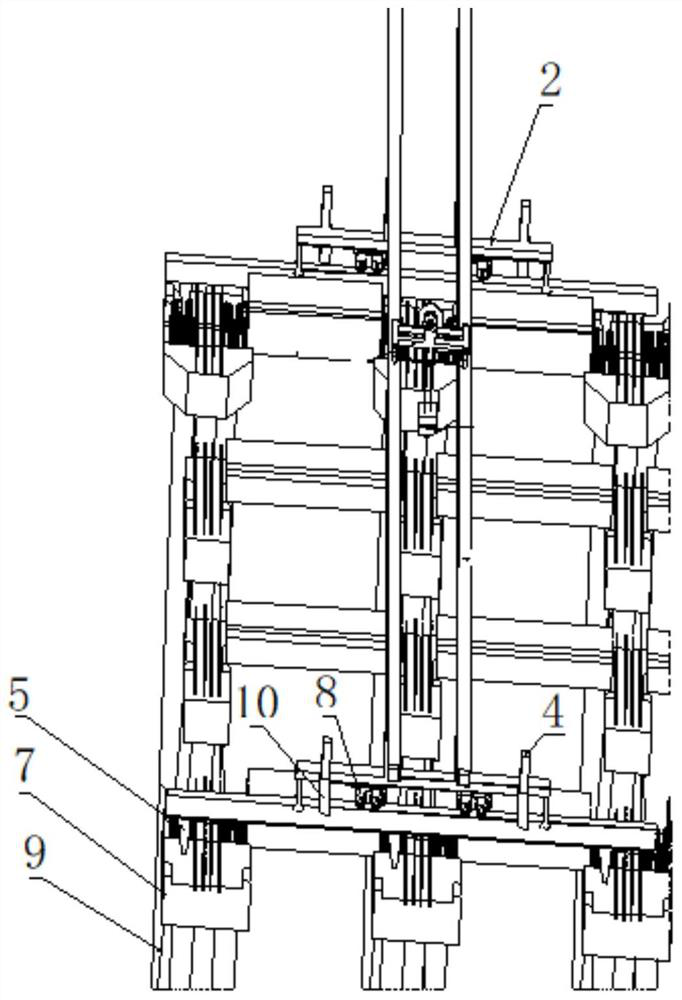

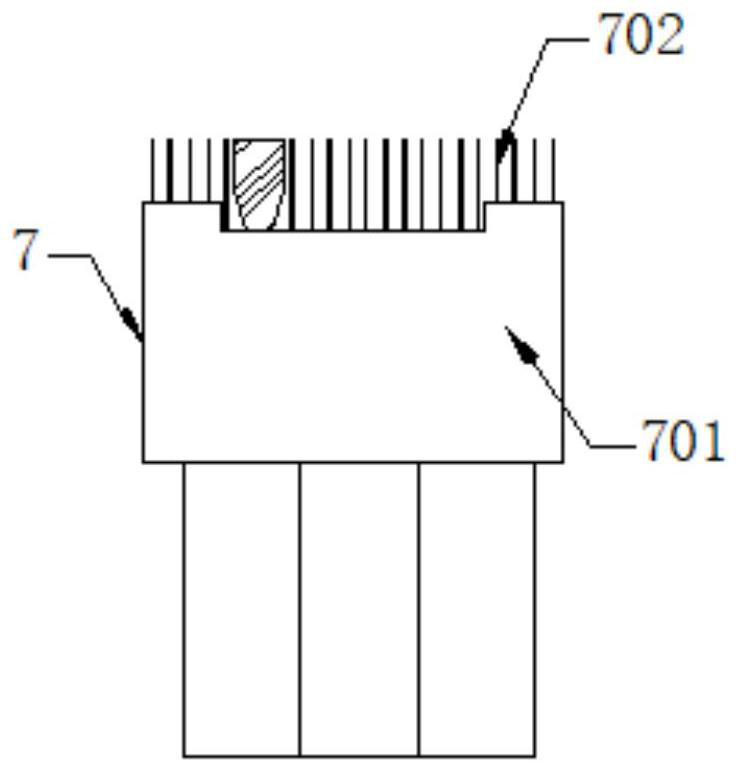

[0084] The integrated construction equipment is supported on the pile caps of the two rows of piles on the outermost side of the wharf through anchor support structures such as solid steel rods, thereby supporting the integrated construction equipment structure and reducing the length of the extension of the structure; through the reasonable arrangement of steel bars 702, Avoid the interference of the extended steel bar 702 of the pier pile cap on the solid steel bar; meanwhile, the fulcrum 5 of the track mechanism is located on the outside of the pile cap, so that the track 6 of the track mechanism and the gantry structure are staggered from the position of the longitudinal beam of the shaft, which is convenient for the installation of the longitudinal beam of the shaft. And on the fulcrum 5 of the track mechanism, the track mechanism track 6 spanning three bent frames is arranged, so as to realize the vertical movement of the integrated construction equipment along the wharf, ...

Embodiment 2

[0085] Embodiment 2, the beam installation steps include:

[0086] 1: Complete the conventional water-based pile sinking and pile cap pouring operations, and prefabricate beams and slabs in the prefabrication plant;

[0087] 2: Assemble integrated construction equipment on the two bent frames that have formed pile caps at the wharf;

[0088] 3: Transport the prefabricated beams and beams to the front of the wharf by water;

[0089] 4: The integrated construction equipment crane moves horizontally above the docked ship at the front of the wharf, lifts the beam and rotates it 90 to pass through the hole, and the crane transports it above the designed position for erection; complete the erection of all the components on the bent frame in turn beam;

[0090] 5: The integrated construction equipment crane traverses to the top of the docked ships at the front of the wharf, lifts the side beams, and lifts the side beams with cantilever beams;

[0091] 6: The integrated constructio...

Embodiment 3

[0092] Embodiment three, the longitudinal beam installation steps include:

[0093] Transport the prefabricated longitudinal girders and prefabricated longitudinal girders to the front of the wharf by water;

[0094] 1: The crane of the integrated construction equipment is moved longitudinally above the position of the designed longitudinal beam, so that the center of the integrated construction equipment and the center of the longitudinal beam are consistent in the longitudinal direction of the wharf;

[0095] 2: The integrated construction equipment crane traverses to the top of the docked ship at the front of the wharf, lifts the longitudinal beam and rotates 90 degrees to pass through the hole, and rotates 90 degrees after passing the hole, and the crane transports it above the designed position for erection; Complete all the longitudinal beams on the bent rack in sequence;

[0096] 3: The integrated construction equipment crane traverses to the top of the docked ships at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com