A Method for Hoisting Pile Legs Using the Principle of Secondary Leverage

A hoisting method and technology of lever principle, which are applied in the directions of transportation and packaging, load hoisting components, and trolley cranes, etc., can solve the problems of unfavorable cost control of shipyard construction progress control, difficulty in water hoisting construction, low operation efficiency, etc. The effect of saving rental costs, reducing construction costs and reducing installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

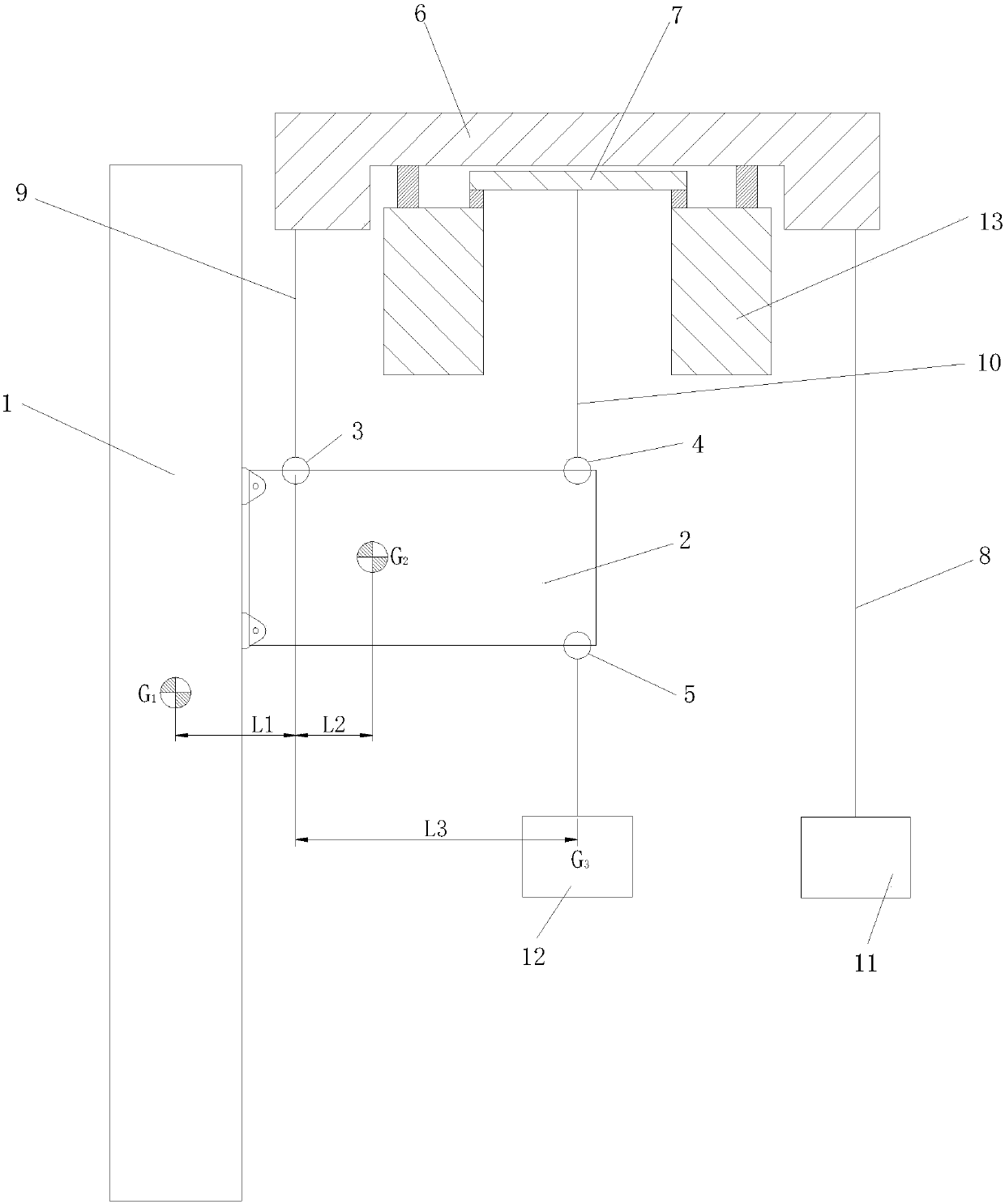

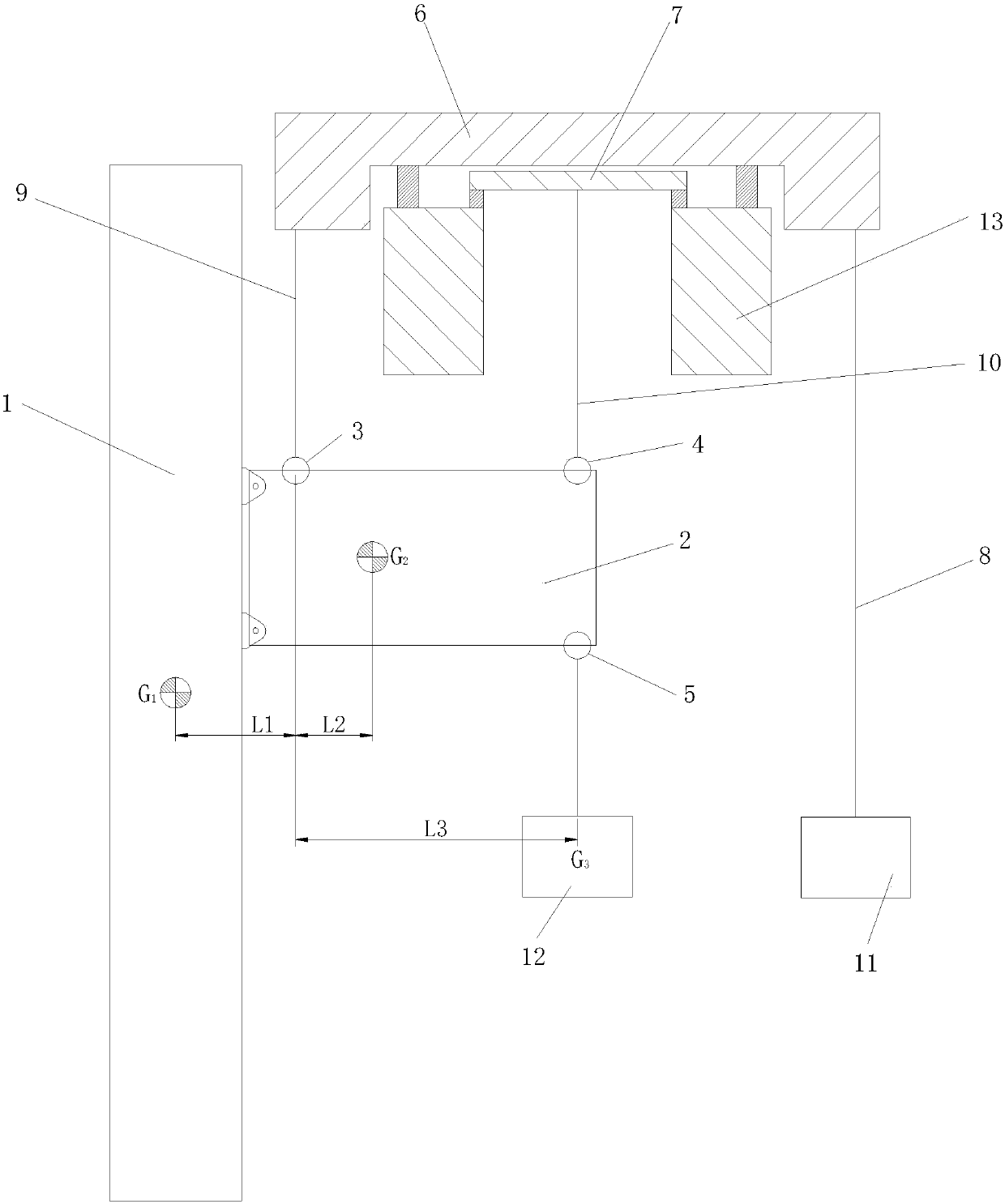

[0026] Such as figure 1 As shown, this embodiment provides a method for hoisting the pile leg 1 using the principle of secondary leverage, including the following steps:

[0027] 1) Make a horizontally installed hoisting tool 2, and connect one end of the hoisting tool 2 to the pile leg 1 to be hoisted, the main hoisting ring 3 is arranged on the end of the hoisting tool 2 close to the pile leg 1, and the hoisting tool 2 The other end is provided with an auxiliary suspension ring 4, and a counterweight suspension ring 5 is provided below the auxiliary suspension ring 4;

[0028] 2) The first hoisting trolley 6 and the second hoisting trolley 7 are respectively arranged on the crossbeam 13 of the gantry crane, and the both sides of the first hoisting trolley 6 are respectively connected with the first suspension hook 8 and the second suspension hook 9. The second hoisting trolley 7 is connected with a third suspension hook 10, the second suspension hook 9 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com