Movable lifting device for steel structure factory building construction and using method thereof

A mobile hoisting and steel structure technology, applied in cranes, traveling gear, transportation and packaging, etc., can solve the problems that the column cannot speed up the progress, cannot speed up the installation, and is laborious and labor-intensive, so as to shorten the construction time and shorten the construction project. time, and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

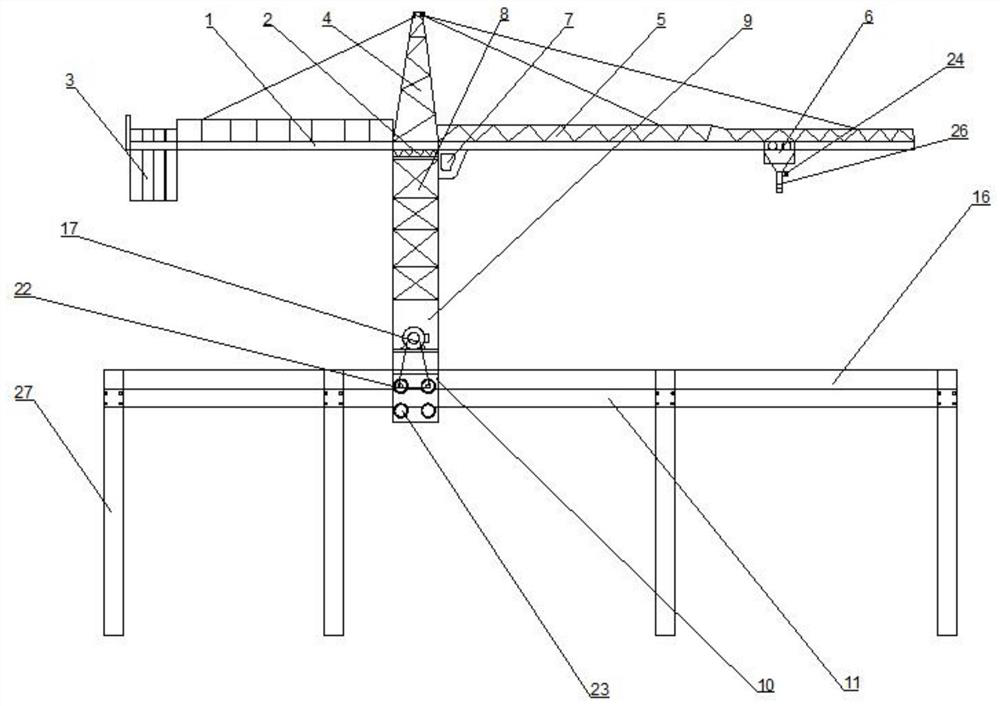

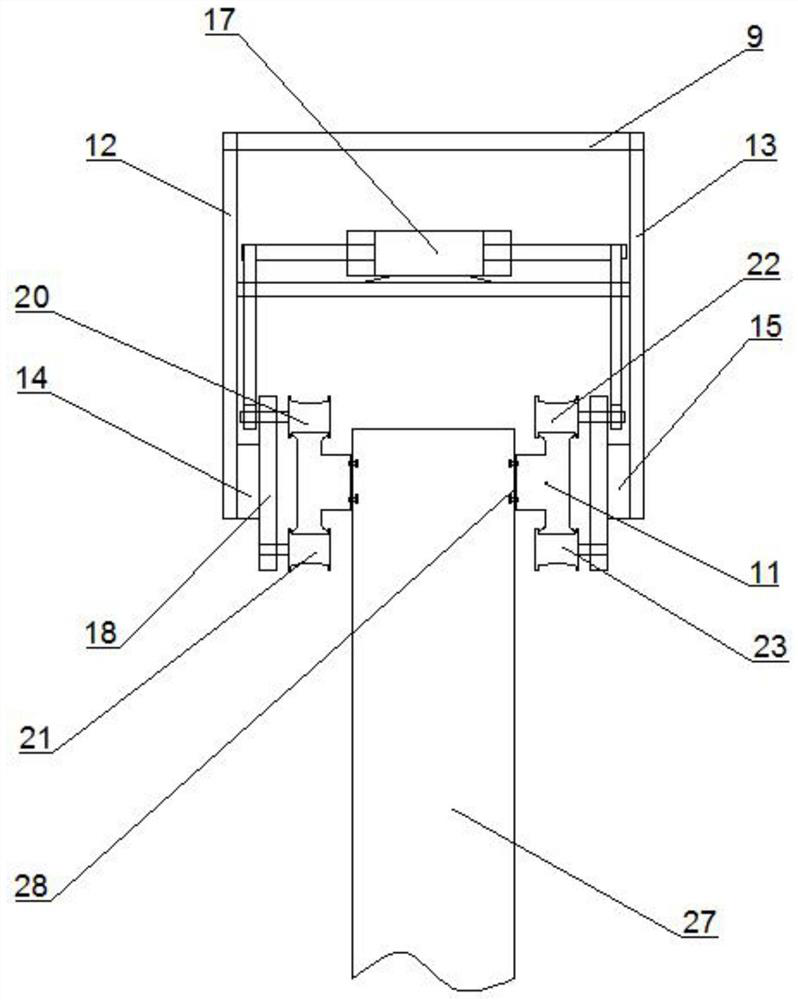

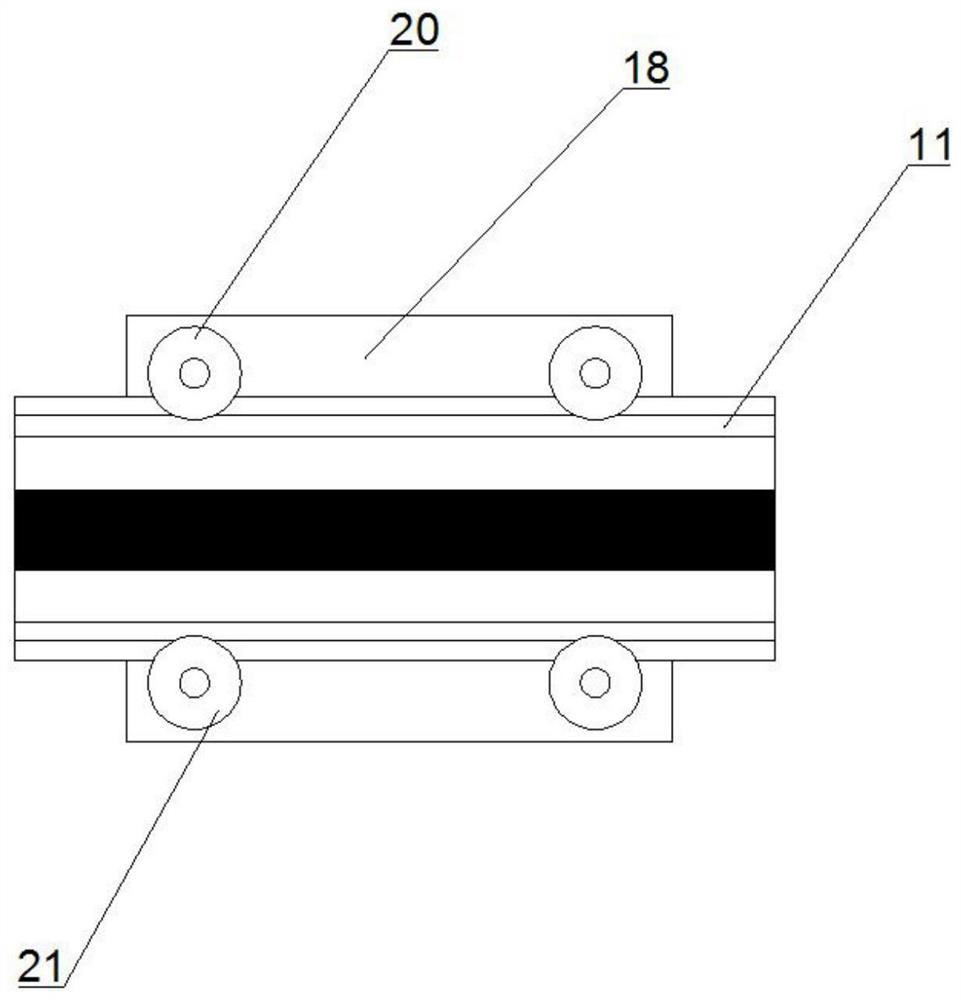

[0027] A mobile lifting device for the construction of a steel structure factory building, comprising a balance arm 1, a slewing mechanism 2 is installed at the front end of the balance arm 1, a counterweight 3 is installed on the balance arm 1, and the upper end of the slewing mechanism 2 is A tower top bracket 4 is installed, a boom 5 is installed at the front end of the slewing mechanism 2, a hoisting vehicle 6 is installed at the lower end of the boom 5, and an operating room 7 is installed on one side of the slewing mechanism 2, and it is characterized in that the A tower frame 8 is installed at the lower end of the slewing mechanism 2, and a moving device is installed at the lower end of the tower frame 8. The moving device includes a sleeve frame 9, and a driving roller portion 10 is installed at the lower end of the sleeve frame 9. The driving roller portion 10 Rotationally connected to the moving guide rail 11, the sleeve frame 9 includes a left bracket 12 and a right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com