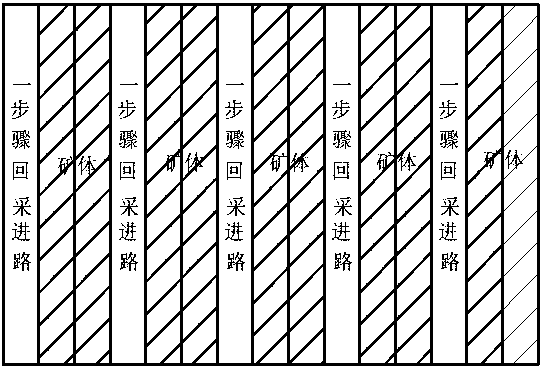

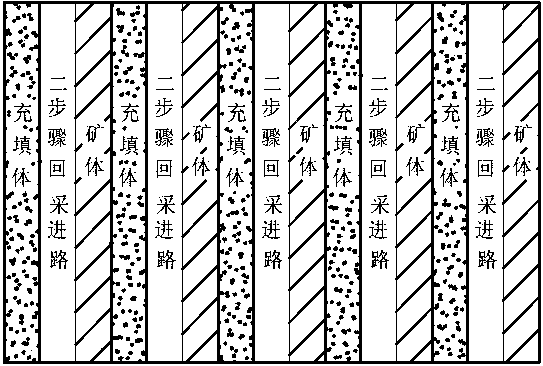

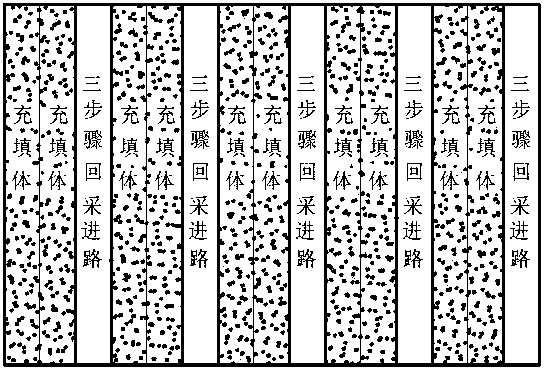

Blasting method applied to access road type extraction

An approach and crushing zone technology, which is used in approach mining to improve blasting quality, and in the field of multi-step approach mining followed by backfill mining, which can solve backfill collapse, mining safety threats, and backfill damage, etc. problem, to achieve the effect of increasing the rock breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] The method of the present invention is applied in the orebody recovery of the No. 2 mining area of Jinchuan Company. Through experimental testing, the rock mechanics parameters of the No. 2 mining area of Jinchuan Company and the charging parameters of the surrounding holes are shown in Table 1 and Table 2 below.

[0073] Table 1 Mechanical parameters of ore body

[0074]

[0075] Table 2 Charge parameters of peripheral holes

[0076]

[0077] Put the ore body mechanical parameters and surrounding hole charge parameters in Table 1 and Table 2 into formula (4) to get , at the same time, will and filling body dynamic compressive strength S=6~10MPa into the formula (8) to get the distance R+R between the surrounding hole and the filling body interface 0 It is 0.3m~0.8m.

[0078] According to the calculation results, when the stress wave in the peripheral hole is transmitted to the junction between the filling body and the ore body after the explosive is deto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com