Ultrahigh-pressure rotary pulse water jet rock breaking mechanism

A water jet and ultra-high pressure technology, applied in cutting machinery, slitting machinery, driving devices, etc., can solve problems such as high efficiency of coal seam roadway, difficulty in safe excavation, insufficient impact and crushing capacity of hard rock, and normal construction of the working face. Achieve the effects of improving mining efficiency and resource recovery rate, suppressing cutting dust, and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings.

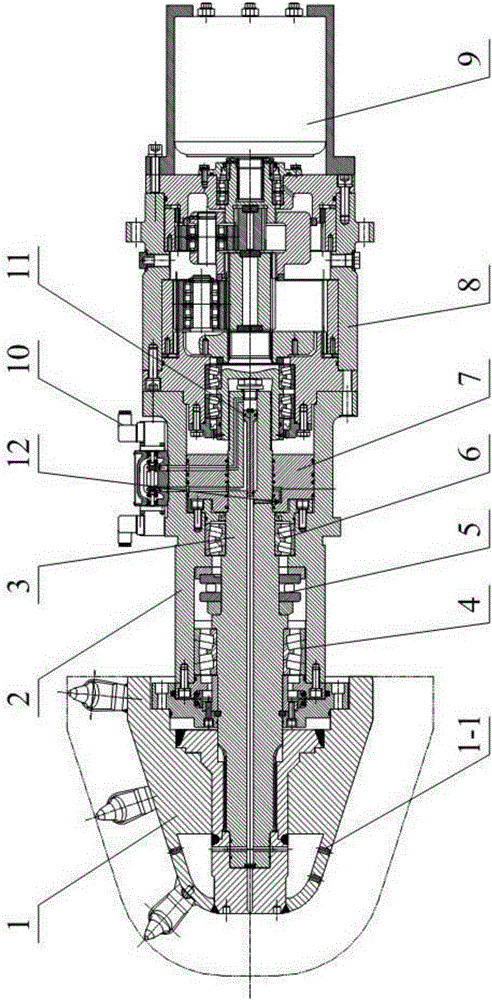

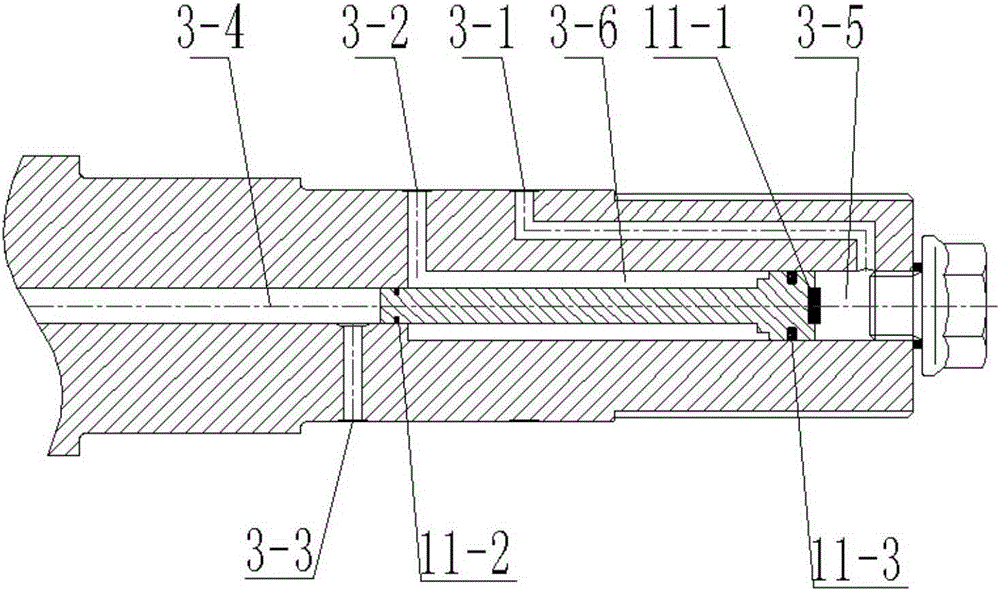

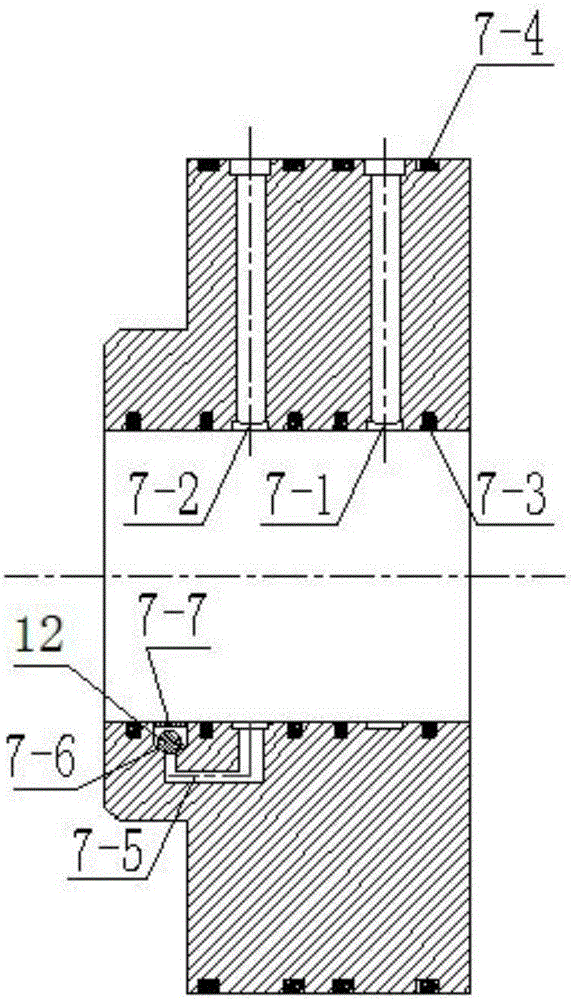

[0017] Such as Figures 1 to 3 As shown, the ultra-high pressure rotary pulse water jet rock breaking mechanism of the present invention includes a water jet cutting head 1 , a rock breaking mechanism housing 2 and a cutting main shaft 3 .

[0018] The cutting main shaft 3 is placed inside the rock breaking mechanism housing 2, and the middle part of the cutting main shaft 3 is connected with the rock breaking mechanism housing 2 through a bearing assembly. The bearing assembly includes a thrust bearing 5, and the two ends of the thrust bearing 5 are arranged symmetrically. The center roller bearing I4 and the self-aligning roller bearing II6, the three bearings respectively support the cutting main shaft 3 at three points, the self-aligning roller bearing I4 and the self-aligning roller bearing II6 ensure the coaxiality of the cutting main shaft 3, The thrust bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com