Rock breaking method

A rock-breaking and rock-breaking machine technology, applied in the field of rock crushing, can solve the problems of ineffective use of machines, increasing the shear force of the rock arm, and low engineering construction efficiency, so as to improve rock-breaking efficiency, enhance stability, reduce The effect of rock breaking energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

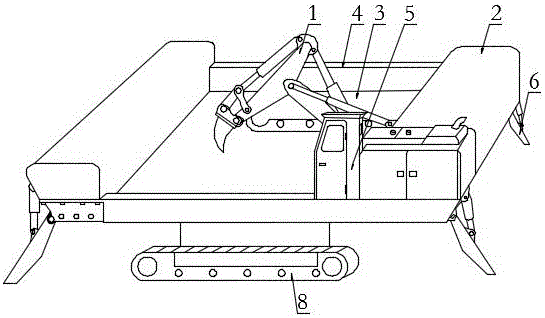

[0044] A rock-breaking method, comprising the steps of:

[0045] A. The rock breaker provided with the rock breaking operation area 3 is exercised or moved to the rock breaking area, so that the rock breaking operation area 3 is located above the rock breaking area, and the rock breaking operation area 3 of the rock breaking machine is It is a hollow area that runs through the body of the rock breaking locomotive and is perpendicular to the ground;

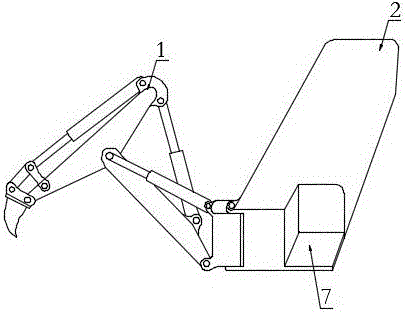

[0046] B. Operate the rock arm 1 to control the rock breaking part on the rock arm 1 to move downward in the rock breaking operation area 3;

[0047] C. The rock breaking part of the rock arm 1 breaks rocks in the rock breaking operation area 3 .

[0048]Wherein, the area of the rock-breaking operation area 3 is set to 7-50 square meters, preferably about 30 square meters, so as to complete a large amount of rock-breaking operations at one time. After the rock-breaking operation area 3 is located above the rock-breaking area, ...

Embodiment 2

[0055] This embodiment is basically the same as Embodiment 1, the main difference is:

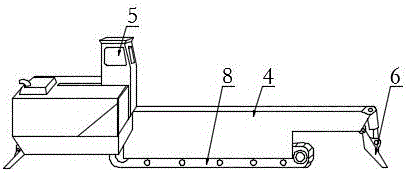

[0056] Described running gear comprises four sets of crawler running gears 8, and each vehicle frame 4 is connected on two sets of crawler running gears 8, and two vehicle frames 4 are respectively symmetrically connected on four sets of crawler running gears 8, and four sets of crawler running gears 8 are all controlled by the control mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com