Ultra-short type continuous advancing tunneling machine and continuous tunneling method

A push-type, ultra-short technology, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of low construction efficiency in short-distance excavation, improve construction efficiency and construction safety factor, high excavation efficiency, and facilitate Effects of manipulation and switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

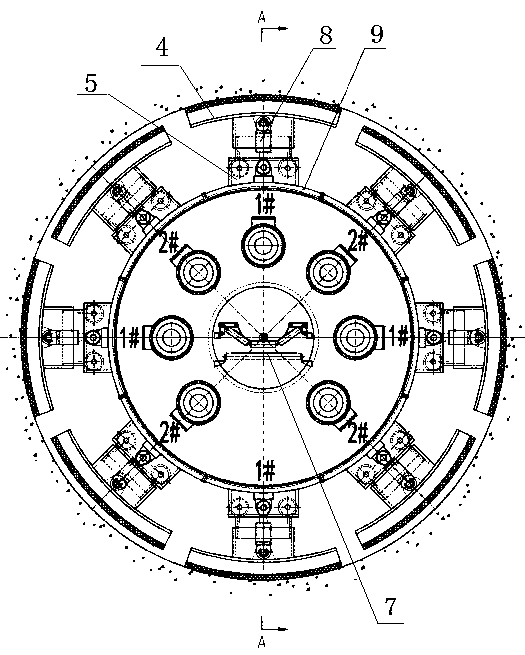

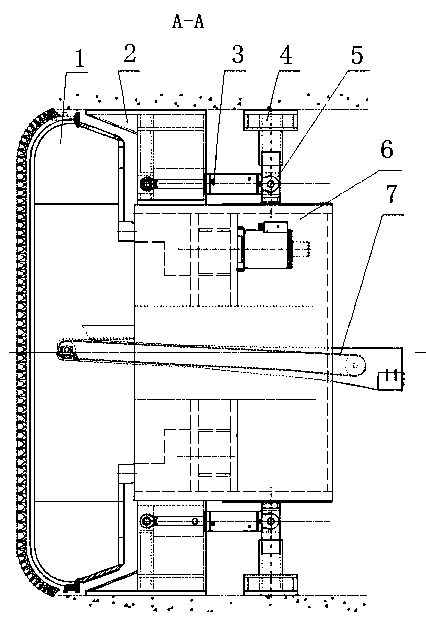

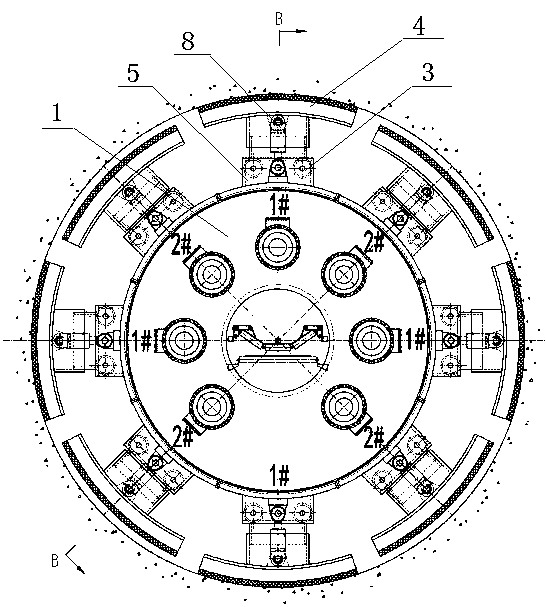

[0032] Embodiment 3: a kind of method for the continuous excavation of ultra-short type continuous propulsion type roadheader as described in embodiment 2, the steps are as follows:

[0033] S1: The propulsion mechanism 3 distributed along the circumferential direction of the main drive 6 and used to connect the shoe unit and the shield body 2 is divided into No. 1 telescopic cylinder and No. 2 telescopic cylinder; No. 1 telescopic cylinder is set as 1# propulsion cylinder, and No. Telescopic oil cylinder is set as 2# propulsion cylinder; 1# propulsion cylinder and 2# propulsion cylinder are set at cross interval;

[0034] S2: During excavation, the shoe unit is braced tightly on the cave wall, and the cutter head rotates to excavate the tunnel face under the action of the main drive. The corresponding No. 1 telescopic cylinder (1# propulsion cylinder) and No. propulsion cylinder) to alternately expand and contract, and continuously propel the main drive and cutterhead to dig ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com