Color sorting apparatus for leaf products

A filter and color technology, used in color measurement devices, sorting and other directions, can solve the problems of changing shapes and sizes, impossible to achieve, and low specific gravity of leaf-shaped objects, so as to reduce photometric errors and prevent color screening efficiency. The effect of falling, uniform luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. In the following description in conjunction with exemplary embodiments of the present invention, the same reference numerals will be used throughout the drawings to designate the same or similar components. Also, when the detailed description of a related known structure or function may make the subject matter of the present invention unclear, the detailed description of the known structure or function will be omitted.

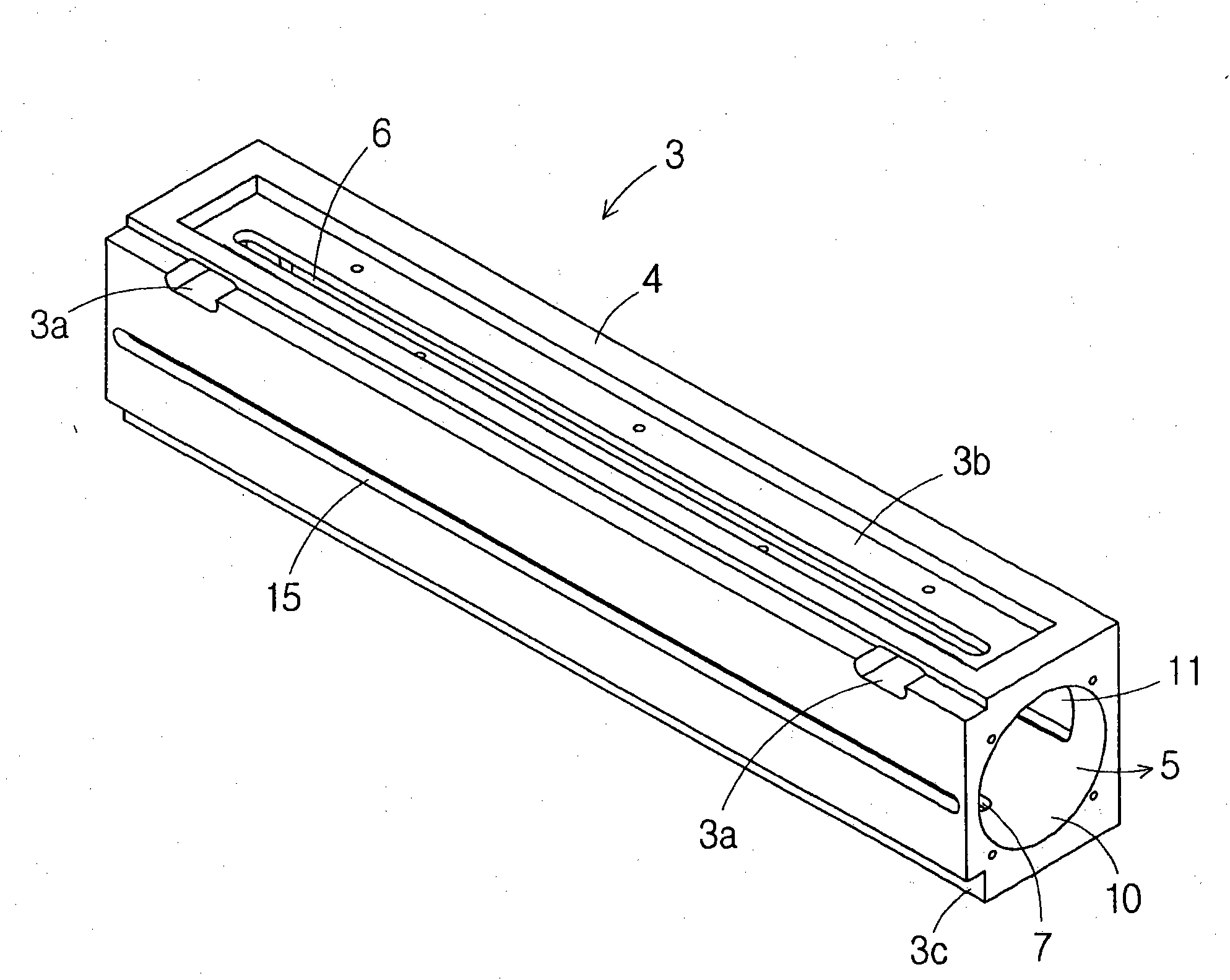

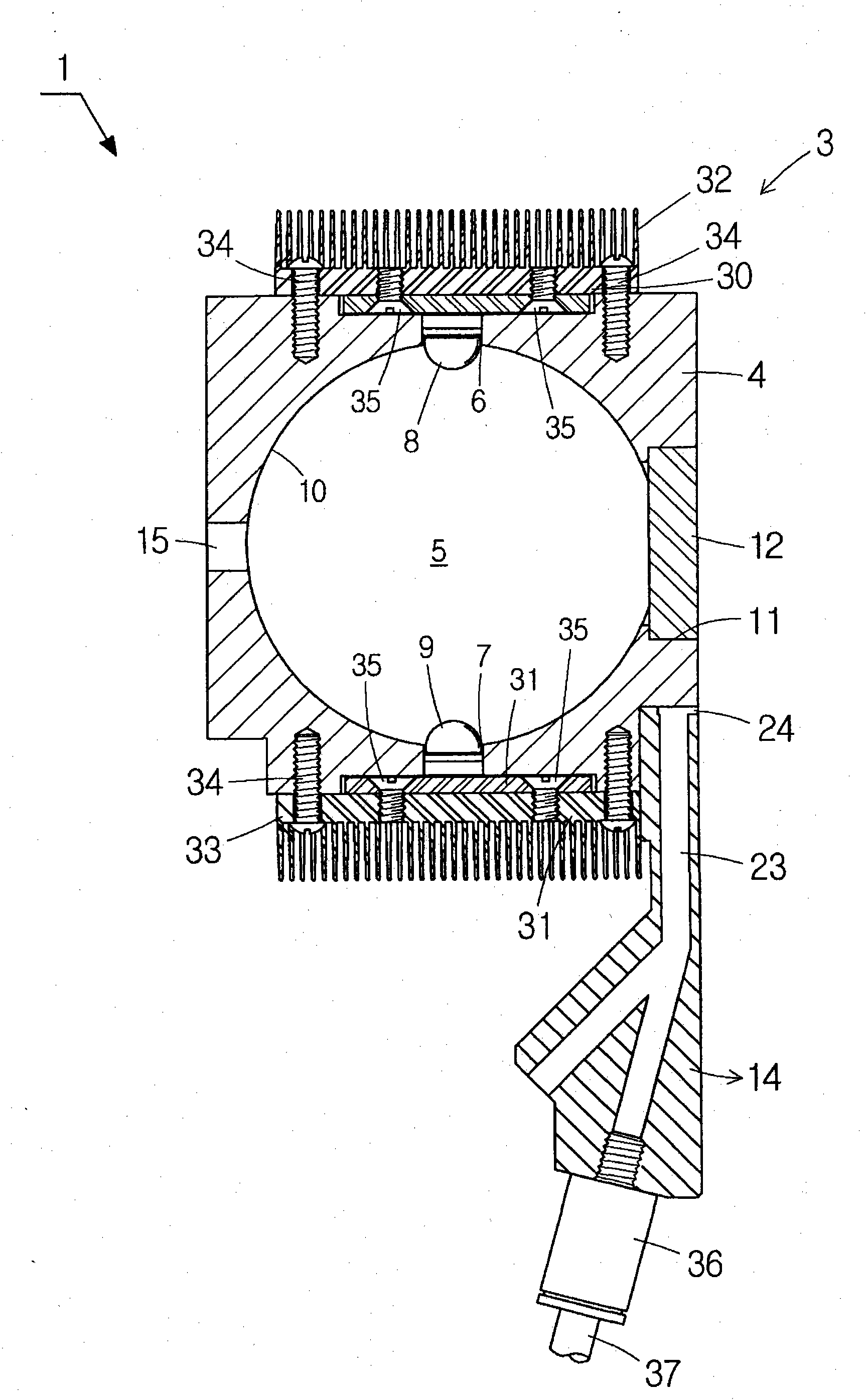

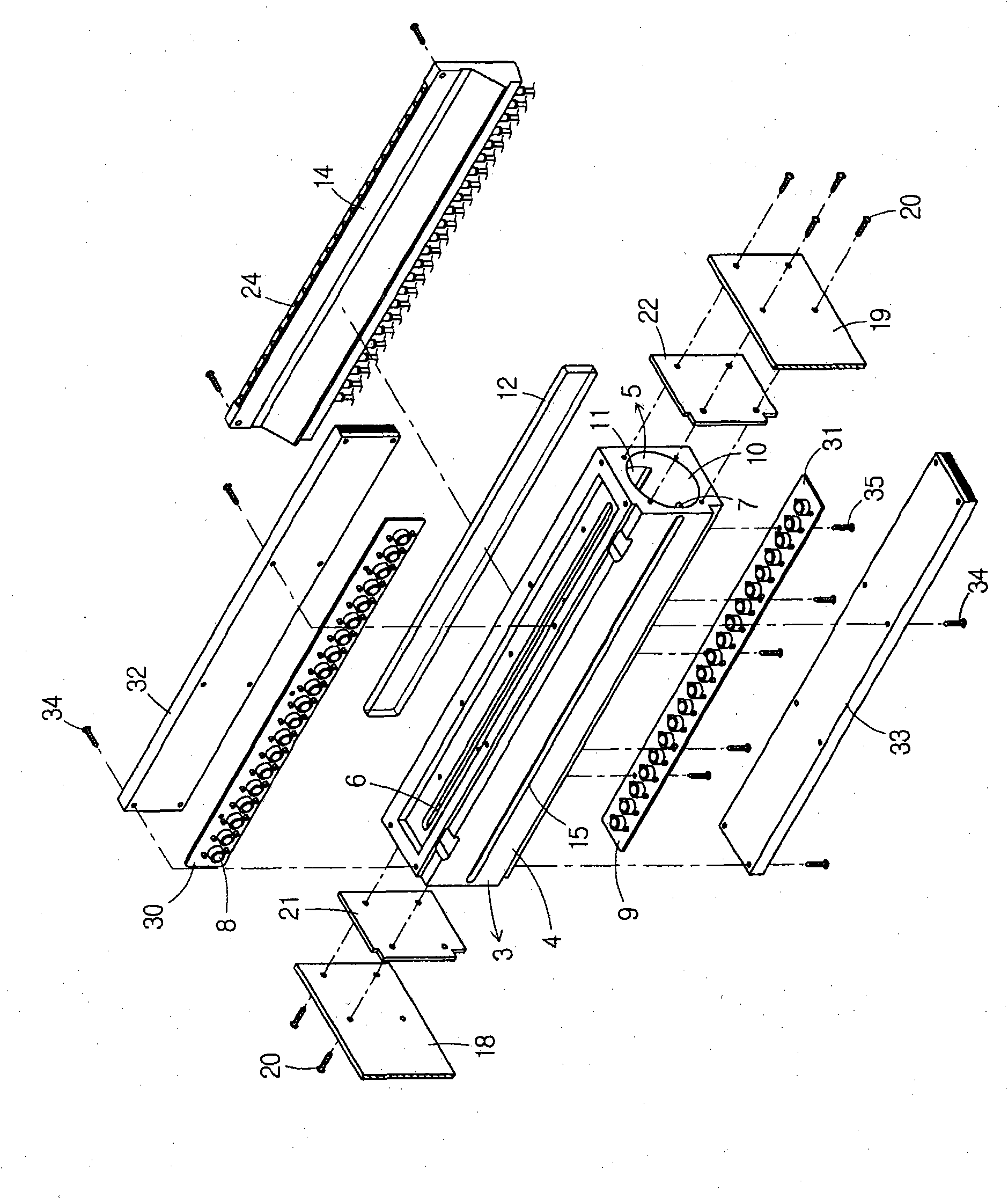

[0029] figure 1 is a partial perspective view of a frame 3 provided in a leaf-shaped color filter 1 according to an exemplary embodiment of the present invention. figure 2 is a sectional view showing an assembled state of the leaf-shaped color filter 1 according to an exemplary embodiment of the present invention. image 3 It is a three-dimensional exploded view of a typical embodiment of the present invention.

[0030]A colo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com