UV LED (ultraviolet light-emitting diode) curing light for printing

A technology for curing lamps and lampshades, applied to general parts of printing machinery, printing, printing machines, etc., can solve the problems of short service life, high power consumption, expensive consumables, etc., achieve uniform luminous intensity, less pollution, and avoid filming The effect of expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

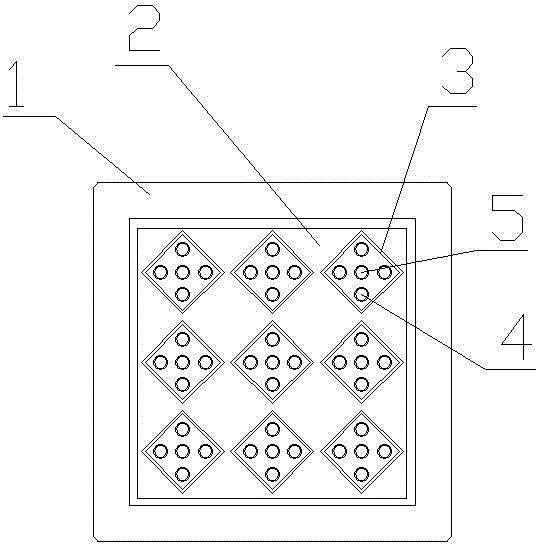

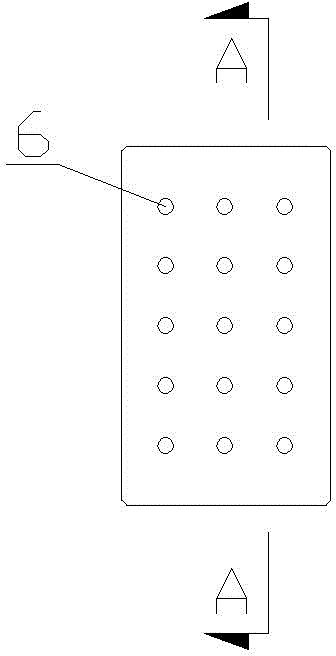

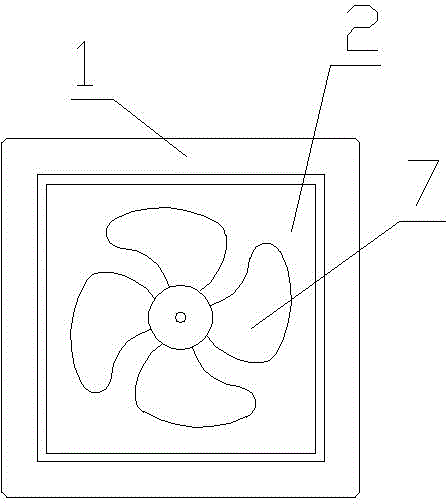

[0016] Combine below Figure 1 to Figure 3 , to further describe the specific implementation of the technical solution of the present invention, but not limited to this description.

[0017] A UV LED curing lamp for printing, comprising an aluminum lampshade 1, a plurality of cooling holes 6 are evenly distributed on the lampshade 1, a copper substrate 2 is arranged inside the lampshade 1, and several ultraviolet lamps are arranged on the substrate 2 in an array. Lamp 3, the ultraviolet lamp 3 is diamond-shaped, UVLED chips 4 are arranged on the four ends of the rhombus-shaped ultraviolet lamp 3, an infrared LED 5 is arranged in the middle of the rhombus-shaped ultraviolet lamp 3, and the lamp mirror of the rhombus-shaped ultraviolet lamp 3 is a convex quartz glass lens , The rear of the substrate 2 is provided with a high-speed fan 7 .

[0018] LED is a cold light source, and an infrared LED 5 is installed in the diamond-shaped ultraviolet lamp 3, which is convenient to adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com