Infrared camera parameter calibration plate

A camera parameter and calibration board technology, applied in the field of optical measurement, can solve the problems affecting the calibration accuracy of camera parameters, inability to accurately obtain the position of the center of the circle, and different luminous intensity, and achieve stable luminous intensity, moderate luminous intensity, and uniform luminous intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The patent solution will be further described below in conjunction with the accompanying drawings.

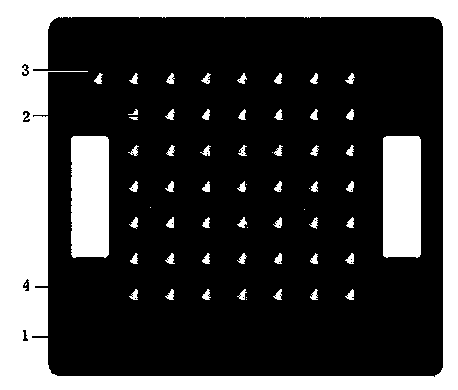

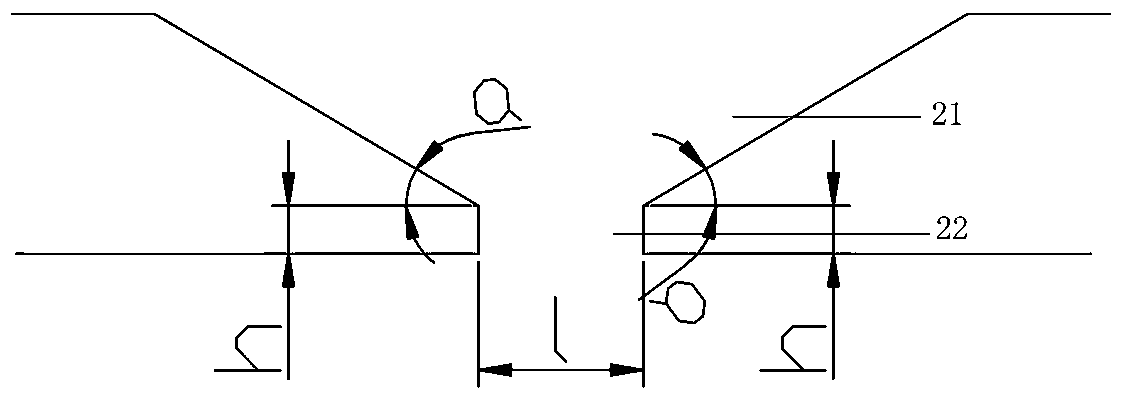

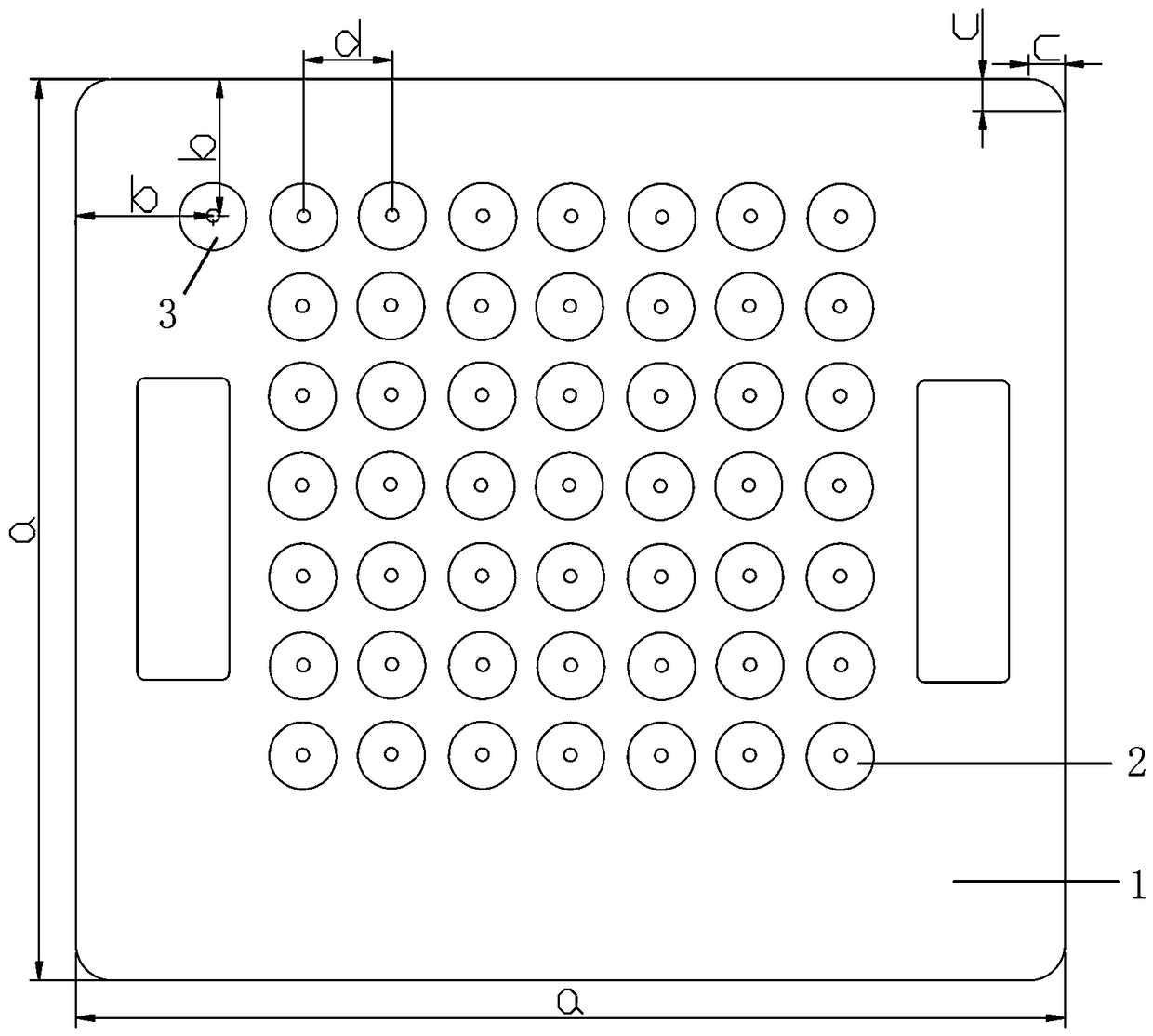

[0022] Such as figure 1 As shown, a near-infrared camera parameter calibration board includes a light-tight substrate 1, and the substrate 1 is provided with an array of circular holes M×N, vertical in rows and columns, and also includes a positioning hole 3, and the positioning hole 3 is set At one corner of the circular hole array, a reflective cloth 4 is arranged in the circular hole 2 in the circular hole array.

[0023] A near-infrared camera parameter calibration board provided by this patent includes a base plate 1 on which a circular hole array M×N is provided. For the convenience of calibration, the circular holes 2 of the circular hole array are evenly distributed on the substrate, and each circular hole 2 There is a fixed distance between them. A reflective cloth 4 is arranged in the round hole 2, and the patent uses the reflective cloth 4 for passive reflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com