High-quality quantum dot fluorescent thin-film material and preparation method thereof

A technology of thin film materials and quantum dots, which is applied in the field of high-quality quantum dot fluorescent film materials and its preparation, can solve the problems that the yield, stability and mechanical properties of quantum dot fluorescent film materials cannot be guaranteed, and achieve good compactness, Strong operability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

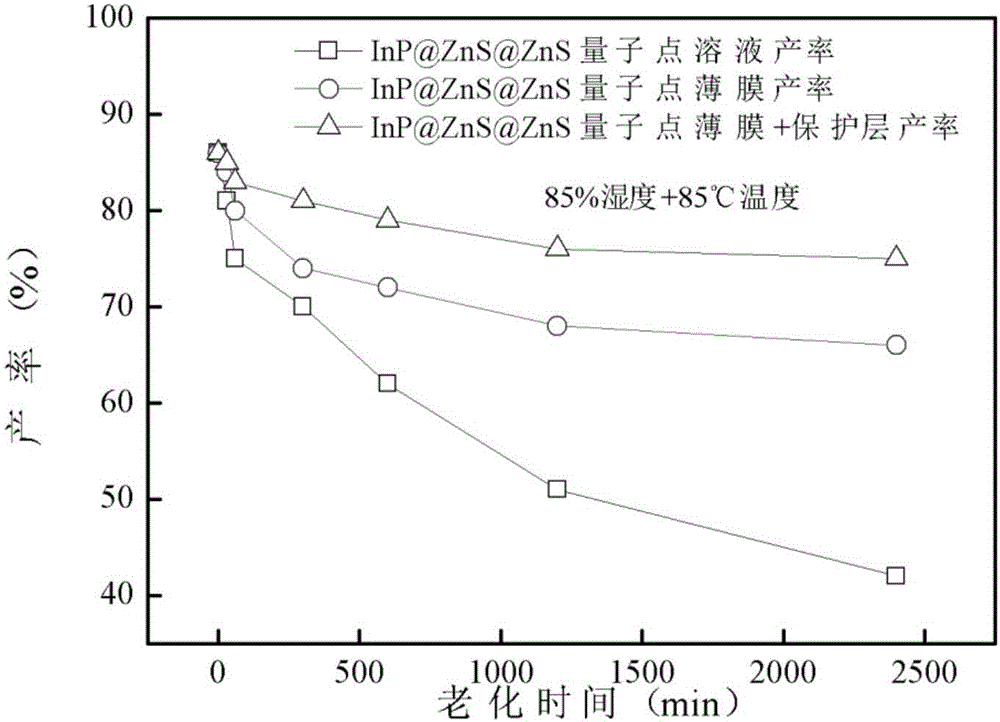

Embodiment 1

[0044] Example 1 Preparation of high-quality quantum dot fluorescent film material using InP@ZnS@ZnS as quantum dots, the preparation method includes:

[0045] Step 1: Prepare a quantum dot solution;

[0046] Take 0.2mmol of tris(dimethylamino)phosphine and 2.2mmol of n-octylamine in the glove box and dissolve it in 2ml of octadecene. After dissolution, it will be recorded as solution A; take 1mmol of zinc stearate and dissolve in 10ml of octadecene, Dissolve it and record it as solution B; take 1mmol of sulfur powder and dissolve it in 10ml octadecene, and record it as solution C after dissolution.

[0047] Take 0.4mmol indium acetate, 1.5mmol myristic acid and 4g octadecene in a 25ml three-necked flask, heat to 100℃ and pump for 1h, then pass in argon for protection, then increase the temperature to 180℃ and then inject solution A, then Cool down to 162°C and hold for 15 minutes to grow InP quantum dots;

[0048] Continue to control the temperature to 145°C and inject 1.2ml of solu...

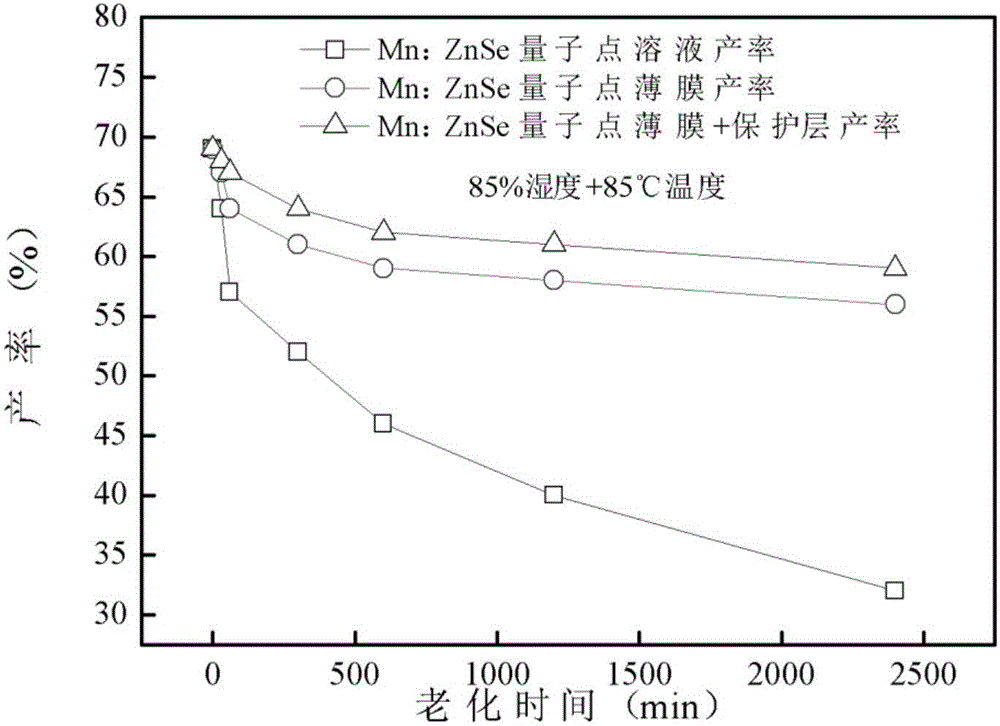

Embodiment 2

[0058] Embodiment 2 Using Mn:ZnSe as doped quantum dots to prepare high-quality quantum dot fluorescent film materials, the preparation method includes:

[0059] Step 1: Prepare a quantum dot solution;

[0060] Dissolve 0.05g manganese stearate in 5g octadecene and heat to 100°C to obtain solution A; take 0.36g zinc stearate, 0.04g stearic acid and 2.4g octadecene to obtain solution B;

[0061] Take 0.0237g of selenium powder, 5g of octadecene and 0.1g of oleylamine in a three-necked flask, heat to 100°C, pump for 20min, then pass in argon, heat up to 260°C until the selenium powder is dissolved, continue to heat up to 275°C for injection 1ml of solution A; further cooling to 260°C and holding for 4min to grow MnSe; then cooling to 240°C and injecting 0.5ml of solution B, reacting for 2h and then cooling to room temperature naturally to obtain Mn: ZnSe doped quantum dots.

[0062] Step 2: Preparation of polystyrene polymer-Mn: ZnSe doped quantum dot bulk material;

[0063] Take 100ml o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com