High-pressure turbine moving blade set with damping vibration attenuation blocks

A high-pressure turbine and damping block technology, applied in the direction of engine components, machines/engines, blade support components, etc., can solve problems that affect the life and safety and reliability of gas turbines, high-cycle fatigue fracture of blades, and forced vibrations, etc. , to achieve good vibration damping effect, improve service life, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

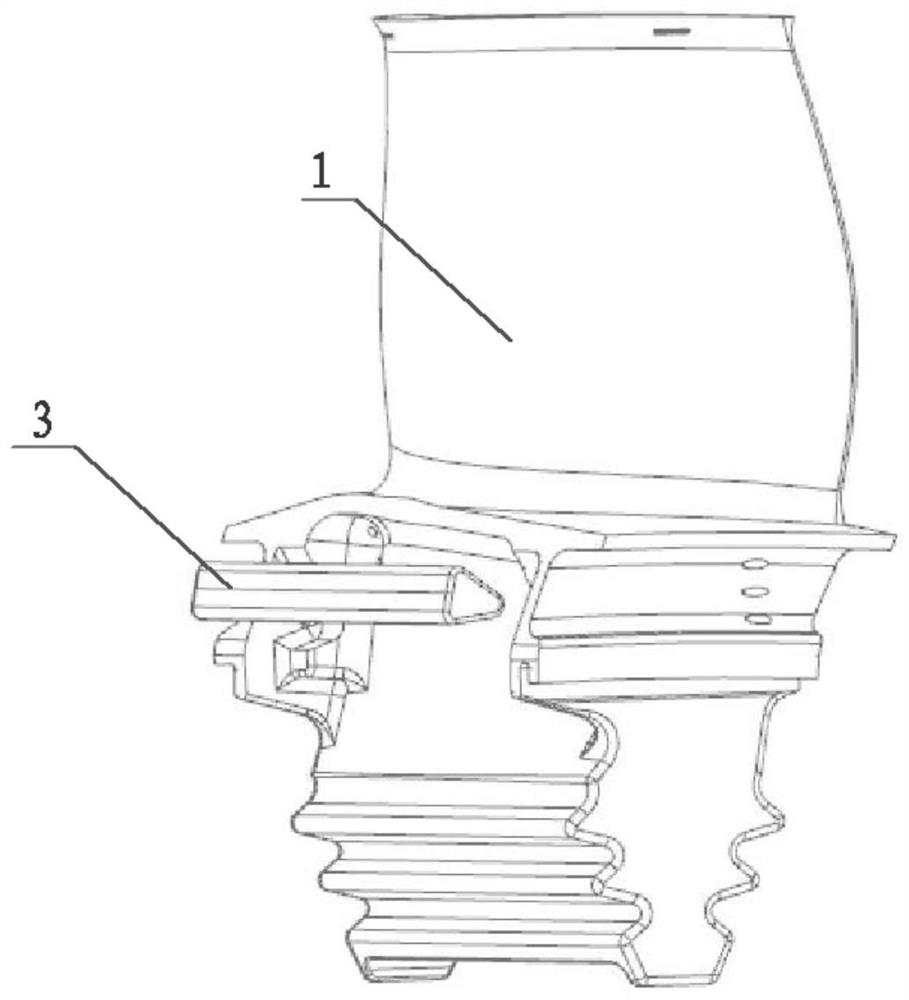

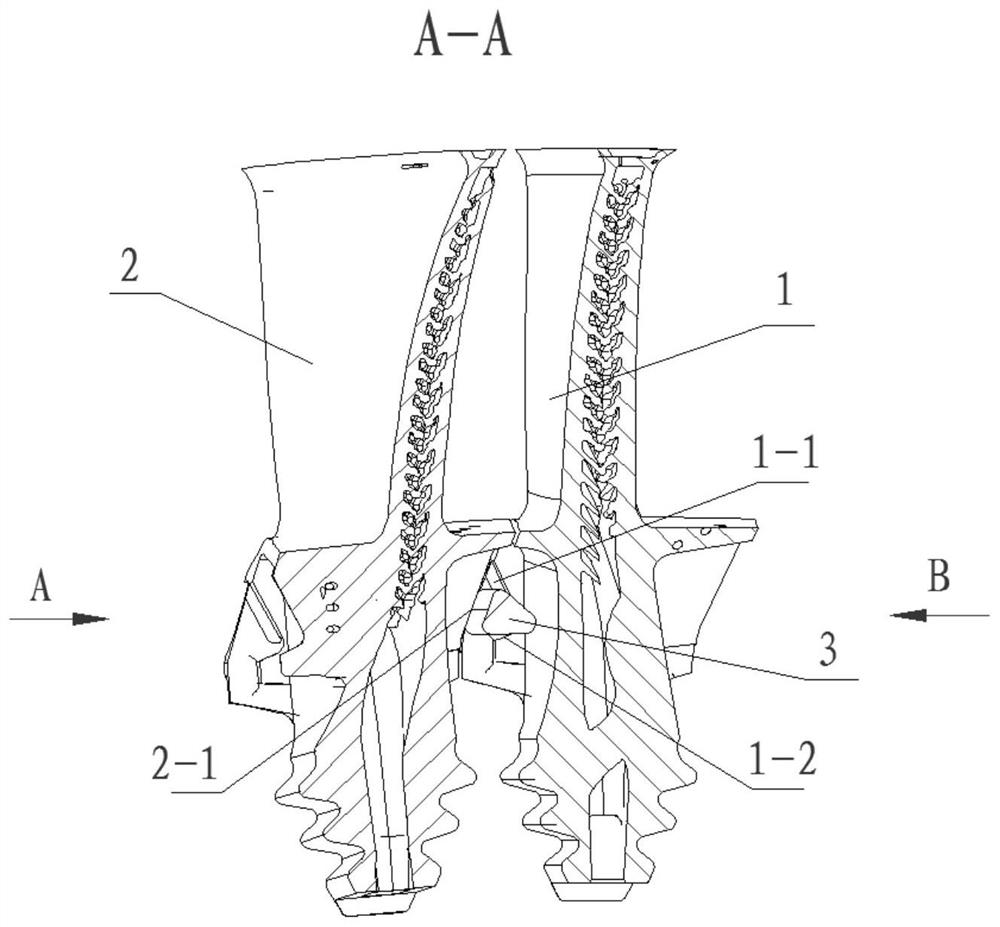

[0031] combine Figure 4 and Figure 7 , there is a first boss 1-10 and a second boss 1-11 at the root of the first high-pressure turbine blade 1 blade back side, the geometric dimensions of the two bosses are equal, and they are used for the positioning of the damping block 3 to prevent The damping damping block 3 falls off. combine Figure 8 , The damping and vibration-absorbing block 3 is a prism-shaped solid structure.

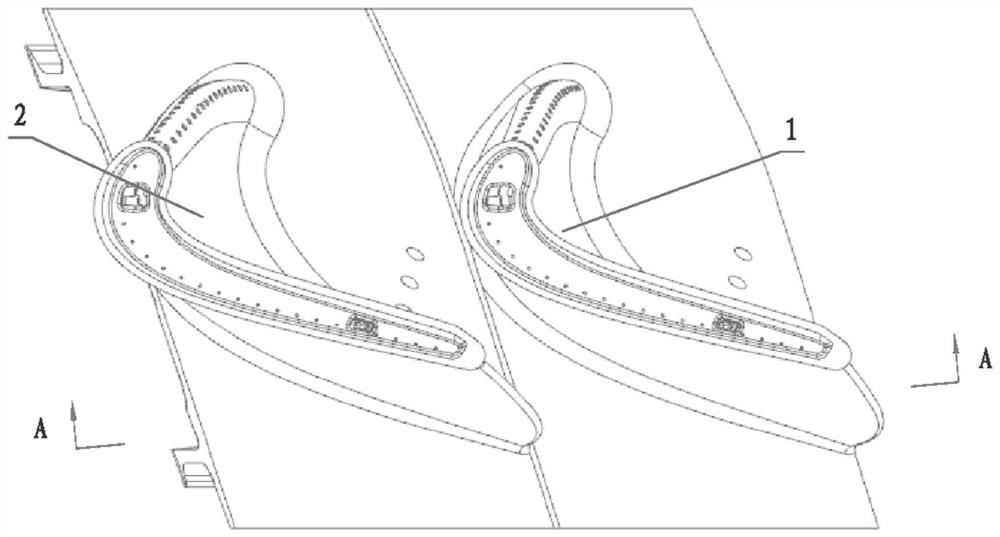

[0032] combine Figure 1 to Figure 8 , the front surface 1-1 and the rear surface 1-4 of the lower edge plate on the back side of the first high-pressure turbine blade 1 form a certain angle with the blade along the blade height direction; the blade basin side of the second high-pressure turbine blade 2 The surface 2-1 of the lower edge plate forms a certain angle with the blade along the blade height direction. The first surface 1-1 and the second surface 1-2 of the lower edge plate on the back side of the first high-pressure turbine blade 1 form the...

Embodiment 2

[0034]The first high-pressure turbine blade 1 and the second high-pressure turbine blade 2 have the same structure, and both are blades without shrouds and have complex cooling structures.

Embodiment 3

[0036] combine Figure 5 to Figure 8 , there is a circular gap of R15 in the damping block 3, the size of which is designed according to the specific shape of the extension root 1-7 on the back side of the first high-pressure turbine blade 1, which can ensure that the damping block 3 and the extension There is a certain gap between the roots 1-7 to ensure the smooth flow of the cooling air and prevent the damping and shock absorbing block 3 and the extension roots 1-7 from being squeezed during the working process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com