Silent chain

A chain and pin hole technology, applied in the direction of belt/chain/gear, chain element, transmission chain, etc., can solve the problems of poor stress balance, deterioration of noise, chain wear and elongation, etc., to prevent wear and elongation and suppress noise. , the effect of simplifying the production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

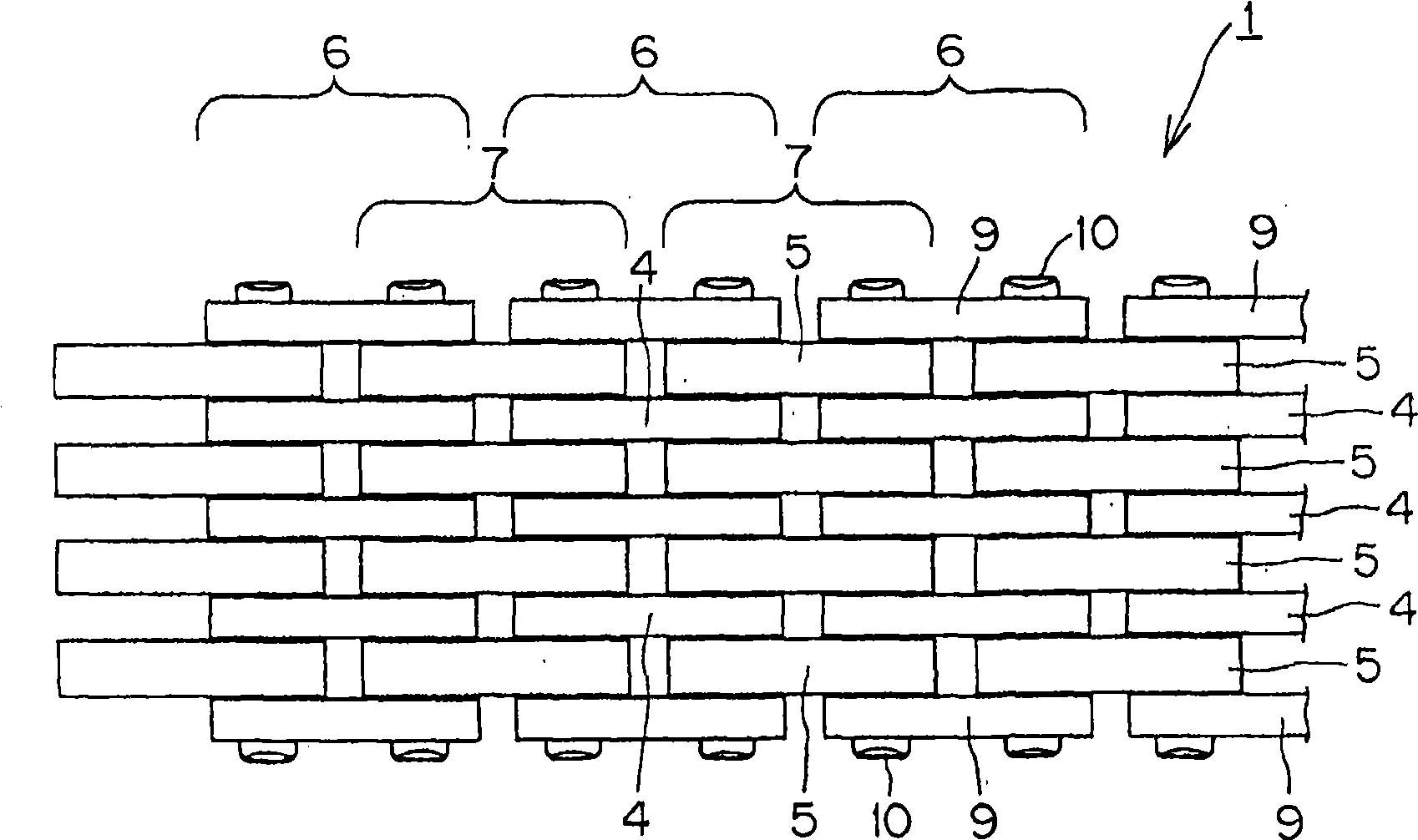

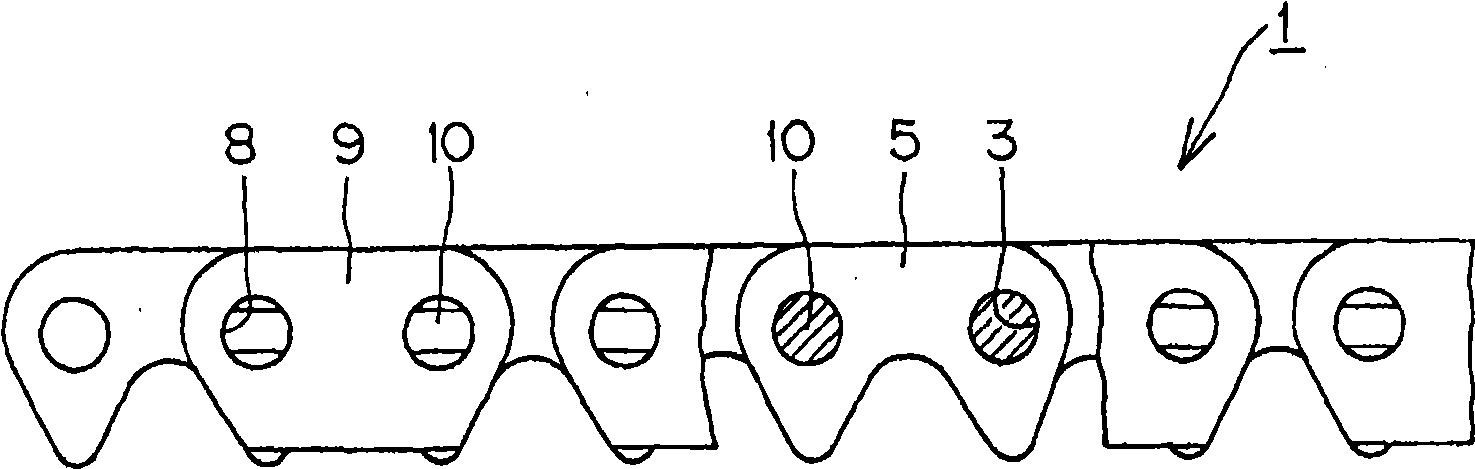

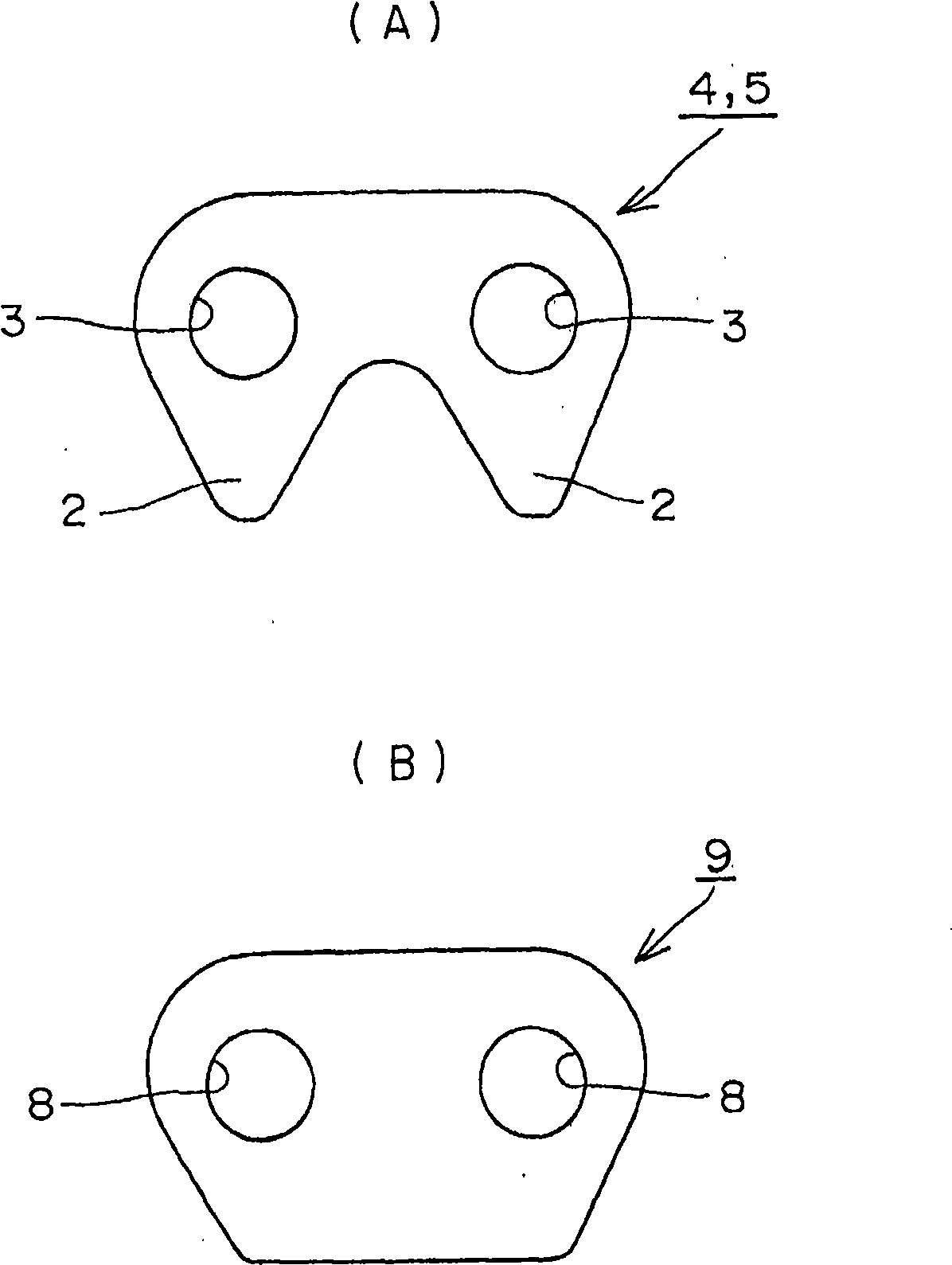

[0037] based on the following Figure 1 to Figure 5 Examples of the present invention will be described. figure 1 is a top view showing part of the silent chain, figure 2 is the main view representing a part of the silent chain, image 3 (A) is the front view of the inner panel, image 3 (B) is the front view of the guide plate, Figure 4 It is an explanatory diagram of the main parts of the silent chain when a low-load tensile tension is applied (initial state), Figure 5 It is an explanatory diagram of the main parts when the silent chain is subjected to a high-load tensile tension so that the connecting pin becomes approximately straight.

[0038] like Figure 1 ~ Figure 3As shown, the silent chain 1 is formed in a ring shape, and a plurality of inner plates 4, 5 with a pair of teeth 2 and a pair of pin holes 3 are arranged in the guide row 6 and the non-guide row respectively in the chain longitudinal direction and alternately staggered positions. row 7, and a guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com