Photovoltaic cells with improved backsheet

A crawler walking device and forestry machinery technology, which is applied to agricultural machinery equipment, forestry, crawler vehicles, etc., can solve problems such as unfavorable installation angles and lagging angles, unevenness, and reduced ability of forestry machinery to move forward

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

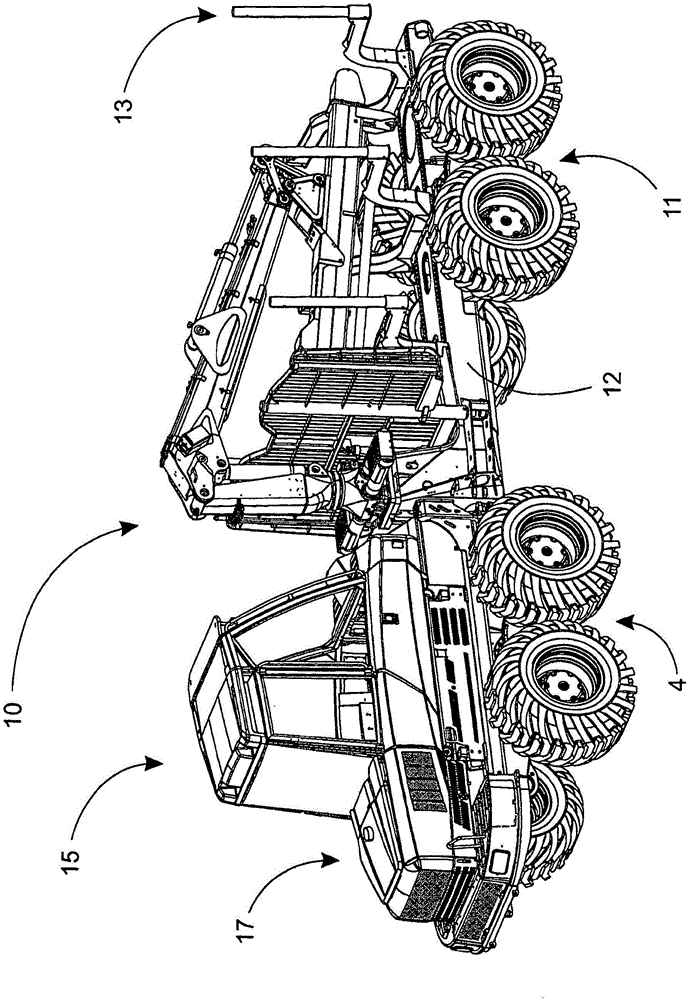

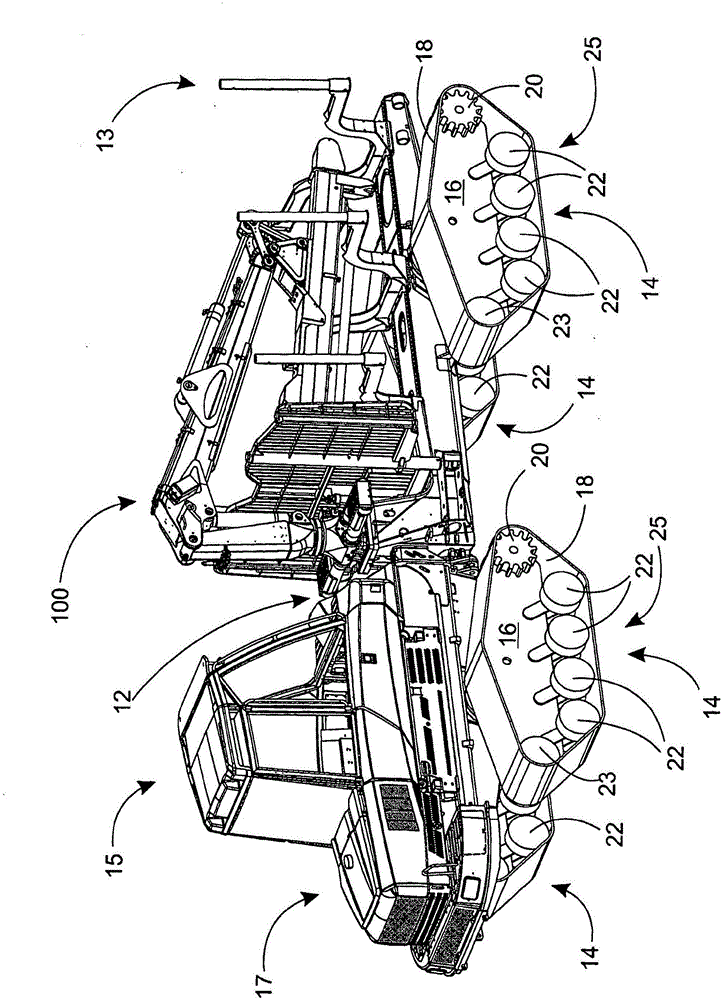

[0056] Fig. 1 shows a forestry machine 10 according to the prior art, which may be a forestry tractor according to the figures, for collecting felled trees and transporting them out of the forest. The forestry machine 10 according to the prior art is supported on the ground by means of bogie wheels 11 on bogie axles, wherein on each bogie axle there are preferably two drive wheels with pneumatic rubber tires. However, rubber tires are expensive constructions with very limited flexibility due to the high pressures used in them. The purpose of using high pressure is to try to ensure sufficient load capacity even when the forestry machine is fully loaded. Consequently, the forestry machine 10 can cause high surface pressure on the ground, thereby damaging the ground. The driving force of the forestry machine 10 according to FIG. 1 is obtained from an engine 17 from which power is transmitted to the respective Wheels pass. This construction requires each wheel to have a separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com