Mounting structure and mounting method for all-glass guardrail

An installation structure and all-glass technology, which is applied in the direction of ladder-like structures, railings, building structures, etc., can solve the problems of the filler in the base affecting the appearance, the density of the mortar base layer is not strong, and the width of the notch is not worth, so as to avoid Hard contact, good coplanarity, and the effect of saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to facilitate the understanding of the present invention, the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments of the specification, but the protection scope of the present invention is not limited to the following specific embodiments. It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

[0054] In order to achieve the purpose of the present invention, the technical solutions provided by the present invention are:

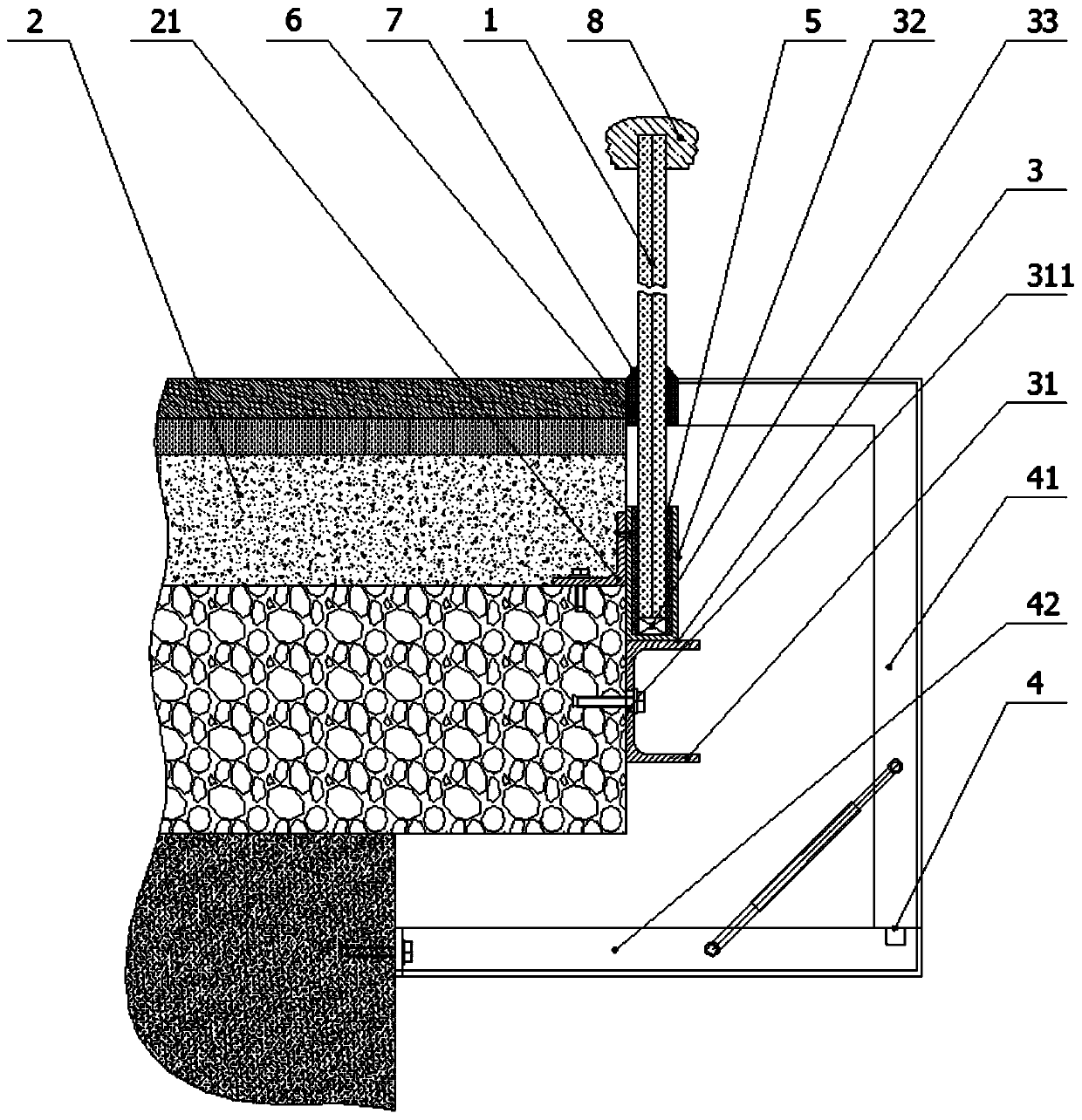

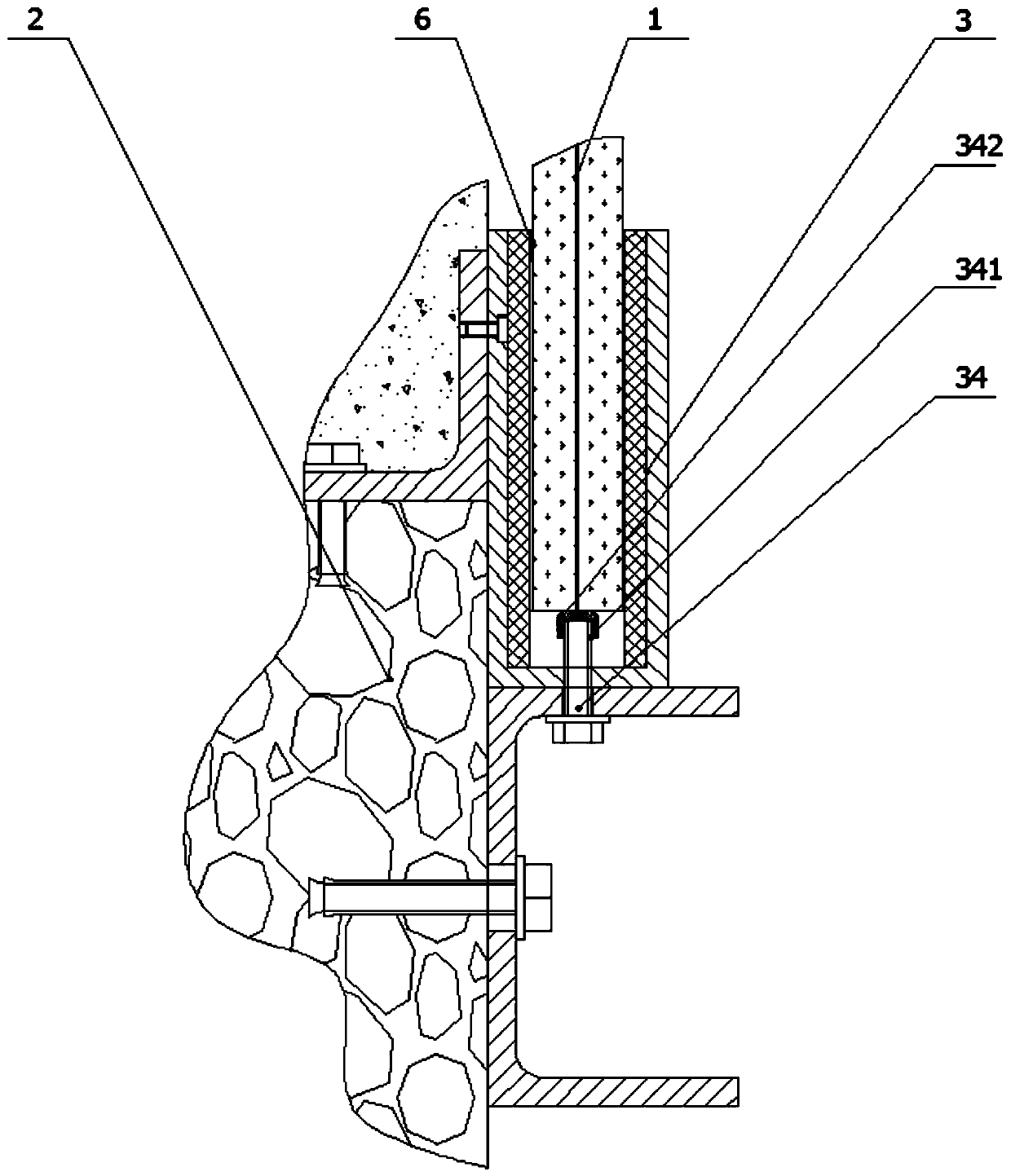

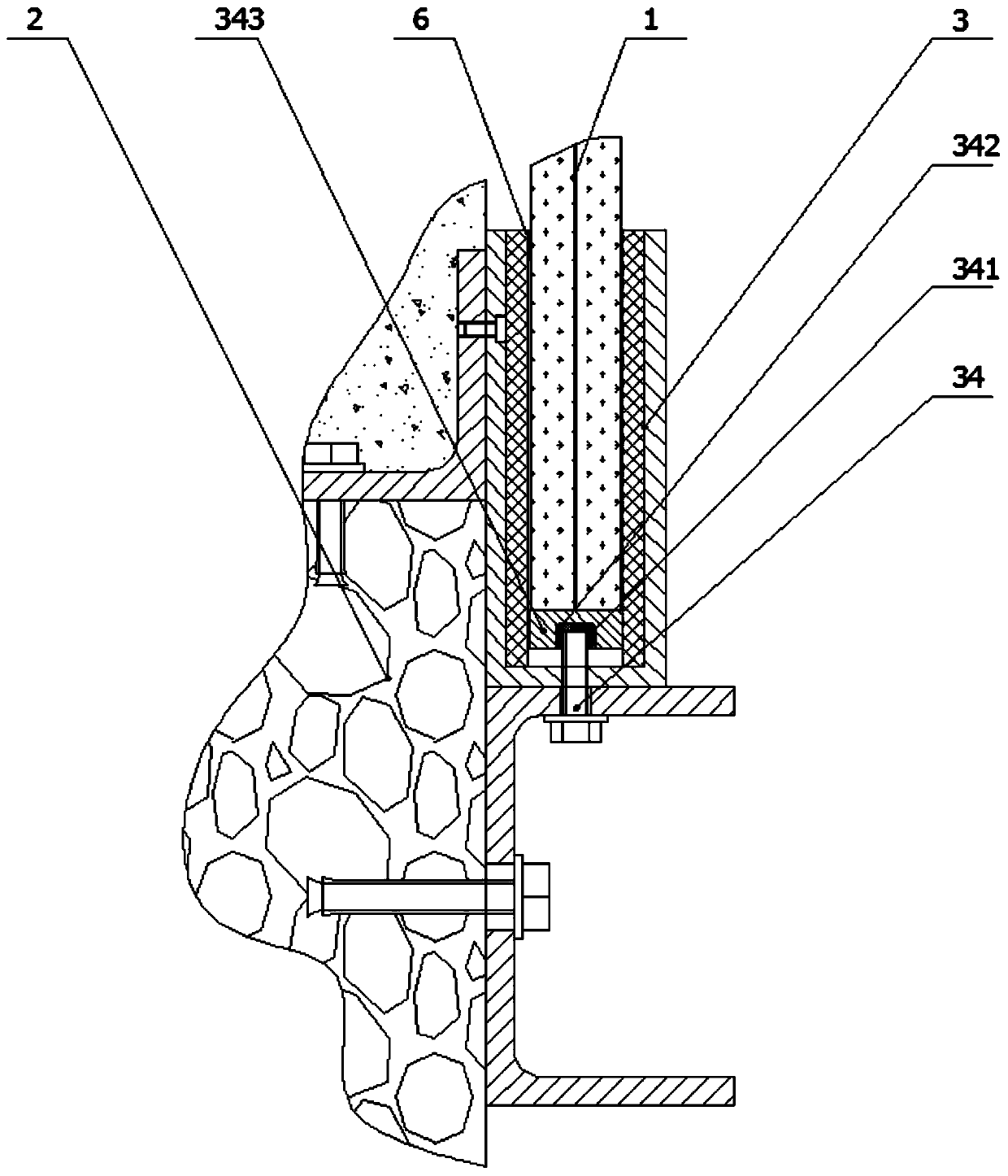

[0055] Such as figure 1 As shown, an installation structure for all-glass guardrails includes: laminated glass 1, that is, tempered laminated glass; cantilevered floor slab 2, including a passing plane for people to walk on, and an installation wall surface for installing laminated glass 1. Embedded angle steel 21 is provided on the wall surface, threaded holes are provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com