Sliding block type converter tapping hole sliding plate slag stopping device

A sliding plate slag blocking and tapping hole technology, which is applied in the manufacture of converters, etc., can solve the problems of uneven pressure on the surface of the sliding plate, instability of the surface pressure on the sliding plate, and affecting the production of steel, and achieve reasonable structure, safe and reliable use, and The effect of preventing steel penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

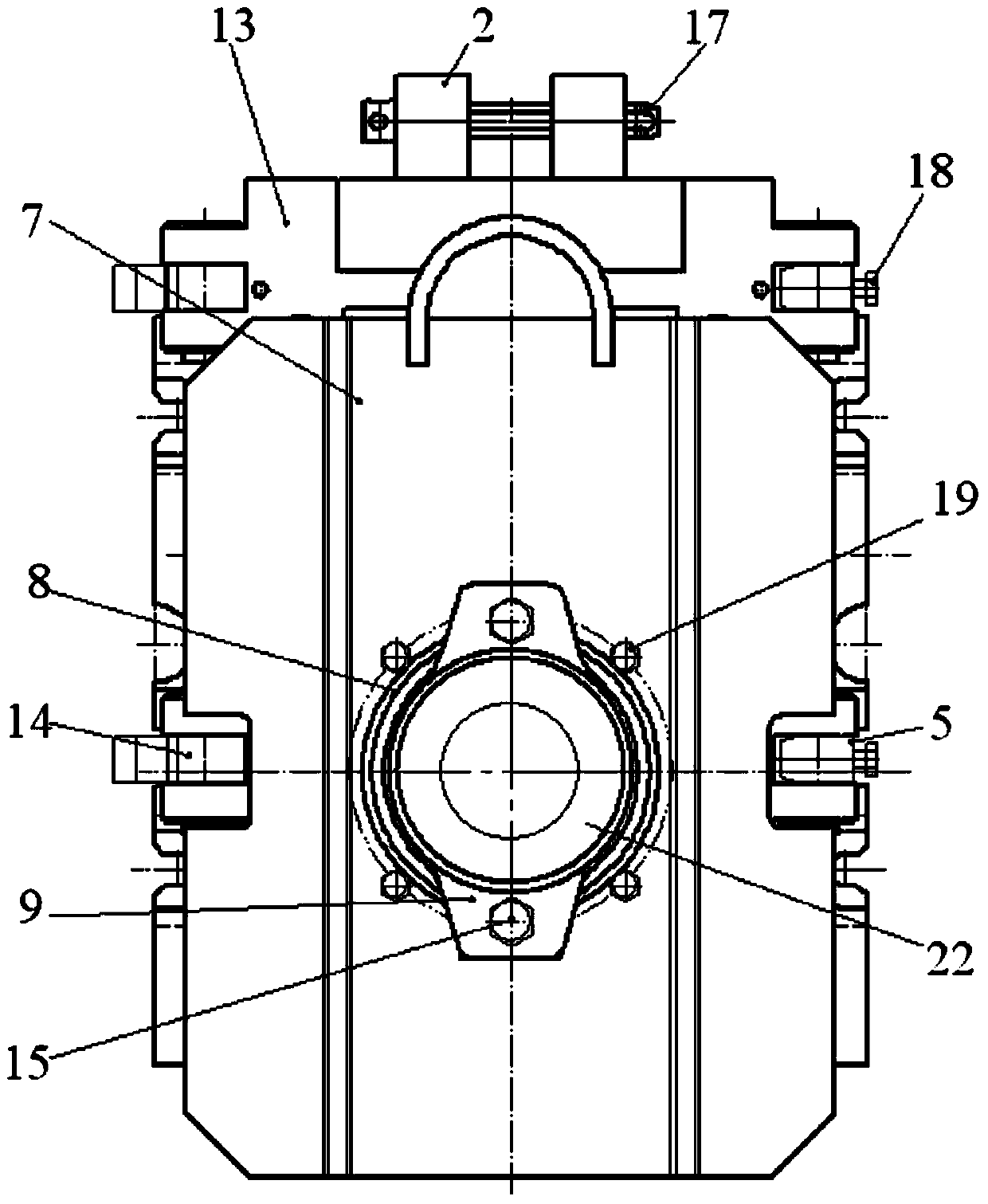

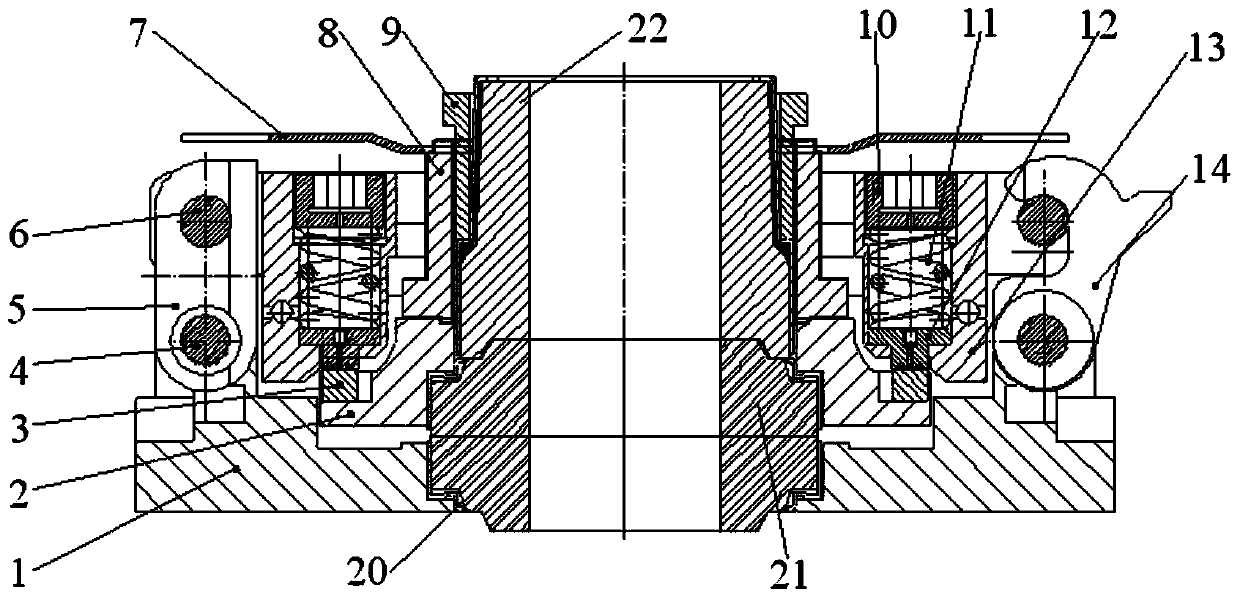

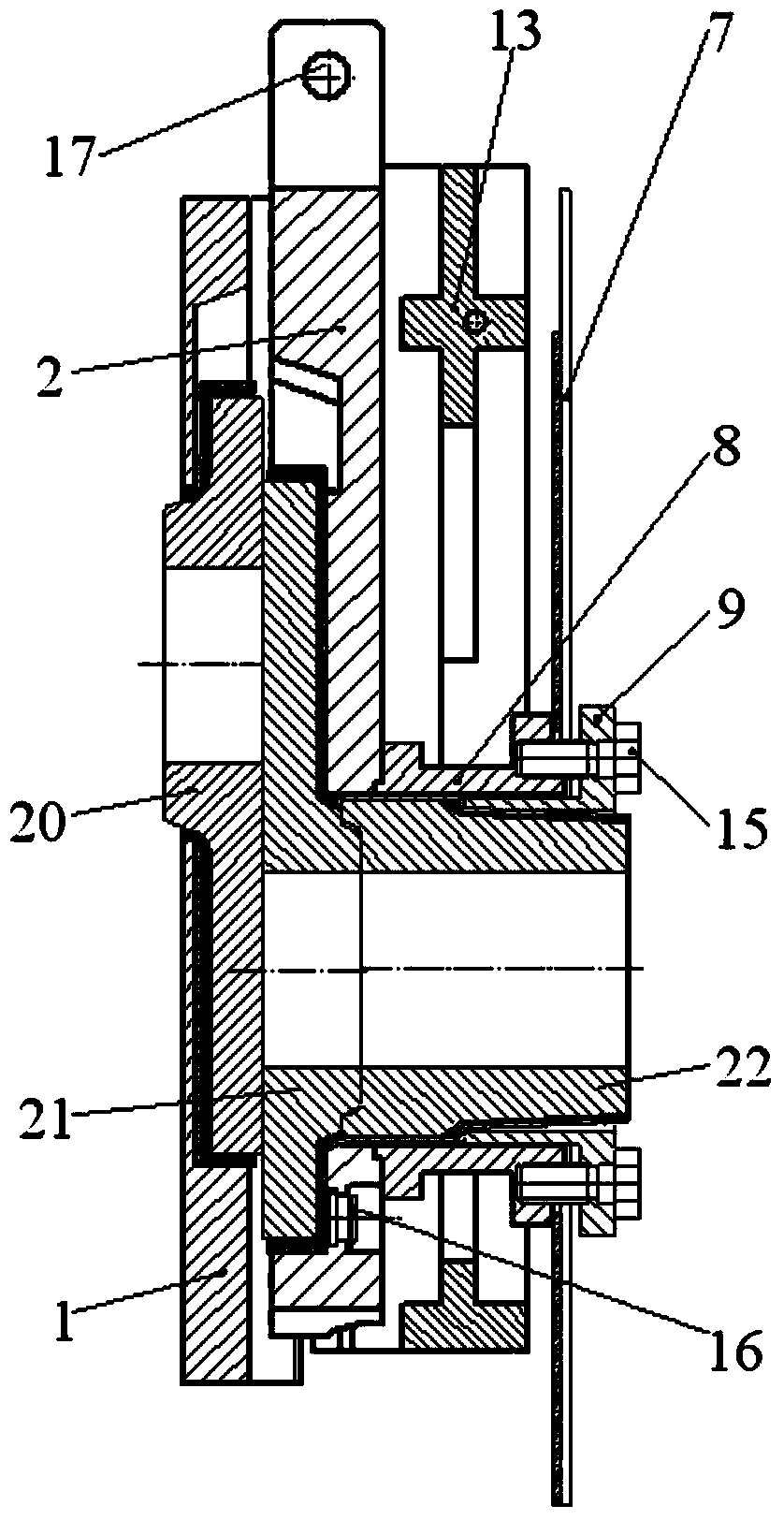

[0024] Such as Figure 1 to Figure 3 As shown: the slider-type converter taphole sliding slag retaining device of the present invention includes a fixed frame 1, a sliding frame 2, a pressing frame 13, a lower nozzle 22, and a lower nozzle support 8; the sliding frame 2 is provided with a sliding bar 3 The sliding frame 2 is located between the fixed frame 1 and the pressing frame 13, and is slidably matched with the sliding groove of the fixed frame 1; Tightener 9, slide bar 3; the coaxial distribution of the drain outlet 22 and the sliding nozzle brick 21; the sliding nozzle brick 21 is locked on the drain outlet support 8 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com