Heat excanger with receiver tank, and refrigeration system

A technology of heat exchangers and liquid storage tanks, applied in heat exchange equipment, refrigerators, refrigeration components, etc., can solve problems such as difficult, cumbersome screw tightening operations, troublesome assembly operations, etc., and achieve the effect of simple and correct connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

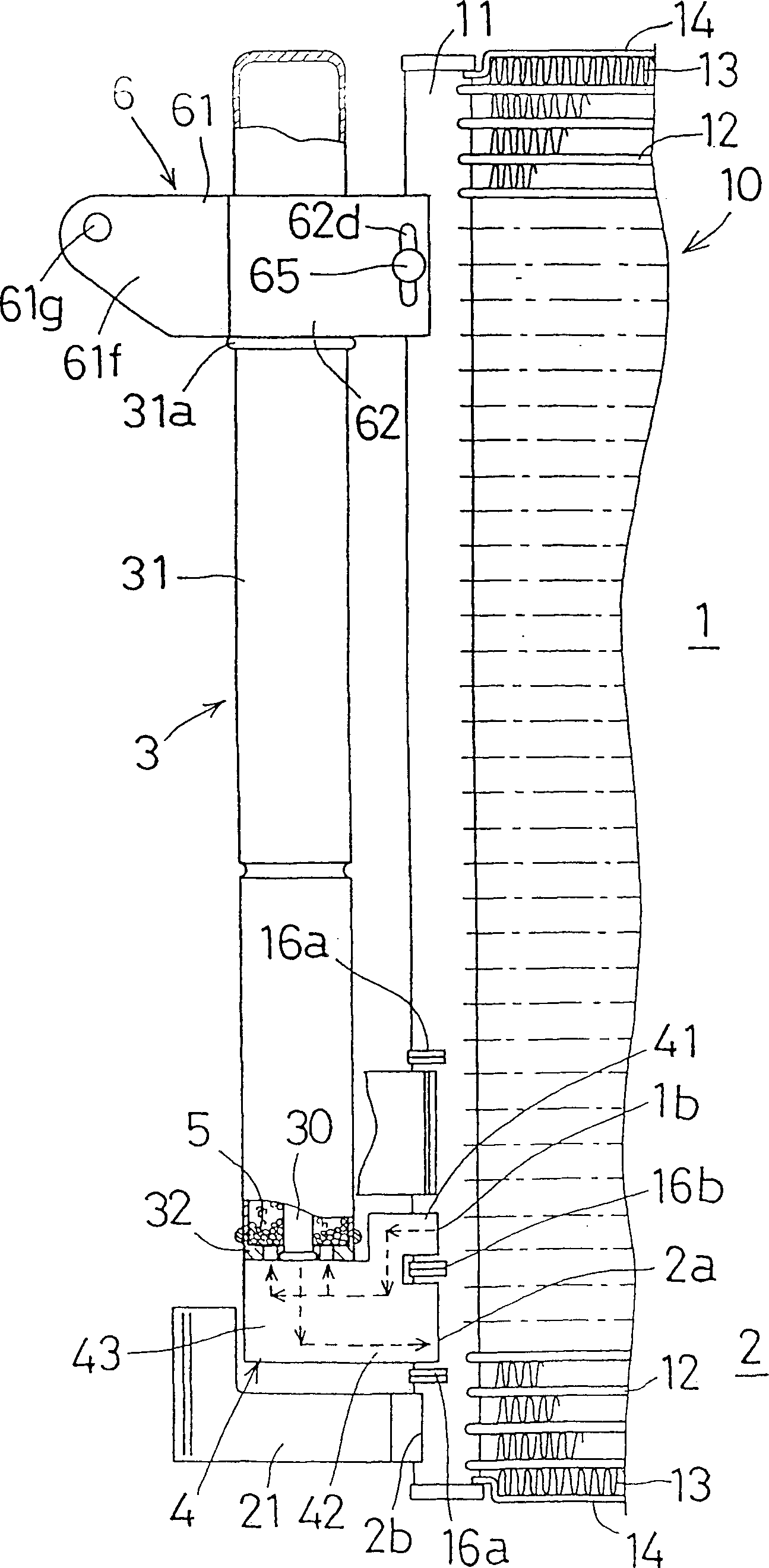

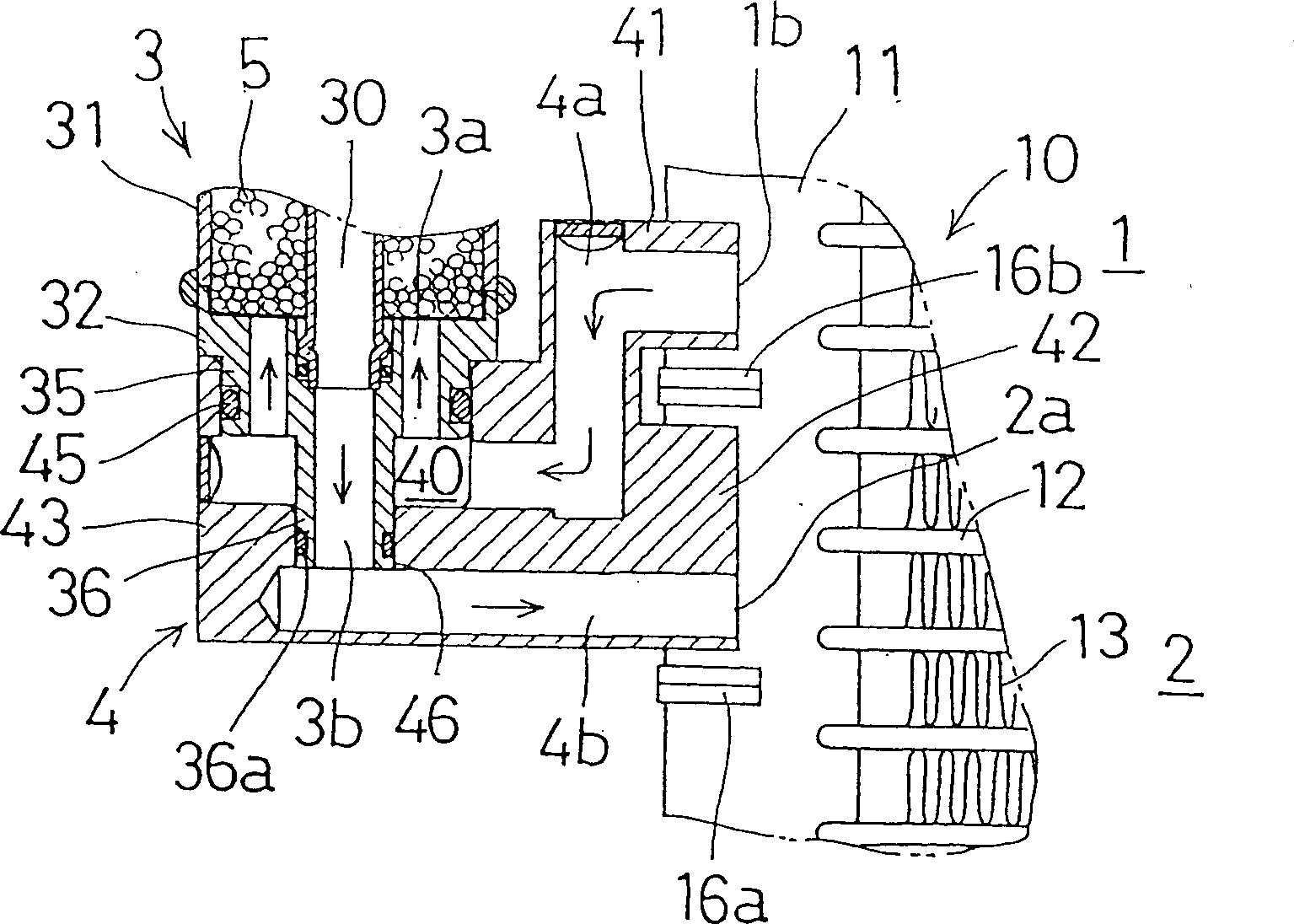

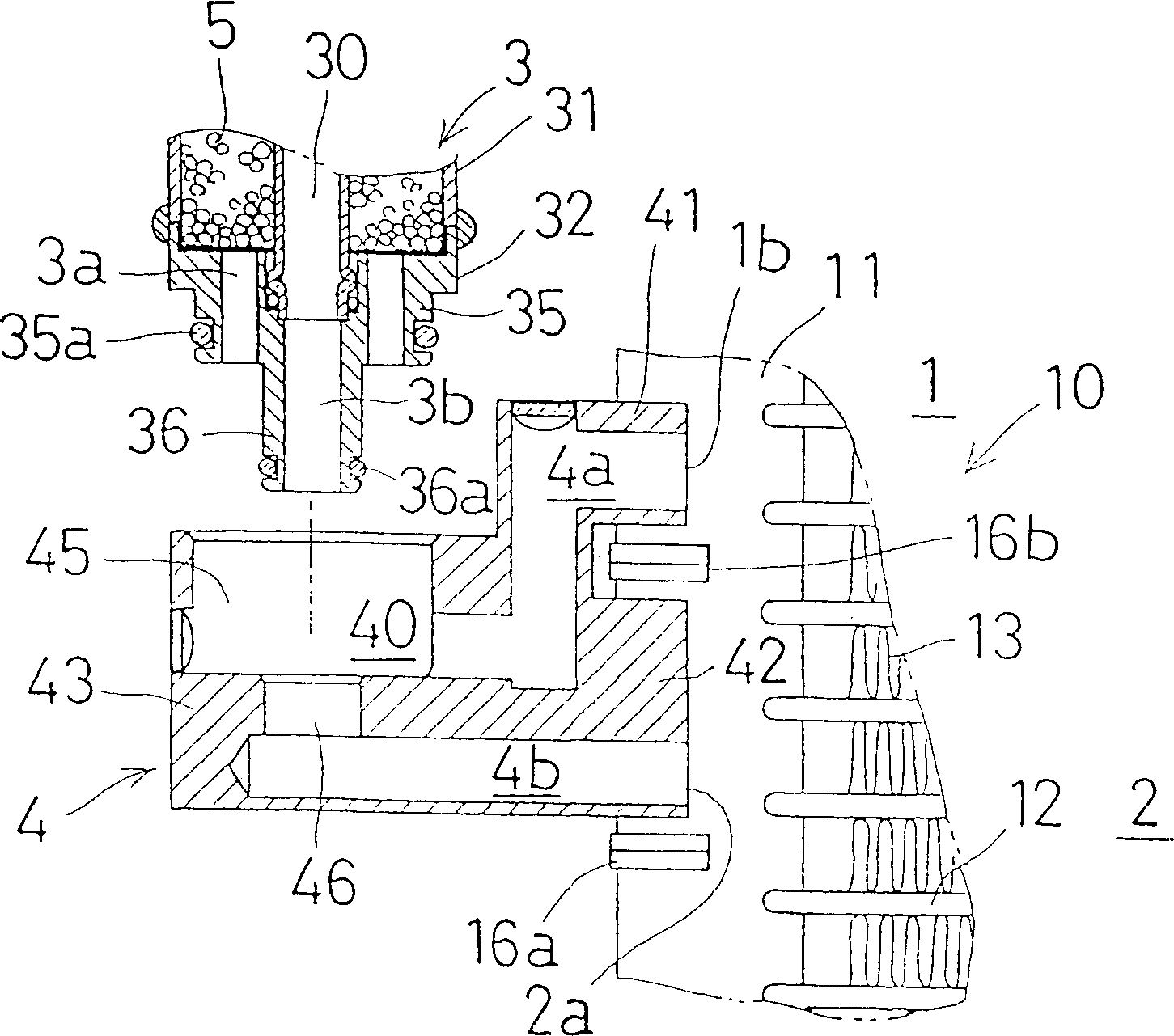

[0284] figure 1 is a front view showing one side of a heat exchanger with a liquid storage tank according to a first embodiment of the present invention, figure 2 is an enlarged partial cutaway cross-sectional view showing the block flange and its surroundings of the heat exchanger, image 3 is a partially cutaway cross-sectional view showing the block flange and its surroundings in the disassembled state.

[0285] As shown in these drawings, the heat exchanger is provided with a so-called multi-flow type heat exchanger body 10, a liquid storage tank 3, and a connecting member constituting for connecting the liquid storage tank 3 to the heat exchanger body 10 The block flange 4.

[0286] The heat exchanger body 10 is provided with a pair of left and right vertical headers 11 arranged at a certain distance. Between the pair of headers 11 are provided a plurality of horizontal flat tubes 12 as heat exchange tubes, which are arranged parallel to each other at a certain inter...

no. 2 example

[0342] Figures 15 to 18 is an enlarged view showing a block flange and its surroundings of a heat exchanger with a liquid storage tank according to a second embodiment of the present invention.

[0343] As shown in these drawings, in this heat exchanger, on both sides of the inlet of the liquid storage tank 3 and the outlet concave step portion 36 of the outlet forming member 32, a pair of laterally protruding pull-out preventing protrusions 37 are provided. and 37.

[0344] On the other hand, on the inner circumference of the outlet concave stepped portion 46 of the block flange 4, a protruding fitting slot 47b is provided in the circumferential direction thereof. In addition, on the peripheral portion of the outlet concave step portion 46 on the bottom surface of the inlet concave step portion 45, a protrusion introduction notch 47a corresponding to the above-mentioned pull-out prevention protrusion 37 and extending in the axial direction thereof is provided. The upper en...

no. 3 example

[0350] Figures 19 to 22 A heat exchanger with a liquid storage tank according to a third embodiment of the present invention is shown.

[0351] As shown in these drawings, similar to the previous embodiment, the heat exchanger is provided with a multi-flow type heat exchanger body 10, a liquid storage tank 3, and a The block flange 4 of the joining element.

[0352] In this heat exchanger body 10, an opening 1b is formed in an end portion of a partition wall 16b that divides the heat exchanger body 10 into a condensing section 1 and a recooling section 2, and this opening 1b constitutes a condensing section outlet 1b. Other structures are the same as in the foregoing embodiments.

[0353] In addition, the liquid storage tank 3 is also provided with the same structure as the previous embodiment.

[0354] For the block flange 4, on the upper surface of the block flange 4 on the side of the liquid storage tank 3, there is provided an entrance concave step whose horizontal sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com