Oil cooling structure for piston rod of piston compressor

A technology of cooling structure and piston rod, which is applied in the direction of liquid variable displacement machinery, mechanical equipment, variable displacement pump components, etc. It can solve the problems of affecting the normal operation of the compressor, easy scaling of the packing water channel, and unsatisfactory cooling effect, etc. , to achieve the effect of reducing unplanned downtime, reducing maintenance workload, and reducing cleaning workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

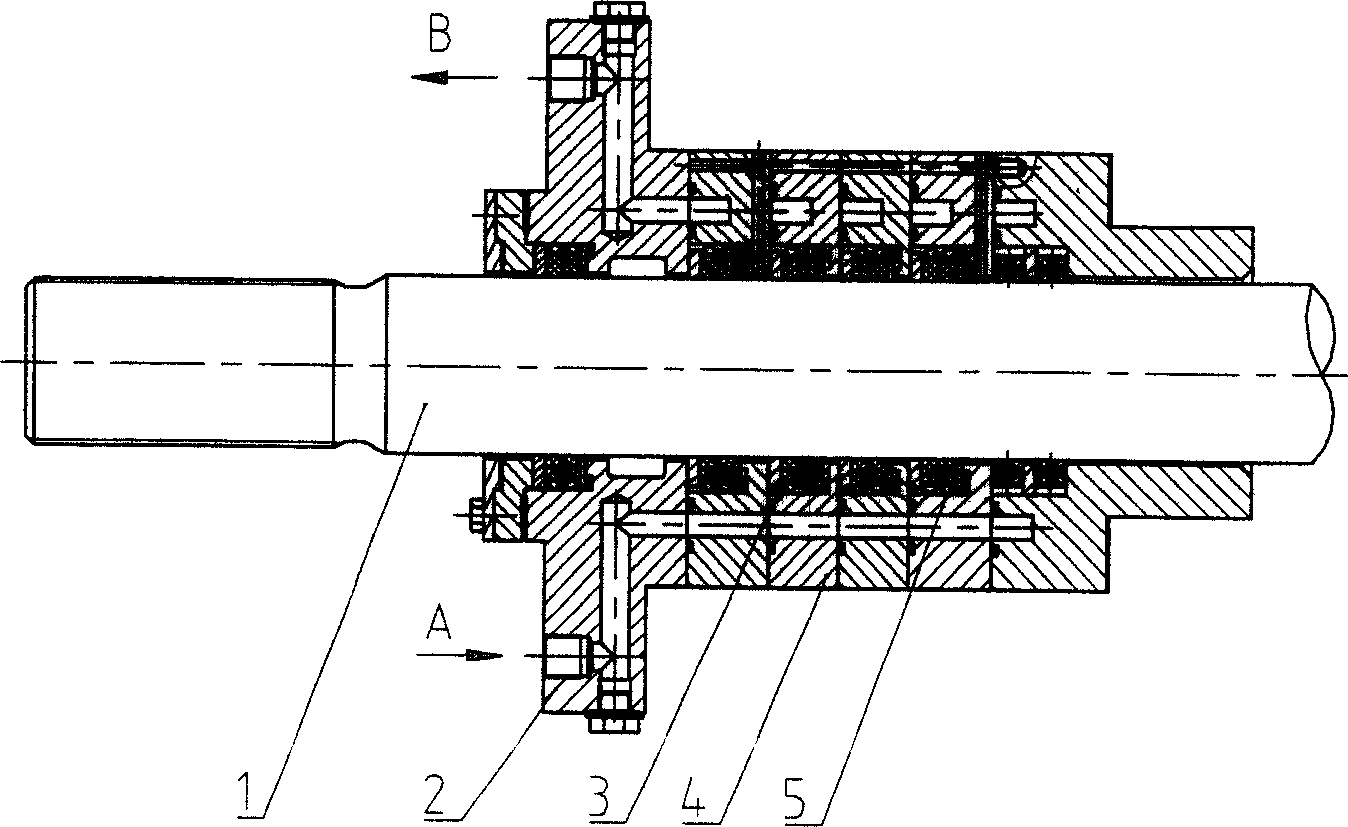

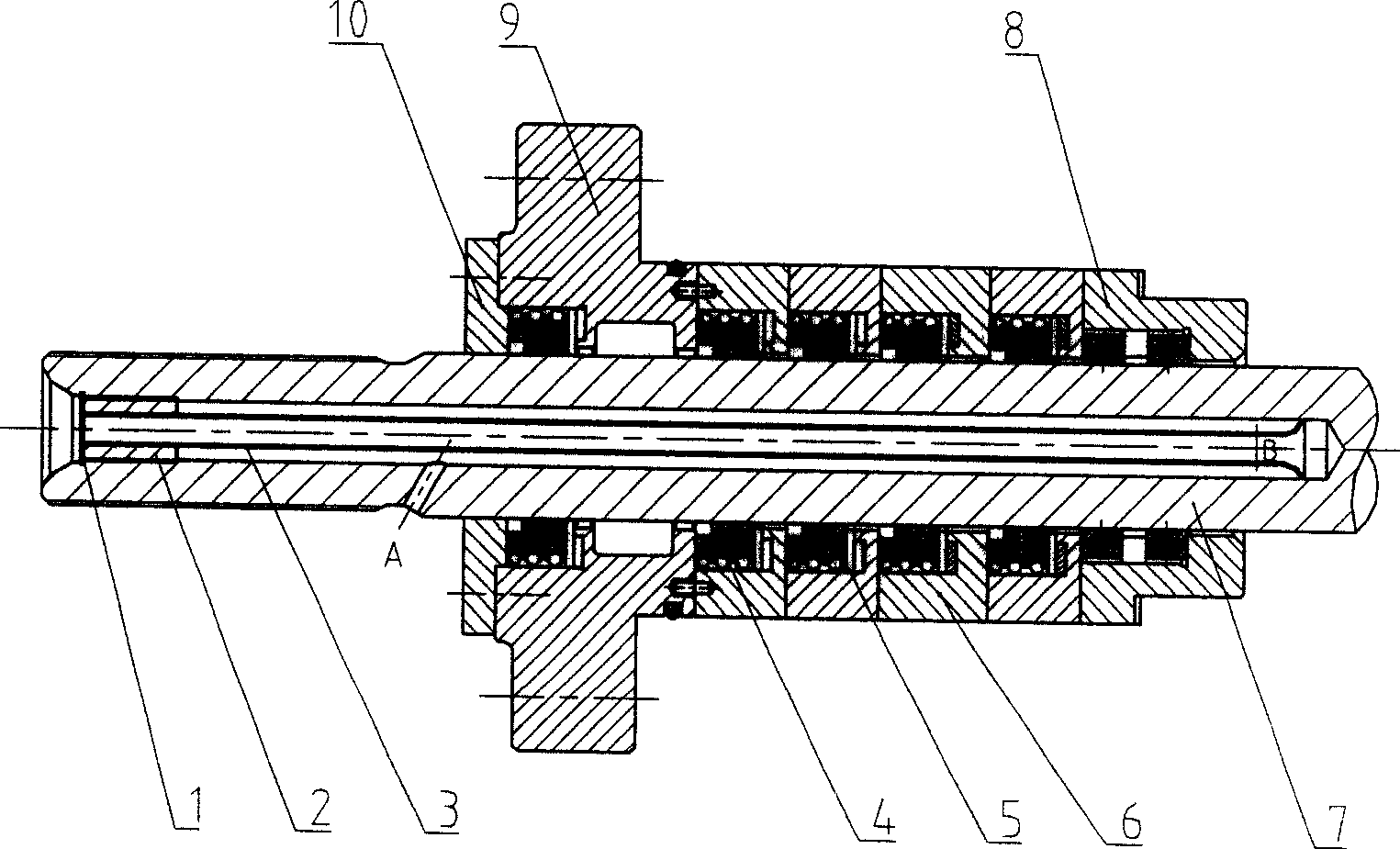

[0013] The present invention is mainly composed of retaining ring 1, joint 2, oil guide pipe 3, packing (sealing ring 4 and locking ring 5), stuffing box 6, piston rod 7, throttling sleeve 8, gland 9 and pressure plate 10, etc.

[0014] The oil-through cooling structure of the present invention is to drill a cooling deep hole from the tail end of the piston rod 7, insert an oil guide pipe 3 in the cooling deep hole, and feed the cooling oil to circulate and cool. The oil guide pipe 3 is pressed on the end of the piston rod 7 by the joint 2 and the retaining ring 1, and the other end of the oil guide pipe 3 is provided with a flanging for support, so as to ensure that the oil guide pipe and the deep hole of the piston rod 7 are basically concentric. Packing (comprising sealing ring 4 and locking ring 5) is contained in the stuffing box 6, and can set mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com