Manufacturing and processing technology of piston barrel

A processing technology and piston cylinder technology, which is applied in the field of piston cylinder manufacturing and processing technology, can solve problems such as insufficient sealing, large roundness tolerance, and complicated welding seam elimination process, so as to improve production and processing efficiency and avoid thickness irregularities. Uniform, process-step-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

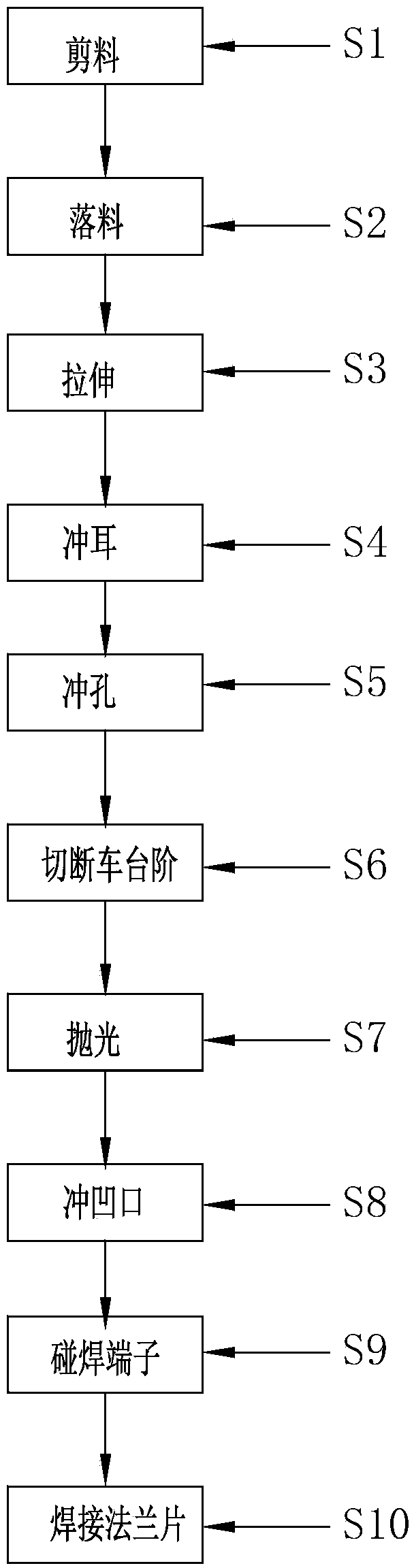

[0046] refer to Figure 1-Figure 20 As shown, it is a manufacturing and processing technology of a piston cylinder of the present invention, but the piston cylinder of the present invention is not limited to the coffee machine described in the background technology, and other electrical products need to use the piston cylinder processing technology of this technical solution. Within the protection scope of the present invention, the following are the concrete steps of protected technology of the present invention:

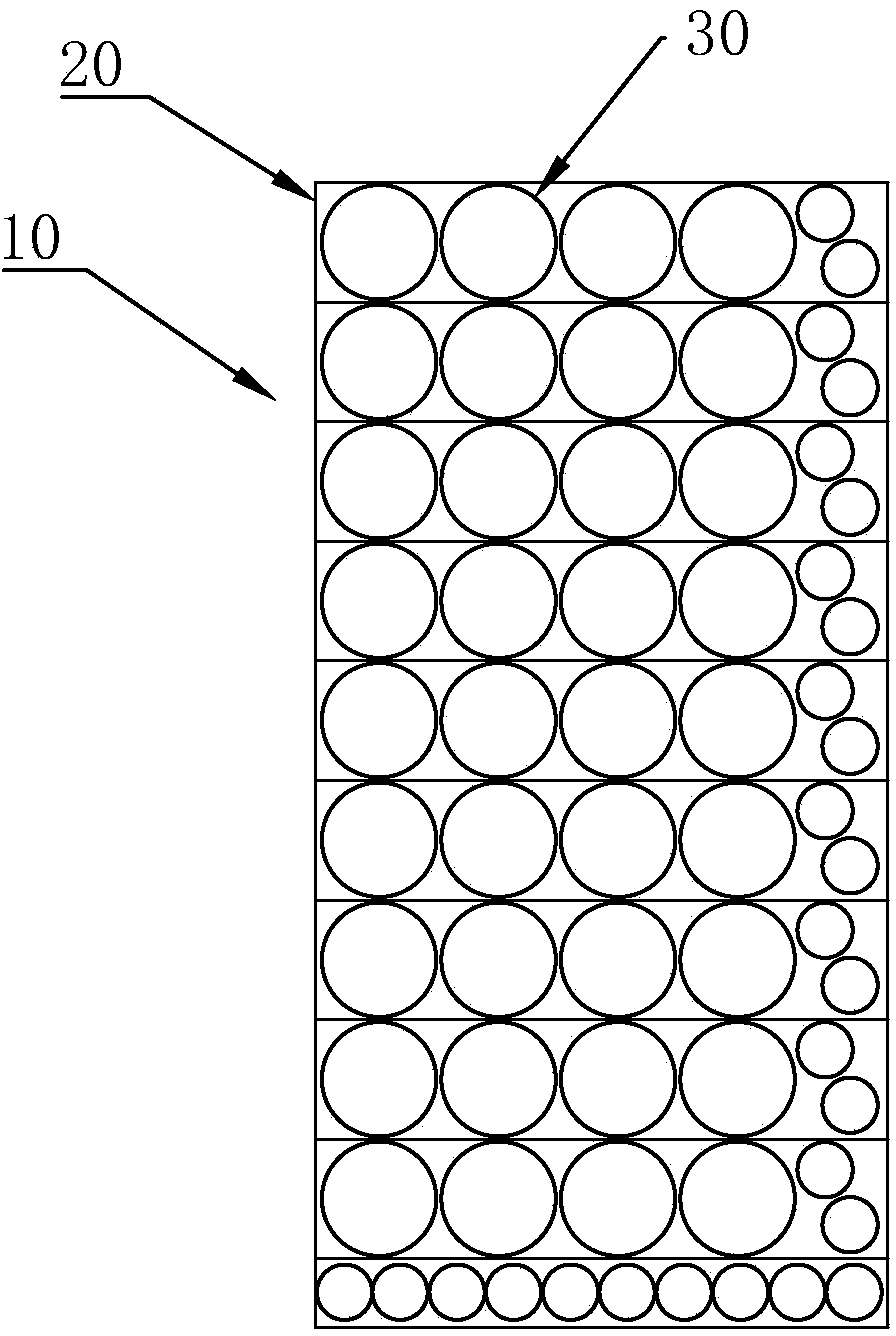

[0047] S1, cutting material, cutting the sheet metal raw material 10 into several strips 20;

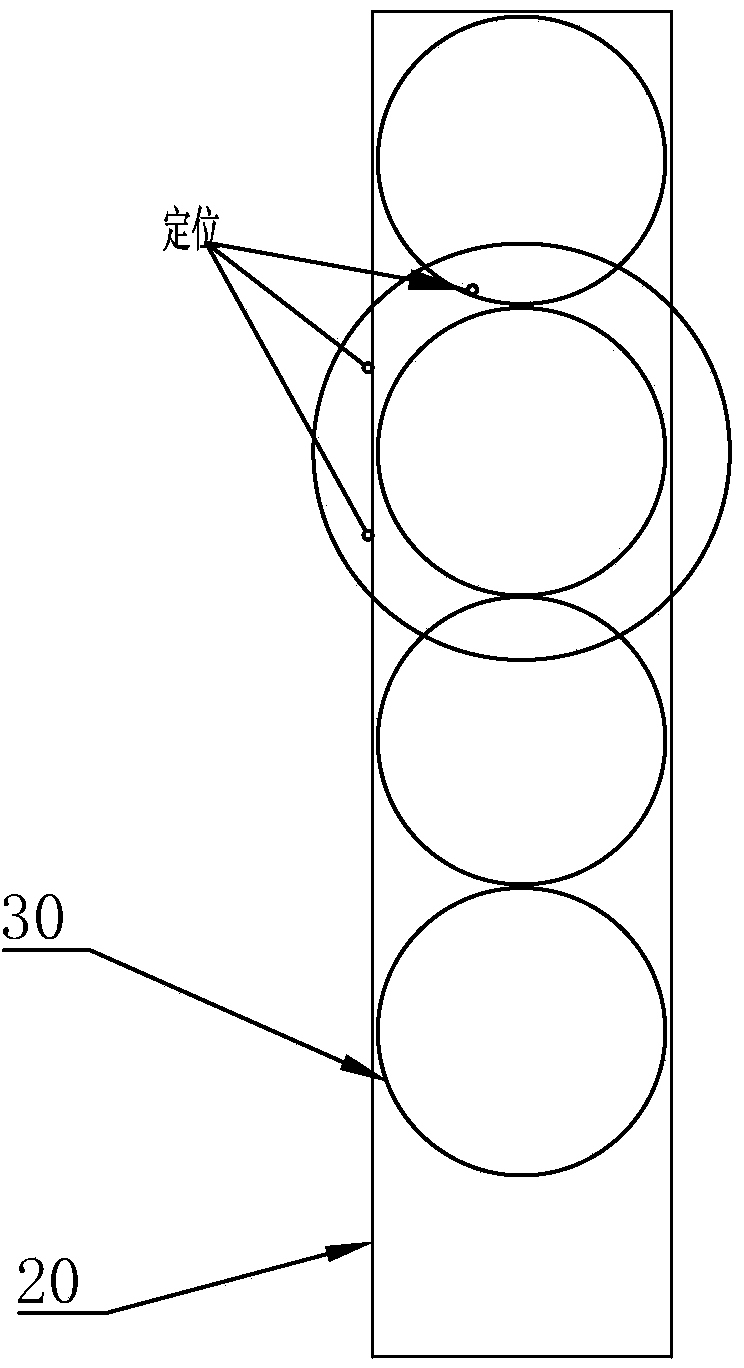

[0048] Such as figure 2 As shown, the material of the raw material selected in this embodiment is sus304-special material for stretching, material thickness: T=1.5mm, and each sheet of material is punched with 36 discs 30 of ?247 and 28 flanges of ?118;

[0049] Pay attention to positioning when cutting materials, and self-check: a. There is no crushing, scratching, wr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com