Threaded joint for pipes

A technology for threaded joints and pipes, which is applied in the direction of threaded connections, pipes/pipe joints/fittings, drill pipes, etc., can solve the problems of airtightness deterioration of threaded joints, improve wear resistance and rust resistance, and prevent pressure The effect of overgrowth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

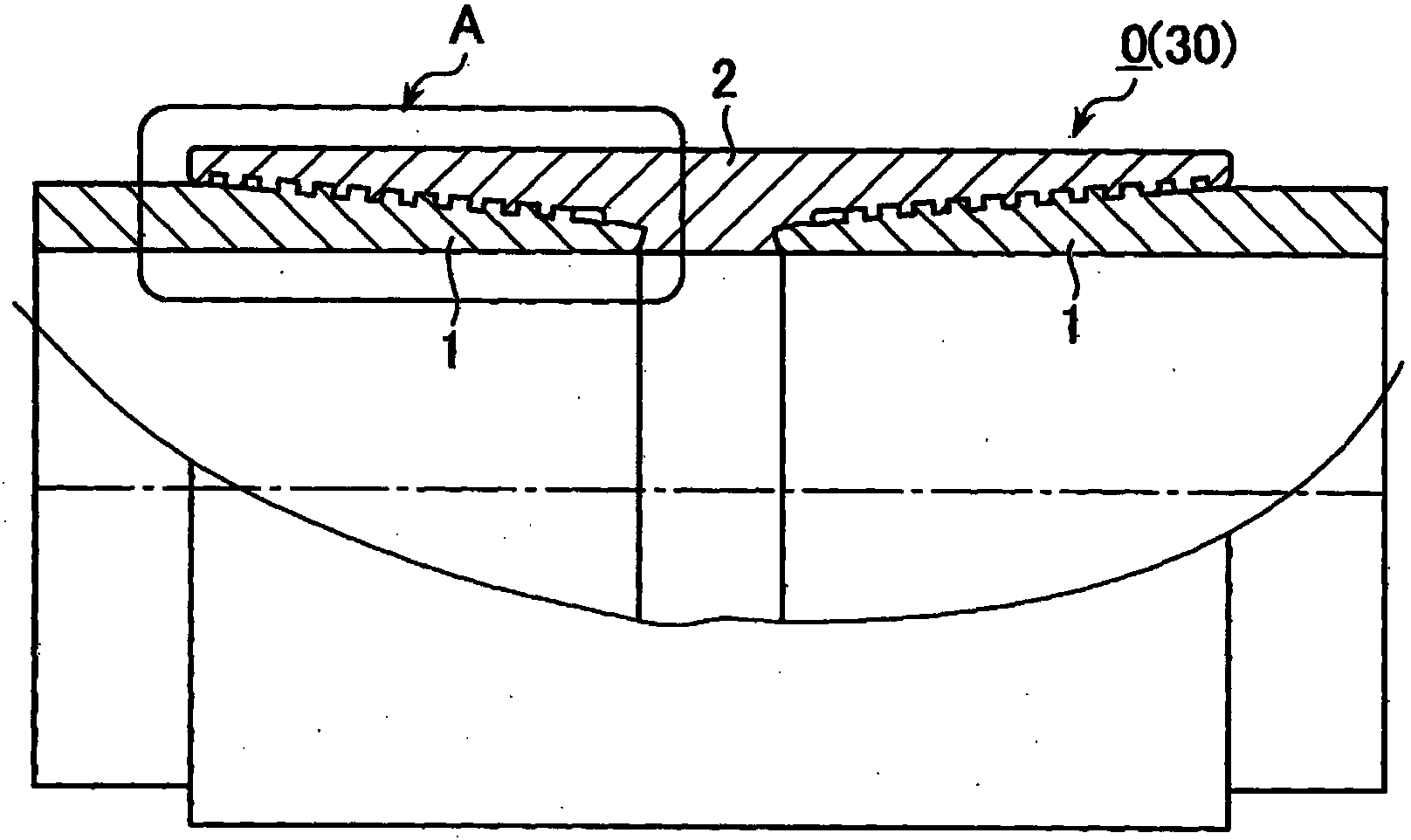

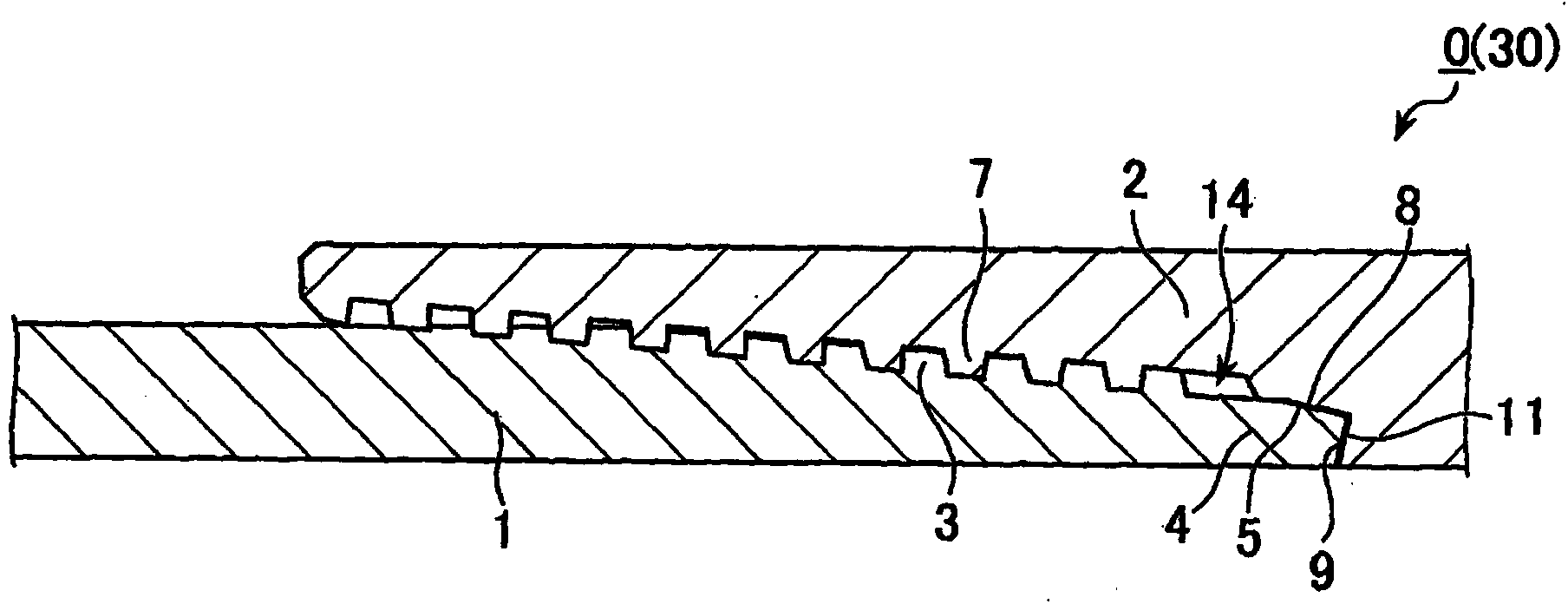

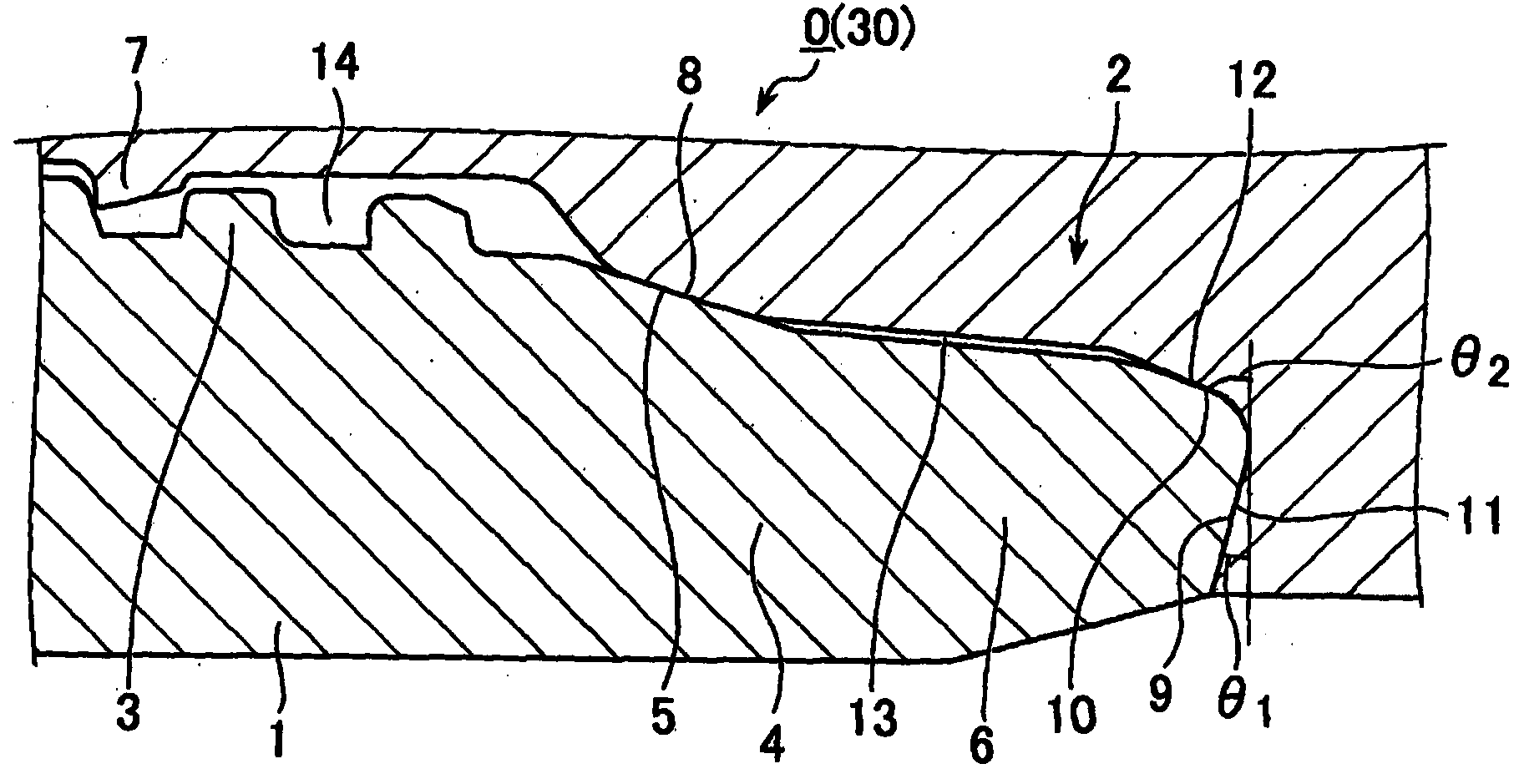

[0134] A threaded joint for pipes having the dimensions shown in Table 1 was used to perform a sealing test (a test in which internal and external pressures are applied to the threaded joint while a tensile load and a compressive load are applied to the threaded joint). The threaded joint has Figure 1A to Figure 1C as well as Figure 2A with Figure 2B In the shape shown in, the groove 9a formed on the shoulder surface has the width and depth shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com