Experimental device for two-phase heat transfer characteristic research and method for measuring wet steam dryness

A technology of experimental device and heat transfer characteristics, applied in the direction of measurement device, material thermal development, instrument, etc., can solve the problem of high experimental cost, and achieve the effect of reducing experimental cost, avoiding insulation sealing and boiling critical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

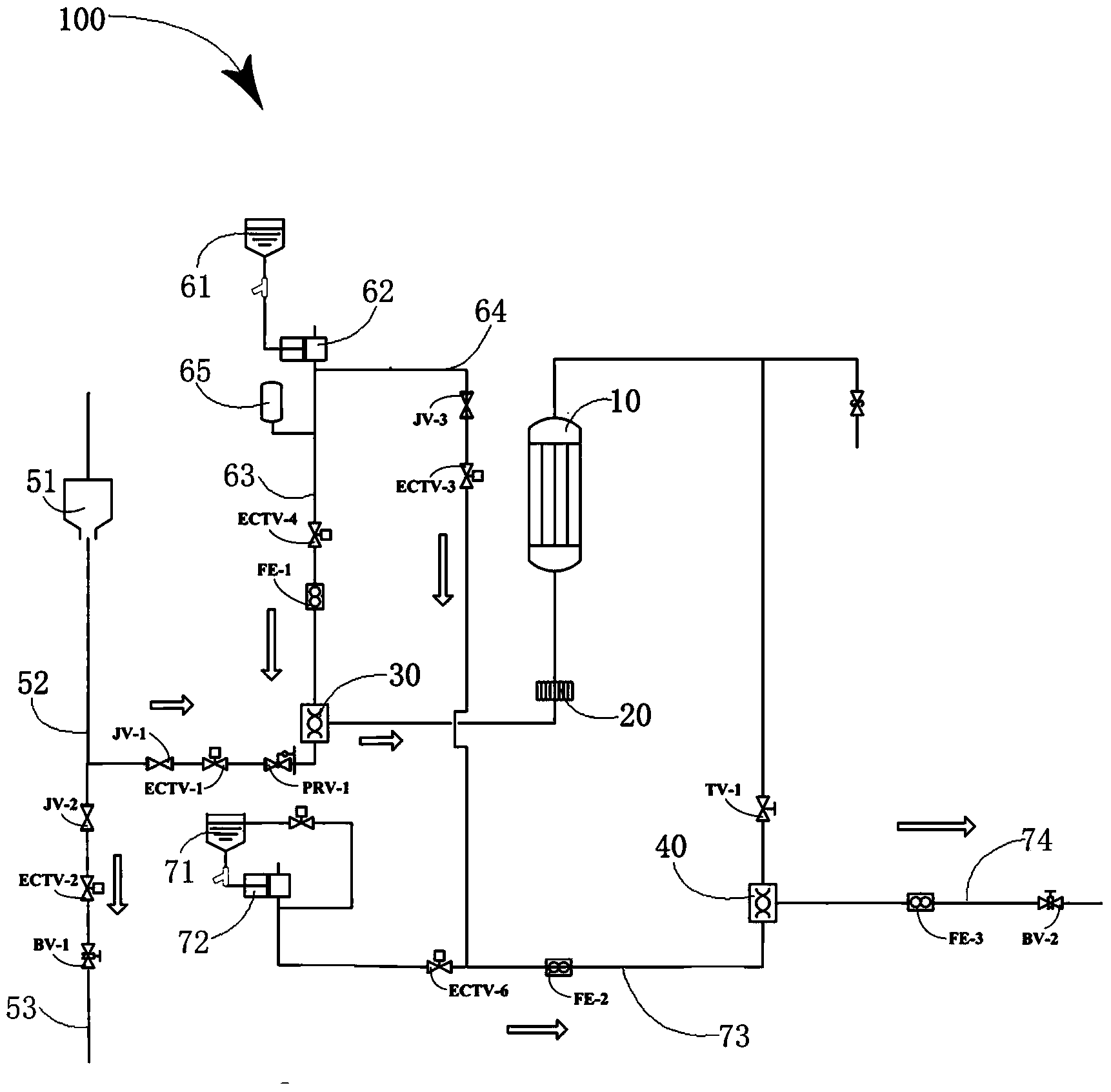

[0039] see figure 1 , the experimental device 100 for the study of the heat transfer characteristics of steam-water two-phase flow shown in the preferred embodiment of the present invention, the experimental device 100 can not only meet the conditions of high pressure and high dryness required for the experiment, but also solve the problem of the existing technology The medium device needs to be insulated and sealed and has defects of boiling criticality, etc., avoiding the use of high-power heat sources and reducing costs. The experimental device 100 includes an experimental body 10, a steam homogenizer 20, a first steam-water mixer 30, and a second steam-water mixer. 40. Steam injection system, first water injection system, second water injection system, and data acquisition and measurement system (not shown).

[0040] One end of the experimental body 10 communicates with the steam homogenizer 20 , and the other end communicates with the second steam-water mixer 40 . The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com