Cylinder liner and piston assembly friction online test device and test method

A piston assembly, online testing technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of inaccurate friction test between cylinder liner and piston assembly, and avoid the influence of sealing performance and test. , the effect of accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

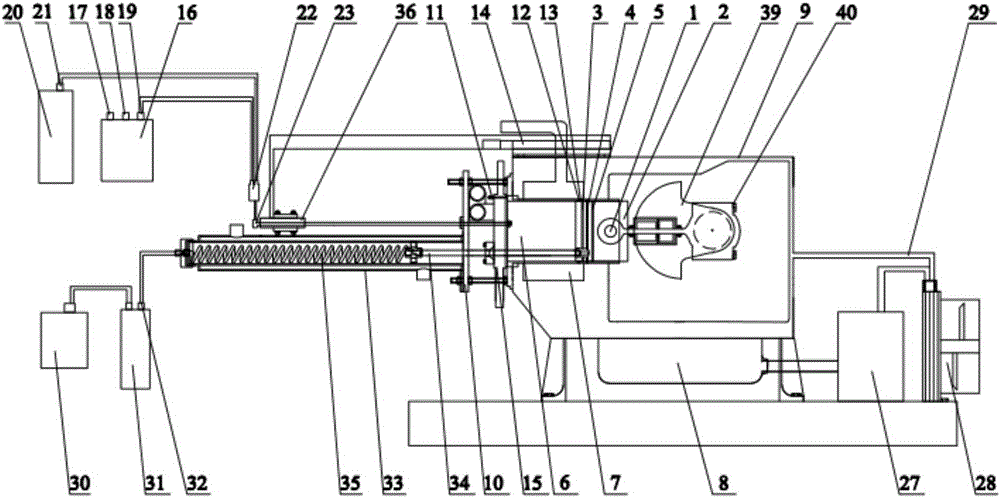

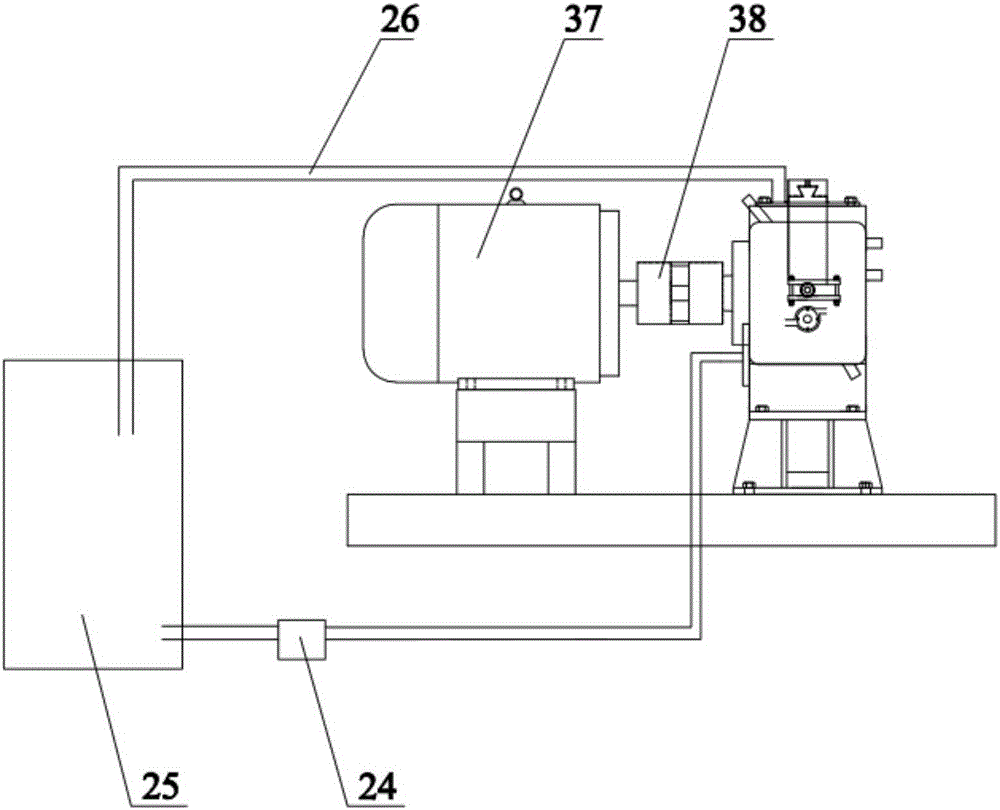

[0028] like Figure 1-Figure 4 As shown, an online testing device for the friction force of a cylinder liner and a piston assembly includes: a power unit for providing reciprocating motion, a piston pin 1, a piston 2, a first air ring 3, a second air ring 4, a scraper Oil ring 5, cylinder liner 6, cylinder block 9, baffle plate 10 and friction sensor 11, cooling cavity 7, oil pan 8, dovetail guide rail 14, fire shield 15, heating unit for heating piston and cylinder liner, A cooling unit and an air supply unit for providing high-pressure gas; the power unit is connected with the piston 2 through the piston pin 1, and the motor 37 in the power unit is connected with the crankshaft 39 through a coupling 38, and the crankshaft 39 It is connected with the piston 2 through the connecting rod 40 .

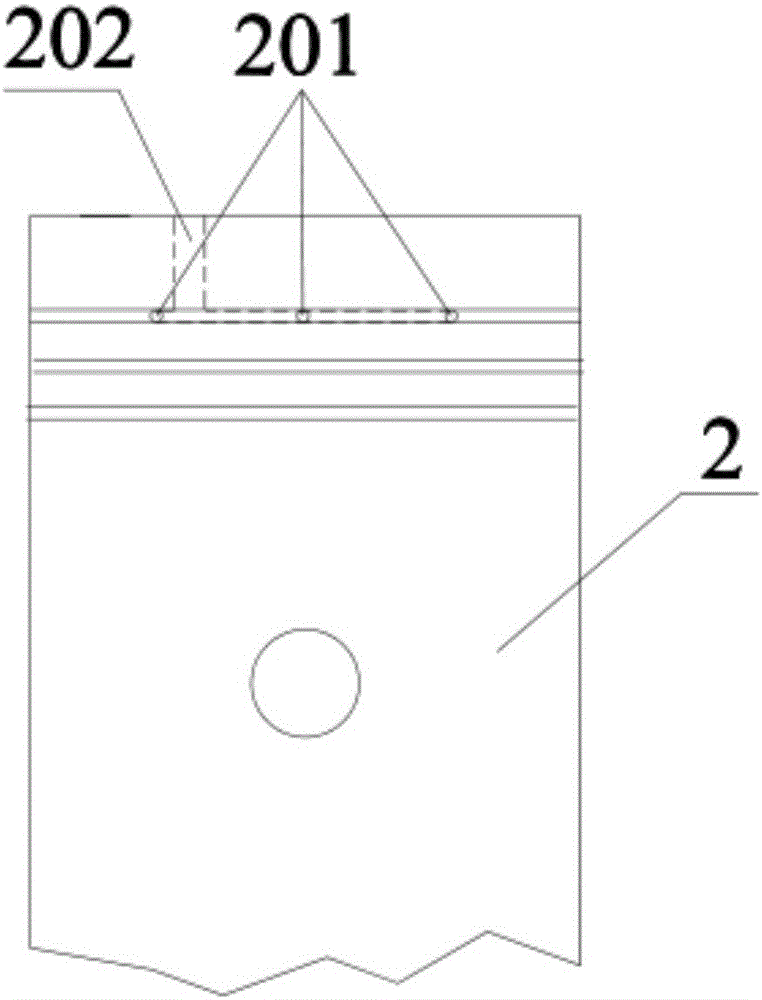

[0029] The piston 2 is sealed and connected to the cylinder liner 6 through the first gas ring 3, the second gas ring 4 and the scraper ring 5 installed in the ring groove of the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com