Piston ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0083]The piston ring of the present invention will be described in more concretely using Examples.

examples 1 to 12

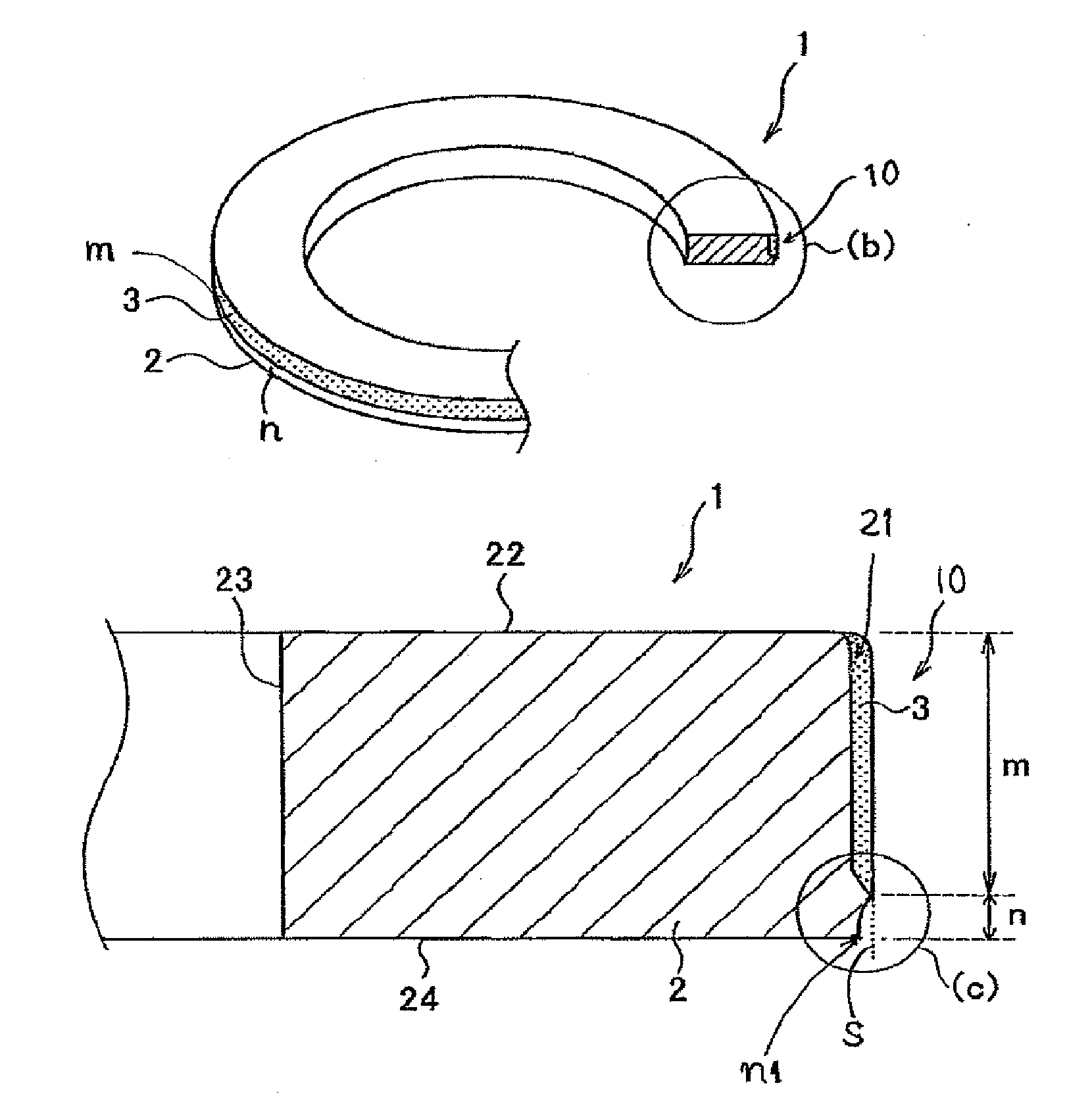

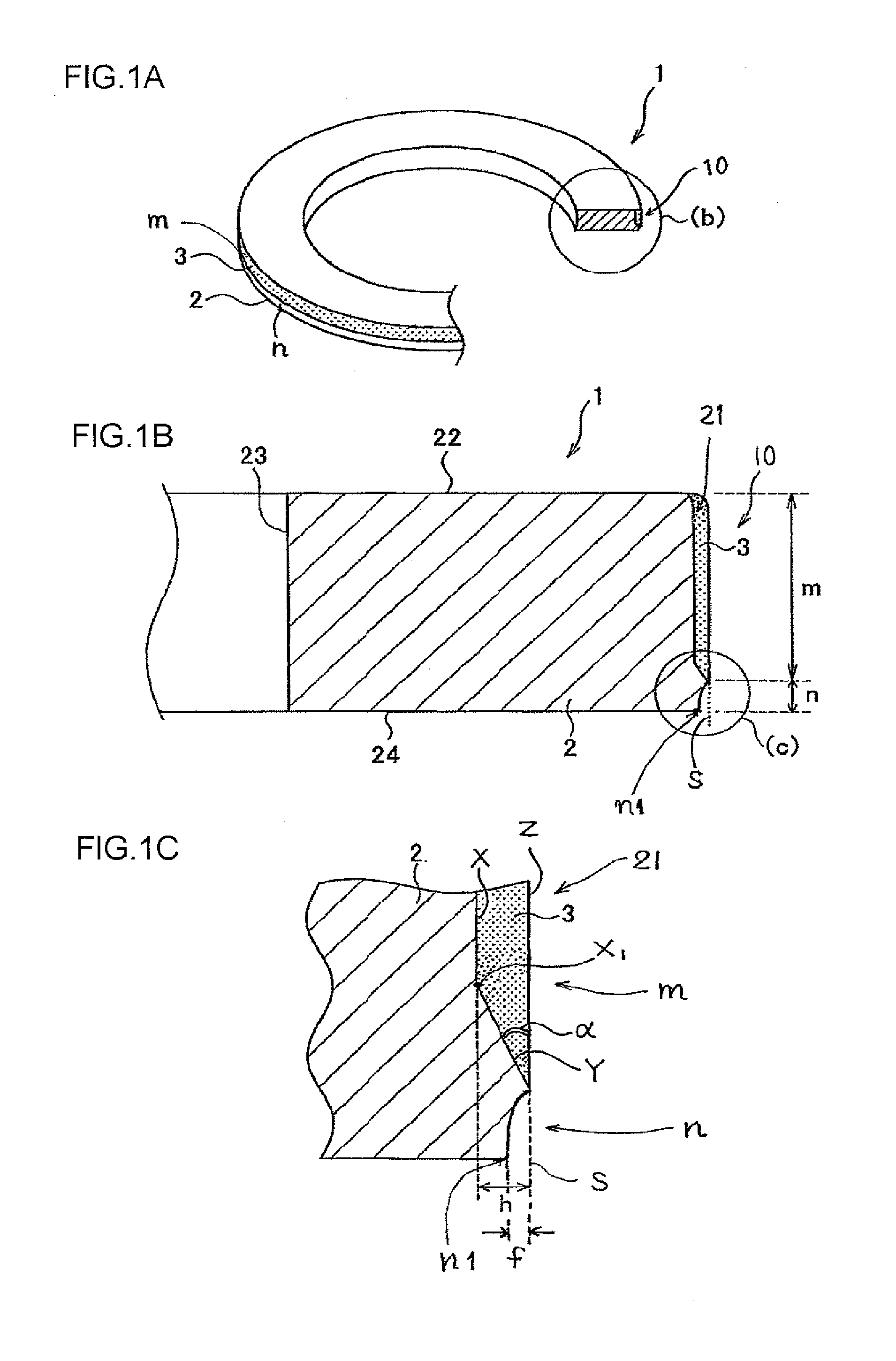

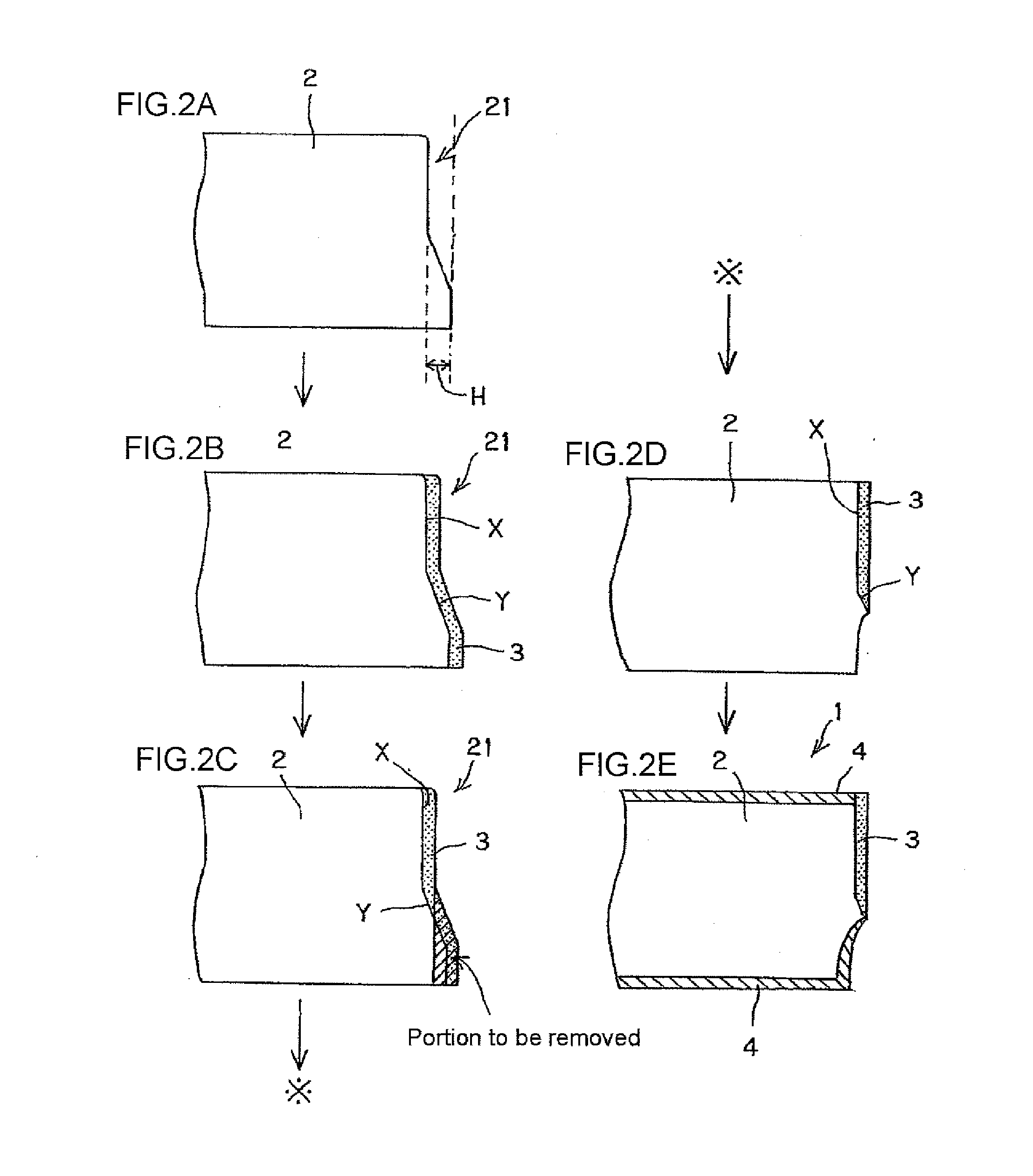

[0084]The piston ring (oil ring) shown in FIGS. 1 was produced using the method explained using FIGS. 2A to 2E.

[0085]Here, SUS440B expressed in JIS was used as the base material (2).

[0086]The hard films (3) were Cr—B—N (Examples 1 to 6) and Cr—N (Examples 7 to 12) formed by the ion plating method.

[0087]Sizes of the produced piston ring were as follows: a diameter was 115 mm, a width (h1) in the axial direction was 3.0 mm, and a width (a1) in the radial direction was 3.95 mm. A length (n) of the base material exposed from a lower portion (edge portion) of an outer peripheral sliding surface of the piston ring was 0.2 to 0.5 mm.

[0088]In the Examples 1 to 12, a value of an angle (a) formed between the piston ring outer peripheral surface (Z) and the second surface (Y) which configures the recess (21) formed in the base material (2) is as shown in Table 1. The piston ring was cut so that a cross section thereof in its axial direction could be observed, the cross section was polished and...

examples 1 to 2

Conventional Examples 1 to 2

[0091]Conventional examples in which hard films (3) were formed on the entire outer peripheral surfaces of the base materials (2) were produced in the same manner as those of the Examples. Details thereof are as shown in Table 1.

[0092]

[0093]A twist test was carried out using a twist peel test machine 40 shown in FIG. 5.

[0094]In the twist test, opposed mating ends of a gap 5 of the piston ring 1 are held by holding tools 41a and 41b, the holding tool 41a is fixed, the holding tool 41b is rotated around an opposite side 6 of the gap in a radial direction of the piston ring 1 as shown with dashed lines, and the piston ring 1 is twisted at a predetermined twisting angle. The twisting angle was 90°. After the piston ring 1 was twisted, the opposite side 6 which was opposite from the gap of the piston ring 1 was cut, and it was visually observed whether a film layer in the cut surface (fracture) was peeled off from a ring base material. As a result of the obser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com