Fabric for airbag, fully moulded airbag as well as manufacturing method thereof

An airbag, fully formed technology, used in vehicle safety arrangements, fabrics, textiles and papermaking, etc., to achieve the effect of reducing costs and good technical results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

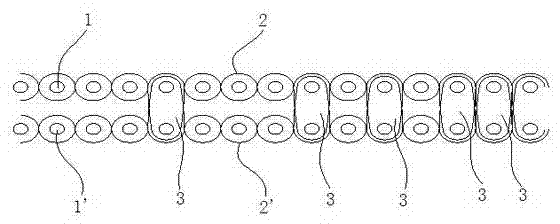

Image

Examples

Embodiment 1

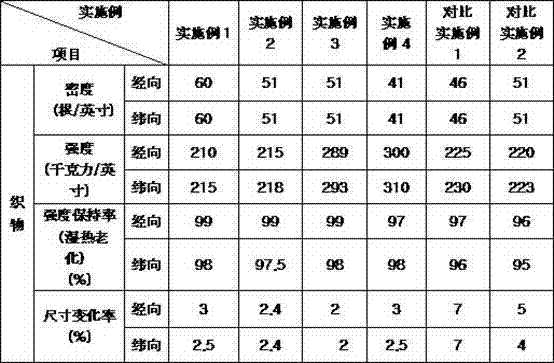

[0036] Nylon 66 with a dry heat shrinkage rate of 4.1% and a boiling water shrinkage rate of 4.3% is used as the warp yarn, and a polyester with a dry heat shrinkage rate of 2.2% and a boiling water shrinkage rate of 1.5% is used as the weft yarn. The CEG content in the polyester is 20meq / kg. After the woven fabric is treated with an aqueous solution containing a refining agent at 60°C for 2 minutes, it is dried and shaped in an oven heated by hot air at 150°C for 1 minute, and then coated with 45g / ㎡ of silica gel. In this process, the warp and weft dimensional change rates of the fabric are 3% and 2.5%, respectively, and the strength retention rate of the fabric after heat and humidity aging is above 97%.

[0037] The physical properties of the yarns used in Example 2-Example 4 and Comparative Example 1 and Comparative Example 2 are shown in Table 1, and the physical properties of the fabric obtained using the same method as in Example 1 are shown in Table 2.

[0038]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com