Nitrogen-oxygen separation device and corresponding oxygenerator

A nitrogen-oxygen separation and molecular sieve technology, applied in the field of oxygen generators, can solve the problems of high production cost, large volume of oxygen generators, poor air tightness, etc., and achieve the effects of low production cost, small volume and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The preferred embodiments of the present invention will be described in detail below with reference to the drawings.

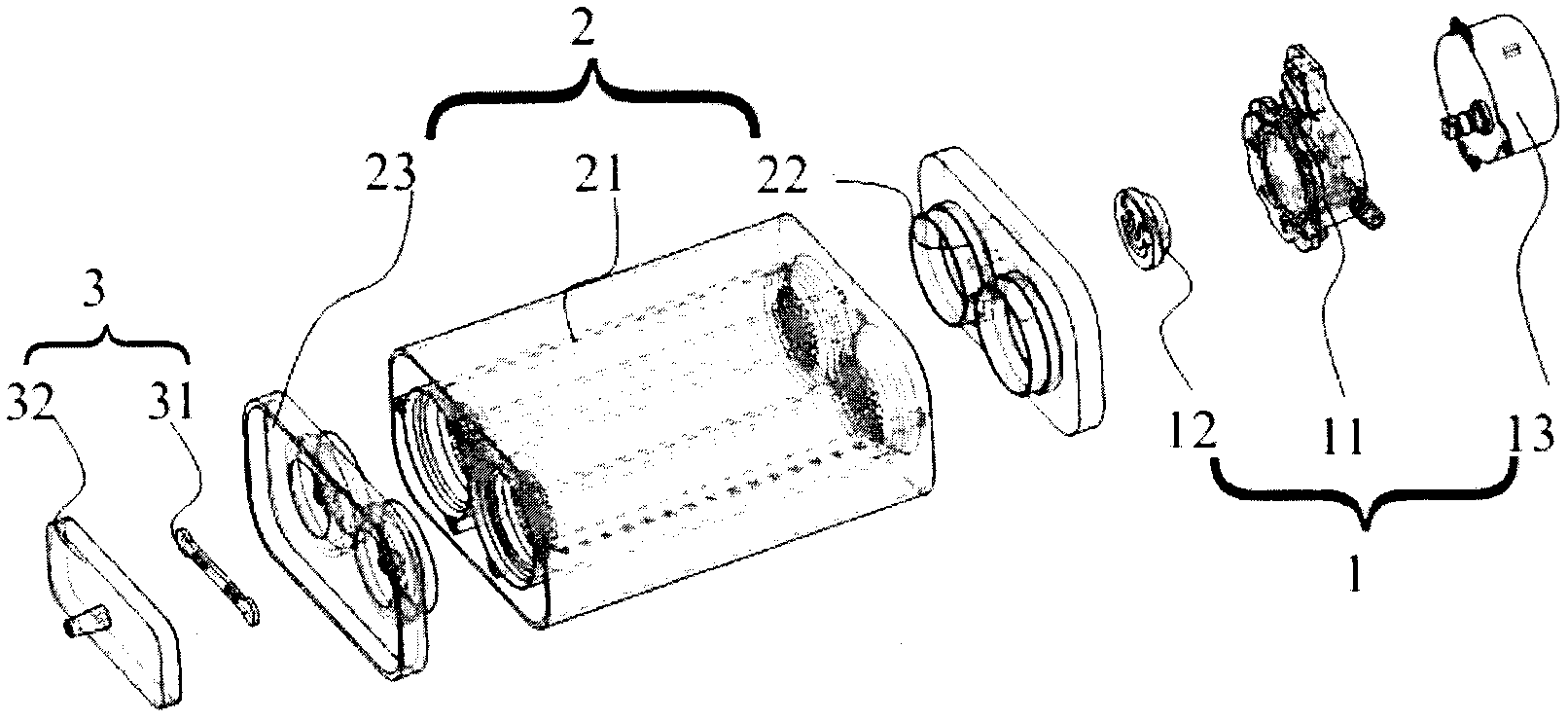

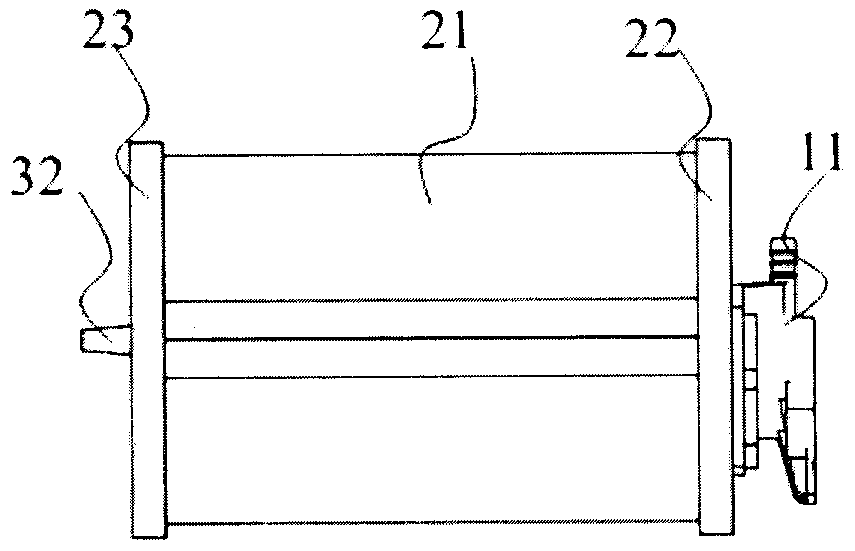

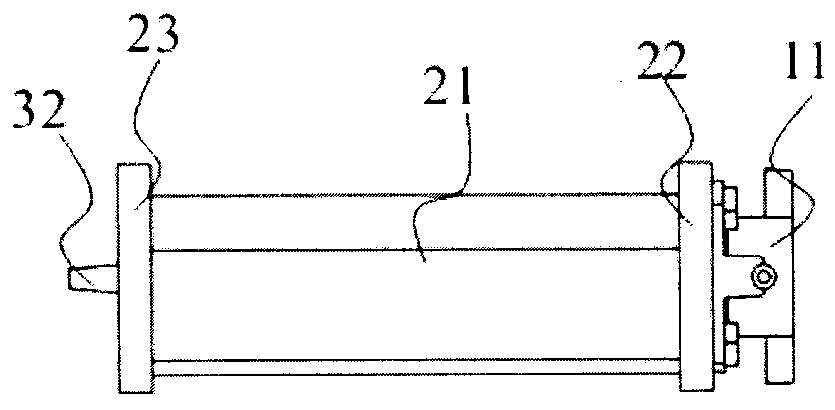

[0067] Please refer to figure 1 , Figure 2A-Figure 2G , figure 1 It is an exploded structure diagram of the first preferred embodiment of the nitrogen-oxygen separation device of the present invention, Figure 2A-Figure 2F It is a six-view diagram of the structure of the preferred embodiment of the nitrogen and oxygen separation device of the present invention (the driving motor is not shown in the figure), Figure 2G It is a structural perspective view of a preferred embodiment of the nitrogen and oxygen separation device of the present invention (the driving motor is not shown in the figure). The nitrogen and oxygen separation device of this preferred embodiment includes an intake module 1, a separation module 2 and an oxygen output module 3; The molecular sieve assembly 21 , the molecular sieve front cover 22 and the molecular sieve rear cover 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com