Corrugated paper printing process for fruit packaging boxes

A technology of corrugated paper and packaging boxes, applied in the field of corrugated paper printing technology for fruit packaging boxes, to achieve the effects of improving printing effects, strong adhesion, and solving poor printing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

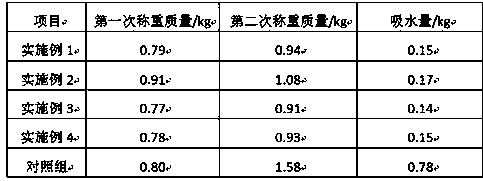

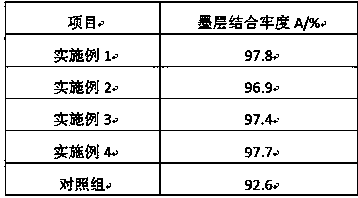

Examples

Embodiment 1

[0024] A corrugated paper printing process for fruit packaging boxes includes the following steps:

[0025] (1) Corrugated paper pretreatment: According to the specifications of the fruit packaging box, the paper is divided and pressed, and the corrugated cardboard is cut according to the pressing line, and then the surface of the cut corrugated paper is cleaned;

[0026] (2) Flexible plate making: According to the designed printing pattern, the photosensitive resin is coated on the plate base, then exposed to ultraviolet light, and then washed, dried, and thermally cured to obtain the required flexible plate for use;

[0027] (3) Corrugated paper surface treatment: Put the corrugated paper cleaned in step (1) into the corona machine, and use high-frequency and high-voltage power supply to corona treatment on the inner and outer surfaces of the corrugated paper, with a corona value of 28W / m;

[0028] (4) Corrugated paper PE coating: the corrugated paper that has been corona treated in ...

Embodiment 2

[0034] (1) Corrugated paper pretreatment: According to the specifications of the fruit packaging box, the paper is divided and pressed, and the corrugated cardboard is cut according to the pressing line, and then the surface of the cut corrugated paper is cleaned;

[0035] (2) Flexible plate making: According to the designed printing pattern, the photosensitive resin is coated on the plate base, then exposed to ultraviolet light, and then washed, dried, and thermally cured to obtain the required flexible plate for use;

[0036] (3) Corrugated paper surface treatment: Put the corrugated paper cleaned in step (1) into the corona machine, and use high-frequency high-voltage power supply to corona treatment on the inner and outer surfaces of the corrugated paper, with a corona value of 32W / m;

[0037] (4) Corrugated paper PE coating: the corrugated paper that has been corona treated in step (3) is sent to the double-sided laminating machine for PE coating, the PE coating temperature is 76...

Embodiment 3

[0043] A corrugated paper printing process for fruit packaging boxes includes the following steps:

[0044] (1) Corrugated paper pretreatment: According to the specifications of the fruit packaging box, the paper is divided and pressed, and the corrugated cardboard is cut according to the pressing line, and then the surface of the cut corrugated paper is cleaned;

[0045] (2) Flexible plate making: According to the designed printing pattern, the photosensitive resin is coated on the plate base, then exposed to ultraviolet light, and then washed, dried, and thermally cured to obtain the required flexible plate for use;

[0046] (3) Corrugated paper surface treatment: Put the corrugated paper cleaned in step (1) into the corona machine, and use high-frequency high-voltage power supply to corona treatment on both the inner and outer surfaces of the corrugated paper, with a corona value of 26W / m;

[0047] (4) Corrugated paper PE coating: the corrugated paper that has been corona treated in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com