Composite material made box body structure for storage and conveying launch box

A composite material and box structure technology, used in projectiles, self-propelled bombs, offensive equipment, etc., can solve problems such as cracks in joints, difficult air tightness of box structure, etc., to achieve good balance and ensure fast speed Combat responsiveness, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

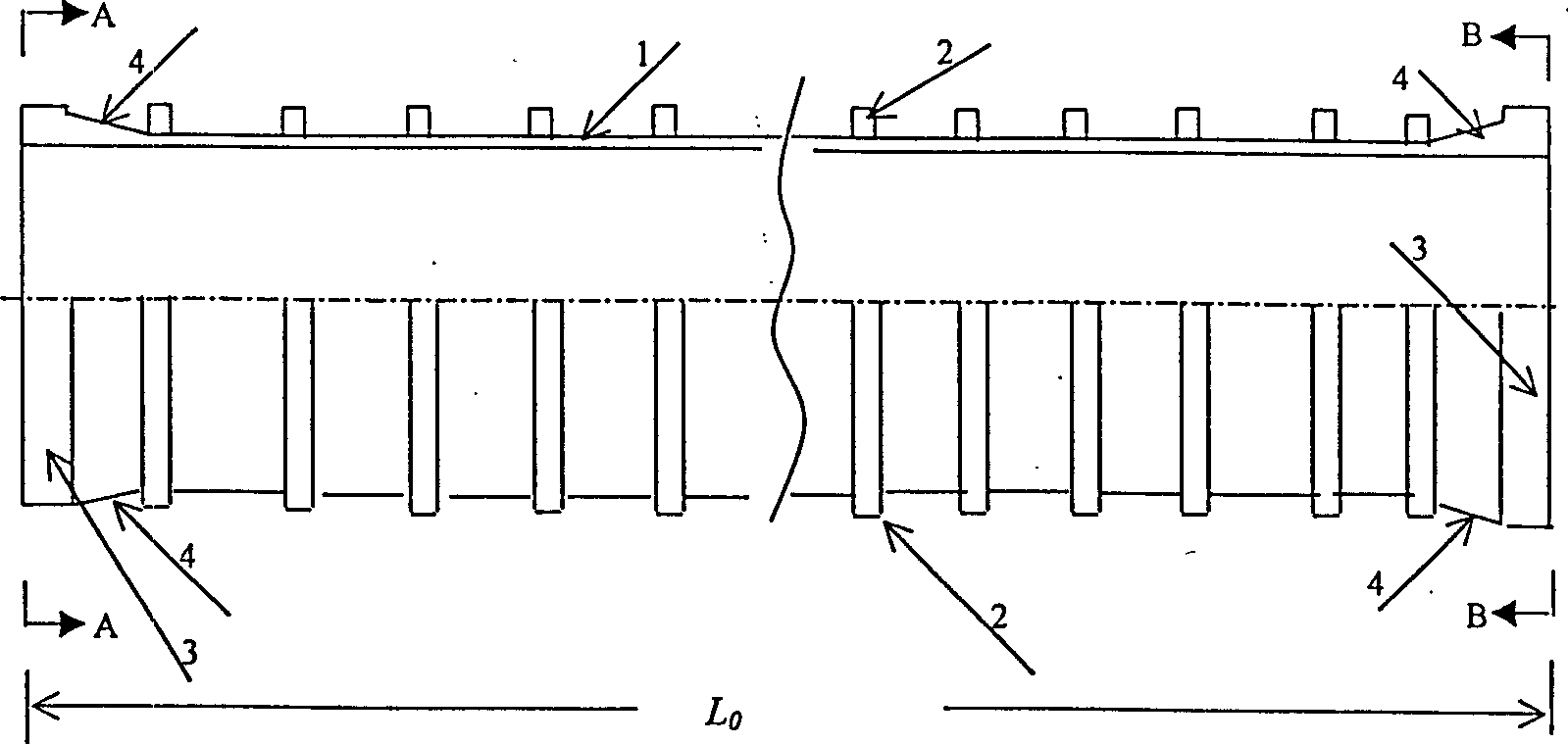

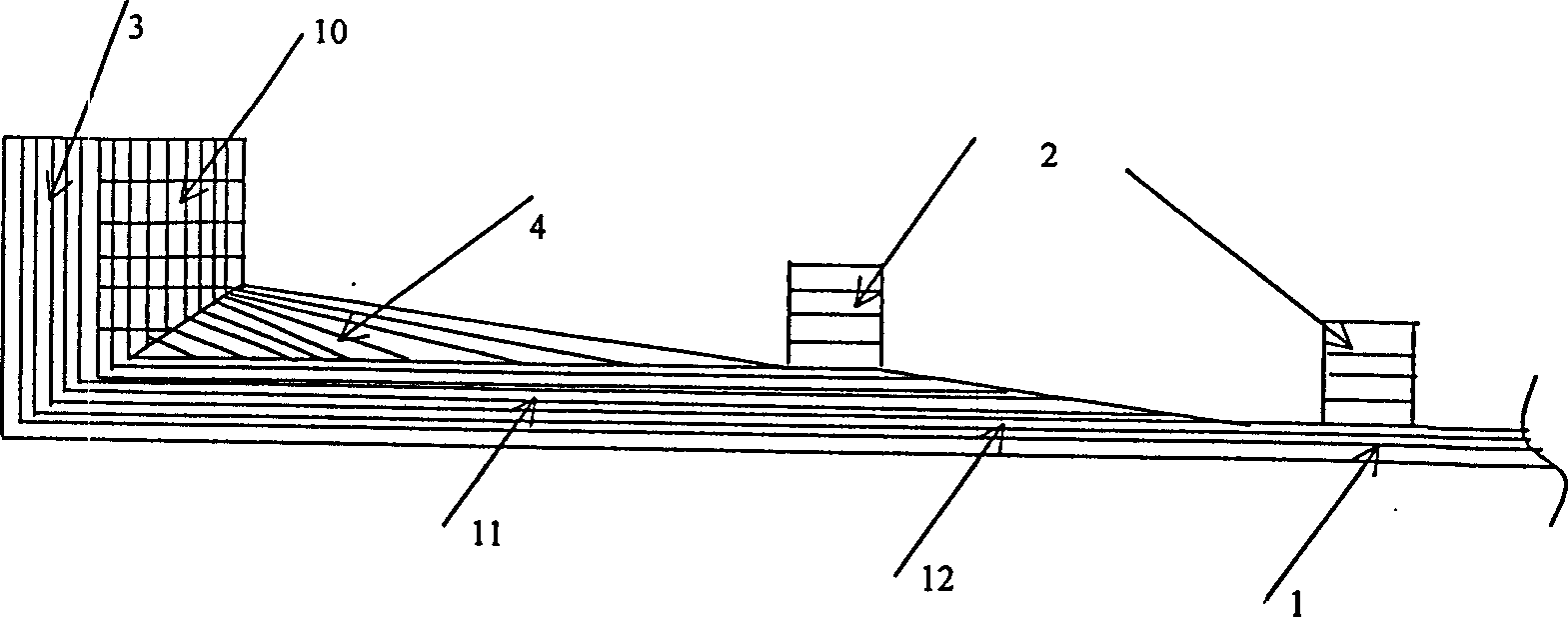

[0037] Composite box body structure of the present invention such asfigure 1 As shown, the box is surrounded by the four-sided base plate 1 of the box body, and transverse reinforcing ribs 2 are arranged at equal intervals along the length direction of the four-sided base plate 1 of the box body. The layers 11 form a whole full-composite flanging flange 3, and there is a reinforcing transition layer 4 between the full-composite flanging flange 3 and the thickened layer 11 at the end of the box substrate.

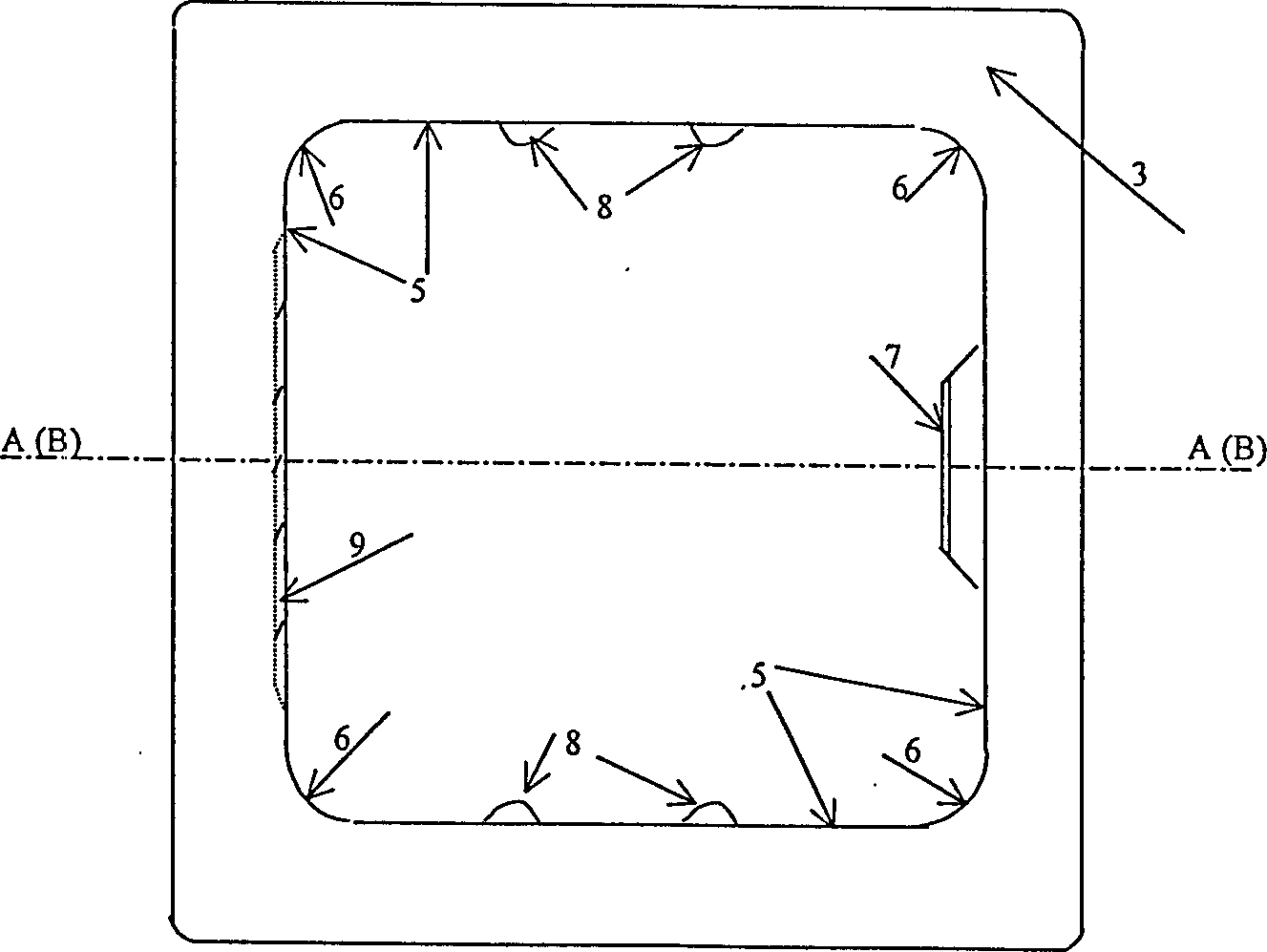

[0038] The box base plate 1 of the present invention is taken as R=R by taking the shallow arched shell plate 5 and the four corners of the box body that the four sides arch height of the box body is f O The cylindrical shell plate consists of 6 smooth connections, such as figure 2 As shown, one side of the four-sided subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com